Content Menu

● Understanding Surface Mount Technology (SMT)

● Advantages of SMT in Transmission Lines

● Impact on Manufacturing Efficiency

● Challenges and Considerations

● Signal Integrity Challenges with SMT

● Design Considerations for Enhanced Performance

● Conclusion

● FAQ

>> 1. What is Surface Mount Technology (SMT)?

>> 2. How does SMT improve signal integrity?

>> 3. What are the main advantages of using SMT over through-hole technology?

>> 4. Are there any challenges associated with using SMT?

>> 5. How does SMT affect manufacturing efficiency?

● Citations:

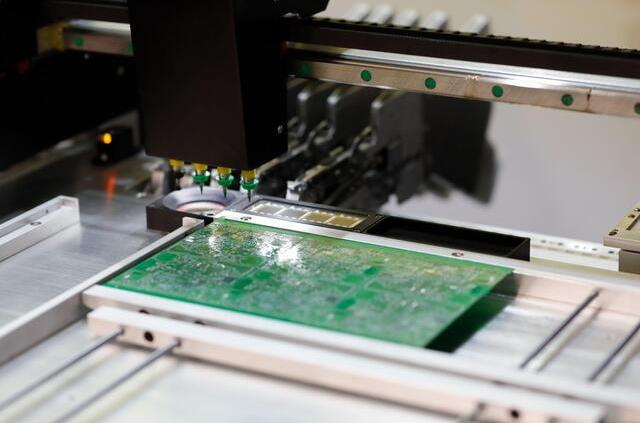

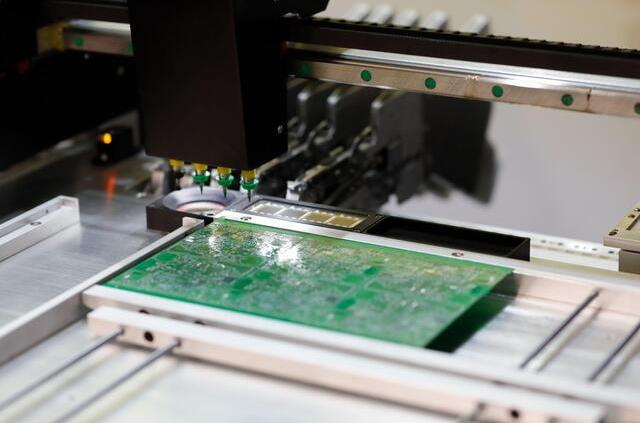

Surface Mount Technology (SMT) has revolutionized the electronics manufacturing landscape, particularly in the assembly of printed circuit boards (PCBs). By allowing components to be mounted directly onto the surface of PCBs, SMT enhances not only the efficiency of production but also the performance of transmission lines. This article explores the various ways SMT improves transmission line performance, focusing on its advantages in electrical performance, design flexibility, and manufacturing efficiency.

Understanding Surface Mount Technology (SMT)

SMT refers to a method where electronic components are attached directly to the surface of a PCB rather than being inserted into holes as in traditional through-hole technology. This mounting technique provides several benefits that significantly influence transmission line performance:

- Reduced Size and Weight: SMT components are typically smaller and lighter than their through-hole counterparts. This reduction in size allows for more compact PCB designs, which is crucial for modern electronic devices that demand miniaturization.

- Higher Component Density: SMT enables a higher density of components on a PCB. This increased density allows for shorter signal paths and reduced parasitic inductance and capacitance, which are critical factors in high-frequency applications.

- Improved Electrical Performance: The shorter leads and lack of holes in SMT components result in lower resistance and inductance at connections. This leads to fewer unwanted radio frequency (RF) effects and better high-frequency performance, enhancing signal integrity across transmission lines.

Advantages of SMT in Transmission Lines

The advantages of SMT extend beyond mere component placement; they have profound implications for the performance of transmission lines:

1. Enhanced Signal Integrity: The compact nature of SMT minimizes the distance that signals must travel across the PCB. Shorter signal paths reduce the likelihood of signal degradation due to resistance and inductance, leading to improved overall signal integrity.

2. Lower Electromagnetic Interference (EMI): SMT's design inherently reduces the loop area for current paths, which decreases EMI susceptibility. This is particularly important in high-speed digital applications where interference can significantly impact performance.

3. High-Frequency Capability: SMT components are designed to operate effectively at higher frequencies. The reduced parasitics associated with these components support faster signal transmission without significant losses, making them ideal for applications such as telecommunications and data processing.

4. Improved Thermal Management: SMT allows for better heat dissipation due to its compact layout. Components can be placed closer together while maintaining adequate thermal pathways, which is essential for maintaining performance in high-power applications.

5. Flexibility in Design: The ability to place components on both sides of a PCB increases design flexibility. Engineers can create more complex circuits without increasing board size, allowing for innovative solutions in transmission line design.

Impact on Manufacturing Efficiency

In addition to improving transmission line performance, SMT enhances manufacturing efficiency:

- Automated Assembly: SMT is highly compatible with automated assembly processes, such as pick-and-place machines that can quickly and accurately place components on PCBs. This automation reduces labor costs and production time.

- Reduced Material Costs: By eliminating the need for drilled holes and reducing board area requirements, SMT decreases material costs associated with PCB production.

- Streamlined Production Processes: The simplified assembly process allows for quicker prototyping and testing phases, enabling faster time-to-market for new electronic devices.

Challenges and Considerations

While SMT offers numerous advantages, it also presents challenges that must be addressed to fully leverage its benefits:

- Reliance on Solder Joints: SMT connections rely heavily on solder joints for both mechanical support and electrical conductivity. Any flaws in these joints can lead to reliability issues.

- Thermal Sensitivity: The smaller size of SMT components means they can be more susceptible to thermal stress during soldering processes. Careful thermal management is essential during manufacturing to prevent damage.

- Complexity in Design: Designing PCBs with high-density SMT components requires advanced skills and tools to ensure manufacturability and reliability.

Signal Integrity Challenges with SMT

Maintaining signal integrity is crucial as it directly affects transmission line performance. As technology advances, the demand for higher speeds and greater bandwidth increases, making it more challenging to ensure undistorted signals reach their destination. Key factors affecting signal integrity include:

- Impedance Mismatch: Discrepancies between the impedance of different segments of a transmission line can lead to reflections that degrade signal quality. Properly designing PCB traces with controlled impedance is essential for minimizing these mismatches.

- Crosstalk: As component density increases, so does the potential for crosstalk between adjacent traces carrying signals. Implementing proper routing techniques and spacing can help mitigate this issue.

- Signal Reflections: High-speed signals are susceptible to reflections caused by discontinuities in trace width or impedance changes along the path. Techniques such as careful trace routing and using termination resistors can help manage these reflections effectively[9][21].

Design Considerations for Enhanced Performance

To maximize the benefits of SMT while addressing potential challenges related to signal integrity, several design considerations should be taken into account:

1. Controlled Impedance Design: Ensuring that traces are designed with controlled impedance helps maintain consistent signal quality throughout the transmission line. This involves calculating trace widths based on substrate materials and desired impedance levels.

2. Differential Signaling: Utilizing differential signaling techniques can significantly improve noise immunity and reduce crosstalk by canceling out common-mode noise[13]. This approach is particularly beneficial in high-speed applications where maintaining signal integrity is paramount.

3. Layer Stack-Up Optimization: Properly designing the layer stack-up within a PCB can enhance signal integrity by minimizing loop inductance and providing effective grounding strategies[18]. Placing power and ground planes adjacent to each other also aids in reducing electromagnetic interference (EMI).

4. Trace Routing Techniques: Employing best practices such as avoiding sharp corners in trace routing helps minimize impedance discontinuities[13]. Keeping high-speed traces as short as possible reduces delay and attenuation effects that can compromise signal quality.

5. Thermal Management Solutions: Given that thermal issues can affect component reliability, implementing effective thermal management strategies is vital[12]. This includes using thermal vias or heat sinks where necessary to dissipate heat effectively from densely packed components.

Conclusion

In conclusion, Surface Mount Technology significantly enhances transmission line performance through improved electrical characteristics, reduced size and weight, increased component density, and greater manufacturing efficiency. While challenges exist—such as ensuring solder joint reliability and managing thermal sensitivity—the benefits of adopting SMT far outweigh these concerns, making it a preferred choice in modern electronics manufacturing. As technology continues to evolve, further advancements in SMT will likely yield even greater improvements in transmission line performance across various applications.

FAQ

1. What is Surface Mount Technology (SMT)?

Surface Mount Technology (SMT) is a method used to mount electronic components directly onto the surface of printed circuit boards (PCBs), allowing for more compact designs compared to traditional through-hole methods.

2. How does SMT improve signal integrity?

SMT improves signal integrity by minimizing signal path lengths and reducing parasitic inductance and capacitance, which helps maintain signal quality at higher frequencies.

3. What are the main advantages of using SMT over through-hole technology?

The main advantages include smaller component sizes, higher component density on PCBs, improved electrical performance at high frequencies, reduced material costs, and enhanced manufacturing efficiency through automation.

4. Are there any challenges associated with using SMT?

Yes, challenges include reliance on solder joint integrity for connections, potential thermal sensitivity during soldering processes, and increased complexity in PCB design due to higher component densities.

5. How does SMT affect manufacturing efficiency?

SMT enhances manufacturing efficiency by enabling automated assembly processes that reduce labor costs and production times while also lowering material costs associated with PCB production.

Citations:

[1] https://www.protoexpress.com/blog/good-not-so-good-sides-surface-mount-technology/

[2] https://vectorbluehub.com/smt-assembly

[3] https://intapi.sciendo.com/pdf/10.2478/jee-2023-0016

[4] https://www.cs.virginia.edu/~skadron/Papers/hpca05.pdf

[5] https://levisonenterprises.com/5-advantages-to-using-smt/

[6] https://www.protoexpress.com/blog/understanding-signal-integrity/

[7] https://www.smtfactory.com/Optimizing-Efficiency-Strategies-for-A-Smooth-SMT-Line-Production-Process-id47463586.html

[8] https://www.blackfox.com/7-benefits-of-surface-mount-technology-smt/

[9] https://cdrdv2-public.intel.com/650327/wp_sgnlntgry.pdf

[10] https://www.wevolver.com/article/smt-process

[11] https://quality-line.com/smt-quality/

[12] https://www.hayawin.com/news-5-advantages-to-using-smt-in-your-electronic-manufacturing-project.html

[13] https://hilelectronic.com/signal-reflections-and-distortion/

[14] https://www.pcbpower.us/blog/unveiling-the-advantages-and-disadvantages-of-surface-mount-technology

[15] https://www.sonicmfg.com/what-are-the-advantages-of-surface-mount-technology-in-pcba/

[16] https://ui.adsabs.harvard.edu/abs/2023JEE....74..122B/abstract

[17] https://scholar.utc.edu/cgi/viewcontent.cgi?article=1754&context=theses

[18] https://fiveable.me/electromagnetic-interference-and-compatibility/unit-7/transmission-line-effects-pcbs/study-guide/YnpFtWFro6ScsKDb

[19] https://www.researchgate.net/publication/370646619_Analysis_of_SMT_component_land_pad_discontinuity_effect_on_the_overall_transmission_line_impedance_in_high-speed_applications

[20] https://core-emt.com/blog/smt-news-1/identifying-addressing-smt-line-bottlenecks-to-plan-line-upgrades-smartly-119

[21] https://www.epectec.com/pcb/signal-integrity.html