Content Menu

● Introduction to SMT and Traditional PCB Assembly

>> What is Traditional PCB Assembly?

>> What is Surface Mount Technology (SMT)?

● Key Differences Between SMT and Traditional PCB Assembly

● Advantages of SMT PCB Solutions

>> Higher Component Density and Miniaturization

>> Faster and More Efficient Production

>> Cost-Effectiveness at Scale

>> Improved Electrical Performance

>> Design Flexibility

● Challenges and Considerations of SMT PCB Assembly

>> Mechanical Strength and Durability

>> Repair and Rework Difficulty

>> Higher Initial Investment

>> Design and Manufacturing Complexity

● Comparison Summary: SMT vs Traditional PCB Assembly

● Conclusion

● Frequently Asked Questions (FAQ)

>> 1. What is the main difference between SMT and traditional through-hole PCB assembly?

>> 2. Why is SMT preferred for modern electronic devices?

>> 3. Are there situations where through-hole assembly is better than SMT?

>> 4. What are the challenges of SMT PCB assembly?

>> 5. Can SMT and through-hole technologies be combined on the same PCB?

● Citations:

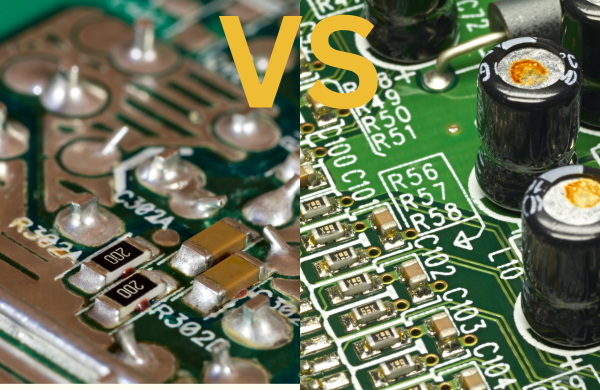

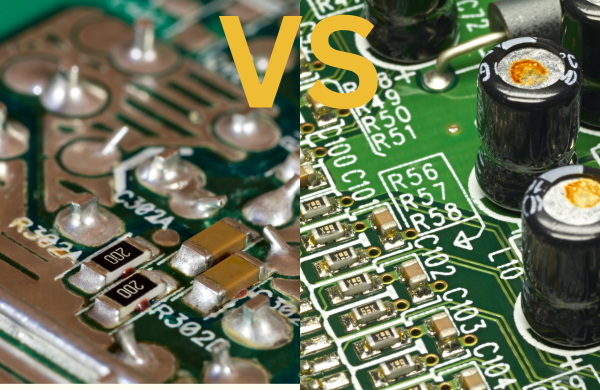

In the rapidly evolving electronics manufacturing industry, Surface Mount Technology (SMT) has become the predominant method for assembling printed circuit boards (PCBs), largely replacing traditional Through-Hole Technology (THT). This article explores how SMT compares to traditional PCB assembly methods, highlighting the advantages, challenges, and key differences. We will also discuss the role of SMT PCB solutions in modern electronics manufacturing.

Introduction to SMT and Traditional PCB Assembly

What is Traditional PCB Assembly?

Traditional PCB assembly, also known as Through-Hole Technology (THT), involves inserting electronic components with long leads through pre-drilled holes in the PCB. These leads are then soldered on the opposite side of the board to create electrical and mechanical connections. This method has been widely used since the early days of electronics manufacturing and is still preferred for components requiring strong mechanical bonds, such as connectors and large transformers[1][5].

What is Surface Mount Technology (SMT)?

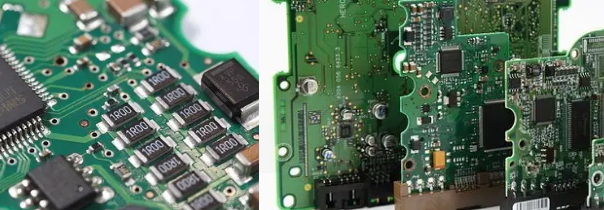

Surface Mount Technology (SMT) is a method where components, called Surface Mount Devices (SMDs), are mounted directly onto the surface of the PCB without the need for drilled holes. SMT components have smaller leads or no leads at all and are soldered onto copper pads on the PCB surface using automated processes like reflow soldering. SMT allows components to be placed on both sides of the PCB, enabling higher density and more compact designs[3][6][8].

Key Differences Between SMT and Traditional PCB Assembly

| Aspect | SMT Assembly (Surface Mount) | Traditional Assembly (Through-Hole) |

| Component Mounting | Components soldered on PCB surface pads | Leads inserted through drilled holes and soldered |

| Component Size & Density | Very small packages, ultra-high density, double-sided mounting | Larger components, lower density, usually single-sided |

| Assembly Speed & Automation | Highly automated, thousands of components placed per hour | Slower, often manual or semi-automated |

| Mechanical Strength | Good electrical reliability but less mechanical strength | Strong mechanical bonds, ideal for high-stress applications |

| Production Cost | Lower cost at volume due to automation | Higher labor and material costs |

| Repairability | More difficult to repair due to small size and solder joints | Easier to repair and replace components |

| Application Suitability | High-frequency, compact, mass-produced electronics | Prototypes, rugged devices, military, aerospace |

This table summarizes the fundamental distinctions that make SMT the preferred choice for most modern electronics, while THT remains relevant for specific use cases[1][5][6][8].

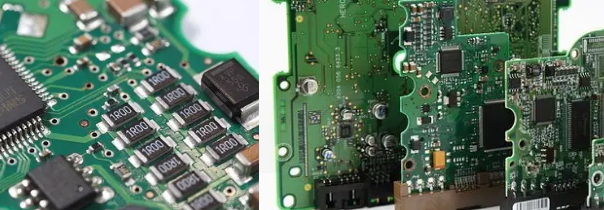

Advantages of SMT PCB Solutions

Higher Component Density and Miniaturization

SMT components are significantly smaller than their through-hole counterparts, allowing for a much higher component density on the PCB. This capability supports the miniaturization of electronic devices, enabling more functionality in smaller form factors. SMT can achieve component densities over 20 times higher than traditional methods, which is crucial for mobile, handheld, and portable electronics[3][7][8].

Faster and More Efficient Production

The SMT PCB solution leverages automated pick-and-place machines and reflow soldering ovens, drastically increasing assembly speed. Some machines can place over 136,000 components per hour, far exceeding the throughput of manual or semi-automated through-hole processes. Automation also reduces human error and improves consistency and quality[6][7][8].

Cost-Effectiveness at Scale

Although SMT requires higher initial capital investment in machinery and setup, it reduces labor costs and assembly time for medium to high-volume production runs. The enhanced reliability of SMT assemblies also lowers rework, scrap, and warranty claim costs, making SMT more economical for mass production[7][9][10].

Improved Electrical Performance

SMT connections have lower resistance and inductance due to shorter leads and smaller solder joints, which reduces electromagnetic interference (EMI) and improves high-frequency performance. This makes SMT especially suitable for modern high-speed and RF electronics[6][10].

Design Flexibility

With SMT, components can be mounted on both sides of the PCB, allowing more complex circuit designs within the same board area. The absence of drilled holes also frees up routing space for inner layers, improving circuit density and performance[3][6].

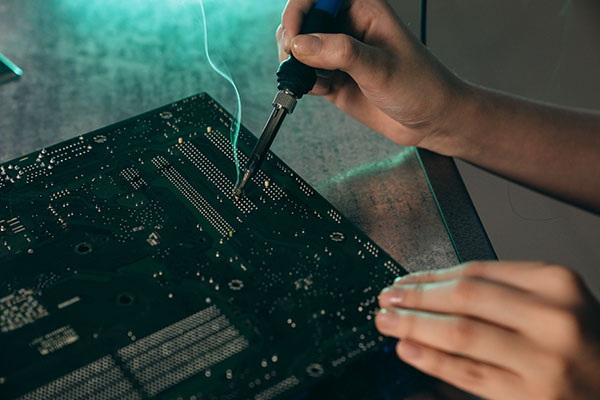

Challenges and Considerations of SMT PCB Assembly

Mechanical Strength and Durability

While SMT solder joints provide good electrical connections, they generally have less mechanical strength compared to through-hole leads. This makes SMT less suitable for components subjected to significant mechanical stress or vibration unless reinforced by other means[1][5].

Repair and Rework Difficulty

The small size of SMT components and their solder joints require specialized tools and skilled technicians for repair or rework. Unlike through-hole components, SMT parts cannot typically be socketed, making replacement more challenging[10].

Higher Initial Investment

Setting up an SMT PCB assembly line involves significant investment in automated equipment such as stencil printers, pick-and-place machines, and reflow ovens. This can be a barrier for low-volume or prototype production where manual assembly might still be preferred[9][10].

Design and Manufacturing Complexity

SMT requires precise application of solder paste and accurate component placement, demanding advanced design and manufacturing expertise. Errors in solder paste printing or component alignment can lead to defects that are harder to detect and fix[3][8].

Comparison Summary: SMT vs Traditional PCB Assembly

| Feature | SMT PCB Solution | Traditional Through-Hole Assembly |

| Assembly Speed | Very fast, automated | Slow, often manual |

| Component Size | Very small, compact | Larger, bulkier |

| Component Density | Very high, supports double-sided mounting | Lower, usually single-sided |

| Mechanical Strength | Moderate, less suited for mechanical stress | High, ideal for rugged applications |

| Cost Efficiency | Cost-effective for large volumes | Higher labor and material costs |

| Repairability | Difficult, requires skill | Easier, components can be replaced |

| Electrical Performance | Superior for high-frequency and RF circuits | Less optimal for high-speed signals |

| Design Flexibility | High, no drilling needed, more routing space | Limited by hole drilling and lead spacing |

This comparison clearly shows why SMT PCB solutions dominate modern electronics manufacturing, offering superior efficiency, miniaturization, and electrical performance, while traditional methods retain niche roles where mechanical robustness is paramount[1][5][6][7][9].

Conclusion

Surface Mount Technology (SMT) has revolutionized PCB assembly by enabling smaller, faster, and more cost-effective manufacturing compared to traditional Through-Hole Technology. SMT PCB solutions provide higher component density, improved electrical performance, and automation capabilities that meet the demands of modern electronics. Despite some challenges in repairability and mechanical strength, SMT remains the industry standard for over 90% of PCB assemblies today. Traditional methods still hold value for specific applications requiring mechanical durability and ease of repair. Understanding the strengths and limitations of each assembly method helps manufacturers choose the optimal solution for their products.

Frequently Asked Questions (FAQ)

1. What is the main difference between SMT and traditional through-hole PCB assembly?

SMT mounts components directly on the PCB surface using solder paste and reflow soldering, enabling smaller parts and higher density. Through-hole inserts component leads through drilled holes and solders them on the opposite side, providing stronger mechanical bonds but lower density[1][6].

2. Why is SMT preferred for modern electronic devices?

SMT allows for miniaturization, faster automated assembly, and better electrical performance, making it ideal for compact, high-speed, and mass-produced electronics[7][8].

3. Are there situations where through-hole assembly is better than SMT?

Yes, through-hole is better for components subjected to mechanical stress, such as connectors or high-power parts, and for easier repair or prototyping[1][5][9].

4. What are the challenges of SMT PCB assembly?

Challenges include higher initial equipment costs, difficulty in repairing small components, and the need for precise solder paste application and component placement[9][10].

5. Can SMT and through-hole technologies be combined on the same PCB?

Yes, many PCBs use a mixed assembly approach, placing SMT components for density and automation benefits, while using through-hole components for parts requiring mechanical strength or special functions[6][8].

Citations:

[1] https://versae.com/surface-mount-vs-through-hole/

[2] https://www.macrofab.com/blog/smt-assembly-vs-through-hole/

[3] https://www.wevolver.com/article/smt-vs-smd-vs-tht-a-comprehensive-guide-to-electronics-assembly-techniques

[4] https://www.hayawin.com/news-pcb-printed-circuit-board-assembly-technologies-smt-vs-through-hole.html

[5] https://cygnuscorp.com/surface-mount-technology-smt-vs-through-hole-technology-a-complete-comparison/

[6] https://en.wikipedia.org/wiki/Surface_mount

[7] https://www.pcbjhy.com/blog/pros-and-cons-of-smt-pcb-assembly/

[8] https://www.wevolver.com/article/smt-pcb-assembly-a-comprehensive-guide-to-surface-mount-technology-in-electronics

[9] https://www.protoexpress.com/blog/good-not-so-good-sides-surface-mount-technology/

[10] https://www.7pcb.com/blog/what-is-smt