Content Menu

● Understanding SMT Assembly

>> Key Components of SMT Assembly

● Efficiency Gains in PCB Manufacturing through SMT Assembly

>> 1. Increased Production Speed

>> 2. Enhanced Space Utilization

>> 3. Improved Electrical Performance

>> 4. Cost-Effectiveness

>> 5. Enhanced Quality and Reliability

>> 6. Flexibility in Manufacturing

>> 7. Advanced Quality Control Measures

● Optimizing SMT Assembly for Maximum Efficiency

>> 1. Design for Manufacturability (DFM)

>> 2. Process Optimization

>> 3. Equipment Maintenance and Upgrades

>> 4. Supply Chain Management

>> 5. Workforce Training and Development

● Impact of SMT on the Electronics Industry

>> 1. Miniaturization of Electronics

>> 2. Advancements in High-Performance Electronics

>> 3. Sustainability in Electronics Manufacturing

>> 4. Globalization of Electronics Manufacturing

● Challenges and Future Trends in SMT Assembly

>> 1. Increasing Complexity

>> 2. Quality Control for High-Density Boards

>> 3. Environmental Concerns

>> 4. Industry 4.0 Integration

● Conclusion

● FAQ

>> 1. What are the main advantages of SMT assembly over through-hole technology?

>> 2. How does SMT assembly improve the reliability of electronic devices?

>> 3. What are the key challenges in implementing SMT assembly?

>> 4. How is SMT assembly adapting to the increasing demand for miniaturization in electronics?

>> 5. What future trends are expected in SMT assembly for PCB manufacturing?

● Citations:

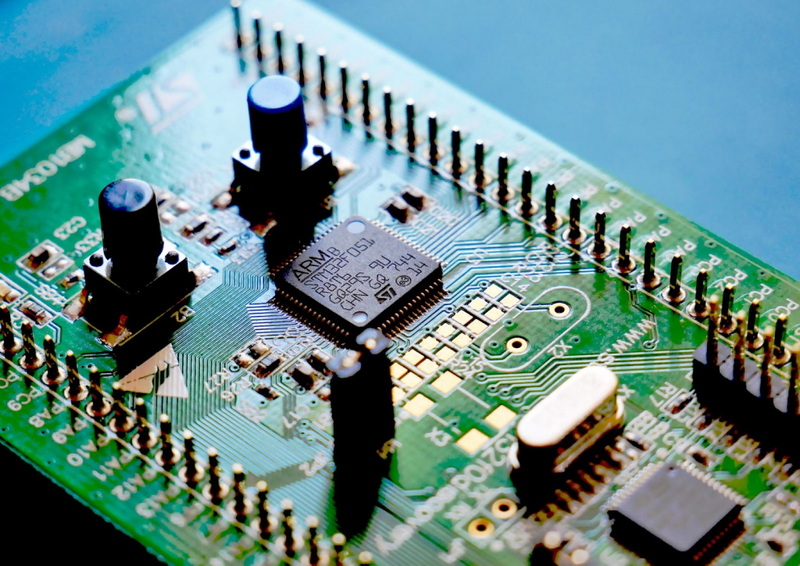

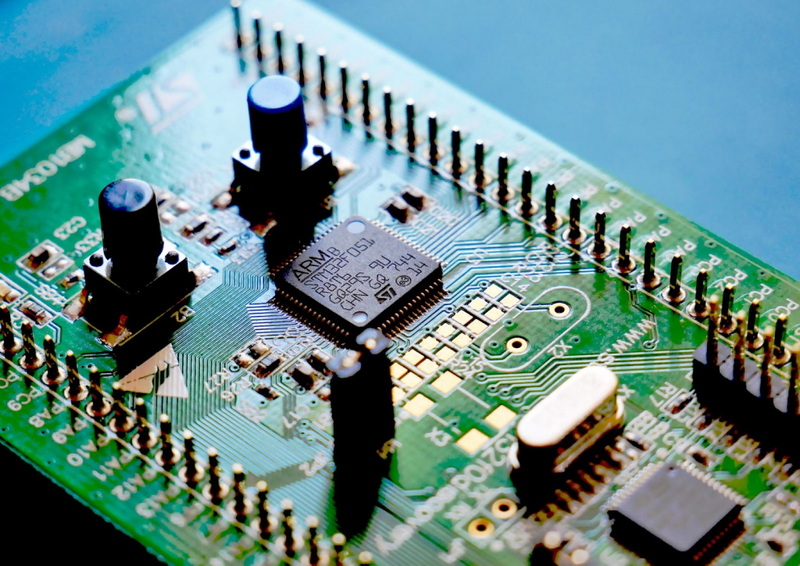

Surface Mount Technology (SMT) has revolutionized the electronics manufacturing industry, particularly in the realm of Printed Circuit Board (PCB) production. This advanced technique has significantly enhanced the efficiency, reliability, and overall quality of PCB manufacturing processes. In this comprehensive article, we will explore the various ways SMT assembly contributes to improved PCB manufacturing efficiency and its impact on the electronics industry as a whole.

Understanding SMT Assembly

Surface Mount Technology is a method where electronic components are mounted directly onto the surface of a printed circuit board[3]. This technique differs from the traditional through-hole technology, where component leads are inserted through holes in the PCB. SMT has become the preferred method for many manufacturers due to its numerous advantages in terms of efficiency, cost-effectiveness, and product quality.

Key Components of SMT Assembly

1. Surface Mount Devices (SMDs): These are the electronic components specifically designed for SMT. They are typically smaller than their through-hole counterparts and have short pins, flat contacts, or solder balls for connection to the PCB[3].

2. PCB Design: SMT-compatible PCBs are designed with pads on the surface for component placement, rather than holes for lead insertion.

3. Automated Assembly Equipment: SMT relies heavily on automated machinery for precise component placement and soldering.

Efficiency Gains in PCB Manufacturing through SMT Assembly

1. Increased Production Speed

One of the most significant advantages of SMT assembly is the dramatic increase in production speed. High-speed pick-and-place machines used in SMT can mount thousands of components per hour with remarkable precision[1][2]. This automation significantly reduces assembly time compared to manual through-hole insertion methods.

- Automated Component Placement: SMT assembly lines utilize advanced pick-and-place machines that can handle a vast number of components quickly and accurately[2].

- Reduced Manual Intervention: The automation in SMT reduces the need for manual handling, which not only speeds up the process but also minimizes human error[2].

2. Enhanced Space Utilization

SMT allows for more efficient use of PCB real estate, leading to more compact and lightweight designs[1].

- Smaller Components: SMT components are generally smaller than through-hole components, allowing for higher component density on the PCB[3].

- Double-Sided Assembly: SMT enables components to be placed on both sides of the PCB, maximizing space utilization[3].

3. Improved Electrical Performance

The direct mounting of components in SMT leads to better electrical characteristics:

- Shorter Signal Paths: With components mounted directly on the surface, signal paths are shorter, reducing signal interference and improving overall performance[1].

- Lower Resistance and Inductance: The direct connections in SMT result in lower resistance and inductance at component connections, enhancing high-frequency performance[3].

4. Cost-Effectiveness

While initial setup costs for SMT equipment can be high, the overall production costs are generally lower:

- Reduced Labor Costs: The high level of automation in SMT assembly significantly reduces labor costs[1].

- Material Savings: Smaller components and more efficient designs lead to reduced material usage and costs[1].

- Higher Throughput: The speed of SMT assembly allows for higher production volumes, spreading fixed costs over more units[2].

5. Enhanced Quality and Reliability

SMT assembly contributes to improved product quality and reliability in several ways:

- Consistent Component Placement: Automated placement ensures high accuracy and consistency across all PCBs[2].

- Reduced Mechanical Stress: Surface-mounted components experience less mechanical stress compared to through-hole components, leading to fewer failures[1].

- Improved Vibration Resistance: SMT assemblies generally have better performance under shock and vibration conditions[3].

6. Flexibility in Manufacturing

SMT offers greater flexibility in the manufacturing process:

- Quick Changeovers: SMT equipment can be quickly reconfigured for different PCB designs, allowing for more agile production[5].

- Scalability: The automated nature of SMT makes it easier to scale production up or down based on demand[2].

7. Advanced Quality Control Measures

SMT assembly processes incorporate sophisticated quality control techniques:

- Automated Optical Inspection (AOI): These systems can quickly scan and inspect PCBs for errors, such as incorrect component placement or soldering defects[2].

- X-ray Inspection: For components with hidden solder joints, X-ray inspection ensures proper connection[6].

Optimizing SMT Assembly for Maximum Efficiency

To fully leverage the benefits of SMT in PCB manufacturing, several optimization strategies can be employed:

1. Design for Manufacturability (DFM)

Implementing DFM principles in PCB design is crucial for efficient SMT assembly:

- Component Selection: Choose SMT components that are compatible with automated placement and soldering processes[5].

- Layout Optimization: Design PCB layouts that facilitate efficient component placement and minimize the need for manual adjustments[5].

2. Process Optimization

Continuous improvement of the SMT assembly process is key to maintaining and increasing efficiency:

- Solder Paste Application: Optimize the solder paste printing process to ensure consistent and accurate application[6].

- Reflow Profile Tuning: Regularly adjust and optimize reflow soldering profiles to ensure proper component attachment[6].

3. Equipment Maintenance and Upgrades

Keeping SMT equipment in top condition is essential for maintaining efficiency:

- Regular Maintenance: Implement a rigorous maintenance schedule to prevent equipment downtime[2].

- Technology Upgrades: Stay updated with the latest SMT equipment and technologies to improve speed and accuracy[5].

4. Supply Chain Management

Efficient material management is crucial in SMT assembly:

- Just-In-Time (JIT) Inventory: Implement JIT practices to reduce inventory costs and ensure component availability[5].

- Supplier Relationships: Develop strong relationships with suppliers to ensure a steady supply of quality components[5].

5. Workforce Training and Development

While SMT is highly automated, skilled personnel are still crucial:

- Continuous Training: Regularly train staff on the latest SMT technologies and best practices[2].

- Cross-Functional Skills: Develop a workforce with diverse skills to handle various aspects of SMT assembly[5].

Impact of SMT on the Electronics Industry

The adoption of SMT assembly has had far-reaching effects on the electronics industry:

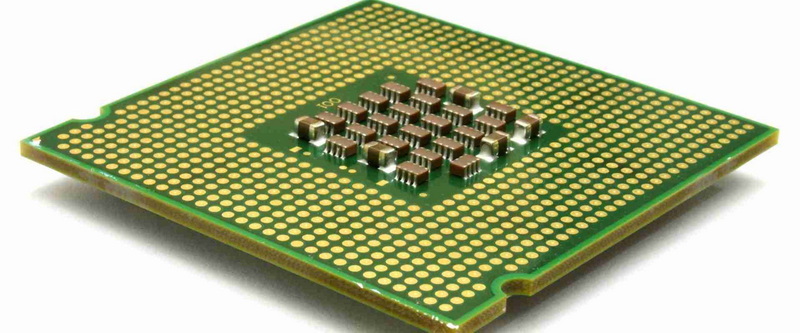

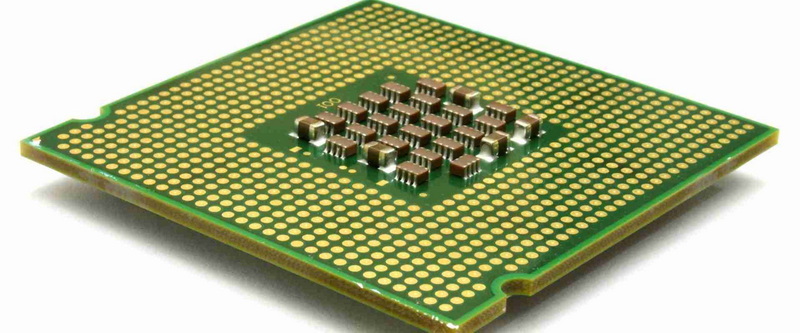

1. Miniaturization of Electronics

SMT has been a key enabler in the trend towards smaller, more compact electronic devices:

- Portable Devices: The ability to create smaller PCBs has been crucial in the development of smartphones, tablets, and wearable technology[1].

- IoT Devices: SMT has facilitated the creation of small, efficient IoT devices for various applications[1].

2. Advancements in High-Performance Electronics

The improved electrical characteristics of SMT assemblies have contributed to advancements in high-performance electronics:

- Computing Devices: SMT has enabled the development of faster, more powerful computing devices[3].

- Telecommunications Equipment: The high-frequency performance benefits of SMT have been crucial in advancing telecommunications technology[1].

3. Sustainability in Electronics Manufacturing

SMT contributes to more sustainable manufacturing practices:

- Reduced Material Waste: The precision of SMT assembly leads to less material waste compared to traditional methods[1].

- Energy Efficiency: The compact nature of SMT assemblies often results in more energy-efficient electronic devices[3].

4. Globalization of Electronics Manufacturing

The efficiency and automation of SMT have facilitated the globalization of electronics manufacturing:

- Standardization: SMT has led to more standardized manufacturing processes across the globe[5].

- Outsourcing: The ease of scaling SMT production has enabled manufacturers to outsource production more effectively[2].

Challenges and Future Trends in SMT Assembly

While SMT has significantly improved PCB manufacturing efficiency, it also presents some challenges:

1. Increasing Complexity

As electronic devices become more complex, SMT assembly faces new challenges:

- Finer Pitch Components: The trend towards smaller components with finer pitches requires even more precise placement and soldering techniques[6].

- Mixed Technology Boards: Many PCBs now require a mix of SMT and through-hole components, adding complexity to the assembly process[3].

2. Quality Control for High-Density Boards

As component density increases, quality control becomes more challenging:

- Advanced Inspection Techniques: Development of more sophisticated inspection methods is necessary to ensure quality in high-density assemblies[6].

- Defect Prevention: Greater emphasis on preventing defects rather than detecting them after assembly[6].

3. Environmental Concerns

The electronics industry faces increasing pressure to adopt more environmentally friendly practices:

- Lead-Free Soldering: Continued refinement of lead-free soldering techniques is necessary to meet environmental regulations[6].

- Recyclability: Designing SMT assemblies for easier recycling and component recovery is becoming more important[5].

4. Industry 4.0 Integration

The future of SMT assembly lies in its integration with Industry 4.0 concepts:

- IoT in Manufacturing: Implementing IoT sensors in SMT equipment for real-time monitoring and predictive maintenance[5].

- Data Analytics: Utilizing big data analytics to optimize SMT processes and predict potential issues[2].

Conclusion

Surface Mount Technology has undeniably revolutionized PCB manufacturing, bringing about significant improvements in efficiency, quality, and capabilities. The ability to produce smaller, more complex, and higher-performing electronic devices has been largely due to the advancements in SMT assembly techniques. As the electronics industry continues to evolve, SMT will play a crucial role in meeting the demands for faster, smaller, and more sophisticated electronic products.

The efficiency gains in production speed, space utilization, and cost-effectiveness have made SMT the preferred choice for most PCB and SMT assembly processes. However, the industry must continue to innovate and address challenges such as increasing complexity, environmental concerns, and the integration of smart manufacturing concepts.

As we look to the future, the continued evolution of SMT assembly will likely focus on even greater precision, increased automation, and smarter manufacturing processes. This will enable the production of next-generation electronic devices that are not only more powerful and efficient but also more sustainable and environmentally friendly.

The impact of SMT on PCB manufacturing efficiency is profound and far-reaching. It has not only transformed manufacturing processes but has also enabled the creation of electronic devices that were once thought impossible. As technology continues to advance, SMT will undoubtedly remain at the forefront of innovation in the electronics manufacturing industry.

FAQ

1. What are the main advantages of SMT assembly over through-hole technology?

SMT assembly offers several advantages over through-hole technology:

- Compact Design: SMT components are smaller, allowing for more compact PCB designs[1].

- Faster Production: Automated SMT assembly is significantly faster than manual through-hole insertion[2].

- Better Performance: SMT components often have better electrical and mechanical performance due to shorter leads and direct surface mounting[3].

- Cost-Effectiveness: Despite higher initial equipment costs, SMT is generally more cost-effective for large-scale production[1].

- Double-Sided Assembly: SMT allows components to be placed on both sides of the PCB, maximizing space utilization[3].

2. How does SMT assembly improve the reliability of electronic devices?

SMT assembly enhances the reliability of electronic devices in several ways:

- Reduced Mechanical Stress: Surface-mounted components experience less mechanical stress than through-hole components[1].

- Better Vibration Resistance: SMT assemblies generally perform better under shock and vibration conditions[3].

- Improved Thermal Management: The direct surface contact in SMT allows for better heat dissipation[1].

- Consistent Connections: Automated placement and soldering result in more consistent and reliable connections[2].

- Fewer Interconnections: SMT often requires fewer interconnections, reducing potential points of failure[3].

3. What are the key challenges in implementing SMT assembly?

Implementing SMT assembly comes with several challenges:

- High Initial Investment: SMT equipment can be expensive, requiring significant upfront investment[1].

- Complexity in Repair: SMT assemblies can be more difficult to repair or rework compared to through-hole assemblies[3].

- Heat Sensitivity: Some SMT components are sensitive to heat, requiring precise control during soldering[6].

- Skill Requirements: Operating and maintaining SMT equipment requires specialized skills and training[2].

- Quality Control: Inspecting SMT assemblies, especially with fine-pitch components, can be challenging and may require advanced inspection technologies[6].

4. How is SMT assembly adapting to the increasing demand for miniaturization in electronics?

SMT assembly is evolving to meet the demands of miniaturization:

- Finer Pitch Components: Development of equipment capable of handling components with increasingly fine pitches[6].

- Advanced Placement Technologies: Improved pick-and-place machines with higher accuracy for smaller components[2].

- 3D Component Stacking: Techniques for vertical stacking of components to increase density[5].

- Embedded Components: Integration of components within the PCB layers to save surface space[5].

- Micro-BGA and Chip-Scale Packages: Adoption of extremely small package types for even greater miniaturization[3].

5. What future trends are expected in SMT assembly for PCB manufacturing?

Several trends are shaping the future of SMT assembly:

- AI and Machine Learning: Integration of AI for process optimization and defect prediction[2].

- Industry 4.0 Integration: Increased use of IoT and data analytics in SMT production lines[5].

- Sustainable Practices: Development of more environmentally friendly materials and processes[6].

- Flexible Electronics: Adaptation of SMT for flexible and stretchable circuit boards[5].

- Additive Manufacturing: Exploration of 3D printing technologies in conjunction with SMT for novel PCB designs[5].

Citations:

[1] https://www.zetwerk.com/resources/knowledge-base/electronics-manufacturing-services-ems/how-smt-pcb-assembly-enhances-efficiency-in-electronics-production/

[2] https://profabelectronics.com/posts/how-automated-pcb-assembly-improves-efficiency/

[3] https://en.wikipedia.org/wiki/Surface_mount

[4] https://rushpcb.com/line-efficiency-of-a-pcb-manufacturer/

[5] https://www.andwinpcb.com/optimizing-pcb-assembly-and-manufacturing-for-efficiency-and-quality/

[6] https://www.ednasia.com/top-12-incredible-techniques-to-control-the-quality-of-pcb-smt-assembly/

[7] https://blogs.sw.siemens.com/valor-dfm-solutions/how-to-optimize-pcb-design-for-the-smt-assembly-process-flow/

[8] https://www.pcbx.com/article/How-to-Increase-Efficiency-in-PCB-Assembly-Manufacturing

[9] https://www.wevolver.com/article/smt-process