Content Menu

● Introduction to SMT and Reel Fast SMT

● Advantages of Reel Fast SMT in Manufacturing Efficiency

>> Faster Assembly and Reduced Labor Costs

>> Increased Component Density and Design Flexibility

>> Improved Reliability and Performance

>> Enhanced Automation and Reduced Setup Costs

>> Cost Efficiency for High-Volume Production

● Challenges and Solutions in Implementing Reel Fast SMT

>> Challenges

>> Solutions

● Case Studies and Real-World Applications

● Future Directions and Innovations

● Role of Automated Storage and Retrieval Systems (ASRS)

● Warehouse Bottlenecks and Solutions

● Efficiency Enhancement Strategies

>> Role of Data-Driven Scheduling

>> Integration with MES/ERP Systems

● Expanded Discussion on Efficiency Enhancement

>> Automation and Training

>> Lean Production and Process Monitoring

>> Supplier Management and Maintenance

● Intelligent SMT Reel Storage Systems

>> Emerging Trends

● Conclusion

● FAQ

>> 1. What are the primary advantages of using Reel Fast SMT in manufacturing?

>> 2. How does Reel Fast SMT contribute to cost efficiency in high-volume production?

>> 3. What are some common challenges in implementing Reel Fast SMT, and how can they be addressed?

>> 4. How does Reel Fast SMT support design flexibility in electronic devices?

>> 5. What role does Reel Fast SMT play in industries with space and weight constraints?

● Citations:

In the realm of electronics manufacturing, Surface Mount Technology (SMT) has revolutionized the way components are assembled onto printed circuit boards (PCBs). One crucial aspect of SMT is the use of reels, particularly in the context of "Reel Fast SMT," which significantly enhances assembly line efficiency. This article delves into the specifics of how Reel Fast SMT improves manufacturing processes, focusing on key benefits such as faster assembly, reduced labor costs, and increased component density.

Introduction to SMT and Reel Fast SMT

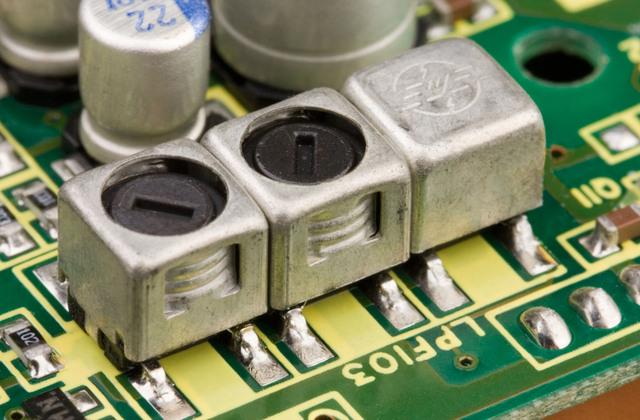

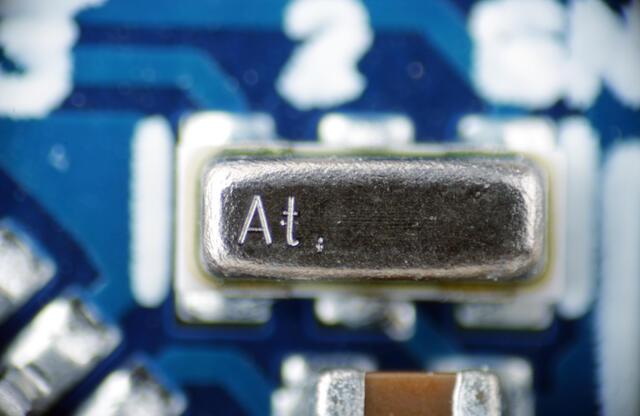

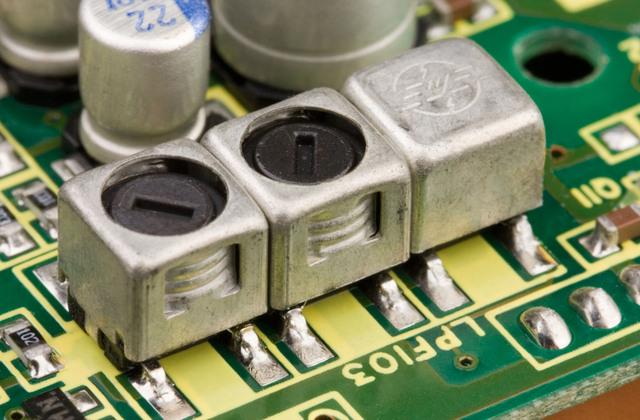

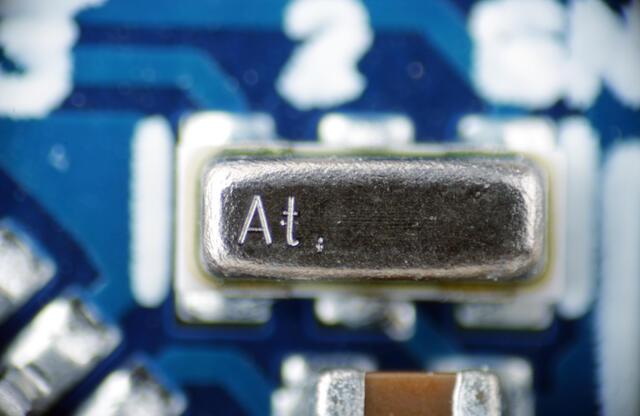

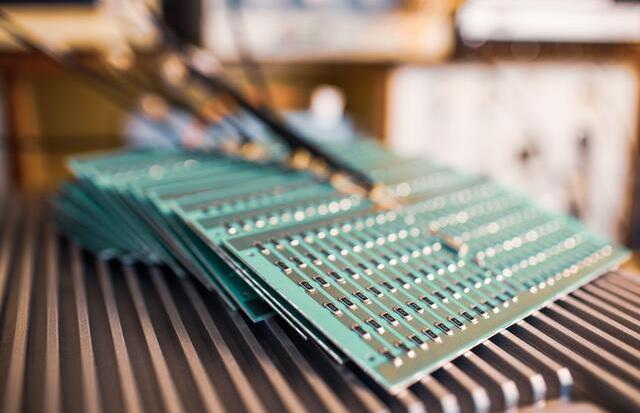

SMT is a method of mounting electronic components directly onto the surface of a PCB without the need for holes. This technique allows for higher component density, faster assembly, and improved reliability compared to traditional through-hole technology. Components are typically supplied on reels, which are spools of material holding components such as resistors, capacitors, and integrated circuits. These reels are designed to be compatible with automated assembly processes, particularly pick-and-place machines, which can rapidly place components onto PCBs.

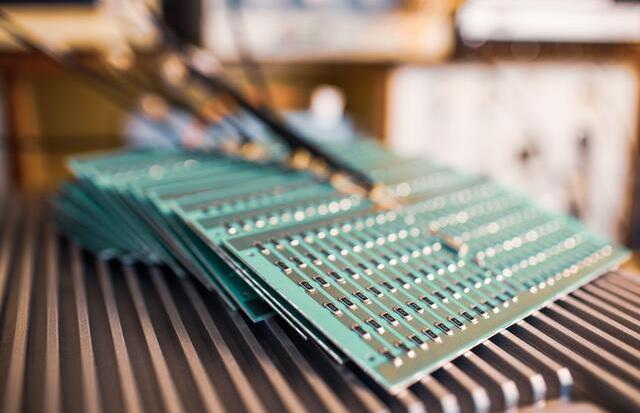

Reel Fast SMT builds upon this foundation by optimizing the use of reels in SMT processes. It involves the efficient management and integration of components on reels into the assembly line, ensuring seamless and rapid production. This approach is particularly beneficial in high-volume manufacturing environments where speed and efficiency are paramount.

Advantages of Reel Fast SMT in Manufacturing Efficiency

Faster Assembly and Reduced Labor Costs

Reel Fast SMT facilitates faster assembly by enabling continuous production without frequent line stoppages. Components are fed directly from the reel into the pick-and-place machine, reducing the need for manual handling and minimizing downtime. This automation leads to significant labor cost savings, as fewer workers are required to manage the assembly process[1].

Increased Component Density and Design Flexibility

SMT components on reels allow for higher component density on PCBs, enabling the production of smaller, more complex electronic devices. This density also provides design flexibility, as components can be placed on both sides of the PCB, enhancing the overall functionality of the device[1].

Improved Reliability and Performance

The smaller size and lower mass of SMT components contribute to better mechanical performance under shock and vibration conditions. Additionally, SMT offers lower resistance and inductance at connections, resulting in improved high-frequency performance and reduced electromagnetic interference (EMI)[1].

Enhanced Automation and Reduced Setup Costs

SMT manufacturing is highly automated, which reduces the initial setup costs for mass production. The use of reels further supports this automation by providing a consistent and reliable supply of components to the assembly line. This consistency is crucial for maintaining high production efficiency and reducing the need for frequent setup changes[1].

Cost Efficiency for High-Volume Production

In high-volume production scenarios, Reel Fast SMT is particularly cost-effective. The automated processes reduce material waste and assembly times, making it an ideal choice for mass-producing electronic devices. The efficiency gained from using reels also helps in reducing the overall production costs by minimizing the need for manual intervention and reducing errors during assembly[1].

Challenges and Solutions in Implementing Reel Fast SMT

Challenges

Implementing Reel Fast SMT can pose challenges, such as the need for specific reel sizes and widths to match the capabilities of pick-and-place machines. Additionally, maintaining and handling reels properly is crucial to prevent component damage and ensure accurate placement on PCBs[1].

Solutions

To address these challenges, manufacturers can invest in standardized reel storage solutions that optimize space, protect components from damage, and ensure efficient retrieval. Automated storage systems, like the Dry Tower, offer controlled climatic conditions and complete traceability, enhancing the overall efficiency of reel management[1].

Case Studies and Real-World Applications

Reel Fast SMT is widely used across various industries, including automotive, medical, communication, gaming, and aerospace. Its compact and efficient design makes it indispensable for producing devices with space and weight constraints. For instance, Smyczek GmbH, a German electronics manufacturer, implemented an automated storage system for SMD component reels, significantly reducing handling time and improving production efficiency[1].

Future Directions and Innovations

The future of Reel Fast SMT involves integrating it with advanced technologies such as miniaturization, high-frequency applications, and digital twin technologies. This integration will further enhance production efficiency and adaptability to evolving manufacturing needs. Data-driven scheduling algorithms can optimize reel exchange times and improve throughput by leveraging component commonality across different products, aligning with lean manufacturing principles[1][5].

Role of Automated Storage and Retrieval Systems (ASRS)

ASRS systems play a crucial role in optimizing SMT reel storage by maximizing space usage, improving inventory management, and enhancing productivity. These systems ensure that components are stored in a controlled environment, reducing the risk of contamination and ensuring FIFO compliance[1][6].

Warehouse Bottlenecks and Solutions

As production efficiency on the shop floor improves, warehouses often face new challenges in managing and delivering materials quickly enough to keep production lines running smoothly. Manual handling processes are time-consuming and prone to errors, leading to bottlenecks in material delivery. To address these bottlenecks, manufacturers can implement semi-automatic storage solutions like smart shelves. These systems use LED indicators to guide workers in picking and returning reels, significantly improving picking performance and accuracy[1].

Efficiency Enhancement Strategies

Implementing lean production principles helps minimize waste and optimize workflows. Continuous monitoring of manufacturing processes is crucial for early error detection and correction, ensuring that production remains efficient and reliable. Strong relationships with suppliers ensure timely delivery of high-quality components, while regular maintenance of machinery is critical for maintaining production line reliability and minimizing downtime[4].

Role of Data-Driven Scheduling

Data-driven scheduling algorithms are becoming increasingly important in optimizing SMT production lines. By analyzing component commonality and production sequences, these algorithms can significantly reduce changeover times and improve throughput. This approach aligns with lean manufacturing principles by minimizing waste associated with frequent reel changes and transitions[5].

Integration with MES/ERP Systems

Integrating scheduling algorithms with Manufacturing Execution Systems (MES) and Enterprise Resource Planning (ERP) platforms enhances real-time decision-making and workflow management. This integration ensures seamless connectivity between production planning, inventory management, and material handling systems, further optimizing production efficiency[5].

Expanded Discussion on Efficiency Enhancement

Automation and Training

Automation is a cornerstone of efficiency in SMT manufacturing, as it boosts production speed and reduces labor costs. Additionally, continuous training and education are essential for ensuring that production teams can effectively utilize automated systems and maintain high-quality standards[4].

Lean Production and Process Monitoring

Lean production is a proven approach to minimizing waste and optimizing workflows. Continuous monitoring of manufacturing processes is crucial for early error detection and correction, ensuring that production remains efficient and reliable[4].

Supplier Management and Maintenance

Relationships with suppliers are a key element of SMT manufacturing. Building and maintaining strong partnerships ensures timely delivery of materials and components of the highest quality. Regular maintenance of machinery is critical for ensuring high availability and reliability of production lines[4].

Intelligent SMT Reel Storage Systems

The Intelligent SMT Reel Storage System market is witnessing remarkable growth, driven by emerging trends such as automation, sustainability, and Industry 4.0 integration. These systems optimize space, reduce waste, and enhance operational efficiency through advanced technologies like AI and IoT[3][6].

Emerging Trends

1. Automation and Efficiency: Intelligent storage systems equipped with robotics and AI algorithms streamline inventory management and reduce human error, accelerating production cycles and enhancing accuracy[3].

2. Sustainability: Manufacturers are adopting eco-friendly practices, leading to a shift towards systems that optimize space and reduce waste. Modular designs allow for scalable operations, accommodating varying production demands while minimizing environmental impact[3].

3. Industry 4.0 and IoT Integration: The integration of IoT devices into storage systems facilitates real-time tracking and predictive maintenance, ensuring that potential issues are identified before they disrupt production[3].

4. Customization and Supply Chain Optimization: Intelligent systems offer dynamic storage configurations that can easily adapt to changing production needs, allowing for quick reconfiguration without significant downtime. Advanced analytics help forecast demand trends, maintaining optimal stock levels and mitigating supply chain risks[3].

Conclusion

Reel Fast SMT plays a pivotal role in enhancing manufacturing efficiency by facilitating faster assembly, reducing labor costs, and improving component density and reliability. Its integration with automated processes and standardized storage solutions further boosts production efficiency. As technology continues to evolve, the importance of Reel Fast SMT will only grow, making it a cornerstone of modern electronics manufacturing.

FAQ

1. What are the primary advantages of using Reel Fast SMT in manufacturing?

The primary advantages include faster assembly, reduced labor costs, increased component density, and improved reliability. Additionally, it supports high automation levels, reducing setup costs and enhancing overall production efficiency.

2. How does Reel Fast SMT contribute to cost efficiency in high-volume production?

Reel Fast SMT contributes to cost efficiency by reducing material waste, minimizing assembly times, and lowering labor costs through automation. This makes it particularly suitable for mass-producing electronic devices.

3. What are some common challenges in implementing Reel Fast SMT, and how can they be addressed?

Common challenges include the need for specific reel sizes and proper handling to prevent component damage. These can be addressed by investing in standardized reel storage solutions and automated storage systems.

4. How does Reel Fast SMT support design flexibility in electronic devices?

Reel Fast SMT supports design flexibility by allowing for higher component density on PCBs. This enables the production of smaller, more complex devices with components placed on both sides of the PCB.

5. What role does Reel Fast SMT play in industries with space and weight constraints?

Reel Fast SMT plays a crucial role in industries with space and weight constraints, such as automotive and aerospace, by enabling the production of compact and efficient electronic devices.

Citations:

[1] https://www.gssmt-parts.com/how-does-reel-smt-improve-manufacturing-efficiency.html

[2] https://www.pemnet.com/products/engineering-guides/reelfast-surface-mount-fasteners/

[3] https://pmarketresearch.com/auto/intelligent-smt-reel-storage-system-market/

[4] https://www.adoptsmt.com/en/efficiency-enhancement-in-smt-manufacturing/

[5] https://www.mdpi.com/2306-5729/10/2/16

[6] https://www.gssmt-parts.com/what-are-the-key-features-of-high-quality-smt-reel-storage-systems.html

[7] https://prototypepcbassembly.com/optimizing-smt-production-lines-for-maximum-efficiency/

[8] https://global.neotel.tech/2022/02/24/5-things-you-must-know-about-smt-reel/

[9] https://resources.sw.siemens.com/en-US/white-paper-smart-solutions-for-smt-reel-storage/

[10] https://www.youtube.com/watch?v=hhufY6xpm6M

[11] https://www.abelwomack.com/take-your-pick-efficiency-accuracy-or-reel-disorganization-blog/

[12] https://smt.asmpt.com/en/products/advanced-packaging/

[13] https://www.eetimes.com/how-smt-component-packages-affect-manufacturing/

[14] https://www.gssmt-parts.com/what-are-the-common-problems-solved-by-an-smt-reel-x-ray-counter.html

[15] https://www.seamarkzm.com/how-smd-reel-counter-machines-optimize-smt-assembly.html

[16] https://www.adoptsmt.com/en/reel-storage-system/

[17] https://blog.kardex-remstar.com/case-studies/rohde-schwarz

[18] https://www.smtusa.com/blog/posts/video-content-trends-shaping-the-future-of-social-media.html

[19] https://www.allsmt.com/automated-warehouse-systems-smt-production

[20] https://cornerstone.lib.mnsu.edu/cgi/viewcontent.cgi?article=2230&context=etds