Content Menu

● The Basics of PCB SMT Assembly

● Factors Influencing PCB SMT Assembly Pricing

>> 1. Board Complexity and Design

>> 2. Component Types and Availability

>> 3. Assembly Technology

>> 4. Order Quantity

>> 5. Turnaround Time

● How Volume Affects PCB SMT Assembly Pricing

>> Low Volume Production (Prototyping and Small Batches)

>> Medium Volume Production

>> High Volume Production

● The Economy of Scale in PCB SMT Assembly

● Strategies for Cost-Effective PCB SMT Assembly at Different Volumes

>> For Low Volume Production:

>> For Medium Volume Production:

>> For High Volume Production:

● The Impact of Global Factors on PCB SMT Assembly Pricing

>> Market Demand

>> Technological Advancements

>> Raw Material Costs

>> Labor Costs

● Future Trends in PCB SMT Assembly Pricing

● Conclusion

● FAQ

>> 1. What is the average cost range for PCB SMT assembly?

>> 2. How does PCB size affect SMT assembly pricing?

>> 3. What role does component selection play in PCB SMT assembly pricing?

>> 4. How do rush orders affect PCB SMT assembly pricing?

>> 5. What strategies can reduce PCB SMT assembly costs for low volume production?

● Citations:

In the world of electronics manufacturing, printed circuit board (PCB) assembly is a crucial process that significantly impacts the final product's cost and quality. Surface Mount Technology (SMT) has become the preferred method for PCB assembly due to its efficiency and cost-effectiveness, especially for high-volume production. However, understanding how PCB SMT assembly prices vary by volume is essential for manufacturers and businesses to make informed decisions and optimize their production costs.

The Basics of PCB SMT Assembly

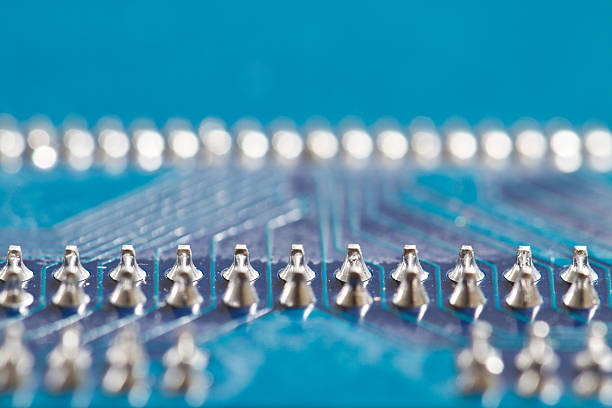

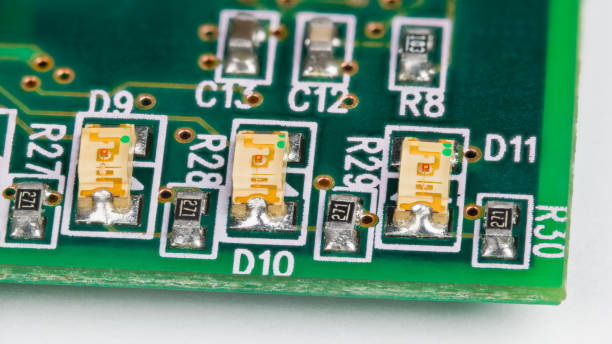

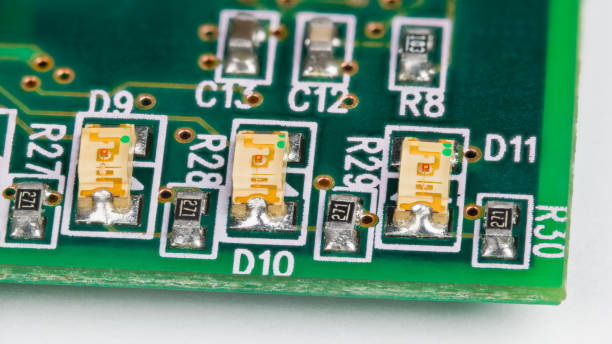

Before delving into the pricing dynamics, it's important to understand what PCB SMT assembly entails. Surface Mount Technology involves directly placing and soldering components onto the surface of a PCB, as opposed to through-hole technology where components are inserted into holes drilled through the board.

SMT assembly offers several advantages:

1. Higher component density

2. Faster assembly process

3. Improved electrical performance

4. Reduced board size and weight

These benefits make SMT the go-to choice for most modern electronic devices, from smartphones to industrial equipment.

Factors Influencing PCB SMT Assembly Pricing

Several factors contribute to the overall cost of PCB SMT assembly, and understanding these can help in estimating how prices might vary with volume:

1. Board Complexity and Design

The complexity of the PCB design directly impacts the assembly cost. More intricate designs with higher layer counts, larger board sizes, and higher component densities require more advanced manufacturing techniques and specialized equipment[1]. As volume increases, the impact of complexity on per-unit cost tends to decrease due to optimized production processes.

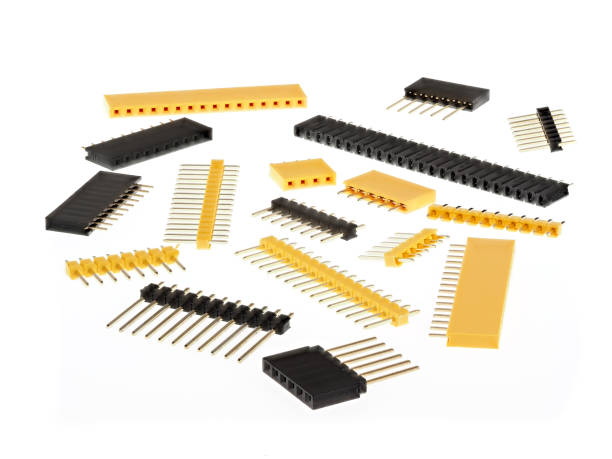

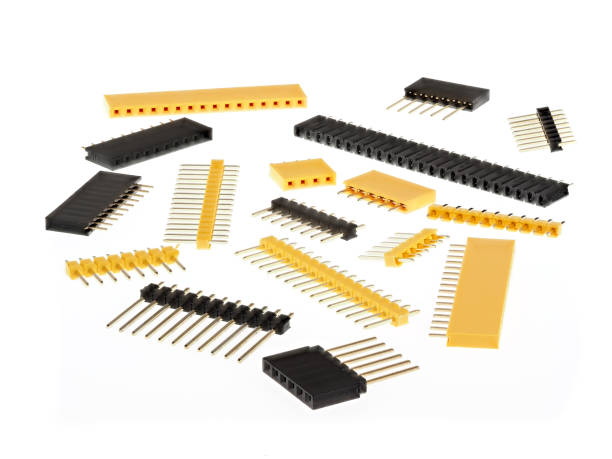

2. Component Types and Availability

The types of components used in a PCB design significantly influence the assembly cost. Surface mount devices (SMDs) are generally more cost-effective to assemble compared to through-hole components[1]. However, the availability and pricing of components can fluctuate, affecting the overall assembly cost. Higher volumes often allow for bulk component purchases, potentially reducing per-unit costs.

3. Assembly Technology

SMT assembly is typically more cost-effective than through-hole assembly, especially for high-volume production runs[1]. The efficiency of SMT increases with volume, as setup times and costs are spread across more units.

4. Order Quantity

Perhaps the most significant factor in determining PCB SMT assembly price is the order quantity. Larger order quantities typically result in lower per-unit costs due to efficiency gains and optimized production processes[1]. This principle of economies of scale is fundamental to understanding how PCB SMT assembly prices vary by volume.

5. Turnaround Time

The urgency of the project can influence the PCB assembly cost. Standard lead times allow for optimized production schedules and cost-effective manufacturing processes. However, expedited services or rush orders may incur additional fees[1]. In high-volume production, longer lead times can be accommodated, potentially reducing costs.

How Volume Affects PCB SMT Assembly Pricing

Now that we've established the key factors influencing PCB SMT assembly costs, let's explore how these costs typically vary with production volume.

Low Volume Production (Prototyping and Small Batches)

For low volume production, typically ranging from a few units to a few hundred, PCB SMT assembly prices tend to be higher per unit. This is due to several factors:

1. Setup Costs: The initial setup for SMT assembly, including programming pick-and-place machines and creating solder stencils, is spread across fewer units.

2. Component Sourcing: Purchasing components in small quantities often results in higher per-unit costs.

3. Labor Costs: More manual intervention may be required for small batches, increasing labor costs per unit.

4. Quality Control: Thorough testing and inspection processes for prototypes or small batches can increase per-unit costs.

In low volume scenarios, PCB SMT assembly prices can range from $100 to $1,000 or more per board, depending on complexity and urgency[4].

Medium Volume Production

As production volumes increase to the thousands or tens of thousands, PCB SMT assembly prices begin to decrease significantly per unit. This is where the benefits of SMT really start to show:

1. Optimized Setup: The initial setup costs are spread across more units, reducing the per-unit impact.

2. Improved Efficiency: Production lines can be optimized for the specific PCB design, increasing throughput.

3. Bulk Component Purchasing: Larger component orders often come with discounts, reducing material costs.

4. Automated Processes: Higher volumes justify more automated processes, reducing labor costs per unit.

In medium volume production, PCB SMT assembly prices might range from $50 to $500 per panel, with the actual per-unit cost depending on the number of PCBs per panel[1].

High Volume Production

For high volume production, typically hundreds of thousands to millions of units, PCB SMT assembly prices reach their lowest points per unit. At this scale:

1. Maximum Efficiency: Production lines are fully optimized, often running 24/7.

2. Bulk Discounts: Significant discounts on components and materials are achieved.

3. Automated Quality Control: Advanced automated inspection and testing systems reduce labor costs while maintaining high quality.

4. Negotiation Power: High volume customers often have more negotiating power with PCB assembly service providers.

In high volume scenarios, PCB SMT assembly prices can drop dramatically, potentially to less than $50 per panel for simpler designs[1].

The Economy of Scale in PCB SMT Assembly

The concept of economy of scale is central to understanding how PCB SMT assembly prices vary by volume. As production volume increases, the fixed costs associated with PCB assembly are spread over more units, reducing the per-unit cost[7].

This principle applies to various aspects of PCB SMT assembly:

1. Equipment Costs: The high cost of SMT equipment is more easily justified and absorbed in high-volume production.

2. Labor Efficiency: Workers become more efficient with repetition, and labor costs per unit decrease.

3. Material Costs: Bulk purchasing of components and materials leads to lower per-unit costs.

4. Process Optimization: With higher volumes, there's more opportunity to optimize processes and reduce waste.

Strategies for Cost-Effective PCB SMT Assembly at Different Volumes

Regardless of production volume, there are strategies to optimize PCB SMT assembly costs:

For Low Volume Production:

1. Design for Manufacturability (DFM): Optimize PCB designs for easier assembly, reducing potential issues and costs.

2. Use Standard Components: Opt for readily available, standard components to reduce sourcing costs and lead times.

3. Combine Orders: If possible, combine multiple small orders into a larger batch to benefit from volume pricing.

For Medium Volume Production:

1. Invest in Tooling: Custom tooling may become cost-effective at this volume, improving efficiency.

2. Optimize Panel Design: Maximize the number of PCBs per panel to reduce waste and improve efficiency.

3. Negotiate Volume Discounts: Begin leveraging your increased volume for better pricing on components and services.

For High Volume Production:

1. Automate Quality Control: Invest in automated optical inspection (AOI) and other advanced testing methods to maintain quality while reducing costs.

2. Vertical Integration: Consider bringing some processes in-house if volumes justify the investment.

3. Long-term Supplier Relationships: Establish strategic partnerships with suppliers for better pricing and priority service.

The Impact of Global Factors on PCB SMT Assembly Pricing

While volume is a crucial factor in determining PCB SMT assembly prices, global economic and industry trends also play a significant role:

Market Demand

The overall demand for PCB assembly services can impact pricing. During periods of high demand, prices may increase due to capacity constraints, while during slower periods, competitive pricing may lead to lower costs[3].

Technological Advancements

As SMT technology continues to evolve, new equipment and processes can impact pricing. Initially, cutting-edge technology may increase costs, but as it becomes more widespread, it often leads to improved efficiency and lower prices[6].

Raw Material Costs

Fluctuations in the costs of raw materials used in PCB manufacturing and components can affect assembly prices. These changes can be due to global economic conditions, supply chain disruptions, or regulatory changes[5].

Labor Costs

The location of the PCB assembly facility significantly impacts labor costs. While labor costs in regions like China have traditionally been lower, rising wages and the trend towards reshoring in some industries are changing the global landscape of PCB assembly pricing[8].

Future Trends in PCB SMT Assembly Pricing

Looking ahead, several trends are likely to influence PCB SMT assembly pricing:

1. Increased Automation: Further advancements in automation technology are expected to reduce labor costs and improve efficiency, potentially lowering prices for high-volume production.

2. Industry 4.0 Integration: The integration of smart manufacturing principles and IoT technologies may lead to more efficient production processes and potentially lower costs.

3. Sustainability Initiatives: Growing emphasis on sustainable manufacturing practices may initially increase costs but could lead to long-term savings and pricing stability.

4. Reshoring and Near-shoring: The trend towards bringing manufacturing closer to end markets may impact pricing structures, potentially increasing costs in some regions while offering benefits in terms of reduced shipping and improved supply chain resilience.

Conclusion

PCB SMT assembly pricing is a complex subject influenced by numerous factors, with production volume being one of the most significant. As volume increases, per-unit costs typically decrease due to economies of scale, improved efficiency, and optimized processes. However, other factors such as board complexity, component selection, global economic conditions, and technological advancements also play crucial roles in determining the final price.

For businesses and manufacturers, understanding these dynamics is essential for making informed decisions about production strategies, supplier selection, and budgeting. By carefully considering the interplay between volume and other cost factors, companies can optimize their PCB SMT assembly processes to achieve the best balance of cost, quality, and efficiency.

As the electronics industry continues to evolve, staying informed about trends in PCB SMT assembly pricing and technology will be crucial for maintaining competitiveness in an increasingly complex global market.

FAQ

1. What is the average cost range for PCB SMT assembly?

The cost of PCB SMT assembly can vary widely depending on factors such as board complexity, volume, and components used. However, a general range can be provided:

- For low volume (prototyping): $100 - $1,000+ per board

- For medium volume: $50 - $500 per panel

- For high volume: Less than $50 per panel for simpler designs

These figures are approximate and can vary significantly based on specific project requirements[1][4].

2. How does PCB size affect SMT assembly pricing?

PCB size directly impacts assembly pricing in several ways:

- Larger boards require more materials, increasing base costs.

- Bigger PCBs may need more components, raising assembly time and complexity.

- Larger sizes can affect the number of boards per panel, influencing production efficiency.

Generally, as board size increases, so does the assembly cost. However, this relationship isn't always linear, as other factors like complexity and volume also play significant roles[2][8].

3. What role does component selection play in PCB SMT assembly pricing?

Component selection is crucial in determining PCB SMT assembly pricing:

- More expensive or specialized components increase overall costs.

- Component availability can affect pricing and lead times.

- The mix of SMT and through-hole components impacts assembly processes and costs.

- Fine-pitch or BGA components may require more advanced equipment and skilled labor.

Choosing readily available, standard components can help keep costs down, especially for lower volume production[1][2].

4. How do rush orders affect PCB SMT assembly pricing?

Rush orders typically increase PCB SMT assembly pricing due to several factors:

- Disruption of normal production schedules.

- Potential overtime labor costs.

- Express shipping fees for components or finished products.

- Possible expedited setup and programming of assembly equipment.

The price increase for rush orders can be significant, sometimes up to 50% or more over standard pricing. It's generally more cost-effective to plan for longer lead times when possible[1][4].

5. What strategies can reduce PCB SMT assembly costs for low volume production?

For low volume PCB SMT assembly, consider these cost-saving strategies:

- Optimize design for manufacturability to reduce potential assembly issues.

- Use standard, readily available components to avoid sourcing delays and premiums.

- Consider panel designs that maximize the number of boards per panel.

- Combine multiple small orders into a larger batch when possible.

- Work with assembly partners who specialize in low volume, high-mix production.

These approaches can help mitigate the higher per-unit costs typically associated with low volume PCB SMT assembly[1][7][8].

Citations:

[1] https://www.pcbelec.com/pcb-assembly-cost-a-comprehensive-guide-for-cost-effective-pcb-manufacturing.html

[2] https://www.linkedin.com/pulse/what-factors-affect-pcb-cost-yolin-gan

[3] https://www.grandviewresearch.com/industry-analysis/surface-mount-technology-market-report

[4] https://blog.thedigisource.com/should-cost-examples-pcba

[5] https://versae.com/factors-that-influence-prices-pcb-manufacturing-assembly/

[6] https://www.marketsandmarkets.com/Market-Reports/surface-mount-technology-market-99662691.html

[7] https://www.nextpcb.com/blog/pcb-assembly-cost-affecting-factors-and-way-to-save-money

[8] https://www.anzer-usa.com/resources/pcb-assembly-cost-factors/

[9] https://www.nextpcb.com/blog/factors-that-affect-pcb-price

[10] https://resources.pcb.cadence.com/blog/2023-10-factors-in-pcb-fabrication-cost-estimation