Content Menu

● Introduction

● Understanding PCB Moisture Absorption

● The Importance of PCB Baking

● The PCB Baking Process

>> Baking Temperature and Time

>> Vertical Baking Method

>> Cooling and Storage

● Effects of Manual Baking on SMT Assembly Quality

>> Improved Solder Joint Quality

>> Enhanced Component Adhesion

>> Reduced Risk of Delamination

>> Minimized Pop-corning Effect

>> Improved Electrical Performance

● Best Practices for PCB Manual Baking

>> 1. Determine Baking Necessity

>> 2. Use Appropriate Baking Equipment

>> 3. Monitor Baking Parameters

>> 4. Implement Proper Cooling Procedures

>> 5. Maintain a Dry Storage Environment

● Challenges and Considerations

>> 1. Time and Resource Allocation

>> 2. Potential for Overheating

>> 3. Handling and Contamination Risks

>> 4. Moisture Reabsorption

● Impact on Different PCB Types

>> FR-4 PCBs

>> High-Temperature PCBs

>> Flexible PCBs

● Future Trends in PCB Baking for SMT Assembly

>> 1. Automated Baking Systems

>> 2. Advanced Moisture Sensing Technologies

>> 3. Alternative Moisture Removal Methods

>> 4. Moisture-Resistant PCB Materials

● Conclusion

● FAQ

>> 1. Why is PCB baking necessary before SMT assembly?

>> 2. What are the optimal temperature and duration for PCB baking?

>> 3. How does PCB baking affect the solderability of the board?

>> 4. Are there any PCB types that should not be baked?

>> 5. How long can a baked PCB be stored before it requires rebaking?

● Citations:

Introduction

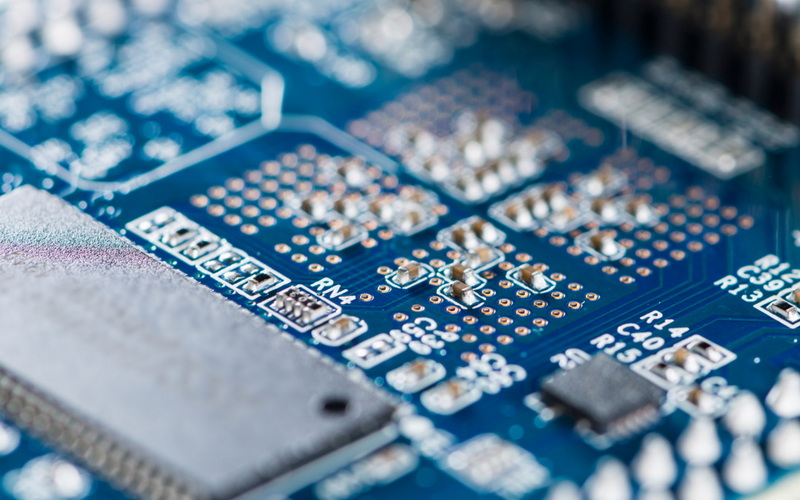

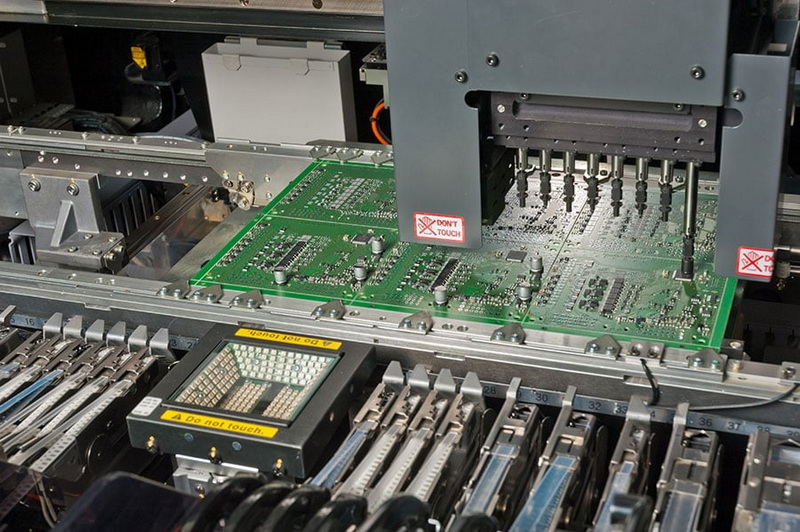

In the world of electronics manufacturing, Surface Mount Technology (SMT) has become the industry standard for assembling printed circuit boards (PCBs). This process involves mounting components directly onto the surface of PCBs, resulting in more compact and efficient electronic devices. However, the quality of SMT assemblies can be significantly affected by various factors, one of which is the moisture content in PCBs. To address this issue, manual baking of PCBs has become a common practice in many manufacturing facilities. This article will explore how PCB manual baking affects the quality of SMT assemblies and why it is a crucial step in the production process.

Understanding PCB Moisture Absorption

Before delving into the effects of manual baking, it's essential to understand why PCBs absorb moisture in the first place. PCBs are typically made of materials such as FR-4, which is a composite of woven fiberglass cloth and epoxy resin. These materials are hygroscopic, meaning they have a tendency to absorb moisture from the surrounding environment[1].

When PCBs are exposed to humid conditions during storage or transportation, they can absorb significant amounts of moisture. This absorbed moisture can lead to various problems during the SMT assembly process, particularly during the reflow soldering stage.

The Importance of PCB Baking

Manual baking of PCBs is a process used to remove moisture from the boards before they undergo SMT assembly. This step is crucial for several reasons:

1. Preventing Delamination: When moisture-laden PCBs are subjected to the high temperatures of reflow soldering, the absorbed water can turn into steam. This rapid expansion can cause the PCB layers to separate, leading to delamination[1].

2. Improving Solderability: Excessive moisture can affect the solderability of the PCB pads and components, potentially leading to poor solder joints and reliability issues[5].

3. Reducing Defects: By removing moisture, baking helps prevent defects such as pop-corning, where trapped moisture causes components to crack or pop off the board during soldering[2].

4. Enhancing Overall Quality: Proper baking can significantly improve the overall quality and reliability of the final SMT assembly.

The PCB Baking Process

Baking Temperature and Time

The baking process involves exposing PCBs to elevated temperatures for a specific duration. Typically, the baking temperature is set at 120±5°C to effectively remove moisture without damaging the PCB[7]. The baking time varies depending on the thickness and size of the PCB, as well as the level of moisture absorption[1].

Vertical Baking Method

When baking PCBs, it is recommended to use a "vertical type" and interval baking method. This approach allows for maximum hot air convection, making it easier for moisture to be baked out of the PCB[1]. However, for larger PCBs, consideration must be given to potential bending deformation when using the vertical method.

Cooling and Storage

After baking, it's crucial to allow the PCBs to cool quickly in a dry environment. Some manufacturers recommend placing an "anti-bending fixture" on top of the PCB during cooling to prevent warpage[1]. Once cooled, the PCBs should be stored in a moisture-controlled environment to prevent reabsorption of moisture.

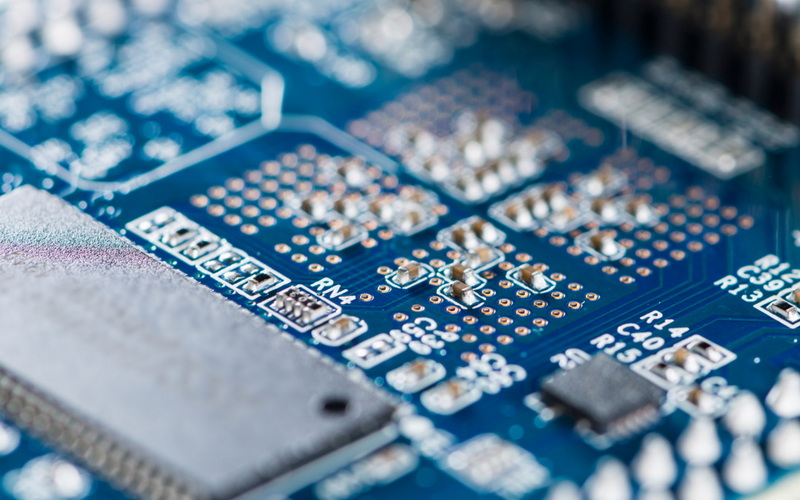

Effects of Manual Baking on SMT Assembly Quality

Improved Solder Joint Quality

One of the primary benefits of manual baking is the improvement in solder joint quality. By removing moisture from the PCB, the risk of solder joint defects such as voids, cold joints, and tombstoning is significantly reduced. This results in stronger, more reliable electrical connections between components and the PCB.

Enhanced Component Adhesion

Moisture in PCBs can interfere with the adhesion of surface mount components during the placement process. By baking the PCBs, the surface becomes more receptive to solder paste and component placement, leading to better overall adhesion and reducing the likelihood of components shifting during reflow.

Reduced Risk of Delamination

As mentioned earlier, delamination is a serious issue that can occur when moisture-laden PCBs are subjected to high temperatures. Manual baking effectively removes this moisture, significantly reducing the risk of delamination during the reflow process. This not only improves the structural integrity of the PCB but also enhances the long-term reliability of the assembled product.

Minimized Pop-corning Effect

The pop-corning effect, where moisture trapped within components or the PCB expands rapidly during reflow, can cause severe damage to both the components and the board. Manual baking helps eliminate this risk by removing the moisture that causes this phenomenon, resulting in fewer component failures and board defects.

Improved Electrical Performance

Moisture in PCBs can affect their electrical properties, potentially leading to issues such as increased signal loss or impedance mismatches. By removing this moisture through baking, the electrical performance of the PCB is maintained, ensuring that the final assembly meets the required specifications.

Best Practices for PCB Manual Baking

To maximize the benefits of manual baking and its positive effects on SMT assembly quality, consider the following best practices:

1. Determine Baking Necessity

Not all PCBs require baking before SMT assembly. The need for baking can be determined by checking the Humidity Indicator Card (HIC) in the PCB's vacuum package. If the HIC shows no signs of moisture exposure, the PCB can potentially be used without baking[1].

2. Use Appropriate Baking Equipment

Invest in high-quality baking ovens that offer precise temperature control and even heat distribution. This ensures that all PCBs are baked uniformly and effectively.

3. Monitor Baking Parameters

Carefully control and monitor the baking temperature and duration. Overbaking can potentially damage the PCB or affect its solderability, while underbaking may not sufficiently remove moisture.

4. Implement Proper Cooling Procedures

After baking, allow PCBs to cool in a controlled environment. Use anti-bending fixtures when necessary to prevent warpage during the cooling process[1].

5. Maintain a Dry Storage Environment

Once baked, store PCBs in a dry environment with controlled humidity to prevent moisture reabsorption. Consider using dry cabinets or moisture barrier bags for storage.

Challenges and Considerations

While manual baking offers numerous benefits for SMT assembly quality, there are some challenges and considerations to keep in mind:

1. Time and Resource Allocation

The baking process adds time to the overall production cycle and requires dedicated equipment and energy resources. Manufacturers must balance these factors against the quality improvements gained.

2. Potential for Overheating

If not carefully controlled, the baking process can potentially damage PCBs or affect their solderability. It's crucial to follow recommended temperature and time guidelines for different PCB types and thicknesses.

3. Handling and Contamination Risks

The additional handling required for the baking process introduces opportunities for contamination or physical damage to the PCBs. Proper handling procedures and clean room practices are essential.

4. Moisture Reabsorption

If baked PCBs are not properly stored or are exposed to humid conditions before SMT assembly, they can quickly reabsorb moisture, negating the benefits of baking. Implementing proper storage and handling procedures is crucial.

Impact on Different PCB Types

The effects of manual baking can vary depending on the type of PCB being processed:

FR-4 PCBs

FR-4 is the most common PCB material and generally responds well to baking. However, the baking process for FR-4 PCBs should be carefully controlled to avoid affecting the material's properties[4].

High-Temperature PCBs

PCBs designed for high-temperature applications, such as those using polyimide materials, may require different baking parameters. These boards often benefit from baking to reduce their high expansion rate during soldering[5].

Flexible PCBs

Flexible PCBs, particularly those made with polyimide, may require special consideration during the baking process to prevent warping or other physical deformations[5].

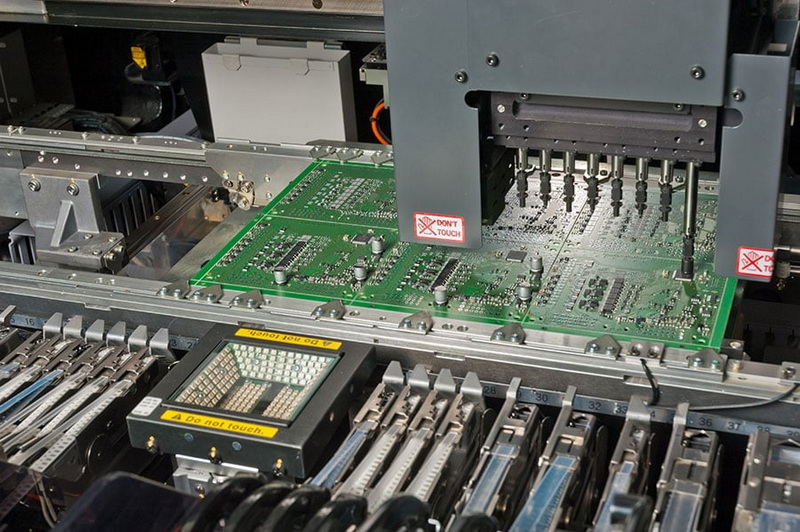

Future Trends in PCB Baking for SMT Assembly

As the electronics industry continues to evolve, so too do the practices surrounding PCB preparation for SMT assembly. Some emerging trends include:

1. Automated Baking Systems

The development of automated baking systems that integrate seamlessly with SMT production lines, reducing handling and improving efficiency.

2. Advanced Moisture Sensing Technologies

New technologies for more accurately detecting moisture levels in PCBs, allowing for more precise determination of baking requirements.

3. Alternative Moisture Removal Methods

Research into new methods of moisture removal that may be faster or more energy-efficient than traditional baking.

4. Moisture-Resistant PCB Materials

Development of new PCB materials with improved moisture resistance, potentially reducing the need for baking in some applications.

Conclusion

Manual baking of PCBs plays a crucial role in ensuring the quality of SMT assemblies. By effectively removing moisture from PCBs, this process helps prevent a range of defects and issues that can arise during the SMT assembly process. From improving solder joint quality and component adhesion to reducing the risk of delamination and pop-corning, the benefits of PCB baking are clear.

However, it's important to approach PCB baking with careful consideration of the specific requirements of each board and assembly process. By following best practices and staying informed about emerging trends and technologies, manufacturers can optimize their PCB baking processes to achieve the highest quality SMT assemblies possible.

As the electronics industry continues to push the boundaries of miniaturization and performance, the importance of proper PCB preparation, including manual baking, will remain a critical factor in producing reliable and high-quality electronic devices.

FAQ

1. Why is PCB baking necessary before SMT assembly?

PCB baking is necessary to remove moisture absorbed by the board during storage or transportation. This moisture can cause various issues during the SMT process, including delamination, poor solder joint quality, and component failures. Baking helps ensure the PCB is in optimal condition for the SMT assembly process.

2. What are the optimal temperature and duration for PCB baking?

The optimal baking temperature is typically around 120±5°C. The duration depends on the PCB thickness and moisture content, but generally ranges from 4 to 8 hours. It's important to follow manufacturer guidelines and industry standards for specific PCB types.

3. How does PCB baking affect the solderability of the board?

Proper baking can improve solderability by removing moisture that might interfere with the soldering process. However, excessive baking can potentially degrade the PCB surface and reduce solderability. It's crucial to balance moisture removal with maintaining the PCB's surface properties.

4. Are there any PCB types that should not be baked?

While most PCBs can benefit from baking, some specialty boards or those with heat-sensitive components may require alternative moisture removal methods. Always consult the PCB manufacturer's guidelines and consider the specific components and materials used in the board.

5. How long can a baked PCB be stored before it requires rebaking?

The storage time for a baked PCB depends on the storage conditions. In a controlled environment with low humidity (typically less than 30% RH), baked PCBs can usually be stored for up to 48 hours. However, if exposed to high humidity, they may require rebaking much sooner. It's best to use moisture-sensitive level (MSL) guidelines for specific storage recommendations.

Citations:

[1] https://www.kingfordpcb.com/pcb-assembly-service/4222.html

[2] https://pmc.ncbi.nlm.nih.gov/articles/PMC9228397/

[3] https://pcbtrace.com/manual-soldering-in-smt-assembly-of-pcb-components/

[4] https://patents.google.com/patent/CN102922070B/en

[5] https://www.wnie.online/library/baking-printed-circuit-boards/

[6] https://www.wevolver.com/article/smt-process

[7] https://www.linkedin.com/pulse/importance-baking-pcbs-before-smt-reflow-processes-ryan-yan-pq94c

[8] https://en.wikipedia.org/wiki/Surface_mount