Content Menu

● Understanding SMT Stencils

>> The Importance of Cleaning SMT Stencils

>> Challenges in Cleaning SMT Stencils

● What is Nano Coating?

>> How Nano Coating Works

● Benefits of Nano Coating for SMT Stencils

>> 1. Enhanced Cleanliness

>> 2. Reduced Adhesion of Solder Paste

>> 3. Increased Durability

>> 4. Improved Operational Efficiency

>> 5. Environmental Benefits

● The Cleaning Process with Nano Coated SMT Stencils

● Conclusion

● FAQ

>> 1. What is the main advantage of using nano coatings on SMT stencils?

>> 2. How does nano coating improve the durability of SMT stencils?

>> 3. Can nano coatings affect the quality of solder paste application?

>> 4. What cleaning agents are recommended for nano coated SMT stencils?

>> 5. Is the application of nano coatings environmentally friendly?

In the world of electronics manufacturing, Surface Mount Technology (SMT) stencils play a crucial role in the assembly process. These stencils are used to apply solder paste onto printed circuit boards (PCBs) before components are placed. However, the cleaning of SMT stencils is a significant challenge that can impact the quality of the final product. Recently, nano coating technology has emerged as a promising solution to enhance the cleaning process of SMT stencils. This article explores how nano coating affects the cleaning process of SMT stencils, its benefits, and its implications for the electronics manufacturing industry.

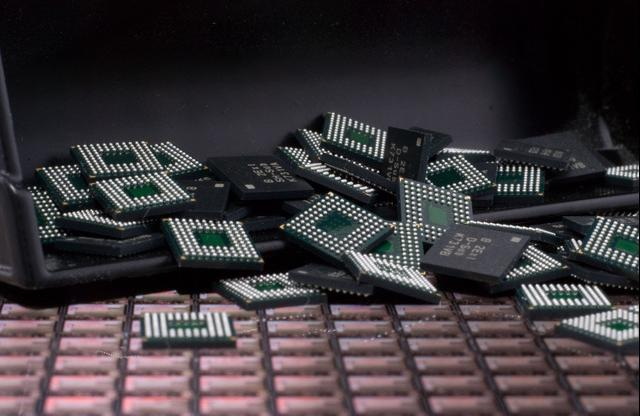

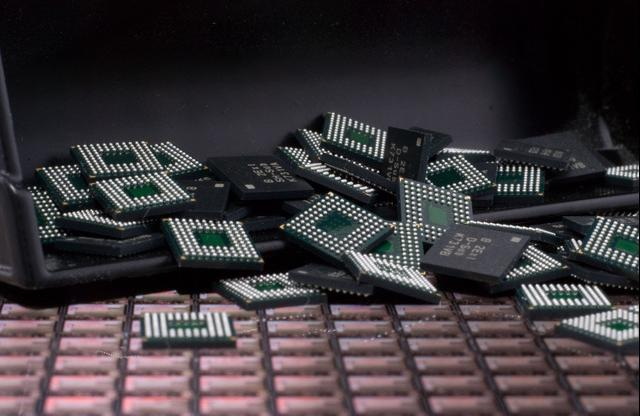

Understanding SMT Stencils

SMT stencils are thin sheets made from stainless steel or other materials with precise openings that correspond to the pads on a PCB. The solder paste is applied through these openings, allowing for accurate placement of solder on the board. After the solder paste application, the stencils must be cleaned to remove any residual paste, which can lead to defects in the assembly process if not properly managed.

The Importance of Cleaning SMT Stencils

Cleaning SMT stencils is essential for several reasons:

1. Quality Assurance: Residual solder paste can cause bridging, insufficient solder, or other defects in the soldering process. Proper cleaning ensures that the stencil is free from contaminants.

2. Stencil Longevity: Regular cleaning extends the life of the stencil. Residual paste can lead to corrosion or damage over time.

3. Operational Efficiency: A clean stencil allows for smoother operation during the solder paste application process, reducing downtime and increasing productivity.

Challenges in Cleaning SMT Stencils

The cleaning process for SMT stencils can be challenging due to several factors:

- Viscosity of Solder Paste: Solder paste can be quite viscous, making it difficult to remove completely from the stencil.

- Material Compatibility: The cleaning agents used must be compatible with the stencil material to avoid damage.

- Time Constraints: In a fast-paced manufacturing environment, cleaning stencils quickly and effectively is crucial to maintain production schedules.

What is Nano Coating?

Nano coating refers to the application of a thin layer of nanomaterials onto a surface to enhance its properties. In the context of SMT stencils, nano coatings can provide several benefits, including improved cleanliness, reduced adhesion of solder paste, and enhanced durability.

How Nano Coating Works

Nano coatings are typically applied using various methods, such as spraying, dipping, or vapor deposition. The resulting layer is usually only a few nanometers thick, but it significantly alters the surface properties of the stencil. This alteration can lead to reduced surface energy, which in turn affects how substances like solder paste adhere to the stencil.

Benefits of Nano Coating for SMT Stencils

1. Enhanced Cleanliness

One of the primary benefits of applying a nano coating to SMT stencils is enhanced cleanliness. The smooth, hydrophobic surface created by the nano coating prevents solder paste from sticking to the stencil. This means that when the stencil is cleaned, the residual paste is more easily removed, leading to a more effective cleaning process.

2. Reduced Adhesion of Solder Paste

Nano coatings can significantly reduce the adhesion of solder paste to the stencil. This is particularly beneficial because it minimizes the amount of paste that remains on the stencil after application. As a result, the cleaning process becomes less labor-intensive and more efficient, allowing manufacturers to maintain higher production rates.

3. Increased Durability

The application of a nano coating can also enhance the durability of SMT stencils. The coating provides a protective layer that can resist scratches, corrosion, and other forms of wear and tear. This increased durability means that stencils can be used for a longer period without needing replacement, which can lead to cost savings for manufacturers.

4. Improved Operational Efficiency

With the benefits of enhanced cleanliness and reduced adhesion, the overall operational efficiency of the SMT assembly process is improved. Manufacturers can spend less time cleaning stencils and more time focusing on production, leading to increased output and reduced costs.

5. Environmental Benefits

Using nano coatings can also have environmental benefits. By reducing the need for harsh cleaning chemicals, manufacturers can decrease their environmental footprint. This aligns with the growing trend towards sustainability in manufacturing processes.

The Cleaning Process with Nano Coated SMT Stencils

The cleaning process for nano coated SMT stencils differs from traditional methods. Here's a general overview of how the cleaning process works with nano coated stencils:

1. Initial Inspection: Before cleaning, the stencil is inspected for any visible residue or damage.

2. Pre-Cleaning: A gentle pre-cleaning step may be performed to remove any large particles or excess solder paste.

3. Cleaning Solution Application: A suitable cleaning solution is applied. Due to the nano coating, less aggressive cleaning agents can often be used.

4. Rinsing: The stencil is rinsed with water or a compatible solvent to remove any remaining cleaning solution and residue.

5. Drying: The stencil is dried using air or a drying oven to ensure no moisture remains.

6. Final Inspection: A final inspection is conducted to ensure the stencil is clean and ready for reuse.

Conclusion

In conclusion, the application of nano coating technology to SMT stencils significantly enhances the cleaning process. By improving cleanliness, reducing the adhesion of solder paste, increasing durability, and improving operational efficiency, nano coatings offer a range of benefits that can positively impact the electronics manufacturing industry. As manufacturers continue to seek ways to improve their processes and reduce costs, the adoption of nano coatings for SMT stencils is likely to become more widespread.

FAQ

1. What is the main advantage of using nano coatings on SMT stencils?

The main advantage is enhanced cleanliness and reduced adhesion of solder paste, which leads to a more efficient cleaning process.

2. How does nano coating improve the durability of SMT stencils?

Nano coatings provide a protective layer that resists scratches and corrosion, extending the life of the stencil.

3. Can nano coatings affect the quality of solder paste application?

Yes, by reducing the adhesion of solder paste, nano coatings can improve the quality of the application and reduce defects.

4. What cleaning agents are recommended for nano coated SMT stencils?

Less aggressive cleaning agents are often recommended, as the nano coating allows for easier removal of solder paste.

5. Is the application of nano coatings environmentally friendly?

Yes, using nano coatings can reduce the need for harsh cleaning chemicals, making the process more environmentally friendly.