Content Menu

● Understanding Surface Mount Technology

● The Role of Design Flexibility in SMT

>> Compact Designs

>> Enhanced Performance

>> Design Iteration and Prototyping

>> Cost-Effectiveness

>> Compatibility with Advanced Technologies

>> Future-Proofing Designs

● Conclusion

● Related Questions

>> 1. What are the main advantages of surface mount technology?

>> 2. How does surface mount technology improve production efficiency?

>> 3. Can surface mount technology be used for all types of electronic components?

>> 4. What industries benefit most from surface mount technology?

>> 5. How does surface mount technology impact product development timelines?

Surface Mount Technology (SMT) has revolutionized the electronics manufacturing industry, offering numerous advantages that cater to the evolving demands of modern electronic devices. One of the most significant benefits of SMT is its flexibility in design, which enhances not only the production process but also the functionality and performance of electronic products. This article delves into how design flexibility enhances SMT, exploring its implications for manufacturers, designers, and end-users.

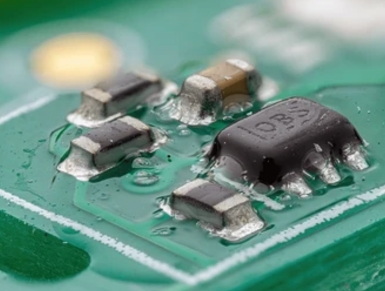

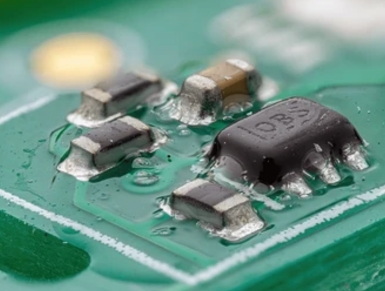

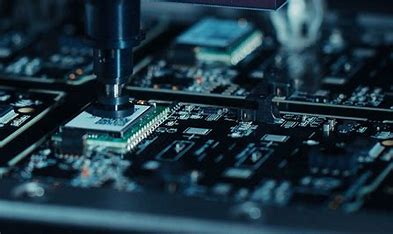

Understanding Surface Mount Technology

Surface Mount Technology is a method used to mount electronic components directly onto the surface of printed circuit boards (PCBs). Unlike traditional through-hole technology, where components are inserted into holes drilled in the PCB, SMT allows for a more compact and efficient layout. This technology has gained popularity due to its ability to support high-density designs and facilitate automated assembly processes.

The advantages of surface mount technology extend beyond mere space-saving. The flexibility in design offered by SMT enables engineers to innovate and create more complex electronic systems while maintaining cost-effectiveness and efficiency.

The Role of Design Flexibility in SMT

Compact Designs

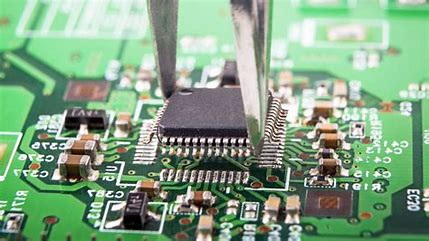

One of the primary advantages of surface mount technology is its ability to accommodate compact designs. SMT components are generally smaller than their through-hole counterparts, allowing for denser packing on PCBs. This compactness is crucial for modern devices such as smartphones, tablets, and wearables, where space is at a premium.

The flexibility in design afforded by SMT means that engineers can create intricate layouts that maximize available space without compromising functionality. This leads to lighter products with improved portability, which is particularly important in today's fast-paced consumer electronics market.

Moreover, compact designs contribute significantly to energy efficiency. Smaller devices often require less power to operate, which aligns with the growing demand for sustainable technology solutions. As consumers become more environmentally conscious, manufacturers are increasingly tasked with creating energy-efficient products that do not sacrifice performance or usability.

Enhanced Performance

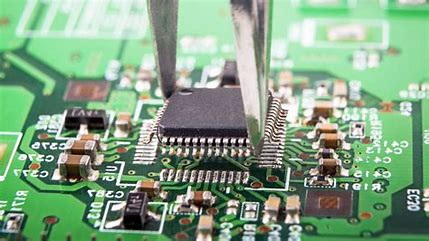

Flexibility in design also contributes to enhanced performance characteristics in electronic devices. SMT allows for shorter interconnections between components, which reduces signal loss and improves overall signal integrity. This is particularly beneficial for high-frequency applications where maintaining signal quality is critical.

Furthermore, the ability to place components on both sides of a PCB increases the design's versatility. Engineers can optimize the layout for thermal management, ensuring that heat-sensitive components are adequately spaced from heat-generating ones. This careful consideration leads to improved reliability and longevity of electronic devices.

In addition to thermal management, SMT's design flexibility allows for better electromagnetic interference (EMI) shielding. By optimizing component placement and routing on the PCB, designers can minimize EMI effects, leading to cleaner signals and better overall performance in sensitive applications such as medical devices or high-speed communication systems.

Design Iteration and Prototyping

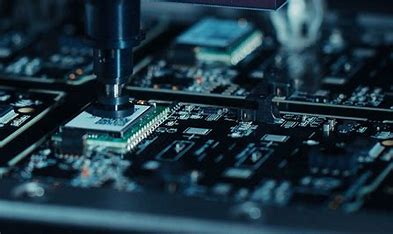

The rapid pace of technological advancement necessitates quick iterations and prototyping in product development. The flexibility inherent in SMT allows designers to easily modify layouts and test new configurations without extensive retooling or redesigning of PCBs.

This adaptability not only accelerates the development process but also enables manufacturers to respond swiftly to market demands or changes in specifications. As a result, companies can bring innovative products to market faster than ever before, gaining a competitive edge.

Additionally, rapid prototyping facilitated by SMT can lead to significant cost savings during the development phase. By identifying potential design flaws early through iterative testing, companies can avoid costly late-stage modifications and ensure that their final products meet quality standards before mass production begins.

Cost-Effectiveness

Cost considerations are always paramount in electronics manufacturing. The flexibility in design offered by SMT contributes significantly to cost-effectiveness through several avenues:

- Reduced Material Costs: Smaller components mean less material is needed for PCBs, reducing overall production costs.

- Lower Labor Costs: Automated assembly processes associated with SMT require less manual labor compared to traditional methods, further driving down costs.

- Minimized Waste: The precision of SMT reduces the likelihood of defects during assembly, leading to less waste and lower rework costs.

By optimizing designs for cost efficiency while maintaining high performance standards, manufacturers can enhance their profit margins without sacrificing quality.

Moreover, as companies scale their production volumes using SMT, they often benefit from economies of scale. The initial investment in automated equipment may be significant; however, as production increases, the per-unit costs decrease substantially due to more efficient use of resources and reduced labor requirements.

Compatibility with Advanced Technologies

As technology continues to evolve, compatibility with advanced technologies becomes increasingly important. SMT's design flexibility allows for seamless integration with emerging technologies such as Internet of Things (IoT) devices, artificial intelligence (AI), and advanced sensors.

For instance, IoT devices often require multiple sensors and communication modules packed into a small form factor. The ability to design compact yet functional PCBs using SMT ensures that these devices can operate effectively within their constraints while offering enhanced features.

Moreover, as AI continues to integrate into various applications—from smart home devices to autonomous vehicles—SMT provides the necessary flexibility for integrating complex algorithms and processing capabilities into smaller hardware platforms. This adaptability is crucial for developing next-generation products that leverage AI technologies effectively.

Future-Proofing Designs

The landscape of electronics is continuously evolving with new standards and technologies emerging regularly. Flexibility in design through SMT allows manufacturers to future-proof their products by enabling easy upgrades or modifications without complete redesigns.

For example, as wireless communication standards evolve from 4G to 5G and beyond, manufacturers can adapt existing designs by simply replacing specific components rather than overhauling entire PCBs. This capability not only saves time but also extends the lifecycle of products in an ever-changing market landscape.

Additionally, future-proofing through flexible designs helps companies maintain customer loyalty by offering upgrade paths for existing products rather than forcing customers into entirely new purchases when technology advances.

Conclusion

In conclusion, the flexibility in design offered by Surface Mount Technology significantly enhances its advantages across various dimensions—compactness, performance, rapid prototyping, cost-effectiveness, compatibility with advanced technologies, and future-proofing capabilities. As electronic devices become more sophisticated and consumer demands evolve, leveraging this flexibility will be crucial for manufacturers aiming to stay competitive in the market.

The advantages of surface mount technology not only streamline production processes but also empower designers to innovate freely without being hindered by traditional constraints. As we look toward the future of electronics manufacturing, it is clear that design flexibility will remain a cornerstone of successful product development within Surface Mount Technology.

Related Questions

1. What are the main advantages of surface mount technology?

The main advantages include reduced size and weight of electronic devices, lower manufacturing costs due to automated assembly processes, improved performance through shorter interconnections, enhanced reliability due to better thermal management options, and increased design flexibility allowing for rapid prototyping.

2. How does surface mount technology improve production efficiency?

SMT improves production efficiency by enabling automated assembly processes that reduce labor costs and minimize human error. Additionally, the compact nature of SMT allows for faster assembly speeds due to less handling time between components.

3. Can surface mount technology be used for all types of electronic components?

While most passive components (like resistors and capacitors) and many active components (like integrated circuits) can be mounted using SMT, some larger or specialized components may still require through-hole mounting techniques due to size or mechanical stability requirements.

4. What industries benefit most from surface mount technology?

Industries such as consumer electronics, telecommunications, automotive electronics, medical devices, and aerospace significantly benefit from surface mount technology due to its advantages in miniaturization and performance enhancement.

5. How does surface mount technology impact product development timelines?

Surface mount technology positively impacts product development timelines by allowing for rapid prototyping and easy modifications during the design phase. This agility enables manufacturers to quickly adapt to changes in market demand or specifications without extensive delays.