Content Menu

● Understanding DIP PCB Technology

>> Key Features of DIP PCB

● Impact on Electronic Performance

>> Reliability and Durability

>> Heat Management

>> Signal Integrity

>> Ease of Repair and Modification

● DIP PCB vs. SMT: A Comparative Analysis

>> Size and Weight

>> Production Efficiency

>> Component Density

>> Cost Considerations

● Applications of DIP PCB in Modern Electronics

>> Industrial Control Systems

>> Automotive Electronics

>> Educational and Prototyping Purposes

>> High-Power Applications

● The Role of DIP in PCBA

>> DIP Soldering Process

>> Quality Assurance in DIP PCBA

>> Hybrid Approaches

● Future Trends and Innovations in DIP PCB Technology

>> Automation Advancements

>> Material Science Developments

>> Integration with Modern Technologies

● Conclusion

● FAQ

>> 1. What are the main differences between DIP and SMT in PCB assembly?

>> 2. How does DIP PCB technology impact the thermal management of electronic devices?

>> 3. In what scenarios is DIP PCB preferred over SMT in modern electronics?

>> 4. How does the cost of DIP PCBA compare to SMT PCBA?

>> 5. What future developments are expected in DIP PCB technology?

● Citations:

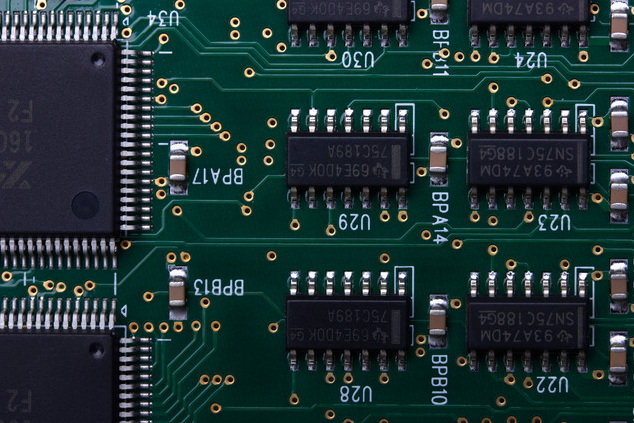

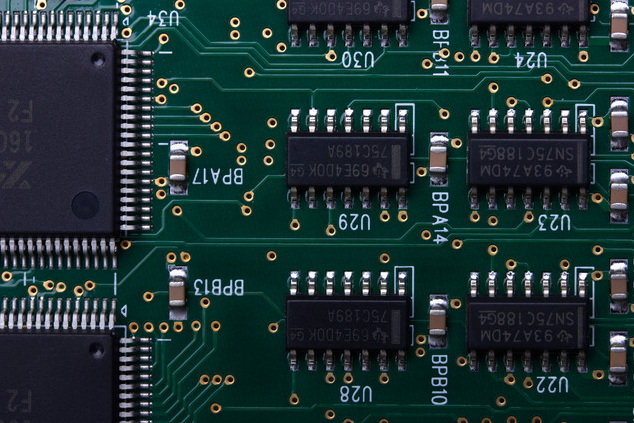

In the ever-evolving world of electronics, the choice of PCB (Printed Circuit Board) technology plays a crucial role in determining the performance, reliability, and overall efficiency of electronic devices. One such technology that has stood the test of time is DIP (Dual In-line Package) PCB. This article delves into the impact of DIP PCB on electronic performance, comparing it with its modern counterpart, SMT (Surface Mount Technology), and exploring its applications in PCBA (Printed Circuit Board Assembly).

Understanding DIP PCB Technology

DIP PCB technology refers to the use of components with pins that are inserted through holes in the circuit board and soldered on the opposite side. This through-hole technology has been a staple in electronics manufacturing for decades, offering unique advantages that continue to make it relevant in certain applications today.

Key Features of DIP PCB

1. Robust Mechanical Connections: DIP components are inserted through holes in the PCB, creating strong mechanical bonds that can withstand significant physical stress[1].

2. Ease of Prototyping: The through-hole design of DIP PCBs facilitates easier insertion and removal of components, making it ideal for prototyping and development stages[1].

3. Heat Dissipation: DIP components, especially those with ceramic or metal bodies, excel in heat dissipation compared to some SMD (Surface Mount Device) components[1].

4. Durability: DIP PCBAs generally exhibit greater robustness compared to SMT assembly, making them suitable for applications subject to vibrations or mechanical shocks[1].

Impact on Electronic Performance

The use of DIP PCB technology can significantly affect the performance of electronic devices in various ways:

Reliability and Durability

DIP PCBs offer superior mechanical strength in their connections, which translates to enhanced reliability in harsh environments[5]. This robustness makes DIP PCBs particularly suitable for applications in military, aerospace, and industrial sectors where devices may be subjected to extreme conditions.

Heat Management

The through-hole design of DIP components allows for better airflow around the component, promoting efficient heat transfer and reducing the risk of overheating[1]. This improved thermal management can lead to more stable performance and longer lifespan of electronic devices, especially in high-power applications.

Signal Integrity

While DIP components generally have higher parasitic capacitance and inductance compared to SMT components, which can potentially affect signal integrity at higher frequencies[5], they still perform admirably in many applications. The larger pin spacing in DIP components can actually be advantageous in certain high-frequency or high-voltage designs where greater isolation between signals is required.

Ease of Repair and Modification

One of the significant advantages of DIP PCBs is the ease with which components can be replaced or modified[6]. This feature not only facilitates easier troubleshooting and repair but also allows for quick upgrades or modifications to existing circuits, enhancing the overall flexibility and longevity of electronic devices.

DIP PCB vs. SMT: A Comparative Analysis

To fully understand the impact of DIP PCB on electronic performance, it's essential to compare it with the more modern SMT approach:

Size and Weight

SMT components are significantly smaller and lighter than their DIP counterparts[2]. This size difference allows for more compact and lightweight electronic devices, which is particularly advantageous in portable consumer electronics.

Production Efficiency

SMT technology generally offers higher production efficiency due to its compatibility with automated assembly processes[2]. DIP assembly, while slower, can still be automated to some extent, bridging the gap in production speed.

Component Density

SMT allows for higher component density on PCBs, enabling more complex circuits in smaller spaces[3]. However, this high density can make manual repairs more challenging compared to DIP PCBs.

Cost Considerations

While SMT may have higher initial setup costs due to the need for specialized equipment, it can be more cost-effective for high-volume production[3]. DIP technology, with its lower setup costs, remains economical for low to medium volume production runs.

Applications of DIP PCB in Modern Electronics

Despite the prevalence of SMT in modern electronics, DIP PCB continues to find applications in various sectors:

Industrial Control Systems

The robustness and reliability of DIP PCBs make them ideal for industrial control systems where durability is paramount.

Automotive Electronics

Certain automotive applications still rely on DIP technology due to its ability to withstand vibrations and extreme temperatures.

Educational and Prototyping Purposes

The ease of assembly and modification makes DIP PCBs excellent for educational purposes and rapid prototyping in research and development.

High-Power Applications

The superior heat dissipation properties of DIP components make them suitable for high-power electronic applications.

The Role of DIP in PCBA

In the context of PCBA (Printed Circuit Board Assembly), DIP technology plays a significant role:

DIP Soldering Process

The DIP soldering process in PCBA involves inserting components through holes in the PCB and soldering them on the opposite side[7]. This process can be done through wave soldering or manual soldering methods, each with its own set of advantages.

Quality Assurance in DIP PCBA

Testing and quality assurance for DIP assemblies often involve in-circuit testing and automated optical inspection[4]. These processes ensure the reliability and functionality of the assembled PCBs.

Hybrid Approaches

Many modern PCBAs employ a hybrid approach, combining both DIP and SMT technologies on the same board[3]. This approach allows manufacturers to leverage the strengths of both technologies, optimizing for performance, cost, and manufacturability.

Future Trends and Innovations in DIP PCB Technology

While SMT has become the dominant technology in many areas of electronics manufacturing, DIP PCB continues to evolve:

Automation Advancements

Innovations in automation are making DIP assembly more efficient, reducing the labor-intensive nature of the process[4].

Material Science Developments

New, eco-friendly materials for DIP casings are being developed to address environmental concerns without compromising performance[4].

Integration with Modern Technologies

The future of DIP technology may lie in its integration with modern SMT techniques, creating hybrid solutions that optimize the advantages of both technologies[4].

Conclusion

DIP PCB technology, despite being an older technology compared to SMT, continues to play a crucial role in the performance of certain electronic devices. Its robustness, ease of repair, and superior heat dissipation make it invaluable in specific applications, particularly those requiring durability and reliability. While SMT dominates in areas where miniaturization and high-volume production are key, DIP PCB remains relevant in industrial, automotive, and educational sectors.

The impact of DIP PCB on electronic performance is multifaceted, affecting aspects such as reliability, thermal management, and ease of modification. As the electronics industry continues to evolve, the choice between DIP and SMT (or a hybrid of both) will depend on the specific requirements of each application, balancing factors like size, cost, durability, and production volume.

Looking forward, innovations in DIP technology, including advancements in automation and materials science, promise to keep this technology relevant in the face of ongoing miniaturization trends. The future of electronics may well lie in the intelligent integration of DIP and SMT technologies, leveraging the strengths of each to create more efficient, reliable, and versatile electronic devices.

FAQ

1. What are the main differences between DIP and SMT in PCB assembly?

DIP (Dual In-line Package) and SMT (Surface Mount Technology) differ significantly in their assembly methods and component characteristics. DIP components have pins that are inserted through holes in the PCB and soldered on the opposite side, while SMT components are mounted directly onto the surface of the PCB[2]. SMT allows for higher component density and is more suitable for automated, high-volume production. DIP, on the other hand, offers stronger mechanical connections and easier manual assembly and repair[3].

2. How does DIP PCB technology impact the thermal management of electronic devices?

DIP PCB technology generally offers better thermal management compared to SMT. The through-hole design of DIP components allows for improved airflow around the component, facilitating more efficient heat dissipation[1]. This characteristic makes DIP PCBs particularly suitable for high-power applications or devices operating in high-temperature environments. The improved heat dissipation can lead to more stable performance and longer lifespan of electronic components.

3. In what scenarios is DIP PCB preferred over SMT in modern electronics?

Despite the prevalence of SMT, DIP PCB is still preferred in several scenarios. These include applications requiring high durability and resistance to mechanical stress, such as in industrial control systems and automotive electronics[1]. DIP is also favored in educational settings and for prototyping due to its ease of assembly and modification. Additionally, certain high-power or high-voltage applications benefit from the larger pin spacing and robust connections offered by DIP technology.

4. How does the cost of DIP PCBA compare to SMT PCBA?

The cost comparison between DIP and SMT PCBA is not straightforward and depends on various factors. DIP technology generally has lower initial setup costs, making it more economical for low to medium volume production runs[3]. SMT, while requiring higher initial investment in specialized equipment, can be more cost-effective for high-volume production due to its higher efficiency and automation capabilities. The choice between DIP and SMT often involves balancing factors such as production volume, component costs, and assembly time.

5. What future developments are expected in DIP PCB technology?

Future developments in DIP PCB technology are likely to focus on enhancing its competitiveness with SMT. This includes advancements in automation to improve assembly efficiency and reduce labor costs[4]. Innovations in material science are expected to produce DIP components with better performance and environmental sustainability. Additionally, there's a trend towards developing hybrid solutions that combine the strengths of both DIP and SMT technologies, potentially leading to more versatile and efficient PCB assemblies[4].

Citations:

[1] https://www.fs-pcba.com/dip-pcb/

[2] https://www.tecooems.com/info/smt-and-dip-difference-95780508.html

[3] https://ipcb.co/comparison-of-dip-and-smt-technology/

[4] https://hilelectronic.com/dip-package/

[5] https://www.fcpcba.com/wiki/dip/

[6] https://www.linkedin.com/pulse/what-smt-dip-difference-between-genevieve-li

[7] https://www.pcbx.com/article/Difference-Between-SMD-Soldering-and-DIP-Soldering

[8] https://www.hongzhousmart.com/pcb-pcba-factory-smt-dip-technology-pcba-assembly-4387.html

[9] https://www.grande-pcba.com/whats-the-difference-between-smt-components-dip-components-used-in-pcb-assembly/

[10] https://www.grande-pcba.com/whats-the-difference-between-smd-dip-components-in-pcba/