Content Menu

● Understanding CNC Technology

>> The Role of CNC in Surface Mount Soldering

>>> Key Features of CNC-Based Soldering Systems

● Benefits of CNC Technology in Soldering

>> Increased Accuracy

>> Enhanced Speed

>> Improved Quality Control

>> Cost Efficiency

>> Flexibility and Scalability

● The Impact of CNC Technology on Product Quality

>> Case Studies: Success Stories in CNC Soldering

● Conclusion

● FAQ

>> 1. What is a CNC-based surface mount device soldering system?

>> 2. How does CNC technology improve soldering accuracy?

>> 3. What are the benefits of using CNC soldering systems?

>> 4. Can CNC soldering systems handle different types of components?

>> 5. How does real-time monitoring work in CNC soldering?

In the rapidly evolving world of electronics manufacturing, precision is paramount. As devices become smaller and more complex, the need for accurate soldering techniques has never been greater. One of the most significant advancements in this field is the integration of CNC (Computer Numerical Control) technology into surface mount device (SMD) soldering systems. This article explores how CNC technology enhances the precision of surface mount soldering, the benefits it brings to the manufacturing process, and its impact on the overall quality of electronic products.

Understanding CNC Technology

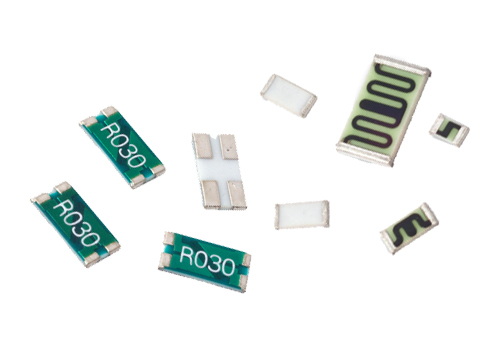

CNC technology refers to the automation of machine tools through the use of computers. In the context of soldering, CNC systems control the movement of soldering equipment with high precision, allowing for intricate and detailed work that manual methods simply cannot achieve. This technology is particularly beneficial in surface mount soldering, where components are mounted directly onto the surface of printed circuit boards (PCBs).

The Role of CNC in Surface Mount Soldering

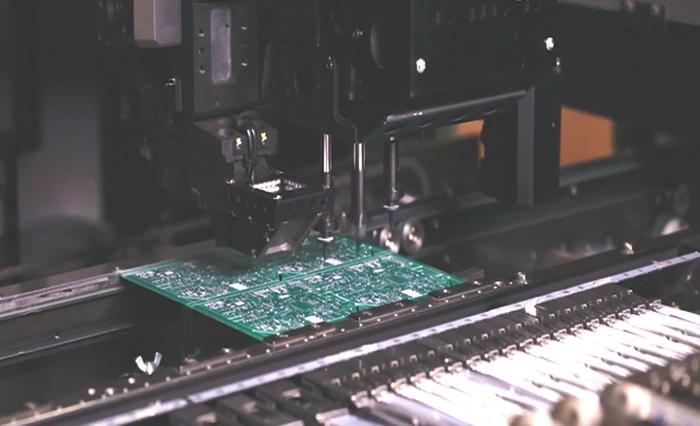

CNC-based surface mount device soldering systems utilize advanced algorithms and software to control the soldering process. This includes the precise placement of solder paste, the accurate positioning of components, and the controlled application of heat. The result is a soldering process that is not only faster but also significantly more accurate than traditional methods.

Key Features of CNC-Based Soldering Systems

1. Automated Component Placement: CNC systems can place components on PCBs with extreme accuracy, reducing the risk of misalignment and ensuring that each component is soldered correctly.

2. Consistent Solder Application: The ability to control the amount of solder paste applied to each joint ensures that there is neither excess nor insufficient solder, which can lead to defects.

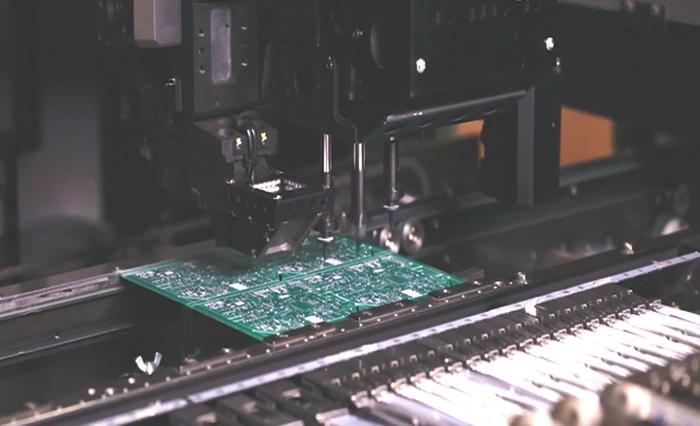

3. Temperature Control: CNC soldering systems can precisely regulate the temperature during the soldering process, which is crucial for preventing damage to sensitive components.

4. Real-Time Monitoring: Many CNC systems come equipped with sensors that monitor the soldering process in real-time, allowing for immediate adjustments to be made if any issues arise.

5. Data Logging and Analysis: CNC technology allows for the collection of data during the soldering process, which can be analyzed to improve future production runs and identify potential areas for improvement.

Benefits of CNC Technology in Soldering

The integration of CNC technology into surface mount soldering systems offers numerous benefits that enhance precision and overall production quality.

Increased Accuracy

One of the most significant advantages of CNC-based soldering systems is their ability to achieve high levels of accuracy. The precision of CNC technology minimizes the risk of human error, which is a common issue in manual soldering processes. This increased accuracy leads to better electrical connections and improved reliability of electronic devices.

Enhanced Speed

CNC systems can operate at much higher speeds than manual soldering methods. This increased speed not only boosts productivity but also allows manufacturers to meet tight deadlines without compromising quality. The ability to quickly and accurately solder components means that production lines can operate more efficiently.

Improved Quality Control

With CNC technology, manufacturers can implement stringent quality control measures. The real-time monitoring capabilities of CNC systems allow for immediate detection of defects, enabling quick corrective actions. This proactive approach to quality control helps to reduce waste and improve the overall quality of the final product.

Cost Efficiency

While the initial investment in CNC-based surface mount device soldering systems may be higher than traditional methods, the long-term cost savings are significant. The increased accuracy and speed lead to lower labor costs, reduced material waste, and fewer defective products. Over time, these savings can offset the initial investment and contribute to a more profitable manufacturing process.

Flexibility and Scalability

CNC technology offers manufacturers the flexibility to adapt to changing production needs. Whether it's a small batch of custom components or a large-scale production run, CNC systems can be easily reprogrammed to accommodate different soldering requirements. This scalability is essential in today's fast-paced electronics market, where demand can fluctuate rapidly.

The Impact of CNC Technology on Product Quality

The integration of CNC technology into surface mount soldering systems has a profound impact on the quality of electronic products. High precision in soldering leads to better electrical performance, reduced risk of failure, and increased longevity of devices. As consumers demand more reliable and efficient electronics, manufacturers must leverage CNC technology to meet these expectations.

Case Studies: Success Stories in CNC Soldering

Several companies have successfully implemented CNC-based surface mount device soldering systems, resulting in significant improvements in their production processes. For instance, a leading electronics manufacturer reported a 30% reduction in production time after switching to CNC soldering. Additionally, they experienced a 25% decrease in defective products, showcasing the effectiveness of CNC technology in enhancing precision and quality.

Conclusion

CNC technology has revolutionized the field of surface mount soldering, providing manufacturers with the tools they need to achieve unprecedented levels of precision and efficiency. By automating the soldering process, CNC systems minimize human error, enhance speed, and improve overall product quality. As the demand for high-quality electronic devices continues to grow, the adoption of CNC-based surface mount device soldering systems will undoubtedly play a crucial role in the future of electronics manufacturing.

FAQ

1. What is a CNC-based surface mount device soldering system?

A CNC-based surface mount device soldering system is an automated soldering solution that uses computer-controlled machinery to precisely place and solder components onto printed circuit boards.

2. How does CNC technology improve soldering accuracy?

CNC technology enhances soldering accuracy by automating the placement of components and controlling the solder application process, significantly reducing the risk of human error.

3. What are the benefits of using CNC soldering systems?

The benefits of CNC soldering systems include increased accuracy, enhanced speed, improved quality control, cost efficiency, and flexibility in production.

4. Can CNC soldering systems handle different types of components?

Yes, CNC soldering systems are highly versatile and can be programmed to handle various types of components, making them suitable for a wide range of electronic manufacturing applications.

5. How does real-time monitoring work in CNC soldering?

Real-time monitoring in CNC soldering involves the use of sensors to track the soldering process, allowing for immediate adjustments to be made if any issues are detected, thus ensuring consistent quality.