Content Menu

● Understanding SMT Pick and Place Machines

>> Key Components of SMT Pick and Place Machines

● The Mechanism Behind Efficiency

● Benefits of Using SMT Pick and Place Machines

● Challenges and Considerations

● Future Trends in SMT Pick and Place Technology

● Conclusion

● FAQ

>> 1. What is an SMT pick and place machine?

>> 2. How does a pick-and-place machine improve production efficiency?

>> 3. What are the key components of a pick-and-place machine?

>> 4. What challenges do manufacturers face when using pick-and-place machines?

>> 5. What future trends can we expect in SMT technology?

● Citations:

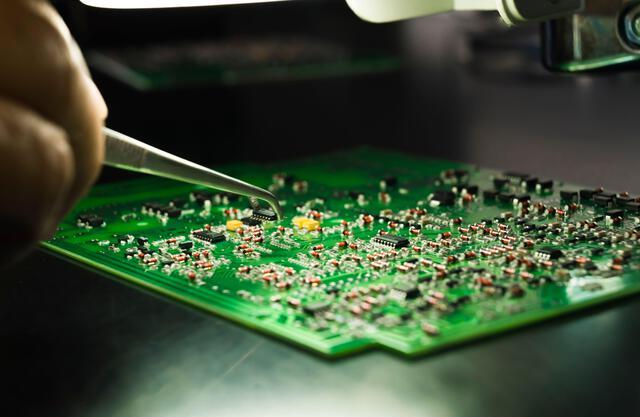

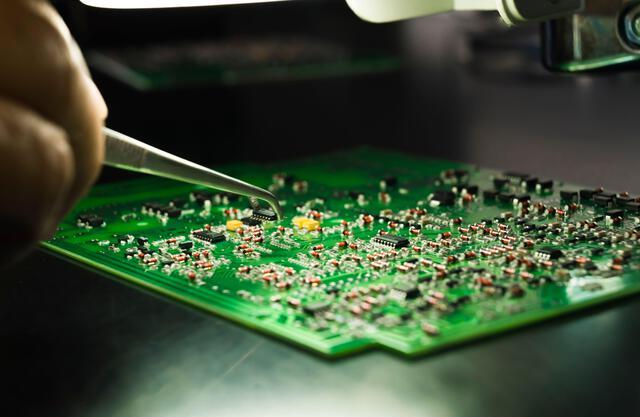

In the fast-paced world of electronics manufacturing, the efficiency of production processes is paramount. Surface Mount Technology (SMT) pick and place machines have revolutionized the way electronic components are assembled onto printed circuit boards (PCBs). These machines automate the placement of components with high speed and precision, significantly enhancing production efficiency. This article explores how SMT pick and place machines contribute to improved production efficiency, examining their operational mechanisms, benefits, and the impact they have on the manufacturing landscape.

Understanding SMT Pick and Place Machines

SMT pick and place machines are specialized robotic systems designed to automate the assembly of electronic components onto PCBs. They operate by picking components from feeders or trays and placing them accurately onto a PCB according to predefined specifications. The core functionality of these machines relies on advanced robotics, computer vision systems, and precise motion control technologies.

Key Components of SMT Pick and Place Machines

- Pick-and-Place Head: The heart of the machine, responsible for picking components using suction or mechanical grippers.

- Vision System: Ensures accurate alignment and placement of components by identifying their exact position on the PCB.

- Feeder System: Holds various components in a structured manner, allowing for quick access during the assembly process.

- Control Software: Manages the entire operation, from programming component placement to monitoring machine performance.

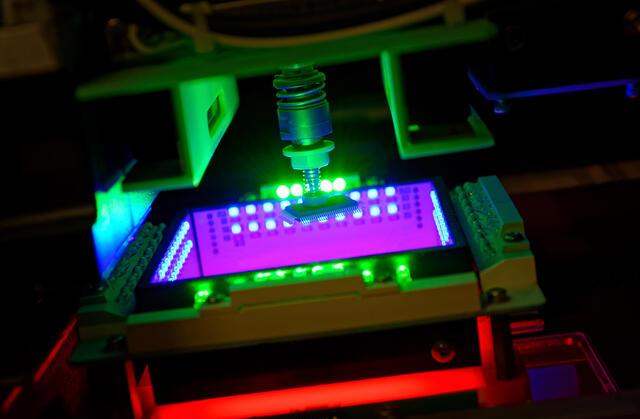

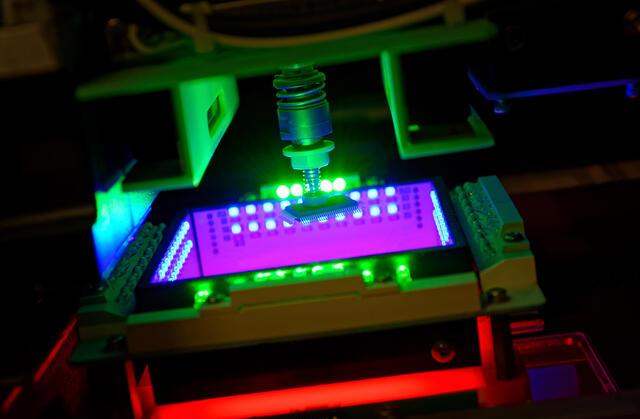

The Mechanism Behind Efficiency

The efficiency of SMT pick and place machines stems from several key factors:

1. High-Speed Operation: Modern pick and place machines can place thousands of components per hour. For example, some high-end models can achieve placement rates exceeding 90,000 components per hour, drastically reducing assembly time compared to manual processes[3][19].

2. Precision Placement: These machines offer exceptional accuracy, often placing components within ±0.1 mm. This precision minimizes defects caused by misalignment, reducing waste and rework costs associated with manual assembly[3][8].

3. Automation: By automating the pick-and-place process, manufacturers can reduce labor costs and minimize human error. This leads to a more streamlined workflow where operators can focus on higher-level tasks rather than repetitive manual placements[13][19].

4. Flexibility: SMT pick and place machines can be easily programmed to handle various component types and sizes. This adaptability allows manufacturers to switch between different product lines without significant downtime[3][4].

5. Integration with Other Systems: Many modern pick and place machines can integrate with other manufacturing equipment such as solder paste printers and reflow ovens, creating a seamless production line that enhances overall efficiency[16][20].

Benefits of Using SMT Pick and Place Machines

The adoption of SMT pick and place machines brings numerous benefits to manufacturers:

- Increased Production Capacity: With faster placement speeds, companies can produce larger quantities of PCBs in shorter timeframes, meeting market demands more effectively.

- Reduced Labor Costs: Automation reduces the need for manual labor in component placement, leading to significant cost savings in labor expenses.

- Improved Quality Control: The precision offered by these machines ensures higher quality assemblies with fewer defects, enhancing product reliability.

- Lower Material Waste: Accurate placements reduce the likelihood of component damage during assembly, leading to lower material costs over time.

- Enhanced Competitive Advantage: Companies that invest in advanced pick and place technology can respond more quickly to market changes, giving them an edge over competitors who rely on slower manual processes[1][3][19].

Challenges and Considerations

While SMT pick and place machines offer substantial benefits, there are also challenges that manufacturers must consider:

- Initial Investment Costs: The upfront cost of acquiring high-quality pick and place machines can be significant. However, this investment often pays off through increased efficiency and reduced operational costs over time[4][9].

- Maintenance Requirements: Regular maintenance is essential to ensure optimal performance. Neglecting maintenance can lead to machine downtime and production delays[12][14].

- Training Needs: Operators must be trained to effectively use these machines. While many systems are user-friendly, understanding programming and troubleshooting is critical for maximizing productivity[5][10].

Future Trends in SMT Pick and Place Technology

The evolution of SMT technology continues to shape the manufacturing landscape. Future trends include:

- Smart Automation: Integration of artificial intelligence (AI) for predictive maintenance and real-time monitoring will enhance machine performance and reduce downtime.

- Increased Speed and Precision: Ongoing advancements in robotics will lead to even faster placement speeds and greater accuracy.

- Sustainability Initiatives: As environmental concerns grow, manufacturers are focusing on reducing waste through more efficient processes enabled by advanced machinery.

Conclusion

SMT pick and place machines represent a cornerstone of modern electronics manufacturing. Their ability to improve production efficiency through high-speed operation, precision placement, automation, flexibility, and integration with other systems makes them invaluable assets for manufacturers seeking to enhance productivity while maintaining quality standards. Despite the challenges associated with initial investments and maintenance requirements, the long-term benefits far outweigh these concerns. As technology continues to advance, we can expect further enhancements in efficiency that will drive innovation in the electronics industry.

FAQ

1. What is an SMT pick and place machine?

An SMT pick and place machine is an automated device used in electronics manufacturing to accurately position surface mount components onto printed circuit boards (PCBs).

2. How does a pick-and-place machine improve production efficiency?

These machines enhance production efficiency by automating component placement at high speeds with high precision while reducing labor costs associated with manual assembly.

3. What are the key components of a pick-and-place machine?

Key components include the pick-and-place head for component handling, a vision system for alignment accuracy, feeders for component storage, and control software for operation management.

4. What challenges do manufacturers face when using pick-and-place machines?

Challenges include initial investment costs, maintenance requirements for optimal performance, and training needs for operators to effectively use the machinery.

5. What future trends can we expect in SMT technology?

Future trends may include smart automation with AI integration for predictive maintenance, increased speed and precision in placements, as well as sustainability initiatives aimed at reducing waste during production.

Citations:

[1] https://www.smtfactory.com/Optimizing-SMT-Manufacturing-The-Crucial-Contribution-of-Pick-And-Place-Machines-To-Maximize-Productivity-id49783497.html

[2] https://www.smtfactory.com/introduction-of-smt-pick-and-place-machine

[3] https://www.machinedesign.com/markets/robotics/article/21122266/10-benefits-of-using-a-pick-and-place-machine

[4] https://www.manufacturingtomorrow.com/news/2024/06/24/choosing-the-right-smt-pick-and-place-machine-a-comprehensive-guide-for-different-buyers/22957

[5] https://www.tronstol.com/the-knowledge-and-steps-you-need-to-know-about-smt-pick-and-place-machine-programs.html

[6] https://www.pcbunlimited.com/pdf/HW-T4-44_50F_PCBU.pdf

[7] https://www.smtglobe.com/product/improve-smt-production-efficiency.html

[8] https://global.neotel.tech/2023/01/12/what-is-pick-and-place-machine/

[9] https://www.zjyingxing.com/info/what-are-the-advantages-of-domestic-sm-102753805.html

[10] https://www.smallsmt.biz/home/know-how/faq-feeder-settings/

[11] https://www.tronstol.com/some-knowledge-about-smt.html

[12] https://www.zjyingxing.com/info/what-are-the-common-smt-pick-and-place-machine-88387624.html

[13] https://www.restronics.com/blog/everything-you-need-to-know-about-smt-pick-and-place-machines

[14] https://www.qhsmt.com/2023/11/29/smt-pick-and-place-most-asked-power-electronics-supply-questions-and-answers/

[15] https://www.tronstol.com/what-is-a-pick-and-place-machine.html

[16] https://blog.matric.com/smt-production-for-pcbs-matric

[17] https://www.tronstol.com/the-three-major-development-trends-of-the-pick-and-place-machine-in-the-future.html

[18] https://www.pcbunlimited.com/blog/purpose-of-a-pick-and-place-machine-in-pcb-assembly/

[19] https://www.wevolver.com/article/smt-process

[20] https://www.neodensmt.com/news/improve-smt-production-efficiency-48868013.html

[21] https://www.microtype.io/should-you-buy-a-pick-and-place-machine/

[22] https://www.linkedin.com/pulse/advantages-smt-manufacturing-practical-cost-effective-nyn3c

[23] https://www.tronstol.com/how-to-improve-the-efficiency-of-pick-and-place-ma.html

[24] https://www.protoexpress.com/blog/good-not-so-good-sides-surface-mount-technology/

[25] https://www.tronstol.com/notes-on-smt-mounters-processing-and-the-advantages.html

[26] https://www.smtneoden.com/news/how-to-effectively-improve-the-production-efficiency-of-pcb-smt-machine/

[27] https://www.itechsmt.com/blogs/pnp-machine-blog/5-benefits-of-pick-and-place-machine-ppm-a320vb

[28] https://www.hct-smt.com/blog/precision-and-efficiency-unleashed--exploring-the-smt-automatic-pick-and-place-machine

[29] https://www.zjyingxing.com/info/how-to-improve-the-manufacturing-effici-102670373.html

[30] https://electronics.stackexchange.com/questions/529958/are-pick-place-machines-allergic-to-bags-of-parts

[31] https://forum.allaboutcircuits.com/threads/diy-smt-pick-and-place-machine.188060/

[32] https://www.ddmnovastar.com/smt-quick-tips-selecting-a-pick-and-place-machine

[33] https://smtnet.com/Forums/index.cfm?fuseaction=view_thread&Thread_ID=11094

[34] https://www.manncorp.com/pages/selecting-a-pick-and-place-machine-introduction

[35] https://www.all-smt.com/support-center/faq/

[36] https://smtfuture.com/faq/

[37] https://community.particle.io/t/manual-smt-pick-and-place-machine/43990