Content Menu

● What is an SMD Reflow Soldering Machine?

● Components of an SMD Reflow Soldering Machine

● Working Principle of an SMD Reflow Soldering Machine

● Temperature Zones in an SMD Reflow Soldering Machine

● Detailed Process Stages in SMD Reflow Soldering

>> 1. Preheating

>> 2. Thermal Soaking

>> 3. Reflow (Peak Temperature)

>> 4. Cooling

● Types of SMD Reflow Soldering Machines

● Advantages of Using an SMD Reflow Soldering Machine

● Key Process Parameters in SMD Reflow Soldering

● Quality Control and Inspection Post-Reflow

● Environmental and Safety Considerations

● Common Challenges and Solutions in SMD Reflow Soldering

● Conclusion

● FAQ

>> 1. What is the main function of an SMD reflow soldering machine?

>> 2. How many temperature zones does a typical reflow oven have?

>> 3. Why is controlled heating important in reflow soldering?

>> 4. What types of heating methods are used in SMD reflow soldering machines?

>> 5. How does the cooling zone affect solder joint quality?

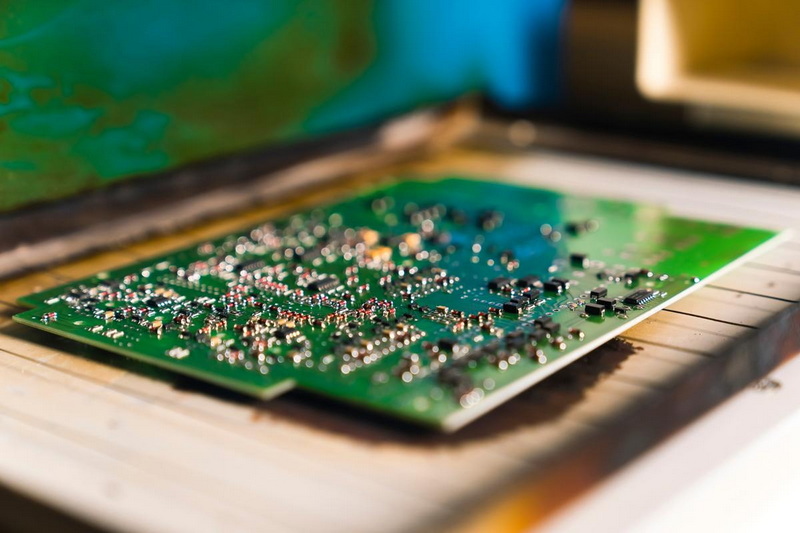

Surface Mount Device (SMD) reflow soldering machines are essential equipment in modern electronics manufacturing, enabling the precise and reliable attachment of tiny electronic components onto printed circuit boards (PCBs). This article provides an in-depth exploration of how an SMD reflow soldering machine works, detailing its components, operational principles, temperature zones, and the overall reflow soldering process. We will also cover different types of reflow ovens, key process parameters, and troubleshooting tips to ensure high-quality solder joints.

What is an SMD Reflow Soldering Machine?

An SMD reflow soldering machine is a specialized oven used in surface mount technology (SMT) manufacturing to solder surface mount components onto PCBs. The machine applies controlled heat to melt solder paste, which bonds components to the board both mechanically and electrically. Unlike traditional wave soldering used for through-hole components, reflow soldering is tailored for the miniaturized, densely packed SMDs, making it indispensable for modern electronics assembly.

Components of an SMD Reflow Soldering Machine

The typical SMD reflow soldering machine consists of three main parts:

- Heater system: Provides the heat necessary to melt solder paste. This can involve infrared lamps, hot air jets, or vapor phase heating.

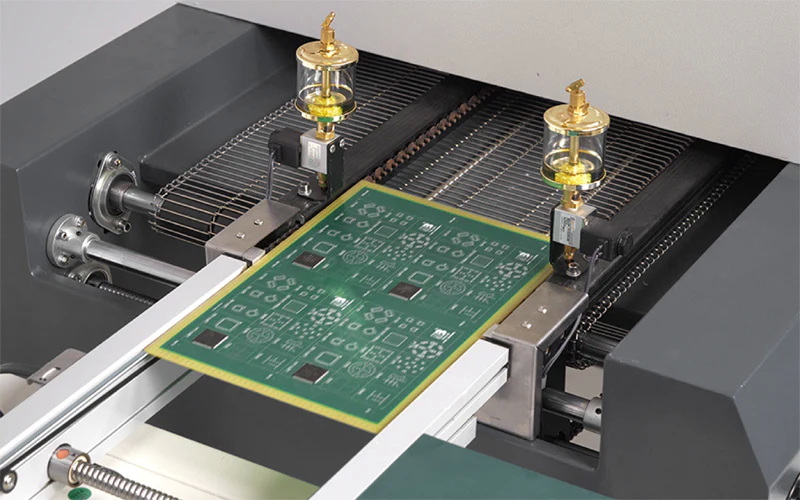

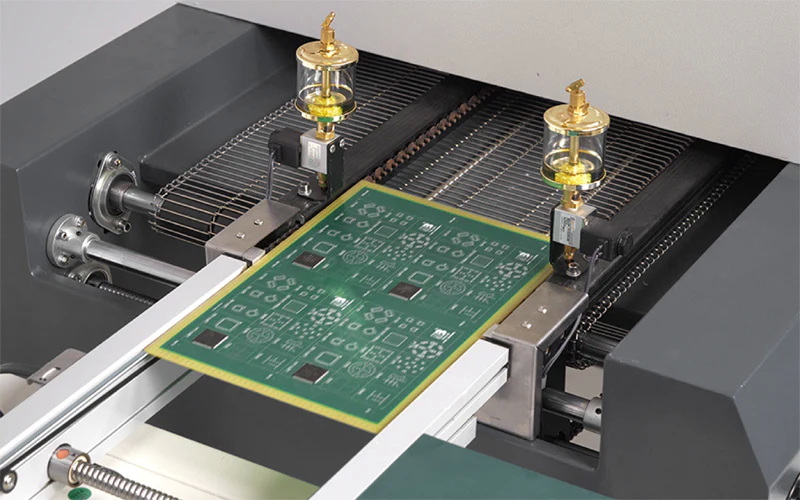

- Conveyor system: Moves the PCB through different temperature zones inside the oven.

- Temperature control system: Monitors and regulates the temperature profile to ensure uniform heating and avoid component damage.

Working Principle of an SMD Reflow Soldering Machine

The core function of the SMD reflow soldering machine is to heat the PCB assembly in a controlled manner so that the solder paste transitions from a solid paste to liquid and then back to solid, forming reliable solder joints.

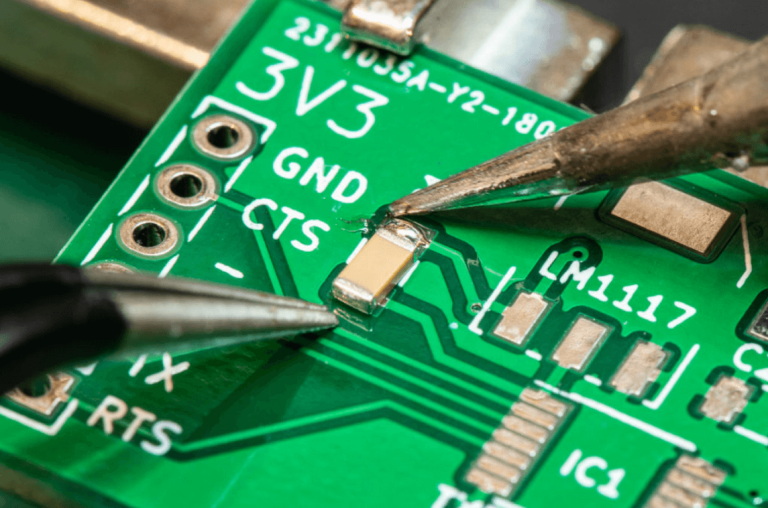

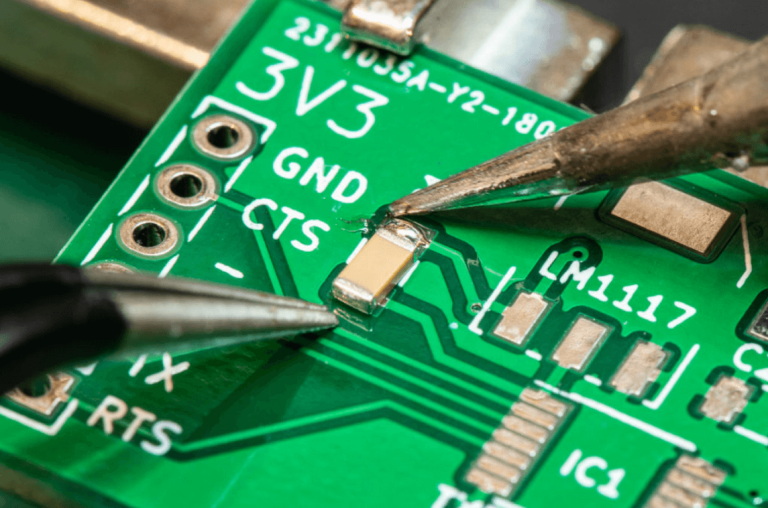

1. Solder paste application: Before entering the machine, solder paste (a mixture of powdered solder alloy and flux) is applied precisely to the PCB pads using a stencil.

2. Component placement: Surface mount components are placed on the solder paste using automated pick-and-place machines.

3. Controlled heating: The PCB with components is conveyed into the reflow oven where it passes through several temperature zones.

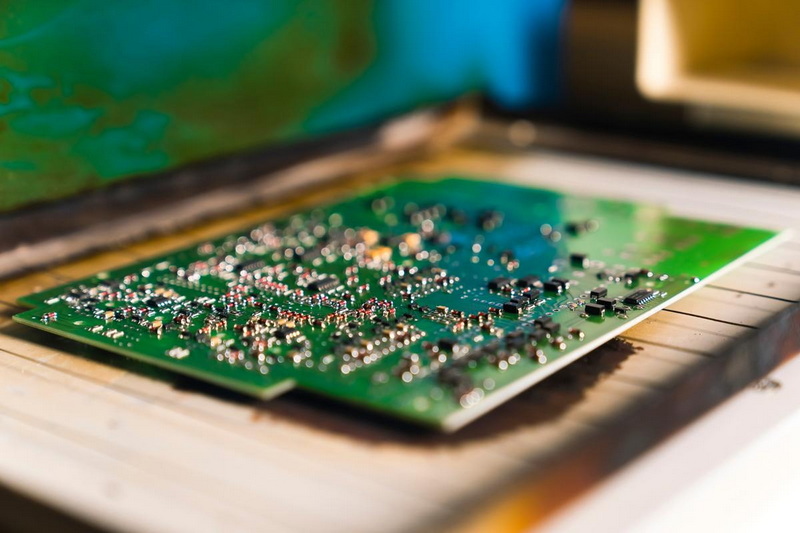

4. Melting and bonding: The solder paste melts, flux activates to remove oxides, and molten solder wets the component leads and pads.

5. Cooling: The assembly is gradually cooled, solidifying the solder joints and completing the process.

Temperature Zones in an SMD Reflow Soldering Machine

The reflow oven is divided into four main temperature zones, each critical for the quality of the solder joints:

| Zone | Purpose |

| Preheat Zone | Gradually raises temperature to prevent thermal shock and activates flux in solder paste. |

| Soaking (Thermal Soak) Zone | Maintains uniform temperature to stabilize components and fully activate flux. |

| Reflow Zone | Heats to peak temperature (220°C–250°C) to melt solder paste and form solder joints. |

| Cooling Zone | Gradually cools the PCB to solidify solder joints and avoid thermal stress. |

The temperature profile is carefully controlled to avoid damaging sensitive components while ensuring solder paste melts and wets properly.

Detailed Process Stages in SMD Reflow Soldering

1. Preheating

The PCB assembly enters the oven and is slowly heated to a temperature typically between 150°C and 180°C. This stage prevents thermal shock that could crack components or the PCB itself. The flux in the solder paste begins to activate, removing oxides from component leads and pads to promote solder wetting.

2. Thermal Soaking

In this phase, the temperature is held steady to allow heat to penetrate uniformly throughout the PCB and components. This ensures that all parts reach a consistent temperature, which is crucial for soldering quality. The flux continues to clean the surfaces, and volatile gases evaporate.

3. Reflow (Peak Temperature)

The temperature rapidly rises to the peak, usually between 220°C and 250°C, depending on the solder alloy. At this point, the solder paste melts (reflows), forming metallurgical bonds between component leads and PCB pads. The time above the liquidus temperature ("time above reflow") is carefully controlled to avoid overheating or insufficient melting.

4. Cooling

After the peak, the PCB is gradually cooled to solidify the solder joints. Controlled cooling prevents thermal stress and ensures strong, defect-free connections. Rapid cooling can cause cracks or weak joints, so this phase is as important as heating.

Types of SMD Reflow Soldering Machines

There are several types of SMD reflow soldering machines, classified by their heating method:

- Infrared Reflow Ovens: Use ceramic infrared heaters to radiate heat directly to the PCB. They are simple but can cause uneven heating due to varying infrared absorption by components.

- Convection Reflow Ovens: Use heated air circulated by fans to transfer heat evenly by convection and conduction. This method provides better temperature uniformity and control.

- Infrared Convection Ovens: Combine infrared radiation with convection heating for efficient and uniform heating.

- Vapor Phase Reflow Ovens: Use the condensation of a vaporized heat transfer liquid with a specific boiling point to heat PCBs. This method is oxygen-free, energy-efficient, and prevents overheating.

- Nitrogen Atmosphere Reflow Ovens: Inject nitrogen gas to reduce oxidation during soldering, improving joint quality.

- Vacuum Reflow Ovens: Add vacuum chambers to reduce voids and bubbles in solder joints, enhancing reliability.

Advantages of Using an SMD Reflow Soldering Machine

- High precision and repeatability: Automated temperature control ensures consistent solder joints.

- Suitable for miniaturized components: Supports dense PCB layouts with tiny SMDs.

- Efficient mass production: Fast processing speeds with minimal manual intervention.

- Reduced defects: Controlled heating profiles minimize solder bridging, tombstoning, and cold joints.

- Adaptability: Various heating methods and atmospheres can be tailored to specific applications.

Key Process Parameters in SMD Reflow Soldering

To achieve optimal soldering results, several parameters must be carefully controlled:

- Ramp-up rate: The speed at which the temperature increases during preheating. Typically 1–3°C per second to avoid thermal shock.

- Soak time and temperature: Duration and temperature in the soaking zone to activate flux and ensure uniform heating.

- Peak temperature: Must be high enough to fully melt the solder paste but below the maximum rating of components (usually 220°C–250°C).

- Time above liquidus (TAL): The period the solder remains above its melting point, generally 30–90 seconds.

- Cooling rate: Should be controlled to avoid thermal stress; typically 2–4°C per second.

Monitoring and adjusting these parameters is vital for preventing defects such as tombstoning, bridging, and cold solder joints.

Quality Control and Inspection Post-Reflow

After soldering, assemblies undergo inspection to ensure solder joint integrity:

- Visual inspection: Identifies obvious defects like solder bridges, insufficient solder, or misaligned components.

- X-ray inspection: Detects hidden defects such as voids, insufficient wetting, or tombstoning.

- Automated Optical Inspection (AOI): Uses cameras and software to detect solder and component placement defects.

- Functional testing: Verifies electrical performance of the assembled PCB.

Consistent quality control is essential to maintain high yields and reliability in electronics manufacturing.

Environmental and Safety Considerations

Modern SMD reflow soldering machines are designed to minimize environmental impact and ensure operator safety:

- Fume extraction systems: Remove harmful flux fumes generated during reflow.

- Energy-efficient designs: Vapor phase and convection ovens consume less energy compared to older methods.

- Use of lead-free solder: Complies with RoHS regulations, though it requires precise temperature control due to higher melting points.

- Nitrogen atmosphere: Reduces oxidation, lowering the need for flux and minimizing harmful emissions.

Proper maintenance and operation protocols ensure safe working environments and compliance with environmental standards.

Common Challenges and Solutions in SMD Reflow Soldering

- Thermal shock: Avoided by gradual preheating and controlled ramp rates.

- Non-wetting or poor solder joints: Caused by improper solder paste application, insufficient flux activation, or incorrect temperature profiles.

- Component damage: Prevented by respecting maximum temperature ratings and uniform heating.

- Solder bridging: Controlled by precise solder paste deposition and optimized reflow profiles.

- Voiding: Reduced by vacuum reflow ovens or nitrogen atmospheres.

- Tombstoning: Minimized by balanced heating and proper solder paste volume.

Understanding these challenges and their solutions improves yield and product reliability.

Conclusion

An SMD reflow soldering machine is a critical piece of equipment in modern electronics manufacturing, enabling the precise and reliable attachment of surface mount components to PCBs. By carefully controlling temperature through distinct zones-preheating, soaking, reflow, and cooling-the machine ensures the solder paste melts and solidifies to form strong electrical and mechanical connections. Various types of reflow ovens provide options for different production needs, from infrared to vapor phase and vacuum reflow. Mastery of the reflow soldering process leads to high-quality, reliable electronic assemblies essential for today's compact and complex devices.

FAQ

1. What is the main function of an SMD reflow soldering machine?

The primary function is to heat PCBs with surface mount components in a controlled manner to melt solder paste and form reliable solder joints between components and the PCB.

2. How many temperature zones does a typical reflow oven have?

A typical reflow oven has four temperature zones: preheat, soaking, reflow (peak temperature), and cooling zones, each serving a specific purpose in the soldering process.

3. Why is controlled heating important in reflow soldering?

Controlled heating prevents thermal shock, ensures uniform temperature distribution, activates flux properly, and avoids defects such as cold joints or component damage.

4. What types of heating methods are used in SMD reflow soldering machines?

Common heating methods include infrared radiation, convection heating with hot air, vapor phase heating, and combinations like infrared convection. Some machines also use nitrogen atmospheres or vacuum chambers for improved quality.

5. How does the cooling zone affect solder joint quality?

The cooling zone solidifies the molten solder joints gradually to prevent thermal stress and cracking, ensuring strong and defect-free electrical and mechanical connections.