Content Menu

● The Role of SMD Machines in Electronics Manufacturing

>> Speed and Precision

>> Handling of Diverse Components

● Optimization Strategies for SMD Machine Efficiency

>> 1. Invest in High-Speed Placement Machines

>> 2. Optimize the SMT Process

>> 3. Implement Inline Inspection Systems

>> 4. Automate Material Handling

>> 5. Enhance Operator Training

● Impact of SMD Machines on Production Costs

● Challenges in Implementing SMD Machines

>> 1. Initial Investment

>> 2. Technical Expertise

>> 3. Rapid Technological Advancements

● Future Trends in SMD Machine Technology

>> 1. Artificial Intelligence and Machine Learning

>> 2. Industry 4.0 Integration

>> 3. Improved Component Handling

>> 4. Enhanced Miniaturization Capabilities

● Conclusion

● Frequently Asked Questions

>> 1. What is an SMD machine and how does it work?

>> 2. How fast can an SMD machine place components?

>> 3. What types of components can an SMD machine handle?

>> 4. How does an SMD machine improve production quality?

>> 5. What maintenance does an SMD machine require?

● Citations:

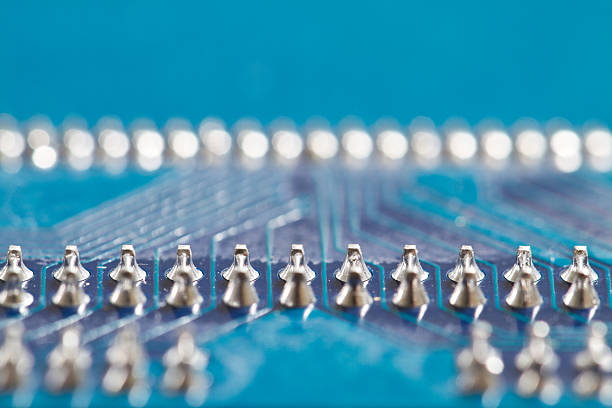

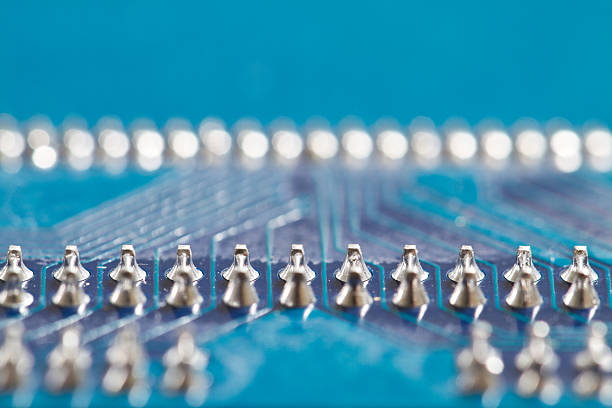

Surface Mount Technology (SMT) has revolutionized the electronics manufacturing industry, and at the heart of this revolution lies the SMD machine. SMD, which stands for Surface Mount Device, refers to the components that are mounted directly onto the surface of printed circuit boards (PCBs). The SMD machine, also known as a pick-and-place machine, is a crucial piece of equipment in the SMT assembly process. This article will explore how SMD machines significantly improve production efficiency in electronics manufacturing.

The Role of SMD Machines in Electronics Manufacturing

SMD machines are designed to automate the process of placing surface mount components onto PCBs. These machines use advanced robotics and computer vision systems to accurately pick up components from reels or trays and place them precisely on the PCB[1]. The efficiency gains from using SMD machines are substantial, as they can place components at speeds that far exceed human capabilities.

Speed and Precision

One of the primary ways SMD machines improve production efficiency is through their incredible speed and precision. Modern high-speed SMD machines can place more than 136,000 components per hour, a rate that would be impossible to achieve with manual assembly[4]. This high-speed operation significantly reduces production time, allowing manufacturers to meet tight deadlines and increase their output.

The precision of SMD machines is equally impressive. These machines can place components with an accuracy of up to 0.02mm, ensuring consistent quality across all PCBs produced[1]. This level of precision not only improves the reliability of the final product but also reduces the need for rework, further enhancing production efficiency.

Handling of Diverse Components

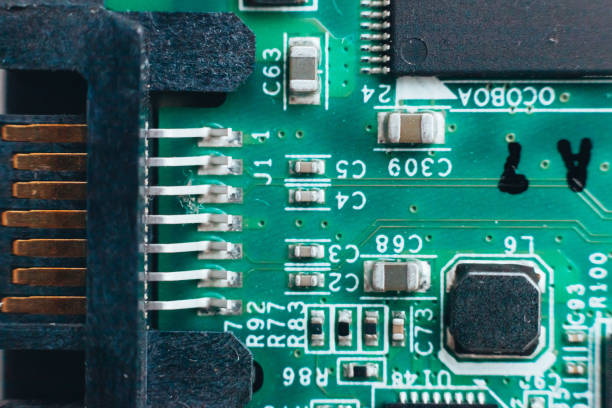

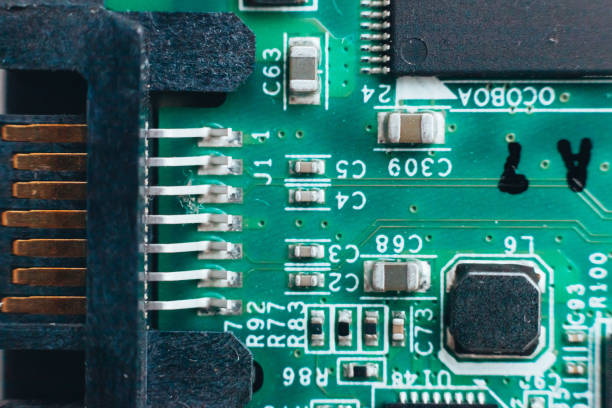

SMD machines are capable of handling a wide variety of component types and sizes. From tiny 0201 resistors to large BGAs (Ball Grid Arrays), these machines can accommodate the diverse range of components used in modern electronics[2]. This versatility eliminates the need for multiple specialized machines or manual placement of certain components, streamlining the production process.

Optimization Strategies for SMD Machine Efficiency

While SMD machines inherently improve production efficiency, there are several strategies that manufacturers can employ to maximize their benefits:

1. Invest in High-Speed Placement Machines

Investing in state-of-the-art SMD machines with high placement speeds is one of the most effective ways to boost production efficiency. These advanced machines often feature multi-head placement systems and laser alignment technologies, allowing for faster and more accurate component placement[1].

2. Optimize the SMT Process

Efficiency can be further improved by optimizing various aspects of the SMT process. This includes:

- Machine Setup Optimization: Carefully planning the machine setup to minimize changeover times between different PCB designs.

- Component Feeder Selection: Choosing the right component feeders and optimizing their arrangement to reduce pick-and-place travel distances.

- Placement Parameter Optimization: Fine-tuning placement parameters such as speed, acceleration, and pick-up force for different component types.

- Production Sequence Optimization: Grouping similar components and using common feeders to reduce the number of machine tooling changes[1].

3. Implement Inline Inspection Systems

Integrating inline inspection systems with SMD machines can significantly enhance production efficiency. These systems use cameras and sensors to detect defects such as component misalignment or insufficient solder paste immediately after placement. By identifying issues early in the process, manufacturers can reduce the risk of downstream failures and minimize rework, thereby improving overall efficiency[1].

4. Automate Material Handling

Automating the material handling process can further increase the efficiency of SMD machine operations. This includes:

- Automated Component Feeder Changeover: Implementing systems that can automatically change component reels or trays, reducing machine downtime.

- Material Management Systems: Using software-driven systems to track component inventory and ensure timely replenishment.

- Automated Guided Vehicles (AGVs): Employing AGVs to transport materials to and from the SMD machines, reducing manual labor and improving material flow[1].

5. Enhance Operator Training

While SMD machines are highly automated, skilled operators are still crucial for maximizing efficiency. Comprehensive training programs should be implemented to ensure operators can:

- Effectively operate SMD machines

- Quickly identify and resolve issues

- Optimize machine settings for different PCB designs

- Perform basic maintenance and troubleshooting[1]

Well-trained operators can significantly reduce machine downtime and improve overall production efficiency.

Impact of SMD Machines on Production Costs

The efficiency improvements brought about by SMD machines translate directly into cost savings for manufacturers. By increasing production speed and reducing labor requirements, SMD machines help lower the per-unit cost of PCB assembly[4]. Additionally, the high precision of these machines leads to fewer defects and less rework, further reducing production costs.

Challenges in Implementing SMD Machines

While SMD machines offer significant benefits, their implementation is not without challenges. Some of the key issues that manufacturers may face include:

1. Initial Investment

High-end SMD machines represent a substantial capital investment. Manufacturers must carefully consider their production volumes and future growth projections to justify this expense[2].

2. Technical Expertise

Operating and maintaining SMD machines requires specialized technical knowledge. Companies may need to invest in training programs or hire skilled technicians to effectively utilize these machines[2].

3. Rapid Technological Advancements

The field of SMT is constantly evolving, with new technologies and capabilities being introduced regularly. Manufacturers must stay informed about these advancements and be prepared to upgrade their equipment to remain competitive[4].

Future Trends in SMD Machine Technology

As technology continues to advance, SMD machines are expected to become even more efficient and capable. Some of the trends that are likely to shape the future of SMD machines include:

1. Artificial Intelligence and Machine Learning

AI and machine learning algorithms are being integrated into SMD machines to optimize component placement, predict maintenance needs, and improve overall efficiency[4].

2. Industry 4.0 Integration

SMD machines are becoming increasingly connected, allowing for real-time data collection and analysis. This integration with Industry 4.0 principles enables predictive maintenance, remote monitoring, and continuous process optimization[4].

3. Improved Component Handling

Advancements in gripper technology and vision systems are allowing SMD machines to handle an even wider range of component sizes and types, including flexible and oddly-shaped components[2].

4. Enhanced Miniaturization Capabilities

As electronic devices continue to shrink, SMD machines are being developed to handle ever-smaller components with greater precision[4].

Conclusion

SMD machines have revolutionized electronics manufacturing by dramatically improving production efficiency. Through their high-speed operation, precision placement, and ability to handle diverse components, these machines have enabled manufacturers to meet the increasing demands of the electronics industry. By implementing optimization strategies such as process refinement, inline inspection, and automation of material handling, companies can further enhance the efficiency gains provided by SMD machines.

As technology continues to advance, SMD machines will likely become even more sophisticated, incorporating AI, machine learning, and Industry 4.0 principles. These advancements will further improve production efficiency, reduce costs, and enable the creation of increasingly complex and miniaturized electronic devices.

The impact of SMD machines on production efficiency is undeniable, and their continued evolution will play a crucial role in shaping the future of electronics manufacturing. As the industry moves forward, the ability to effectively implement and optimize SMD machine technology will be a key factor in determining a manufacturer's competitiveness and success in the global market.

Frequently Asked Questions

1. What is an SMD machine and how does it work?

An SMD (Surface Mount Device) machine, also known as a pick-and-place machine, is an automated device used in electronics manufacturing to place surface mount components onto printed circuit boards (PCBs). It works by using a combination of computer vision systems, precision robotics, and vacuum nozzles to pick up components from reels or trays and place them accurately on the PCB. The machine's software controls the movement and placement based on predetermined coordinates for each component.

2. How fast can an SMD machine place components?

Modern high-speed SMD machines are capable of placing more than 136,000 components per hour. However, the actual speed can vary depending on the specific model of the machine, the types of components being placed, and the complexity of the PCB design. Some advanced machines can achieve even higher speeds for certain types of components.

3. What types of components can an SMD machine handle?

SMD machines are designed to handle a wide variety of surface mount components, ranging from tiny 0201 resistors (0.6 mm x 0.3 mm) to larger integrated circuits and Ball Grid Arrays (BGAs). They can typically accommodate components up to 50 mm x 50 mm in size, although some specialized machines can handle even larger components. The versatility of SMD machines allows them to work with resistors, capacitors, inductors, diodes, transistors, ICs, and various other electronic components used in modern PCB designs.

4. How does an SMD machine improve production quality?

SMD machines significantly improve production quality through their high precision and consistency. These machines can place components with an accuracy of up to 0.02mm, which is far more precise than manual placement. This level of accuracy ensures that components are correctly positioned, reducing the risk of short circuits or open connections. Additionally, the consistency of machine placement reduces variations between PCBs, leading to more uniform product quality. Many SMD machines also incorporate vision systems for real-time inspection, further enhancing quality control by detecting placement errors or component defects immediately.

5. What maintenance does an SMD machine require?

Regular maintenance is crucial for ensuring the optimal performance and longevity of an SMD machine. Typical maintenance tasks include:

- Daily cleaning of nozzles, feeders, and conveyor belts to prevent contamination

- Regular calibration of the vision system and placement heads to maintain accuracy

- Lubrication of moving parts as per the manufacturer's recommendations

- Inspection and replacement of wear items such as nozzles and belts

- Software updates to ensure the machine is running the latest firmware

- Periodic full servicing by trained technicians, typically annually or bi-annually

Proper maintenance not only extends the life of the machine but also helps maintain its efficiency and accuracy, ensuring consistent production quality.

Citations:

[1] https://www.zjyingxing.com/info/what-are-the-ways-to-improve-the-efficiency-of-88896111.html

[2] https://scanditronictech.com/resources/smd-soldering-rework-stations/

[3] https://patents.google.com/patent/CN104244605B/zh

[4] https://jlcpcb.com/blog/the-characteristics-of-surface-mount-technology

[5] https://versae.com/smt-assembly-faq/

[6] https://patents.google.com/patent/CN106743907A/zh

[7] https://vohrum.com/unlocking-the-full-potential-of-surface-mount-technology-tips-and-techniques-for-efficient-implementation/

[8] https://www.aixuntech.com/newsinfo/5%20Frequently%20Asked%20Questions%20about%20SMD%20soldering/

[9] https://www.163.com/dy/article/EDIGQUV605370K28.html