Content Menu

● Introduction to SMD Component Mounting Machines

>> Key Components of SMD Mounting Machines

● Advantages of SMD Component Mounting Machines

>> High-Speed Placement

>> Enhanced Accuracy

>> Flexibility and Versatility

>> Reduced Labor Costs

>> Compact PCB Designs

● Improving Efficiency with SMD Component Mounting Machines

● Applications of SMD Component Mounting Machines

● Technological Trends and Future Developments

>> Integration of AI and Machine Learning

>> High-Speed Pick-and-Place Machines

>> Regional Developments

● Challenges and Solutions in SMT

>> Ensuring Component Placement Accuracy

>> Achieving Consistent Solder Paste Application

● Case Study: SMT Pick-and-Place Machines in Industrial Control Systems

>> Efficiency

>> Reliability

>> Cost-Effectiveness

● Future of SMD Component Mounting Machines

● Conclusion

● Frequently Asked Questions

>> 1. What is the primary advantage of using SMD component mounting machines?

>> 2. How do SMD component mounting machines improve accuracy?

>> 3. What role does automation play in SMD component mounting?

>> 4. Can SMD component mounting machines handle a variety of components?

>> 5. How does SMT technology contribute to compact PCB designs?

● Citations:

Surface Mount Technology (SMT) has revolutionized the electronics manufacturing industry by providing a fast, precise, and cost-effective method for assembling printed circuit boards (PCBs). At the heart of this technology is the SMD component mounting machine, which plays a crucial role in enhancing production efficiency. This article will delve into the ways an SMD component mounting machine improves production efficiency and explore its applications, advantages, and the future of SMT in electronics manufacturing.

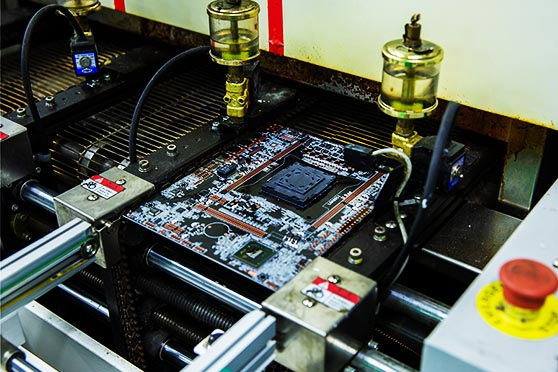

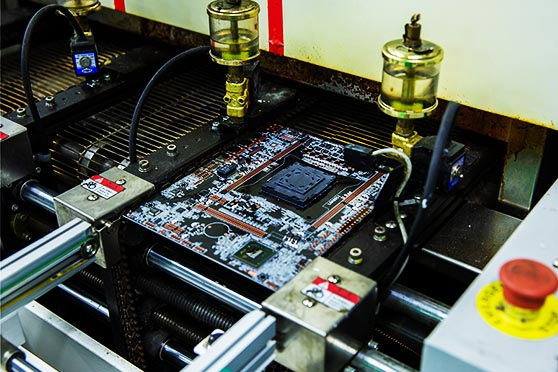

Introduction to SMD Component Mounting Machines

SMD component mounting machines, also known as SMT mounters, are precision industrial robots that utilize advanced technologies such as laser alignment and multi-head placement systems to mount components onto PCBs. These machines are designed to optimize the assembly process by increasing speed, accuracy, and reliability. The integration of machine photoelectric and computer control technologies enables SMT mounters to perform complex tasks with minimal human intervention, significantly improving production efficiency.

Key Components of SMD Mounting Machines

1. Mounting Heads: These are responsible for picking and placing components onto the PCB. Modern machines often feature multiple heads to increase throughput.

2. Component Feeders: These supply the components to the mounting heads. Automated feeder systems can reduce changeover times and improve material handling.

3. PCB Bearing Devices: These hold the PCB in place during the assembly process, ensuring stability and precision.

4. Computer Control Systems: These manage the entire process, from component recognition to placement, using sophisticated algorithms and machine vision.

Advantages of SMD Component Mounting Machines

High-Speed Placement

SMD component mounting machines can place components at incredibly high speeds, often exceeding 136,000 components per hour. This capability significantly boosts production output, allowing manufacturers to meet high demand levels efficiently.

Enhanced Accuracy

These machines use advanced vision systems and laser alignment to ensure precise component placement. This reduces errors and the need for manual inspection, further increasing efficiency and quality.

Flexibility and Versatility

SMT mounters can handle a wide range of components, from small resistors to complex ICs. This flexibility allows for the assembly of diverse PCBs, catering to various industries such as consumer electronics, telecommunications, and medical devices.

Reduced Labor Costs

By automating the assembly process, SMD component mounting machines minimize the need for manual labor. This not only reduces labor costs but also decreases the risk of human error, leading to higher quality products.

Compact PCB Designs

SMT components are smaller and lighter than their through-hole counterparts, enabling the design of more compact PCBs. This compactness is crucial for modern electronic devices, where space is limited and functionality is paramount.

Improving Efficiency with SMD Component Mounting Machines

To maximize the efficiency of SMD component mounting machines, several strategies can be employed:

1. Invest in High-Speed Placement Machines: Upgrading to machines with advanced placement technologies can significantly increase production output.

2. Optimize the SMT Process: This includes optimizing machine setup, selecting the right component feeders, and optimizing placement parameters.

3. Implement Inline Inspection Systems: Automated inspection systems can detect defects early in the process, reducing rework and improving quality control.

4. Automate Material Handling: Automating the component feeder changeover process and using material management systems can reduce manual intervention and increase material uptime.

5. Train Operators Effectively: Well-trained operators can optimize machine settings, troubleshoot issues, and perform minor repairs, ensuring the machine operates at its best.

Applications of SMD Component Mounting Machines

SMD component mounting machines are widely used across various industries due to their versatility and efficiency:

- Consumer Electronics: High-volume production of smartphones, laptops, and televisions relies heavily on SMT technology.

- Telecommunications: SMT is used in the assembly of network devices, routers, and communication equipment.

- Medical Devices: The precision and reliability of SMT are crucial for medical devices, where quality is paramount.

- Industrial Control Systems: SMT components are used in control panels and automation systems due to their reliability and compactness.

Technological Trends and Future Developments

The SMT industry is witnessing rapid technological advancements driven by the growing demand for more efficient and flexible manufacturing processes. One of the most significant trends is the continued development of automated solutions, which are enhancing production efficiency and precision. These advancements are largely driven by the need to reduce human intervention, increase production speed, and meet the demand for miniaturized electronic devices[1].

Integration of AI and Machine Learning

The integration of artificial intelligence (AI) and machine learning into SMT machines is improving the ability to detect errors in real-time, ensuring higher quality production with reduced wastage. This technology also enables predictive maintenance and adaptive manufacturing processes, further enhancing efficiency and reliability[1].

High-Speed Pick-and-Place Machines

The development of high-speed pick-and-place machines is enabling manufacturers to achieve faster production cycles while maintaining precision. These machines are crucial for meeting the evolving needs of industries such as automotive, consumer electronics, and telecommunications, where precision and efficiency are paramount[1].

Regional Developments

The Asia-Pacific region is a hub for technological advancements in SMT, driven by rapid industrialization and technological advancements in countries such as China, Japan, and South Korea. This region accounts for a significant share of the global SMT market and is expected to continue growing[1].

Challenges and Solutions in SMT

Despite its advantages, SMT faces several challenges, including ensuring component placement accuracy and achieving consistent solder paste application. To overcome these challenges, manufacturers can invest in high-precision placement machines and implement automated inspection systems[4].

Ensuring Component Placement Accuracy

Misaligned components can lead to short circuits, open circuits, or reduced performance. The solution involves using high-precision placement machines and regularly calibrating them. Training operators on the importance of placement accuracy and maintaining equipment regularly is also crucial[4].

Achieving Consistent Solder Paste Application

Inconsistent or insufficient solder paste application can lead to weak solder joints, tombstoning, and bridging. Utilizing high-quality stencils specifically designed for the PCB layout and implementing automated solder paste inspection (SPI) systems can help resolve this issue[4].

Case Study: SMT Pick-and-Place Machines in Industrial Control Systems

SMT Pick-and-Place machines have significantly improved the efficiency, reliability, and cost-effectiveness of PCB assembly in industrial control systems. These machines can place hundreds of components per minute with high precision and accuracy, reducing assembly time and increasing production capacity[3].

Efficiency

The use of SMT Pick-and-Place machines has greatly increased the efficiency of PCB assembly. By automating the placement process, these machines reduce manual labor and increase throughput, allowing for faster production and shorter lead times[3].

Reliability

These machines ensure that each component is placed correctly and with consistent accuracy, reducing the likelihood of PCB failures and improving overall product reliability[3].

Cost-Effectiveness

While SMT Pick-and-Place machines have a high initial cost, they are more cost-effective in the long run. They reduce labor costs, decrease scrap rates, and increase throughput, leading to a lower cost per PCB and higher profit margins[3].

Future of SMD Component Mounting Machines

As technology advances, SMD component mounting machines are expected to become even more sophisticated. Trends include:

- Artificial Intelligence Integration: AI can enhance machine learning capabilities, allowing for real-time optimization of the assembly process.

- Increased Automation: Further automation of material handling and inspection processes will continue to reduce manual intervention.

- Miniaturization: The ability to handle even smaller components will enable the creation of more compact electronic devices.

The SMT industry is projected to grow significantly, driven by the increasing demand for miniaturized consumer electronics and the adoption of electric vehicles. By 2028, the SMT market is expected to reach USD 8.4 billion, growing at a CAGR of 7.8%[6].

Conclusion

SMD component mounting machines have transformed the electronics manufacturing landscape by offering unparalleled efficiency, precision, and cost-effectiveness. By leveraging these machines, manufacturers can significantly improve production output, reduce defects, and enhance product quality. As technology continues to evolve, the role of SMD component mounting machines will remain central to the advancement of the electronics industry.

Frequently Asked Questions

1. What is the primary advantage of using SMD component mounting machines?

The primary advantage of using SMD component mounting machines is their ability to increase production efficiency through high-speed component placement and reduced manual intervention.

2. How do SMD component mounting machines improve accuracy?

SMD component mounting machines improve accuracy by using advanced vision systems and laser alignment to ensure precise component placement, reducing the need for manual inspection and minimizing errors.

3. What role does automation play in SMD component mounting?

Automation plays a crucial role in SMD component mounting by minimizing manual labor, reducing changeover times, and increasing material uptime, thereby enhancing overall production efficiency.

4. Can SMD component mounting machines handle a variety of components?

Yes, SMD component mounting machines are versatile and can handle a wide range of components, from small resistors to complex ICs, making them suitable for diverse PCB assemblies.

5. How does SMT technology contribute to compact PCB designs?

SMT technology contributes to compact PCB designs by using smaller and lighter components compared to through-hole technology, enabling the creation of more compact electronic devices.

Citations:

[1] https://www.cognitivemarketresearch.com/articles/surface-mount-technology-smt-market-trends-and-future-opportunities

[2] https://www.pcbcart.com/article/content/smt-assembly-development-trend.html

[3] https://www.hwgcsmt.com/info/case-study-on-smt-pick-and-place-machines-102765232.html

[4] https://www.bigmateph.com/what-are-the-common-challenges-of-smt-and-how-to-overcome-it/

[5] https://novaenginc.com/why-surface-mount-technology-is-better-than-conventional-technique/

[6] https://www.linkedin.com/pulse/surface-mount-technology-smt-industry-set-growth-demand-p-virkhe-fd6kf

[7] https://emsginc.com/resources/the-evolution-of-surface-mount-technology/

[8] https://www.pcbjhy.com/blog/pros-and-cons-of-smt-pcb-assembly/

[9] https://www.wevolver.com/article/smt-vs-smd-vs-tht-a-comprehensive-guide-to-electronics-assembly-techniques

[10] https://arshon.com/blog/pick-and-place-machines-revolutionizing-pcb-assembly/

[11] https://www.starengineeringinc.com/the-role-of-smt-assemblies-in-the-future-of-automotive-electronics/

[12] https://www.hwgcsmt.com/info/case-study-on-the-use-of-smt-equipment-in-medi-102765180.html

[13] https://www.pcb-hero.com/blogs/lisas-column/surface-mount-technology-common-problems-and-solutions-for-efficient-smt-assembly

[14] https://jlcpcb.com/blog/the-characteristics-of-surface-mount-technology

[15] https://www.reportsnreports.com/semiconductor-and-electronics/the-future-of-surface-mount-technology-innovations-and-opportunities-in-the-smt-market/

[16] https://www.pcbpower.us/blog/trends_in_surface_mount_technology_and_its_relevance_with_pcb_surface_finish

[17] https://www.visualcomponents.com/case-studies/europlacer-project-case-study-designing-total-line-solutions-in-a-flash/

[18] https://jhdpcb.com/blog/efficient-smt-assembly/

[19] https://www.protoexpress.com/blog/good-not-so-good-sides-surface-mount-technology/

[20] https://www.nbk1560.com/en-US/resources/mechatronics/article/SMT/?SelectedLanguage=en-US