Content Menu

● The Importance of Accurate Solder Paste Application

● The Evolution of Solder Paste Application Methods

● How SMT Stencil Printers Work

>> Stencil

>> Alignment System

>> Squeegee System

>> Paste Dispensing System

>> Programmable Controls

● Factors Influencing Solder Paste Application Accuracy

>> Precise Stencil-to-Board Alignment

>> Controlled Squeegee Pressure and Speed

>> Stencil Separation Speed

>> Environmental Control

>> Paste Handling and Dispensing

● Benefits of Using SMT Stencil Printers

>> Enhanced Accuracy and Consistency

>> Increased Productivity

>> Reduced Operator Dependency

>> Adaptability to Different Board Designs

>> Minimized Waste

>> Improved Quality Control

● Optimizing SMT Stencil Printer Performance

>> Stencil Design and Quality

>> Solder Paste Selection

>> Printer Setup and Maintenance

>> Process Parameter Optimization

>> Environmental Control

● The Future of SMT Stencil Printing

● Conclusion

● Frequently Asked Questions

>> 1. What is the difference between a manual solder paste printer and an SMT stencil printer?

>> 2. How does an SMT stencil printer improve PCB assembly quality?

>> 3. What factors should be considered when choosing an SMT stencil printer?

>> 4. How often should an SMT stencil printer be maintained?

>> 5. Can an SMT stencil printer handle different solder paste types?

● Citations:

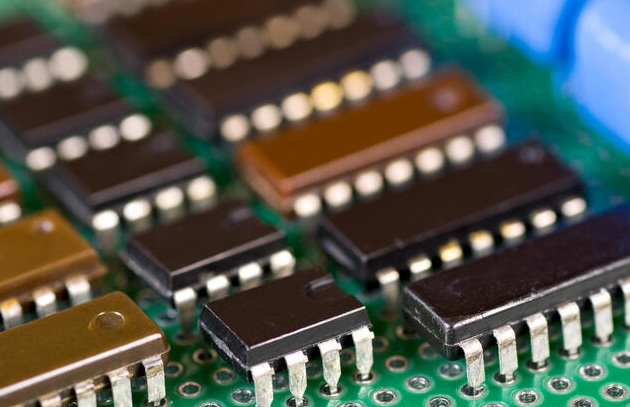

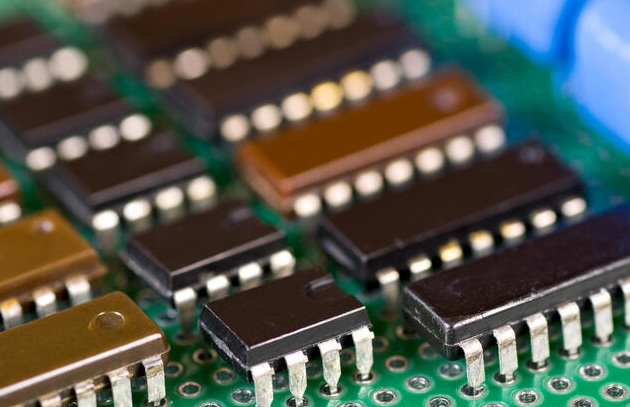

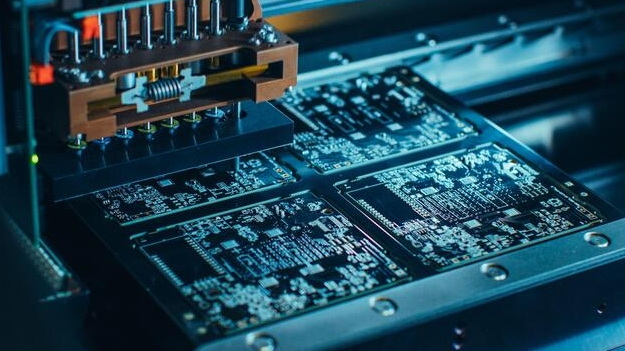

Surface Mount Technology (SMT) has revolutionized the electronics manufacturing industry, enabling the production of smaller, more complex, and highly efficient electronic devices. At the heart of this technology lies the crucial process of solder paste application, which plays a pivotal role in ensuring the quality and reliability of electronic assemblies. The SMT stencil printer has emerged as an indispensable tool in this process, significantly enhancing the accuracy and consistency of solder paste application. This article delves into the ways in which SMT stencil printers improve solder paste application accuracy, exploring their mechanisms, benefits, and impact on the overall manufacturing process.

The Importance of Accurate Solder Paste Application

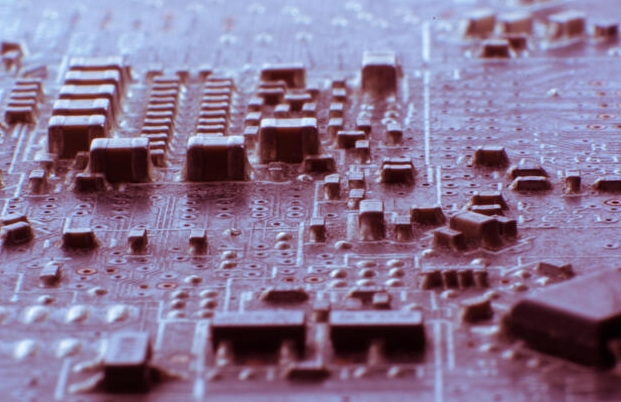

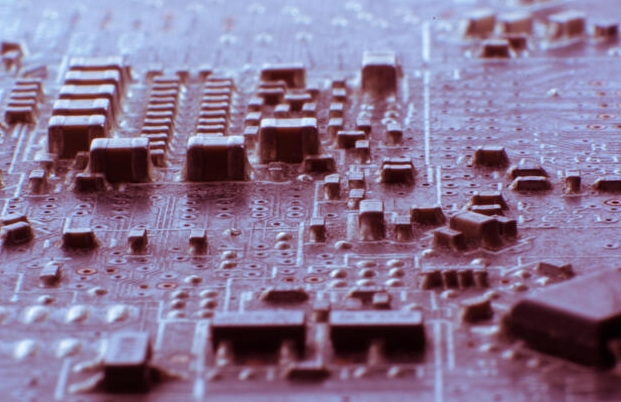

Before we examine the role of SMT stencil printers, it's essential to understand why precise solder paste application is critical in electronics manufacturing. Solder paste, a mixture of tiny metal particles and flux, serves as the conductive material that forms electrical and mechanical connections between components and the printed circuit board (PCB). The accuracy of its application directly influences the quality of these connections, which in turn affects the functionality and reliability of the final product[1].

Inaccurate solder paste application can lead to a myriad of issues, including:

1. Solder bridges: Excess paste can cause unwanted connections between adjacent pads.

2. Insufficient solder: Too little paste may result in weak or incomplete connections.

3. Component misalignment: Uneven paste distribution can cause components to shift during reflow.

4. Tombstoning: Unbalanced paste volumes can cause smaller components to stand on end.

These defects not only compromise the functionality of the electronic device but also increase production costs due to rework and waste. Therefore, achieving high accuracy in solder paste application is paramount for manufacturers striving for quality and efficiency.

The Evolution of Solder Paste Application Methods

The journey towards improved solder paste application accuracy has seen several milestones:

1. Manual application: In the early days of SMT, solder paste was often applied manually using syringes or dispensers. While this method offered flexibility, it was highly dependent on operator skill and prone to inconsistencies.

2. Manual stencil printing: The introduction of stencils marked a significant improvement. Operators would manually align a metal stencil with pre-cut apertures over the PCB and use a squeegee to force solder paste through the openings. This method improved consistency but still relied heavily on operator technique.

3. Semi-automatic printers: These machines automated some aspects of the printing process, such as squeegee movement, but still required manual PCB and stencil alignment.

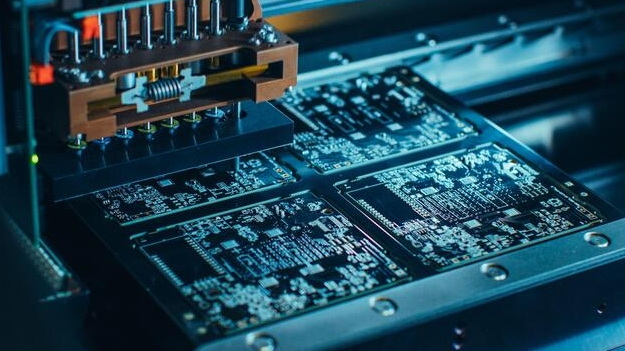

4. Fully automatic SMT stencil printers: The latest evolution in solder paste application technology, these machines automate the entire process, from board alignment to paste deposition, significantly enhancing accuracy and repeatability.

How SMT Stencil Printers Work

SMT stencil printers are sophisticated machines designed to apply solder paste with high precision and consistency. Here's an overview of their key components and operation:

Stencil

The stencil is a thin metal sheet (typically stainless steel) with precisely cut apertures that correspond to the solder pad locations on the PCB. The quality of the stencil is crucial for accurate paste deposition[4].

Alignment System

Advanced vision systems and fiducial markers ensure precise alignment between the stencil and the PCB. This alignment is critical for ensuring that solder paste is deposited exactly where it's needed.

Squeegee System

The squeegee, typically made of metal or polyurethane, moves across the stencil to force solder paste through the apertures. Modern printers often use dual squeegees for bidirectional printing, enhancing speed and consistency.

Paste Dispensing System

Some advanced printers incorporate automated paste dispensing systems that maintain a consistent amount of paste on the stencil, reducing waste and ensuring uniform application.

Programmable Controls

Microprocessor-controlled systems allow for precise adjustment of printing parameters such as squeegee pressure, speed, and angle, enabling optimization for different board designs and paste types.

Factors Influencing Solder Paste Application Accuracy

Several factors contribute to the improved accuracy achieved by SMT stencil printers:

Precise Stencil-to-Board Alignment

SMT stencil printers use advanced vision systems and fiducial markers to ensure exact alignment between the stencil and the PCB. This precision is crucial for depositing solder paste accurately on the intended pads, especially for fine-pitch components[2].

Controlled Squeegee Pressure and Speed

The ability to precisely control squeegee pressure and speed allows for optimal paste transfer. Too much pressure can cause smearing, while insufficient pressure may result in incomplete aperture filling. The right balance ensures consistent paste volume across the board.

Stencil Separation Speed

The speed at which the stencil separates from the PCB after printing affects paste release. SMT stencil printers offer controlled separation, which helps in achieving clean, well-defined paste deposits.

Environmental Control

Many SMT stencil printers incorporate climate control features to maintain optimal temperature and humidity levels. This is crucial as solder paste properties can be significantly affected by environmental conditions.

Paste Handling and Dispensing

Automated paste dispensing systems in advanced printers ensure a consistent amount of paste on the stencil, reducing the risk of over or under-printing due to paste volume variations.

Benefits of Using SMT Stencil Printers

The use of SMT stencil printers offers numerous advantages over manual or semi-automatic methods:

Enhanced Accuracy and Consistency

By automating the printing process and precisely controlling various parameters, SMT stencil printers achieve a level of accuracy and consistency that is virtually impossible with manual methods. This leads to more reliable solder joints and fewer defects[6].

Increased Productivity

Automated stencil printers can process boards much faster than manual methods, significantly increasing throughput. This is particularly beneficial for high-volume production environments.

Reduced Operator Dependency

While skilled operators are still valuable, SMT stencil printers reduce the impact of human variability on the printing process. This leads to more consistent results across different shifts or operators.

Adaptability to Different Board Designs

Modern SMT stencil printers can be quickly programmed and adjusted for different PCB layouts, making them ideal for both high-mix and high-volume production environments.

Minimized Waste

Precise control over paste deposition reduces excess paste usage and minimizes waste, leading to cost savings in material usage.

Improved Quality Control

Many SMT stencil printers incorporate inspection capabilities, allowing for real-time monitoring of paste deposition quality. This enables quick adjustments and reduces the likelihood of defective boards progressing through the assembly process.

Optimizing SMT Stencil Printer Performance

While SMT stencil printers offer significant improvements in solder paste application accuracy, achieving optimal performance requires attention to several factors:

Stencil Design and Quality

The stencil is a critical component in the printing process. Factors such as stencil thickness, aperture design, and manufacturing quality all impact printing accuracy. For fine-pitch components, advanced stencil technologies like nano-coated or step stencils may be necessary[4].

Solder Paste Selection

Different solder paste formulations have varying rheological properties that affect their printing behavior. Selecting the right paste for the application and ensuring it's properly handled and prepared is crucial for optimal results.

Printer Setup and Maintenance

Regular calibration and maintenance of the SMT stencil printer are essential for maintaining accuracy. This includes checking squeegee condition, ensuring proper stencil tension, and verifying alignment system accuracy.

Process Parameter Optimization

Fine-tuning printing parameters such as squeegee pressure, speed, and separation speed for each board design can significantly improve printing results. Many modern printers offer automated optimization features to assist with this process.

Environmental Control

Maintaining consistent temperature and humidity in the printing area helps ensure stable solder paste properties and consistent printing results.

The Future of SMT Stencil Printing

As electronics continue to miniaturize and increase in complexity, the demands on solder paste application accuracy will only grow. Future developments in SMT stencil printing technology are likely to focus on:

1. Enhanced automation and integration with other SMT processes.

2. Advanced materials for stencils and squeegees to improve paste release and definition.

3. Incorporation of artificial intelligence for real-time process optimization and defect prediction.

4. Further improvements in vision systems for even more precise alignment and inspection capabilities.

Conclusion

SMT stencil printers have revolutionized the solder paste application process, offering unprecedented levels of accuracy, consistency, and efficiency. By automating and precisely controlling various aspects of the printing process, these machines have significantly reduced defects, increased productivity, and enabled the production of increasingly complex electronic assemblies. As the electronics industry continues to evolve, SMT stencil printers will undoubtedly play a crucial role in meeting the challenges of future manufacturing requirements.

The journey from manual solder paste application to advanced SMT stencil printers exemplifies the continuous drive for improvement in electronics manufacturing. By leveraging technology to enhance precision and repeatability, these machines have not only improved product quality but also contributed to the overall efficiency and cost-effectiveness of the SMT assembly process. As we look to the future, further advancements in stencil printing technology will continue to push the boundaries of what's possible in electronics manufacturing, enabling the creation of ever more sophisticated and reliable electronic devices.

Frequently Asked Questions

1. What is the difference between a manual solder paste printer and an SMT stencil printer?

A manual solder paste printer typically requires an operator to manually align the stencil, apply pressure, and move the squeegee to deposit solder paste. In contrast, an SMT stencil printer automates these processes, offering precise control over alignment, pressure, speed, and other parameters. SMT stencil printers generally provide higher accuracy, consistency, and speed compared to manual printers, making them suitable for high-volume or high-precision applications.

2. How does an SMT stencil printer improve PCB assembly quality?

An SMT stencil printer improves PCB assembly quality by ensuring accurate and consistent solder paste deposition. It achieves this through precise stencil-to-board alignment, controlled squeegee pressure and speed, and automated paste dispensing. These factors contribute to uniform solder joints, reduced defects such as solder bridges or insufficient solder, and improved overall reliability of the assembled PCB.

3. What factors should be considered when choosing an SMT stencil printer?

When selecting an SMT stencil printer, consider the following factors:

- Printing accuracy and repeatability

- Maximum board size and thickness capability

- Cycle time and throughput

- Ease of programming and operation

- Compatibility with your existing SMT line

- Available features such as automatic paste dispensing or inspection capabilities

- Maintenance requirements and support availability

- Cost and return on investment

4. How often should an SMT stencil printer be maintained?

The maintenance frequency for an SMT stencil printer depends on usage, but generally, daily, weekly, and monthly maintenance tasks should be performed. Daily tasks might include cleaning the stencil and squeegees. Weekly tasks could involve checking alignment accuracy and inspecting moving parts. Monthly maintenance might include more thorough cleaning, lubrication of mechanical components, and calibration checks. Always refer to the manufacturer's recommendations for specific maintenance schedules.

5. Can an SMT stencil printer handle different solder paste types?

Yes, most SMT stencil printers can handle various solder paste types, including lead-based and lead-free formulations. However, different pastes may require adjustments to printing parameters such as squeegee pressure, speed, or separation speed to achieve optimal results. Some advanced printers offer preset profiles for different paste types or automatic parameter optimization features to simplify the process of switching between paste formulations.

Citations:

[1] https://www.ipc.org/system/files/technical_resource/E15&S27_01.pdf

[2] https://www.fitech-solderpaste.com/industry-news/61.html

[3] https://www.flason-smt.com/download/SMT-Stencil-Printer-User-Manual.html

[4] https://pmc.ncbi.nlm.nih.gov/articles/PMC9316595/

[5] https://www.reddit.com/r/AskElectronics/comments/ivrx72/details_about_stencils_and_solder_paste/

[6] https://www.globalwellpcba.com/solder-paste-in-electronics-manufacturing/

[7] https://www.pcbunlimited.com/pdf/SMT-Stencil-Printers-SD-360U_Manual.pdf

[8] https://meridian.allenpress.com/ism/article/2015/1/000126/187595/Optimal-SMT-Electronics-Assembly-Guidelines-for

[9] https://www.pcbunlimited.com/t/smt-equipment/smt-stencil-printers

[10] https://www.ipc.org/system/files/technical_resource/E39&S11_01%20-%20Keith%20Bryant%20-%20UPDATED.pdf

[11] https://www.emerald.com/insight/content/doi/10.1108/ssmt-08-2021-0056/full/html