Content Menu

● Introduction to SMT Assembly

>> Advantages of SMT Over THT

● Role of Prototype SMT PCB Loader

>> Key Features of Prototype SMT PCB Loaders

● Ensuring Precision in PCB Assembly

>> 1. Solder Paste Printing

>> 2. Solder Paste Inspection (SPI)

>> 3. Pick and Place Machines

>> 4. Reflow Soldering

>> 5. Automated Optical Inspection (AOI)

● Technologies Enhancing Precision

● Benefits of Precision in PCB Assembly

● Trends in PCB Assembly

>> Impact of Miniaturization

>> Role of Automation

● Innovations in PCB Assembly

>> High-Speed Assembly Equipment

>> Advanced Materials

● Challenges in Achieving Precision

● Future of PCB Assembly

● Conclusion

● FAQs

>> 1. What is the primary function of a prototype SMT PCB loader?

>> 2. How does solder paste inspection (SPI) enhance precision in PCB assembly?

>> 3. What role do pick and place machines play in precision PCB assembly?

>> 4. How does automated optical inspection (AOI) contribute to precision in PCB assembly?

>> 5. What are the benefits of using advanced vision systems in SMT assembly?

In the realm of electronics manufacturing, precision is paramount, especially when it comes to Surface Mount Technology (SMT) assembly. A prototype SMT PCB loader plays a crucial role in ensuring that printed circuit boards (PCBs) are assembled with high accuracy and efficiency. This article delves into the mechanisms and technologies that enable prototype SMT PCB loaders to achieve precision in PCB assembly.

Introduction to SMT Assembly

SMT assembly is a method of mounting electronic components directly onto the surface of a PCB. This technique has become the backbone of modern electronics manufacturing due to its ability to increase component density, reduce production costs, and enhance product reliability. Unlike traditional through-hole technology (THT), SMT allows for smaller components, faster assembly times, and improved signal integrity, making it ideal for complex and compact electronic devices.

Advantages of SMT Over THT

- Higher Component Density: SMT components are smaller and can be placed closer together, allowing more components on a smaller PCB area.

- Faster Assembly: Automated SMT assembly lines can place thousands of components per hour, significantly reducing production time.

- Improved Signal Integrity: Shorter interconnection lengths reduce parasitic capacitance and inductance, enhancing high-frequency performance.

Role of Prototype SMT PCB Loader

A prototype SMT PCB loader is a critical component in the SMT assembly process. Its primary function is to automatically load bare PCBs into the production line, ensuring a seamless and efficient workflow. These loaders are designed to handle PCBs of various sizes and types, making them versatile for different manufacturing operations.

Key Features of Prototype SMT PCB Loaders

- Automatic Loading: Reduces manual labor and minimizes the risk of human error.

- High Capacity: Can hold multiple PCBs, allowing for continuous operation.

- Advanced Vision Systems: Enable accurate detection of PCB positions and orientations.

- PLC Control Systems: Provide precise control over the loading process, making them easy to operate and maintain.

Ensuring Precision in PCB Assembly

Precision in PCB assembly is achieved through several key technologies and processes:

1. Solder Paste Printing

Before component placement, solder paste is applied to the PCB using a stencil printer. The solder paste must be accurately deposited on the PCB pads to ensure proper component adhesion during reflow soldering. High precision in PCB stencil manufacturing is crucial for this step, as it ensures accurate solder paste deposition and minimizes defects such as solder bridging.

2. Solder Paste Inspection (SPI)

SPI machines use optical and laser technologies to verify the volume, area, and height of solder paste deposits. This step detects issues such as insufficient or excess paste, ensuring that only PCBs with qualified solder paste proceed to component placement.

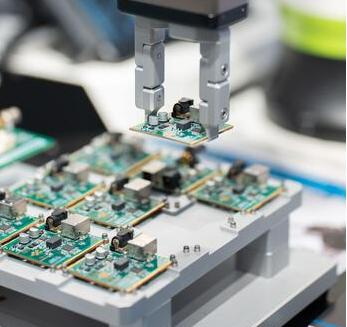

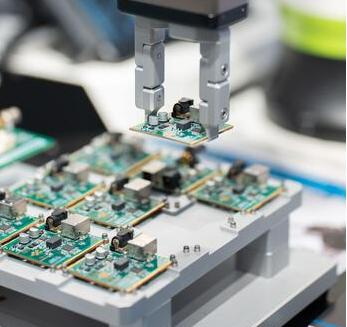

3. Pick and Place Machines

These machines are the heart of SMT assembly, capable of placing thousands of components per hour with high accuracy. Advanced vision systems and robotic arms ensure precise component placement, often down to fractions of a millimeter. The integration of automation and robotics in pick-and-place machines has significantly enhanced efficiency and quality in PCB assembly.

4. Reflow Soldering

After components are placed, the PCB is sent through a reflow oven where the solder paste melts and solidifies, bonding components to the PCB. The reflow process is carefully controlled to ensure optimal soldering conditions.

5. Automated Optical Inspection (AOI)

AOI machines inspect the assembled PCBs for defects such as misaligned components, solder bridges, or missing components. This step ensures that only defect-free PCBs proceed to the final stages of production.

Technologies Enhancing Precision

Several technologies contribute to the precision of prototype SMT PCB loaders and the overall SMT assembly process:

- Advanced Vision Systems: These systems enable accurate component recognition and placement, ensuring that components are correctly aligned and positioned on the PCB.

- Robotic Arms: Provide precise movement and placement capabilities, allowing for the handling of small and delicate components.

- PLC Control Systems: Offer precise control over the assembly process, ensuring consistent and reliable operation.

Benefits of Precision in PCB Assembly

Achieving precision in PCB assembly offers several benefits:

- Reduced Defects: Minimizes errors and defects, leading to higher quality products.

- Increased Efficiency: Automates processes, reducing manual labor and increasing production speed.

- Cost Savings: Reduces rework and repair costs associated with defects.

Trends in PCB Assembly

Recent trends in PCB assembly include advancements in SMT, such as finer pitch components and increased component density. These advancements are supported by high-speed assembly equipment and advanced materials, which enhance manufacturing efficiency and product performance.

Impact of Miniaturization

The miniaturization of components has significantly impacted PCB design and assembly. Smaller components allow for more compact devices, but they also require more precise assembly techniques. This trend has driven the development of high-speed pick-and-place machines capable of handling fine-pitch components with high accuracy.

Role of Automation

Automation plays a crucial role in modern PCB assembly. From pick-and-place machines to automated inspection systems, robotics are transforming the way PCBs are manufactured. Automation reduces manual errors, increases production speed, and enhances product quality.

Innovations in PCB Assembly

Recent innovations in PCB assembly include advancements in SMT, such as finer pitch components and increased component density. These advancements are supported by high-speed assembly equipment and advanced materials, which enhance manufacturing efficiency and product performance.

High-Speed Assembly Equipment

High-speed pick-and-place machines are crucial for handling fine-pitch components with high accuracy. These machines can place thousands of components per hour, significantly reducing production time and enhancing manufacturing efficiency.

Advanced Materials

The choice of materials and substrates can significantly impact the performance and reliability of a PCB. In recent years, there has been a growing demand for high-performance materials such as flexible PCBs, rigid-flex PCBs, and metal core PCBs. These materials cater to diverse application requirements, meeting the needs of industries like wearables and IoT gadgets.

Challenges in Achieving Precision

Despite the advancements in technology, achieving precision in PCB assembly remains challenging. Factors such as component size, PCB complexity, and manufacturing process variability can affect precision. Therefore, continuous innovation and improvement in manufacturing technologies are essential to maintain high precision standards.

Future of PCB Assembly

The future of PCB assembly is closely tied to advancements in automation, robotics, and advanced materials. As technology continues to evolve, we can expect to see even more efficient and precise manufacturing processes. The integration of emerging technologies like virtual and augmented reality could further enhance manufacturing efficiency and product quality.

Conclusion

Prototype SMT PCB loaders are essential for ensuring precision in PCB assembly by automating the loading process, reducing human error, and integrating with advanced technologies like SPI and AOI. These loaders, combined with pick and place machines and reflow soldering, form a highly efficient and precise SMT assembly line. As electronics manufacturing continues to evolve, the role of prototype SMT PCB loaders will remain critical in producing high-quality, complex electronic devices.

FAQs

1. What is the primary function of a prototype SMT PCB loader?

A prototype SMT PCB loader is designed to automatically load bare PCBs into the production line, ensuring a seamless and efficient workflow by reducing manual labor and minimizing errors.

2. How does solder paste inspection (SPI) enhance precision in PCB assembly?

SPI machines verify the volume, area, and height of solder paste deposits on PCB pads, detecting issues such as insufficient or excess paste. This ensures that only PCBs with qualified solder paste proceed to component placement, reducing defects.

3. What role do pick and place machines play in precision PCB assembly?

Pick and place machines accurately place components onto PCBs using advanced vision systems and robotic arms. They can handle a wide range of component sizes and types, making them versatile tools in the assembly process.

4. How does automated optical inspection (AOI) contribute to precision in PCB assembly?

AOI machines inspect assembled PCBs for defects such as misaligned components or solder bridges. This step ensures that only defect-free PCBs proceed to the final stages of production, enhancing overall product quality.

5. What are the benefits of using advanced vision systems in SMT assembly?

Advanced vision systems enable accurate component recognition and placement, ensuring that components are correctly aligned and positioned on the PCB. This enhances precision, reduces errors, and improves the overall efficiency of the assembly process.