Content Menu

● Understanding PCB SMT Spring Contacts

>> What Are PCB SMT Spring Contacts?

>> Key Features of SMT Spring Contacts

● How PCB SMT Spring Contacts Reduce Signal Loss

>> 1. Consistent Contact Force

>> 2. Low Contact Resistance

>> 3. Vibration and Shock Resistance

>> 4. Arc Suppression

>> 5. Adaptability to Surface Variations

● Advanced Design Considerations for PCB SMT Spring Contacts

>> Material Selection

>> Geometric Optimization

● Manufacturing Processes and Quality Control

● Applications of PCB SMT Spring Contacts

>> 1. Consumer Electronics

>> 2. Automotive Electronics

>> 3. Medical Devices

>> 4. Industrial Automation

>> 5. Renewable Energy Systems

● Advantages Over Traditional Connectors

● Challenges and Solutions

● Future Trends in PCB SMT Spring Contact Technology

● Conclusion

● FAQs

>> 1. What is the primary function of a PCB SMT spring contact?

>> 2. How do SMT spring contacts handle vibrations?

>> 3. Can SMT spring contacts be used in high-frequency applications?

>> 4. What materials are commonly used for SMT spring contacts?

>> 5. Are there any limitations to using SMT spring contacts?

Printed Circuit Boards (PCBs) are the backbone of modern electronics, and the Surface Mount Technology (SMT) spring contact plays a pivotal role in ensuring efficient electrical connections. These components, also known as spring-loaded contacts or pogo pins, are small yet powerful tools designed to reduce signal loss while enhancing connectivity. This article explores how PCB SMT spring contacts contribute to minimizing signal loss, their design advantages, and their applications across various industries.

Understanding PCB SMT Spring Contacts

What Are PCB SMT Spring Contacts?

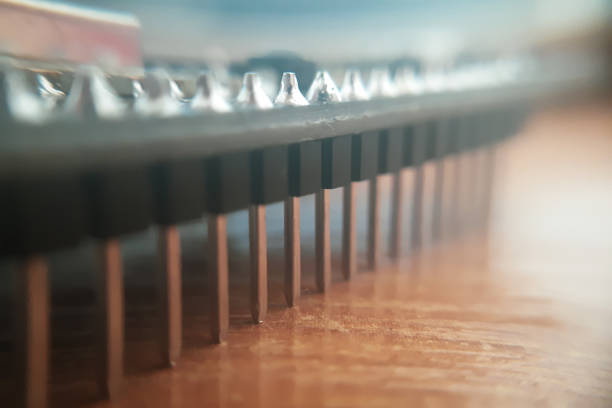

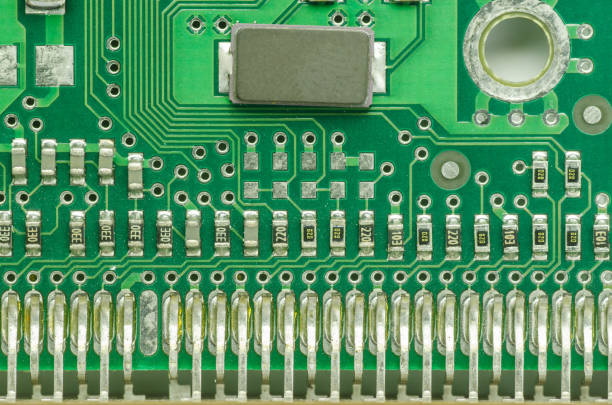

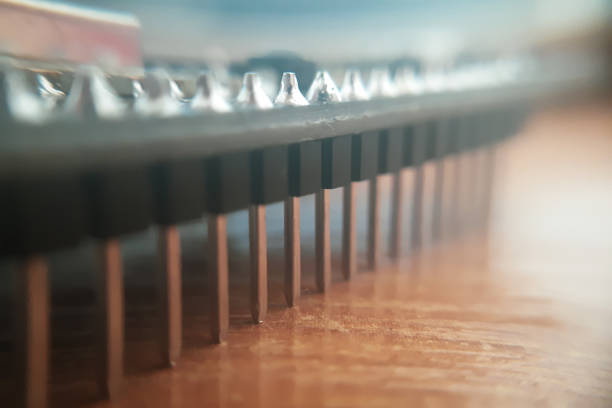

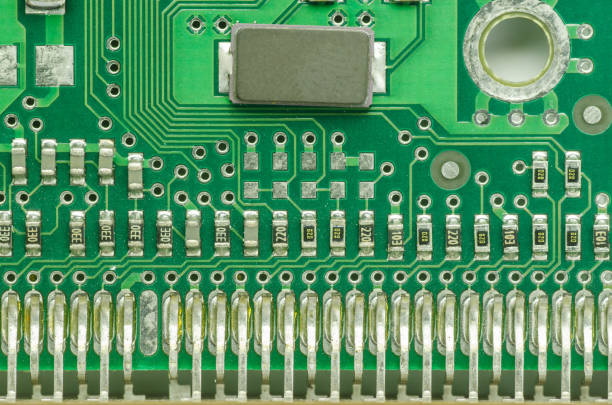

PCB SMT spring contacts are mechanical components used to establish temporary or permanent electrical connections between PCBs or other electronic components. They are designed for surface mount applications, enabling automated assembly processes. These contacts consist of a plunger, a spring, and a barrel, which work together to maintain consistent electrical conductivity.

Key Features of SMT Spring Contacts

- Compact and Lightweight: Ideal for space-constrained designs.

- High Mating Cycles: Can withstand up to 10,000 mating cycles, ensuring longevity.

- Low Contact Resistance: Promotes efficient signal transmission with minimal loss.

- Surface Mount Design: Compatible with automated pick-and-place assembly.

- Versatility: Suitable for grounding, shielding, and data transmission applications.

How PCB SMT Spring Contacts Reduce Signal Loss

1. Consistent Contact Force

One of the primary reasons for signal loss in electronic systems is inconsistent contact force. PCB SMT spring contacts are designed to maintain a stable and consistent force against the mating surface. This ensures uninterrupted electrical conductivity, even in environments with vibrations or shocks.

The spring mechanism within these contacts is engineered to provide a specific range of force, typically between 20 to 100 grams, depending on the application requirements. This consistent force helps to maintain a low and stable contact resistance, which is crucial for minimizing signal loss.

2. Low Contact Resistance

The low resistance of SMT spring contacts minimizes energy dissipation during signal transmission. This feature is particularly beneficial for high-frequency applications where maintaining signal integrity is critical.

Typical contact resistance for high-quality PCB SMT spring contacts ranges from 20 to 50 milliohms. This low resistance is achieved through the use of highly conductive materials and precision manufacturing processes. The result is a significant reduction in signal attenuation, especially over longer transmission paths or in high-speed data applications.

3. Vibration and Shock Resistance

In dynamic environments such as automotive or industrial applications, vibrations can disrupt connections and lead to signal loss. The spring mechanism in these contacts absorbs shocks and maintains a steady connection, ensuring reliable performance under challenging conditions.

The design of PCB SMT spring contacts often incorporates features like internal damping systems or specialized spring geometries that help to mitigate the effects of vibration. This resilience is particularly valuable in applications such as aerospace, where equipment must withstand extreme vibration and shock loads while maintaining signal integrity.

4. Arc Suppression

Traditional connectors may generate arcs during insertion or extraction, leading to potential damage and signal degradation. SMT spring contacts mitigate this risk by requiring low insertion and extraction forces, reducing the likelihood of arc formation.

The smooth engagement and disengagement characteristics of SMT spring contacts help to prevent the sudden breaks in current flow that can cause arcing. This is especially important in power applications or in environments where sparks could pose safety hazards.

5. Adaptability to Surface Variations

PCB surfaces often have imperfections that can interfere with electrical connections. The spring-loaded design compensates for these variations, ensuring consistent contact and reducing the chances of signal interruptions.

The plunger in an SMT spring contact can typically accommodate vertical travel of up to 1-2mm, allowing it to maintain contact even when there are slight height differences or warpage in the PCB. This adaptability is crucial for ensuring reliable connections across large surface areas or in applications where thermal expansion may cause dimensional changes.

Advanced Design Considerations for PCB SMT Spring Contacts

Material Selection

The choice of materials for PCB SMT spring contacts is critical to their performance in reducing signal loss. Common materials include:

- Beryllium Copper: Offers excellent spring properties and conductivity.

- Phosphor Bronze: Provides good conductivity and corrosion resistance.

- Gold Plating: Used for its excellent conductivity and resistance to oxidation.

The selection of these materials is based on factors such as the expected number of mating cycles, environmental conditions, and the specific electrical requirements of the application.

Geometric Optimization

The geometry of SMT spring contacts is carefully designed to balance several factors:

- Spring Force: Optimized to provide sufficient contact pressure without causing excessive wear.

- Contact Area: Maximized to reduce contact resistance and improve current carrying capacity.

- Plunger Travel: Designed to accommodate manufacturing tolerances and surface irregularities.

Advanced computer-aided design (CAD) and finite element analysis (FEA) tools are often employed to optimize these geometric parameters, ensuring the best possible performance in reducing signal loss.

Manufacturing Processes and Quality Control

The production of high-quality PCB SMT spring contacts involves several sophisticated manufacturing processes:

1. Precision Stamping: For creating the basic shape of the contact components.

2. CNC Machining: Used for more complex geometries and tighter tolerances.

3. Heat Treatment: To achieve the desired spring properties.

4. Plating: Application of conductive coatings like gold or nickel.

Quality control measures are crucial to ensure consistent performance:

- Automated Optical Inspection (AOI): For detecting surface defects and dimensional inconsistencies.

- X-ray Inspection: To verify internal structures and solder joints.

- Electrical Testing: To confirm resistance and continuity specifications.

These rigorous manufacturing and testing processes contribute to the reliability and effectiveness of PCB SMT spring contacts in reducing signal loss.

Applications of PCB SMT Spring Contacts

1. Consumer Electronics

SMT spring contacts are widely used in mobile devices, wearable technology, and IoT devices for antenna connections and internal grounding. In smartphones, for example, these contacts are often used to connect the main PCB to secondary boards, antennas, or battery terminals, ensuring reliable signal transmission in a compact form factor.

2. Automotive Electronics

In vehicles, these contacts play a crucial role in infotainment systems, sensors, and control units by ensuring reliable data transmission under harsh conditions. The automotive industry's shift towards electric and autonomous vehicles has increased the demand for high-reliability connectors that can withstand vibration, temperature extremes, and long-term use without signal degradation.

3. Medical Devices

Medical equipment demands high precision and reliability. SMT spring contacts are used in diagnostic tools and monitoring devices to maintain stable connections. In portable medical devices, these contacts enable quick and secure connections for disposable sensors or electrodes, ensuring accurate data collection and patient safety.

4. Industrial Automation

Robotic arms, motion controllers, and sensors rely on these components for seamless data transfer and control signals in automated systems. The ability of SMT spring contacts to maintain consistent connections despite movement and vibration makes them ideal for use in factory automation equipment and industrial robots.

5. Renewable Energy Systems

In solar panels and wind turbines, SMT spring contacts facilitate efficient power transmission between components while withstanding environmental stresses. These contacts are often used in junction boxes or inverter connections, where they must perform reliably under varying temperatures and weather conditions.

Advantages Over Traditional Connectors

| Feature | SMT Spring Contacts | Traditional Connectors |

| Contact Resistance | Low | Higher |

| Vibration Resistance | Excellent | Moderate |

| Mating Cycles | Up to 10,000 | Limited |

| Insertion/Extraction Forces | Low | High |

| Adaptability | Compensates for surface variations | Less adaptable |

Challenges and Solutions

While PCB SMT spring contacts offer numerous benefits, they are not without challenges:

- Oxidation or Debris Accumulation: Regular cleaning is essential to maintain optimal performance. In some cases, self-cleaning contact designs or protective coatings can be employed to mitigate this issue.

- Wear Over Time: High-quality materials like gold plating can extend lifespan. Additionally, advanced lubricants or surface treatments can be applied to reduce friction and wear, especially in high-cycle applications.

- Alignment Issues: Proper design and automated assembly techniques minimize misalignments. The use of alignment features or guide pins in the PCB design can help ensure accurate positioning during assembly.

Future Trends in PCB SMT Spring Contact Technology

As electronic devices continue to evolve, so too does the technology behind PCB SMT spring contacts. Some emerging trends include:

1. Miniaturization: Development of even smaller spring contacts to accommodate the ongoing trend of device miniaturization.

2. Higher Frequency Capabilities: Design innovations to support the increasing frequencies used in 5G and beyond technologies.

3. Smart Contacts: Integration of sensors within spring contacts to monitor connection quality and predict maintenance needs.

4. Advanced Materials: Exploration of new alloys and coatings to further improve conductivity and durability.

5. Environmental Sustainability: Focus on eco-friendly materials and manufacturing processes to reduce environmental impact.

These advancements will likely lead to even more efficient signal transmission and reduced losses in future electronic systems.

Conclusion

PCB SMT spring contacts are indispensable components in modern electronics due to their ability to reduce signal loss while providing reliable connections. Their low contact resistance, vibration resistance, and adaptability make them ideal for various applications ranging from consumer electronics to industrial automation. By addressing common challenges through proper maintenance and material selection, these components can deliver long-term performance benefits.

As technology continues to advance, the role of PCB SMT spring contacts in reducing signal loss will become even more critical. Their ongoing development and refinement will contribute significantly to the performance and reliability of next-generation electronic devices and systems.

FAQs

1. What is the primary function of a PCB SMT spring contact?

PCB SMT spring contacts establish reliable electrical connections between PCBs or other components while minimizing signal loss through consistent contact force and low resistance.

2. How do SMT spring contacts handle vibrations?

The built-in spring mechanism absorbs shocks and compensates for vibrations, ensuring stable connections even in dynamic environments like automotive systems.

3. Can SMT spring contacts be used in high-frequency applications?

Yes, their low contact resistance makes them suitable for high-frequency data transmission where maintaining signal integrity is critical.

4. What materials are commonly used for SMT spring contacts?

High-quality materials such as gold plating are often used to enhance conductivity and prevent corrosion.

5. Are there any limitations to using SMT spring contacts?

While they offer numerous advantages, issues like wear over time or debris accumulation can affect performance if not addressed through regular maintenance.