Content Menu

● Introduction

● Understanding Manual Stencil Printers

>> Advantages of Manual Stencil Printers

● Role in PCB Assembly Efficiency

● Best Practices for Using Manual Stencil Printers

● Comparison with Automated Systems

>> Key Differences Between Manual and Automated Systems

● Future of Manual Stencil Printers in SMT Assembly

>> Emerging Trends and Technologies

● Case Studies: Successful Implementation of Manual Stencil Printers

● Challenges and Solutions

● Conclusion

● FAQs

>> 1. What are the primary benefits of using manual stencil printers in PCB assembly?

>> 2. How do manual stencil printers improve precision in PCB assembly?

>> 3. What are some best practices for maximizing efficiency with manual stencil printers?

>> 4. How do manual stencil printers compare to automated systems in terms of efficiency and cost?

>> 5. What role will manual stencil printers play in future SMT assembly processes?

Introduction

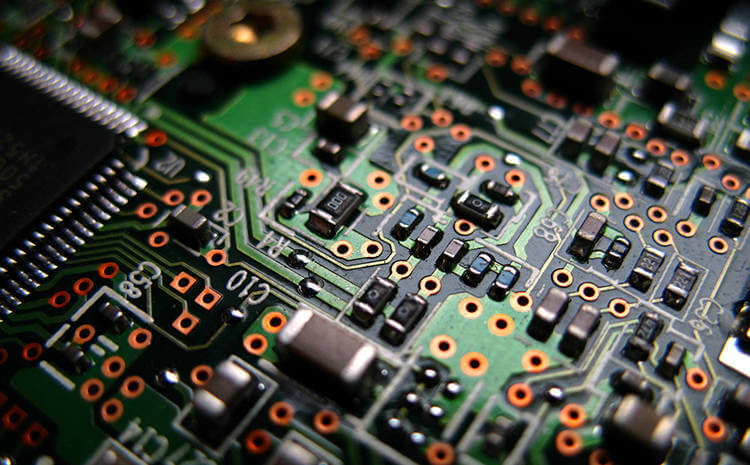

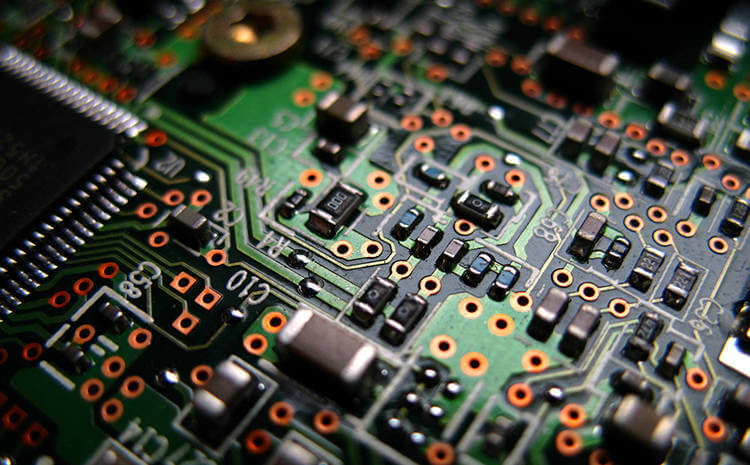

In the realm of Surface Mount Technology (SMT) assembly, efficiency and precision are paramount for producing high-quality printed circuit boards (PCBs). One crucial tool that enhances these aspects is the manual stencil printer. This device plays a pivotal role in applying solder paste to PCBs, ensuring accurate and consistent results. In this article, we will delve into how manual stencil printers improve PCB assembly efficiency, their benefits, and their role in modern electronics manufacturing.

Understanding Manual Stencil Printers

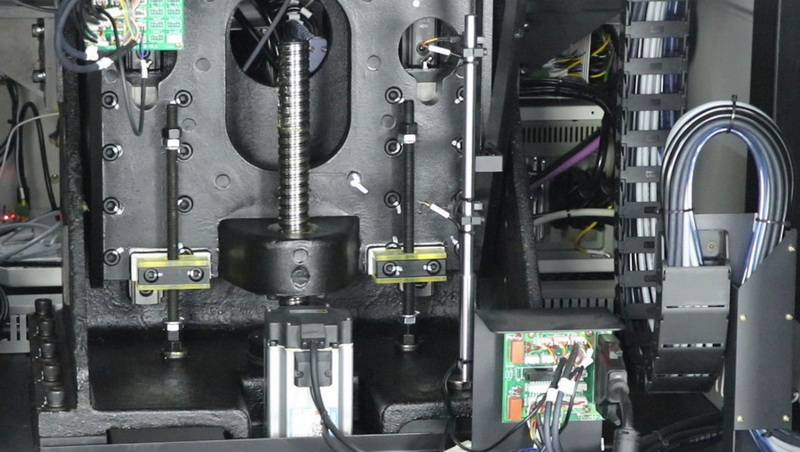

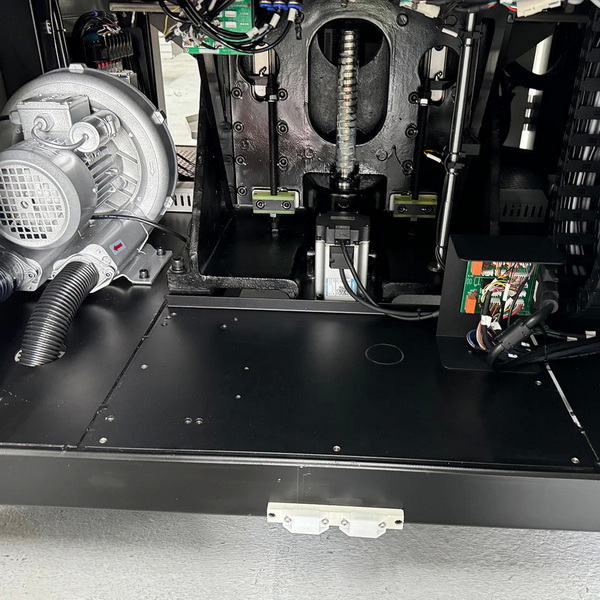

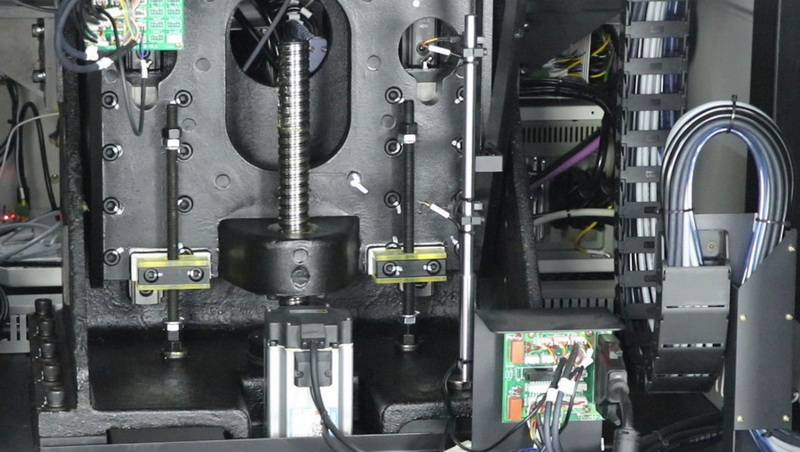

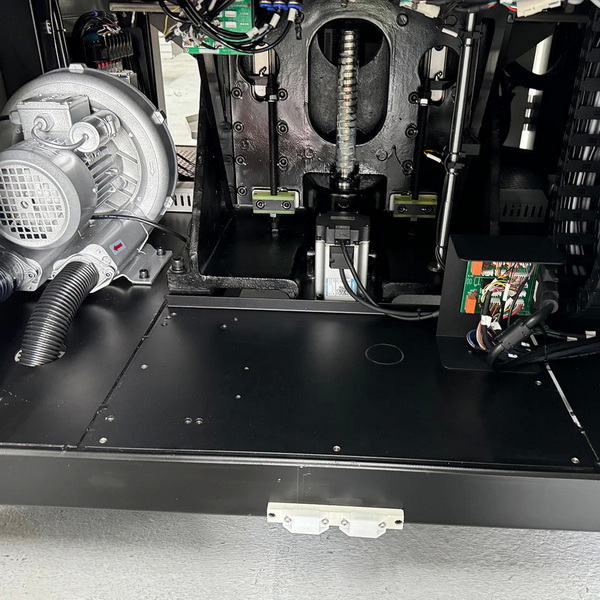

Manual stencil printers are designed to facilitate the precise application of solder paste onto PCBs. These printers are particularly useful for small to medium-scale production runs, offering a cost-effective solution compared to automated systems. They are constructed from durable materials, ensuring longevity and consistent performance. Key features include adjustable frames to accommodate various PCB sizes and fine pitch printing capabilities, making them ideal for intricate circuit designs.

Advantages of Manual Stencil Printers

1. Cost-Effectiveness: Manual stencil printers are less expensive than automated systems, making them suitable for operations with limited budgets or those requiring flexibility in production runs.

2. Flexibility: These printers can be quickly adjusted for different PCB designs, allowing for rapid prototyping and small batch production.

3. Low Maintenance: Manual printers are less complex than automated ones, resulting in lower maintenance requirements and longer service life.

4. Precision: Despite being manual, these printers can achieve high precision in solder paste application, especially when used with well-designed stencils.

Role in PCB Assembly Efficiency

Manual stencil printers significantly enhance PCB assembly efficiency by:

- Reducing Setup Time: They require minimal setup time, allowing for quick adjustments between different PCB designs.

- Improving Precision: By ensuring accurate solder paste application, manual stencil printers reduce the risk of defects such as bridging or insufficient solder, which are common issues in manual paste application.

- Increasing Productivity: Although manual, these printers streamline the solder paste application process, making it more efficient than completely manual methods. This is particularly beneficial in environments where automation is not feasible.

- Enhancing Quality Control: The use of stencils with manual printers ensures consistent solder paste volumes, which is crucial for reliable solder joints and overall PCB quality.

Best Practices for Using Manual Stencil Printers

To maximize efficiency and quality when using manual stencil printers, consider the following best practices:

1. Proper Stencil Design: Ensure that the stencil is designed with precise apertures to match the PCB's component pads. This is crucial for achieving accurate solder paste deposition.

2. Cleanliness and Maintenance: Regularly clean and maintain the printer to prevent solder paste buildup and ensure consistent performance.

3. Operator Training: Provide operators with thorough training on the use of manual stencil printers to minimize human error and optimize production.

4. Quality Control Checks: Implement regular quality control checks to ensure that solder paste application meets the required standards.

5. Optimized Solder Paste Selection: Choose solder paste with optimal viscosity and composition for the specific PCB design to enhance print quality and reliability.

Comparison with Automated Systems

While manual stencil printers offer several advantages for small-scale operations, automated stencil printers are more suitable for high-volume production. Automated systems provide faster production rates and reduce human error, making them ideal for large-scale manufacturing environments. However, for operations requiring flexibility and cost-effectiveness, manual stencil printers remain a viable option.

Key Differences Between Manual and Automated Systems

- Speed: Automated systems are significantly faster, capable of handling large production volumes efficiently.

- Accuracy: Automated systems typically offer higher precision due to their ability to maintain consistent pressure and alignment.

- Cost: Manual systems are more cost-effective for small-scale operations, while automated systems require a larger upfront investment.

Future of Manual Stencil Printers in SMT Assembly

As technology continues to evolve, the role of manual stencil printers in SMT assembly will likely remain significant, especially in niche markets or for prototyping purposes. Innovations in materials and design could further enhance their efficiency and precision, making them even more attractive for small to medium-scale producers. For instance, advancements in stencil materials could improve paste release properties, enhancing print quality.

Emerging Trends and Technologies

1. Advanced Stencil Materials: New materials with improved paste release properties are being developed, which could enhance print quality and reduce defects.

2. Hybrid Systems: Some manufacturers are exploring hybrid systems that combine elements of manual and automated printers, offering a balance between cost and efficiency.

3. Digital Integration: Integrating digital tools for stencil design and printer control could further optimize the printing process, reducing setup times and improving accuracy.

Case Studies: Successful Implementation of Manual Stencil Printers

Several companies have successfully integrated manual stencil printers into their production lines, achieving significant improvements in efficiency and quality. For example, a small electronics manufacturer in Europe increased its production capacity by 30% after adopting manual stencil printers for prototyping and small batch production. This allowed them to quickly respond to customer demands without investing in expensive automated systems.

Challenges and Solutions

Despite their benefits, manual stencil printers also present some challenges, such as operator variability and the need for consistent quality control. To address these challenges, manufacturers can implement rigorous training programs for operators and invest in quality control equipment to monitor print quality.

Conclusion

Manual stencil printers play a vital role in enhancing PCB assembly efficiency by providing a cost-effective, flexible, and precise method for solder paste application. Their ability to streamline production processes, reduce setup times, and improve quality control makes them an indispensable tool in the SMT assembly process. As the electronics industry continues to grow and demand more complex PCB designs, the importance of manual stencil printers will endure, particularly in environments where automation is not feasible or necessary.

FAQs

1. What are the primary benefits of using manual stencil printers in PCB assembly?

Manual stencil printers offer cost-effectiveness, flexibility, low maintenance requirements, and precision in solder paste application, making them ideal for small to medium-scale production runs.

2. How do manual stencil printers improve precision in PCB assembly?

Manual stencil printers improve precision by using stencils with precise apertures to ensure accurate solder paste deposition on PCB pads, reducing defects like bridging or insufficient solder.

3. What are some best practices for maximizing efficiency with manual stencil printers?

Best practices include proper stencil design, regular cleanliness and maintenance, operator training, and quality control checks to ensure consistent and high-quality solder paste application.

4. How do manual stencil printers compare to automated systems in terms of efficiency and cost?

Manual stencil printers are more cost-effective and flexible but slower than automated systems. They are suitable for small-scale operations, while automated systems are better for high-volume production due to their speed and reduced human error.

5. What role will manual stencil printers play in future SMT assembly processes?

Manual stencil printers will continue to be significant in niche markets and for prototyping purposes. They may see further innovations that enhance their efficiency and precision, maintaining their relevance in small to medium-scale production environments.