Content Menu

● Understanding Manual SMD Pick and Place Machines

>> Technical Specifications and Workflow

● Automated SMD Pick and Place Systems

>> Core Technologies in Automation

● In-Depth Comparison: Manual vs. Automated Systems

>> 1. Cost Analysis

>> 2. Precision and Error Rates

>> 3. Scalability and Throughput

>> 4. Flexibility and Customization

>> 5. Quality Control and Inspection

● Emerging Trends and Hybrid Solutions

>> Semi-Automated Machines

>> Desktop Automated Systems

>> AI-Driven Optimization

>> Collaborative Robots (Cobots)

● Conclusion

● FAQ Section

>> 1. Can a manual SMD pick and place machine handle fine-pitch components?

>> 2. How do automated systems manage component feeders?

>> 3. What safety features exist for manual machines?

>> 4. Are there open-source alternatives for manual pick and place?

>> 5. How does humidity affect manual vs. automated placement?

Surface-mount technology (SMT) pick and place machines are the backbone of modern electronics manufacturing, enabling the assembly of everything from smartphones to medical devices. The choice between a manual SMD pick and place machine and an automated system hinges on production scale, technical requirements, and budget. This 2,700+ word guide provides a granular comparison, exploring their strengths, limitations, and evolving roles in today's manufacturing landscape.

Understanding Manual SMD Pick and Place Machines

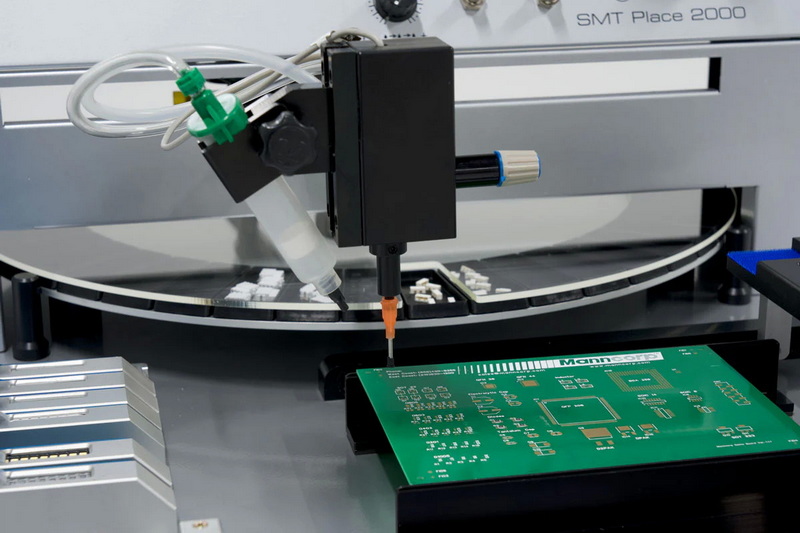

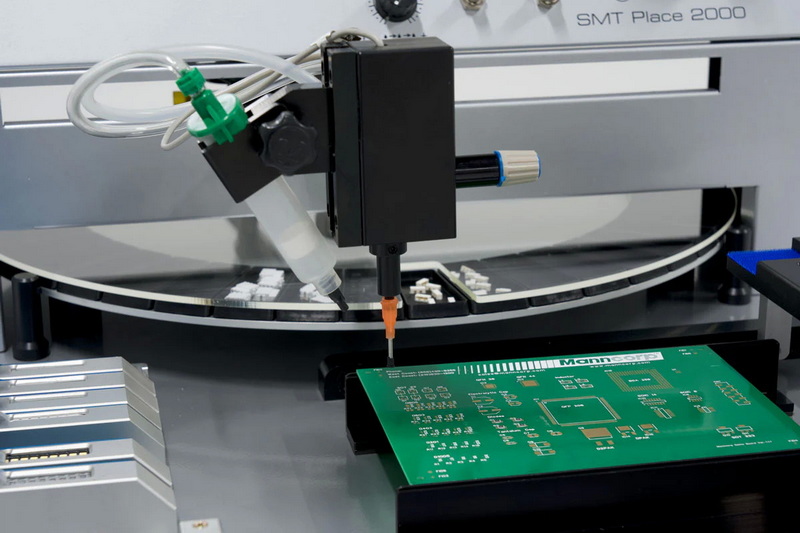

A manual SMD pick and place machine is a human-operated tool designed for low-volume PCB assembly, prototyping, and specialized projects. Unlike automated systems, it relies on operators to physically pick components using vacuum pens or tweezers and place them onto solder-pasted boards.

Technical Specifications and Workflow

- Component Handling:

- Typical Range: 0402 (0.4 mm x 0.2 mm) to larger connectors or LEDs.

- Exceptions: Skilled operators can handle 0201 components with magnification tools.

- Placement Speed: 100–300 components per hour (CPH), depending on operator expertise.

- Vision Assistance: Basic models include magnifying lenses, while advanced versions offer camera-assisted alignment (e.g., ManuPick Pro with 5x optical zoom).

- Ergonomics: Adjustable workstations and anti-fatigue mats reduce strain during extended sessions.

Example Workflow:

1. The operator loads a solder-pasted PCB onto the machine's vacuum table.

2. Using a vacuum pen, they pick up a component from a tray or tape reel.

3. They align the component using visual markers or camera guidance.

4. The component is placed, and the process repeats until the board is populated.

Automated SMD Pick and Place Systems

Automated systems, such as those from Fuji NXT or Siemens SIPLACE, use robotic arms, high-resolution vision systems, and reel-fed component trays to achieve speeds exceeding 50,000 CPH. These machines dominate high-volume production lines for consumer electronics, automotive systems, and IoT devices.

Core Technologies in Automation

- Multi-Nozzle Heads: Robotic arms with 12–24 nozzles handle diverse component sizes (01005 to 50 mm²).

- Vision Systems:

- Fiducial Recognition: Cameras with 10–25 μm resolution align PCBs using fiducial markers.

- 3D Inspection: Laser triangulation detects coplanarity issues in BGA components.

- Software Integration: CAD/CAM files (e.g., Gerber) are imported to automate placement paths.

- Closed-Loop Feedback: Real-time adjustments compensate for PCB warping or feeder errors.

Example Workflow:

1. The machine loads a PCB from a stacker using a conveyor belt.

2. Robotic nozzles pick components from tape reels, sticks, or trays.

3. Vision systems verify component orientation and placement accuracy.

4. Components are placed at speeds up to 0.05 seconds per placement.

In-Depth Comparison: Manual vs. Automated Systems

1. Cost Analysis

Breakdown:

- Manual Advantage: Startups and R&D labs avoid high upfront costs, but labor expenses accumulate over time.

- Automated ROI: A $200,000 machine producing 10,000 boards/month breaks even in 18–24 months compared to manual labor.

2. Precision and Error Rates

- Manual Machines:

- Placement Accuracy: ±0.1–0.3 mm.

- Error Sources: Human fatigue, misalignment, static discharge, or solder paste smudging.

- Rework Rate: 5–15% for complex boards (e.g., quad-layer PCBs with 500+ components).

- Automated Systems:

- Placement Accuracy: ±0.025–0.05 mm.

- Error Rate: <0.01% with AOI (automated optical inspection).

- Self-Correction: Vision systems adjust placements in real time, even compensating for warped PCBs.

Case Study: A medical device manufacturer reduced placement errors from 8% (manual) to 0.2% (automated) when assembling hearing aid components.

3. Scalability and Throughput

- Manual Throughput:

- 1–50 boards/day (8-hour shift).

- Bottlenecks: Operator speed, component handling complexity (e.g., QFN packages).

- Automated Throughput:

- 500–5,000+ boards/day.

- Parallel Processing: Dual-lane systems double output; modular designs allow expansion.

Example: A drone manufacturer reduced assembly time per unit from 45 minutes (manual) to 8 minutes (automated), scaling production from 20 to 200 units/day.

4. Flexibility and Customization

- Manual Systems:

- Ideal for mixed-technology boards (SMD + through-hole).

- Rapid design changes without reprogramming.

- Customized Component Handling: Operators can place non-standard parts (e.g., heat sinks).

- Automated Systems:

- Limited flexibility for irregularly shaped components (e.g., tall electrolytic capacitors).

- Reprogramming Time: 2–8 hours for new PCB designs.

Niche Application: Aerospace prototypes often use manual machines for bespoke layouts requiring frequent iterations.

5. Quality Control and Inspection

- Manual:

- Operators visually inspect each placement under magnification.

- Challenges: Oversight with miniaturized components (e.g., 0201 resistors).

- Automated:

- AOI Systems: Detect soldering defects, tombstoning, or skewing with 99.98% accuracy.

- X-Ray Inspection: Verifies hidden connections in BGA or QFN packages.

- Traceability: Logs defect data for process optimization.

Emerging Trends and Hybrid Solutions

Semi-Automated Machines

Tools like the Voltera V-One blend manual loading with automated paste dispensing and placement guidance, offering a middle ground for small batches.

Desktop Automated Systems

Entry-level machines like LumenPnP ($7,500) provide basic automation for makers and startups, handling 1,000–2,000 CPH.

AI-Driven Optimization

Advanced systems now use machine learning to optimize nozzle paths, reducing placement time by 15–30%.

Collaborative Robots (Cobots)

Cobots like Universal Robots UR5e assist operators in manual setups, automating repetitive tasks while allowing human oversight.

Conclusion

The manual SMD pick and place machine remains a cornerstone for prototyping, education, and low-volume production, offering unmatched flexibility and affordability. However, automated systems dominate high-volume manufacturing with unparalleled speed, precision, and scalability.

As technology evolves, hybrid solutions and affordable automation are democratizing access to advanced PCB assembly. Small businesses can now leverage desktop automated machines, while large manufacturers integrate AI and cobots to enhance efficiency. The future lies in adaptive systems that balance human ingenuity with robotic precision, ensuring electronics manufacturing remains agile in a fast-paced world.

FAQ Section

1. Can a manual SMD pick and place machine handle fine-pitch components?

While possible, placing components smaller than 0402 (e.g., 0201 or 01005) requires exceptional operator skill and magnification tools. Automated systems are better suited for fine-pitch work.

2. How do automated systems manage component feeders?

Automated machines use tape-and-reel feeders, stick feeders, or tray systems. Advanced models auto-switch feeders to minimize downtime.

3. What safety features exist for manual machines?

Anti-static mats, grounded workstations, and ESD-safe vacuum pens prevent electrostatic discharge damage.

4. Are there open-source alternatives for manual pick and place?

Projects like OpenPnP offer DIY solutions using 3D-printed parts and Arduino controllers, though precision is limited.

5. How does humidity affect manual vs. automated placement?

High humidity causes solder paste to absorb moisture, leading to defects. Automated systems with climate-controlled chambers mitigate this risk, while manual setups require external humidity control.