Content Menu

● Introduction to SMT Stencil Printers

>> Key Features of High Precision SMT Stencil Printers

● Benefits of High Precision SMT Stencil Printers in PCB Assembly

>> Precision and Accuracy

>> Efficiency and Cost-Effectiveness

>> Adaptability and Flexibility

● Types of SMT Stencils Used with High Precision Printers

>> Framed SMT Stencils

>> Frameless SMT Stencils

>> Prototype SMT Stencils

● Future Trends and Innovations

● Challenges and Solutions in SMT Stencil Printing

>> Challenges

>> Solutions

● Case Studies: Success Stories with High Precision SMT Stencil Printers

● Conclusion

● FAQs

>> 1. What is the primary function of a high precision SMT stencil printer?

>> 2. How do high precision SMT stencil printers improve PCB assembly efficiency?

>> 3. What types of stencils are commonly used with high precision SMT stencil printers?

>> 4. How does the integration of AI and machine learning enhance the performance of SMT stencil printers?

>> 5. What are some future trends in SMT stencil printing technology?

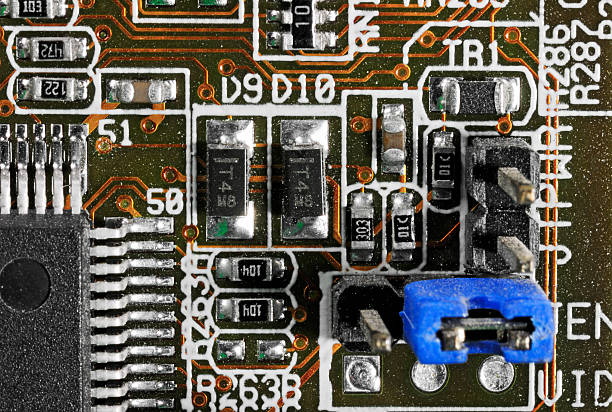

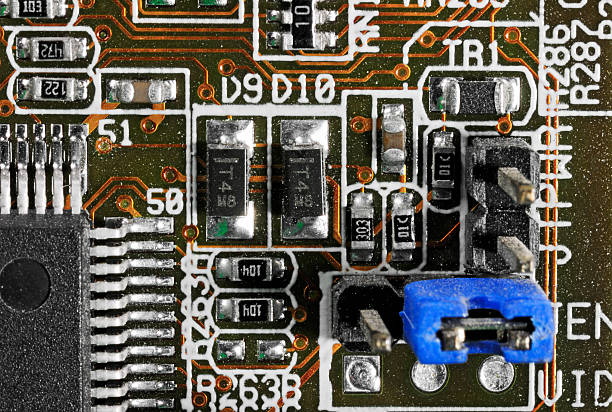

In the realm of electronics manufacturing, precision is paramount. One of the critical tools that ensures this precision is the high precision SMT stencil printer. This device plays a pivotal role in the surface mount technology (SMT) assembly process by accurately applying solder paste onto printed circuit boards (PCBs). The accuracy and reliability of PCB assembly are directly influenced by the quality of solder paste deposition, making high precision SMT stencil printers indispensable in modern electronics manufacturing.

Introduction to SMT Stencil Printers

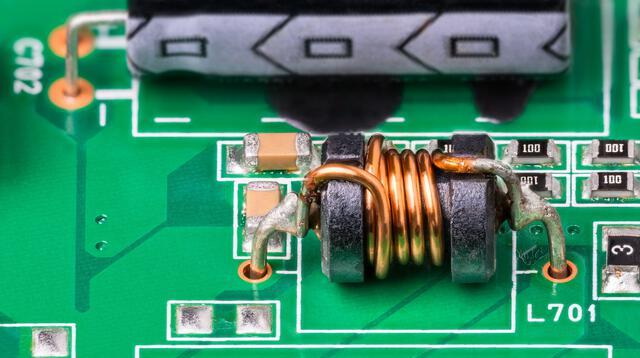

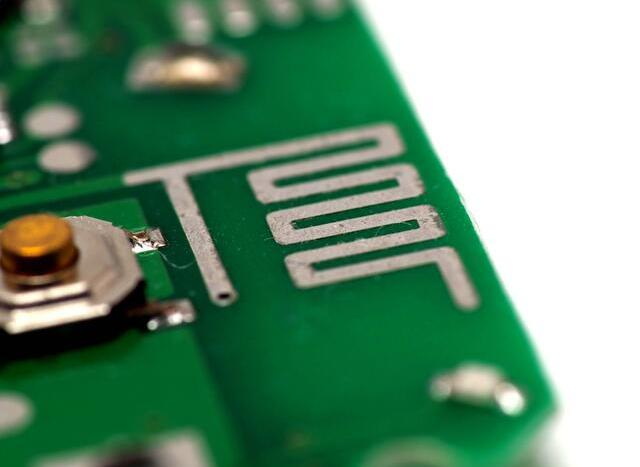

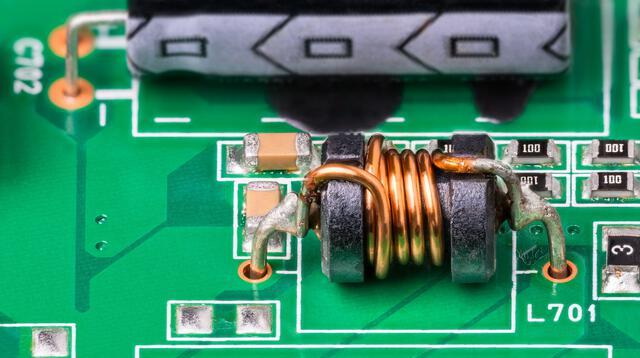

SMT stencil printers are specialized machines designed to apply solder paste onto PCBs using stencils. These stencils are typically made from materials like stainless steel or nickel, with precision-cut apertures that match the pad layout on the PCB. The process involves aligning the stencil over the PCB, applying solder paste using a squeegee, and then lifting the stencil to leave a precise layer of paste on the pads. This technique ensures that the correct amount of solder paste is applied to each pad, which is crucial for achieving strong electrical connections and reliable component placement.

Key Features of High Precision SMT Stencil Printers

High precision SMT stencil printers incorporate several advanced features that enhance their performance:

- Vision Systems: These printers often include advanced vision systems that enable precise alignment of the stencil with the PCB. This ensures that the solder paste is applied exactly where needed, minimizing errors and improving overall assembly quality.

- Precision Mechanics: The printers are equipped with precise mechanical systems that control the movement of the squeegee and the pressure applied during paste deposition. This ensures uniform coverage and prevents excess paste from being applied, which can lead to defects like bridging or tombstoning.

- Automated Processes: High precision SMT stencil printers are typically automated, allowing for high-volume production with minimal human intervention. This automation reduces the risk of human error and increases production efficiency.

- Material Handling: These printers often include features for stable material handling, ensuring consistent solder paste viscosity and preventing variations that could affect print quality.

Benefits of High Precision SMT Stencil Printers in PCB Assembly

The use of high precision SMT stencil printers offers several benefits in PCB assembly:

Precision and Accuracy

- Improved Solder Joint Quality: By ensuring that solder paste is applied accurately and consistently, these printers help achieve high-quality solder joints. This is crucial for the reliability and performance of electronic devices.

- Reduced Defects: Precise solder paste deposition minimizes defects such as insufficient solder, bridging, or tombstoning, which can lead to faulty PCBs.

Efficiency and Cost-Effectiveness

- Increased Production Speed: High precision SMT stencil printers can handle large volumes of PCBs quickly, making them ideal for mass production environments. They significantly reduce the time required for solder paste application compared to manual methods.

- Cost Savings: While the initial investment in a high precision SMT stencil printer may be substantial, the long-term benefits include reduced material waste, lower defect rates, and increased production efficiency. These factors contribute to cost savings over time.

Adaptability and Flexibility

- Compatibility with Various PCB Designs: These printers can handle a wide range of PCB designs and component types, including fine-pitch components and complex layouts. This adaptability makes them versatile tools in modern electronics manufacturing.

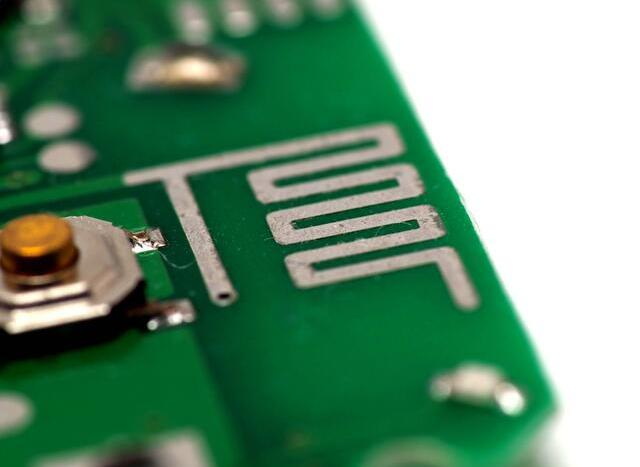

Types of SMT Stencils Used with High Precision Printers

SMT stencils come in different types, each suited to specific production needs:

Framed SMT Stencils

- Durability and Consistency: Framed stencils are preferred for high-volume production due to their durability and ability to maintain consistent results across multiple PCBs. The rigid frame ensures stability during the printing process.

Frameless SMT Stencils

- Flexibility and Cost-Effectiveness: Frameless stencils are ideal for prototypes or small-scale production. They are flexible, easy to handle, and cost-effective, making them suitable for environments where frequent design changes occur.

Prototype SMT Stencils

- Rapid Prototyping: These stencils support rapid prototyping by allowing quick adjustments and iterations in PCB design. They facilitate agile product development processes.

Future Trends and Innovations

The SMT stencil printing industry is evolving rapidly, driven by advancements in technology and the demand for miniaturization in electronic devices. Some of the emerging trends include:

- Integration of AI and Machine Learning: Modern SMT stencil printers are increasingly incorporating AI and machine learning algorithms to analyze print data, predict potential failures, and adjust settings for optimal results. This not only improves efficiency but also reduces errors and waste.

- Sustainability Initiatives: There is a growing focus on sustainability, with manufacturers adopting green materials and energy-efficient printing technologies. This includes the use of lead-free solders and waste recycling systems.

- Precision and Repeatability: As electronic components become smaller and more complex, the need for precision in solder paste deposition is becoming more critical. High precision SMT stencil printers are being developed to handle these demands, ensuring that solder paste is applied with micron-level accuracy.

Challenges and Solutions in SMT Stencil Printing

Despite the advantages of high precision SMT stencil printers, there are challenges that manufacturers face:

Challenges

- Component Miniaturization: The trend towards smaller components requires even higher precision in solder paste application, which can be challenging for some printers.

- Material Variability: Variations in solder paste viscosity or stencil material can affect print quality, requiring careful material management.

Solutions

- Advanced Vision Systems: Implementing advanced vision systems can help address the challenge of component miniaturization by ensuring precise alignment and monitoring of the printing process.

- Automated Material Handling: Using automated systems to manage solder paste and stencil materials helps maintain consistency and reduce variability.

Case Studies: Success Stories with High Precision SMT Stencil Printers

Several companies have reported significant improvements in PCB assembly quality and efficiency after adopting high precision SMT stencil printers:

- Increased Yield: One major electronics manufacturer reported a 20% increase in production yield due to reduced defects and improved solder joint quality.

- Reduced Production Time: Another company achieved a 30% reduction in production time by automating the solder paste application process with high precision printers.

These success stories highlight the potential benefits of integrating high precision SMT stencil printers into manufacturing workflows.

Conclusion

High precision SMT stencil printers are essential tools in modern PCB assembly, offering unparalleled precision, efficiency, and reliability. By ensuring accurate solder paste deposition, these printers play a critical role in achieving high-quality solder joints and minimizing defects. As electronics manufacturing continues to evolve, the importance of these printers will only grow, driven by the need for precision, sustainability, and technological innovation.

FAQs

1. What is the primary function of a high precision SMT stencil printer?

- The primary function of a high precision SMT stencil printer is to accurately apply solder paste onto PCB pads using a stencil, ensuring precise alignment and uniform coverage for reliable component placement.

2. How do high precision SMT stencil printers improve PCB assembly efficiency?

- High precision SMT stencil printers improve PCB assembly efficiency by automating the solder paste application process, reducing manual intervention, and enabling high-volume production with minimal defects.

3. What types of stencils are commonly used with high precision SMT stencil printers?

- Common types of stencils used with high precision SMT stencil printers include framed, frameless, and prototype stencils, each suited to different production needs and environments.

4. How does the integration of AI and machine learning enhance the performance of SMT stencil printers?

- The integration of AI and machine learning enhances the performance of SMT stencil printers by enabling real-time data analysis, predictive maintenance, and automatic adjustments to optimize print quality and reduce errors.

5. What are some future trends in SMT stencil printing technology?

- Future trends include the integration of AI, increased focus on sustainability with green materials and energy efficiency, and advancements in precision to handle smaller and more complex electronic components.