Content Menu

● Introduction to SMT and Tape and Reel Packaging

● DIY SMD Tape and Reel Machine: Design and Functionality

>> Key Components of a DIY SMD Tape and Reel Machine

● Benefits of Using a DIY SMD Tape and Reel Machine

>> Enhanced Efficiency

>> Cost-Effectiveness

>> Environmental Considerations

● DIY vs. Commercial Machines

● Challenges and Considerations

>> Overcoming Challenges

● Future Developments and Trends

● Conclusion

● Frequently Asked Questions

>> 1. What are the primary benefits of using a DIY SMD tape and reel machine?

>> 2. How does a DIY SMD tape and reel machine compare to commercial models?

>> 3. What types of components can a DIY SMD tape and reel machine handle?

>> 4. What are the key components of a DIY SMD tape and reel machine?

>> 5. What are some common challenges when building a DIY SMD tape and reel machine?

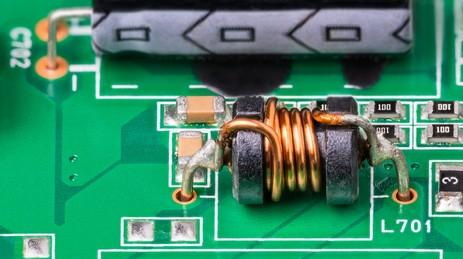

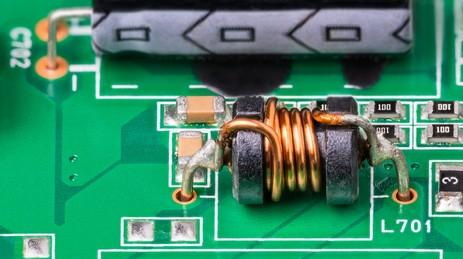

In the realm of electronics manufacturing, efficiency and precision are paramount. The use of Surface Mount Technology (SMT) has revolutionized the way components are mounted onto Printed Circuit Boards (PCBs), allowing for higher density and reliability. A crucial aspect of this process is the packaging and handling of SMT components, where the DIY SMD tape and reel machine plays a significant role. This article explores how a DIY SMD tape and reel machine can enhance PCB assembly efficiency, focusing on its design, functionality, and benefits.

Introduction to SMT and Tape and Reel Packaging

SMT involves mounting components directly onto the surface of a PCB, which requires precise handling and placement. The tape and reel packaging system is a standard method for organizing SMT components, ensuring they are fed into pick-and-place machines efficiently. This system involves placing components in pockets on a carrier tape, which is then sealed with cover tape and wound onto a reel. The reel format allows for easy integration with automated assembly lines, enhancing production speed and accuracy.

The tape and reel system also provides protection for components during storage and transportation, reducing the risk of damage from static electricity or physical stress. This is particularly important for sensitive components like ICs and capacitors, which are prone to damage if not handled properly.

DIY SMD Tape and Reel Machine: Design and Functionality

A DIY SMD tape and reel machine is designed to automate the process of organizing components into tape and reel format. This machine typically includes a feeding mechanism, a component placement system, and a reel winding mechanism. The feeding mechanism can be customized to handle different types of components and tape widths, allowing for flexibility in production. The component placement system ensures that components are accurately positioned in the tape pockets, while the reel winding mechanism securely winds the tape onto a reel for storage or immediate use.

Key Components of a DIY SMD Tape and Reel Machine

1. Feeding Mechanism: This can include vibrating disc feeding, pallet feeding, or belt feeding, depending on the component type and production requirements. Vibrating disc feeding is often used for small components like resistors and capacitors, while pallet feeding may be more suitable for larger components.

2. Component Placement System: Utilizes precision mechanisms to place components into the tape pockets, ensuring alignment and minimizing errors. This system may include optical sensors to verify component orientation and position.

3. Reel Winding Mechanism: Automatically winds the filled tape onto a reel, maintaining tension and preventing damage to the components or tape. The mechanism can be adjusted to accommodate different reel sizes and tape lengths.

Benefits of Using a DIY SMD Tape and Reel Machine

Enhanced Efficiency

- Automated Process: Reduces manual labor, allowing workers to focus on tasks requiring human expertise, such as quality control and machine maintenance.

- Increased Speed: Processes components quickly, minimizing downtime and improving overall production throughput. This is particularly beneficial in high-volume manufacturing environments.

- Precision: Ensures components are accurately placed and packaged, reducing errors and improving product quality. Automated systems can achieve higher precision than manual handling, reducing the need for rework.

Cost-Effectiveness

- Reduced Labor Costs: By automating the packaging process, labor costs associated with manual handling are significantly reduced. This can lead to substantial savings, especially in operations with high labor costs.

- Minimized Errors: Automated precision reduces the likelihood of component damage or misplacement, saving on rework and scrap costs. This also contributes to higher overall product quality and reliability.

- Flexibility: DIY machines can be designed or modified to handle a variety of components and production scenarios, making them versatile tools for small-scale manufacturers.

Environmental Considerations

The use of DIY SMD tape and reel machines can also contribute to more sustainable manufacturing practices. By reducing waste and minimizing the need for manual handling, these machines help decrease the environmental impact of electronics production. Additionally, the efficient use of materials and energy can lead to cost savings and improved operational efficiency.

DIY vs. Commercial Machines

While commercial SMD tape and reel machines offer high precision and speed, DIY machines provide an affordable entry point for small-scale manufacturers or hobbyists. DIY machines can be designed with flexibility in mind, allowing users to adapt them to various component types and production scenarios. However, they may require more manual intervention and maintenance compared to commercial models.

Commercial machines often come with advanced features such as automated inspection systems and high-speed processing capabilities, making them ideal for large-scale production environments. In contrast, DIY machines are better suited for prototyping, small batch production, or educational purposes.

Challenges and Considerations

Implementing a DIY SMD tape and reel machine involves several challenges:

- Design Complexity: Requires knowledge of mechanical engineering and automation principles. Designing a machine that can accurately handle components and maintain precision is crucial.

- Component Handling: Sensitive components need careful handling to prevent damage. This includes ensuring proper grounding to prevent static electricity damage.

- Maintenance and Calibration: Regular maintenance is crucial to ensure precision and reliability. This includes cleaning, lubricating moving parts, and calibrating the placement system.

Overcoming Challenges

To overcome these challenges, manufacturers can invest in training and education for staff, ensuring they have the necessary skills to design, build, and maintain DIY machines. Additionally, collaborating with other DIY enthusiasts or seeking guidance from online forums can provide valuable insights and solutions to common problems.

Future Developments and Trends

As technology advances, there is a growing trend towards integrating DIY solutions with more sophisticated automation systems. This could involve incorporating AI for predictive maintenance or using IoT sensors to monitor machine performance in real-time. Such advancements could further enhance the efficiency and reliability of DIY SMD tape and reel machines, making them more competitive with commercial models.

Moreover, the rise of open-source hardware and collaborative design platforms is facilitating the development of more sophisticated DIY machines. These platforms allow users to share designs, modifications, and improvements, creating a community-driven approach to innovation in electronics manufacturing.

Conclusion

A DIY SMD tape and reel machine can significantly improve PCB assembly efficiency by automating the packaging process, enhancing precision, and reducing labor costs. While it presents challenges, the benefits in terms of flexibility and cost-effectiveness make it an attractive option for small-scale manufacturers and hobbyists. As technology advances, the potential for DIY solutions to integrate with more sophisticated automation systems will continue to grow, further enhancing their utility in modern electronics manufacturing.

Frequently Asked Questions

1. What are the primary benefits of using a DIY SMD tape and reel machine?

The primary benefits include enhanced efficiency through automation, reduced labor costs, and improved precision in component packaging. This leads to higher quality products and lower production costs.

2. How does a DIY SMD tape and reel machine compare to commercial models?

While commercial machines offer higher precision and speed, DIY machines provide flexibility and cost-effectiveness, making them suitable for small-scale or hobbyist projects. However, DIY machines may require more manual intervention.

3. What types of components can a DIY SMD tape and reel machine handle?

These machines can handle a variety of SMT components, including small passives and larger ICs, depending on the design and customization of the machine.

4. What are the key components of a DIY SMD tape and reel machine?

The key components include a feeding mechanism, a component placement system, and a reel winding mechanism. Each component is crucial for ensuring efficient and precise packaging.

5. What are some common challenges when building a DIY SMD tape and reel machine?

Common challenges include design complexity, careful handling of sensitive components, and the need for regular maintenance and calibration to ensure precision and reliability.