Content Menu

● Understanding SMT Pick and Place in PCB Assembly

>> What is SMT Pick and Place?

>> Importance in PCB Assembly

● Key Strategies to Optimize Your SMT Pick and Place PCB Assembly Line

>> 1. Optimize SMT Line Layout and Workflow

>> 2. Invest in Advanced SMT Pick and Place Technology

>> 3. Standardize and Streamline Processes

>> 4. Design for Manufacturability (DFM)

>> 5. Implement Real-Time Monitoring and Data Analytics

>> 6. Train and Develop Skilled Workforce

● Detailed SMT Pick and Place Process Overview

● Enhancing SMT Pick and Place Efficiency with Automation and Integration

● Common Challenges and Solutions in SMT Pick and Place PCB Assembly Optimization

>> Challenge 1: Component Variety and Complexity

>> Challenge 2: Minimizing Downtime

>> Challenge 3: Maintaining High Placement Accuracy

>> Challenge 4: Managing Small Batch and Prototype Runs

● The Role of Software and Programming in SMT Pick and Place Optimization

● Future Trends in SMT Pick and Place PCB Assembly

● Conclusion

● FAQ

>> 1. What is the role of SMT pick and place machines in PCB assembly?

>> 2. How does layout design affect SMT assembly line efficiency?

>> 3. What are key features to look for in SMT pick and place machines?

>> 4. How can PCB design be optimized for SMT assembly?

>> 5. Why is operator training important in SMT assembly?

Optimizing a PCB assembly line is critical for manufacturers aiming to enhance productivity, reduce costs, and maintain high product quality. Surface Mount Technology (SMT) pick and place machines play a pivotal role in this optimization by automating the precise placement of electronic components onto printed circuit boards (PCBs). This article explores comprehensive strategies to optimize your PCB assembly line using SMT pick and place solutions, highlighting key technologies, layout design, process improvements, and workforce training.

Understanding SMT Pick and Place in PCB Assembly

What is SMT Pick and Place?

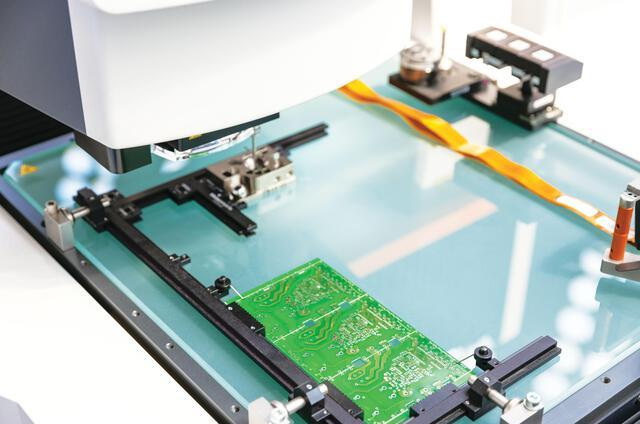

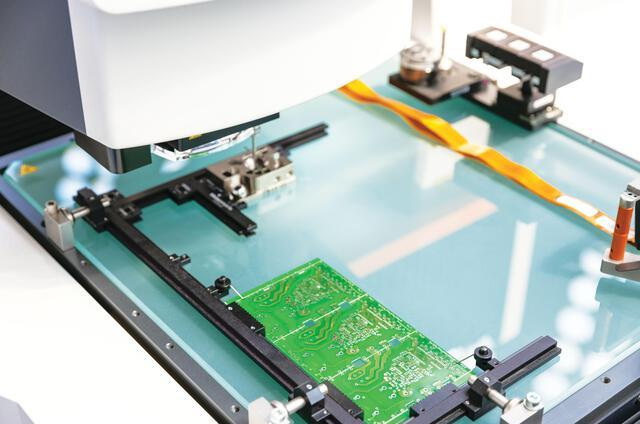

SMT pick and place machines are automated devices designed to pick electronic components from feeders and accurately place them on the PCB surface. These machines handle various surface-mount devices (SMDs) such as resistors, capacitors, and integrated circuits, using vacuum nozzles or grippers for component manipulation.

Importance in PCB Assembly

The precision and speed of SMT pick and place machines directly impact the efficiency and quality of the PCB assembly line. High-speed, multi-head pick and place machines can place thousands of components per hour with micron-level accuracy, reducing human error and increasing throughput.

Key Strategies to Optimize Your SMT Pick and Place PCB Assembly Line

1. Optimize SMT Line Layout and Workflow

A well-planned SMT assembly line layout minimizes material handling time and labor costs, improving overall production efficiency. Common layout designs include:

- U-shaped layout: Enables a smooth "one flow" production process, reducing walking distances and cycle times.

- Petal-type layout: Enhances cooperation between workstations to balance the production line.

- Ring layout: Best for small-lot, multi-type production with flexible response to demand changes.

Optimizing the physical arrangement of solder paste printers, pick and place machines, reflow ovens, and inspection stations ensures a streamlined workflow and reduces bottlenecks.

2. Invest in Advanced SMT Pick and Place Technology

Modern SMT pick and place machines incorporate features such as:

- Multi-head gantry systems for simultaneous placement of multiple components, increasing speed.

- Vision systems with cameras or lasers for precise component alignment and fiducial recognition.

- Automated nozzle changers to handle various component sizes and shapes without manual intervention.

Adopting state-of-the-art equipment with these capabilities enhances placement accuracy and reduces cycle times, boosting overall line efficiency.

3. Standardize and Streamline Processes

Implementing standardized operating procedures for SMT assembly ensures consistent quality and minimizes errors. This includes:

- Detailed work instructions specifying component placement sequences, tooling, and quality checkpoints.

- Use of lean manufacturing principles such as 5S, Kanban, and visual management to eliminate waste and optimize material flow.

Balancing workloads across stations prevents delays and harmonizes production rhythm, ensuring smooth line operation.

4. Design for Manufacturability (DFM)

Optimizing PCB design for SMT assembly can significantly reduce assembly complexity and errors. Key DFM considerations include:

- Aligning SMT components in a single direction to facilitate faster, error-free placement.

- Maintaining proper spacing and clearances to avoid soldering defects.

- Using standard component sizes and footprints to simplify feeder setups and reduce lead times.

Early collaboration with manufacturing partners during the design phase helps identify and mitigate potential assembly challenges.

5. Implement Real-Time Monitoring and Data Analytics

Integrating IoT and data analysis technologies allows real-time monitoring of the SMT assembly line to detect deviations and optimize performance. Predictive maintenance and quality control algorithms can minimize downtime and improve product reliability.

6. Train and Develop Skilled Workforce

Even with advanced automation, skilled operators are essential for troubleshooting, maintenance, and quality assurance. Comprehensive training programs enhance operator proficiency in equipment handling and process management, contributing to smoother production and fewer errors.

Detailed SMT Pick and Place Process Overview

To truly optimize your PCB assembly line, it's important to understand the detailed workflow involved in SMT pick and place operations:

1. Solder Paste Application: The process begins with a solder paste printer applying solder paste onto the PCB pads using a stencil. This step is crucial because the quality and consistency of solder paste deposition directly affect component adhesion and solder joint reliability.

2. Component Pickup: The SMT pick and place machine selects the appropriate nozzle based on component size and shape and picks components from feeders or trays. Efficient feeder setup and management are vital to prevent downtime and ensure continuous operation.

3. Component Recognition: Advanced vision systems integrated into SMT pick and place machines verify the component type, orientation, and position. This step ensures that only correctly oriented components are placed, reducing defects.

4. Component Placement: The machine places components accurately on the PCB according to the design specifications. Precision placement reduces rework and improves solder joint quality.

5. Reflow Soldering: The PCB passes through a reflow oven where the solder paste melts, creating strong mechanical and electrical connections between components and PCB pads.

6. Inspection: Automated Optical Inspection (AOI) and Solder Paste Inspection (SPI) systems check for placement accuracy, solder joint integrity, and other defects. Early detection of errors prevents defective products from advancing through the production line.

Enhancing SMT Pick and Place Efficiency with Automation and Integration

Automation is at the heart of optimizing SMT pick and place PCB assembly lines. Integrating various machines and systems into a cohesive, automated production line offers several advantages:

- Automated Material Handling: Conveyors, robotic arms, and automated guided vehicles (AGVs) can transport PCBs between workstations, reducing manual handling and speeding up production cycles.

- Inline Quality Control: Incorporating inspection systems directly into the line allows immediate feedback and corrective actions, minimizing scrap and rework.

- Data-Driven Decision Making: Collecting and analyzing production data in real time helps identify bottlenecks, predict maintenance needs, and optimize machine settings.

- Flexible Manufacturing Systems (FMS): These systems adapt quickly to changes in product design or volume, supporting just-in-time manufacturing and reducing inventory costs.

Common Challenges and Solutions in SMT Pick and Place PCB Assembly Optimization

Challenge 1: Component Variety and Complexity

Modern electronics often require placing thousands of components of varying sizes, shapes, and sensitivities. Managing this variety can slow down the SMT pick and place process.

Solution: Use modular pick and place machines with flexible feeders and automated nozzle changers. Implement software that optimizes placement sequences based on component characteristics to maximize speed and accuracy.

Challenge 2: Minimizing Downtime

Machine downtime due to feeder jams, nozzle blockages, or maintenance can severely impact production efficiency.

Solution: Implement predictive maintenance using sensor data and analytics to schedule maintenance before failures occur. Train operators in quick troubleshooting and preventive care.

Challenge 3: Maintaining High Placement Accuracy

High-speed placement can sometimes compromise accuracy, leading to defects.

Solution: Invest in advanced vision systems and precision motion control. Regularly calibrate equipment and conduct process audits to ensure consistent quality.

Challenge 4: Managing Small Batch and Prototype Runs

Frequent changeovers for small batches or prototypes can reduce line efficiency.

Solution: Adopt flexible SMT pick and place machines with quick feeder changeover capabilities. Use software tools to streamline programming and setup for new products.

The Role of Software and Programming in SMT Pick and Place Optimization

Software plays a critical role in maximizing the performance of SMT pick and place machines and the overall PCB assembly line. Key software functionalities include:

- Programming and Simulation: Offline programming software allows engineers to create and simulate placement programs before production, reducing setup time and errors.

- Machine Control and Monitoring: Real-time control software manages machine operations, monitors performance, and alerts operators to issues.

- Data Analytics and Reporting: Collecting data on placement accuracy, cycle times, and defects helps identify trends and areas for improvement.

- Integration with ERP and MES: Linking SMT equipment with enterprise resource planning (ERP) and manufacturing execution systems (MES) ensures seamless production planning, inventory management, and traceability.

Future Trends in SMT Pick and Place PCB Assembly

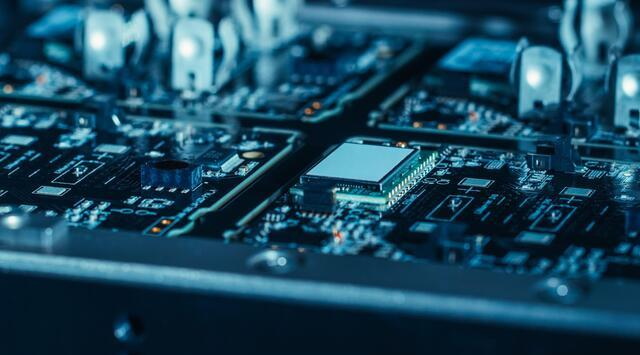

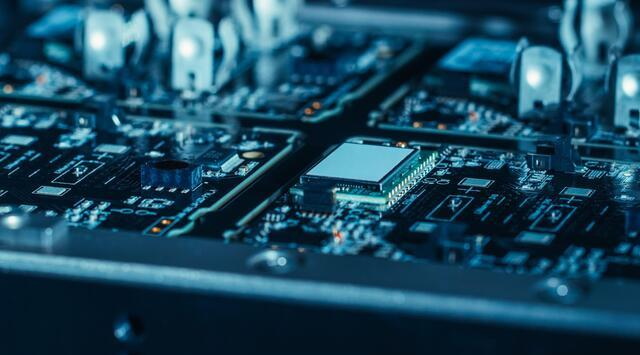

As electronics manufacturing evolves, several trends are shaping the future of SMT pick and place technology:

- Artificial Intelligence (AI) and Machine Learning: AI algorithms will enhance defect detection, predictive maintenance, and process optimization.

- Miniaturization and High-Density PCBs: SMT pick and place machines will need to handle increasingly smaller components with higher precision.

- 3D Printing and Additive Manufacturing: Hybrid assembly lines combining SMT with 3D printing may emerge for rapid prototyping and complex assemblies.

- Sustainability and Energy Efficiency: Green manufacturing practices will drive the development of energy-efficient SMT equipment and processes.

Conclusion

Optimizing your PCB assembly line with SMT pick and place solutions requires a holistic approach that combines advanced technology, efficient layout design, process standardization, and skilled workforce development. By investing in high-performance pick and place machines, designing PCBs for manufacturability, and implementing lean manufacturing principles, manufacturers can significantly enhance production efficiency, reduce costs, and improve product quality. Real-time monitoring and continuous improvement further ensure the assembly line operates at peak performance, meeting the demands of modern electronics manufacturing.

The integration of automation, data analytics, and flexible manufacturing systems will continue to drive innovation in SMT pick and place PCB assembly, enabling manufacturers to stay competitive in a rapidly evolving industry.

FAQ

1. What is the role of SMT pick and place machines in PCB assembly?

SMT pick and place machines automate the precise placement of surface-mount components onto PCBs, significantly increasing assembly speed and accuracy while reducing human error.

2. How does layout design affect SMT assembly line efficiency?

A well-optimized layout minimizes material handling and walking distances, balances workloads, and reduces cycle times, leading to smoother workflow and higher productivity.

3. What are key features to look for in SMT pick and place machines?

Important features include multi-head gantry systems, advanced vision alignment, automated nozzle changers, and high-speed placement capabilities to handle various component types efficiently.

4. How can PCB design be optimized for SMT assembly?

Designing with aligned components, proper spacing, standardized footprints, and early collaboration with manufacturers helps reduce assembly complexity and errors.

5. Why is operator training important in SMT assembly?

Even with automation, skilled operators are essential for equipment operation, troubleshooting, maintenance, and quality control, ensuring consistent production and minimizing downtime.