Content Menu

● Introduction to SMT Screen Stencil Printers

● Importance of Maintenance

● Maintenance and Cleaning Practices

>> Daily Maintenance

>> Weekly Maintenance

>> Monthly Maintenance

● Operational Best Practices

>> Stencil Handling and Storage

>> Solder Paste Management

>> Printer Settings Optimization

>> Environmental Considerations

● Troubleshooting Common Issues

>> Solder Bridging

>> Insufficient Fills

>> Misregistration

● Advanced Maintenance Techniques

>> Laser-Cut Stencil Maintenance

>> Electroformed Nickel Stencil Maintenance

>> Automated Maintenance Tools

● Role of Technology in Maintenance

● Training and Documentation

● Conclusion

● FAQ

>> 1. How Often Should I Clean My SMT Stencil?

>> 2. What Are the Signs That My Stencil Needs Replacement?

>> 3. Can I Use the Same Stencil for Different Solder Paste Types?

>> 4. How Do I Optimize Squeegee Settings for Better Print Quality?

>> 5. What Are the Benefits of Regular Maintenance for My SMT Stencil Printer?

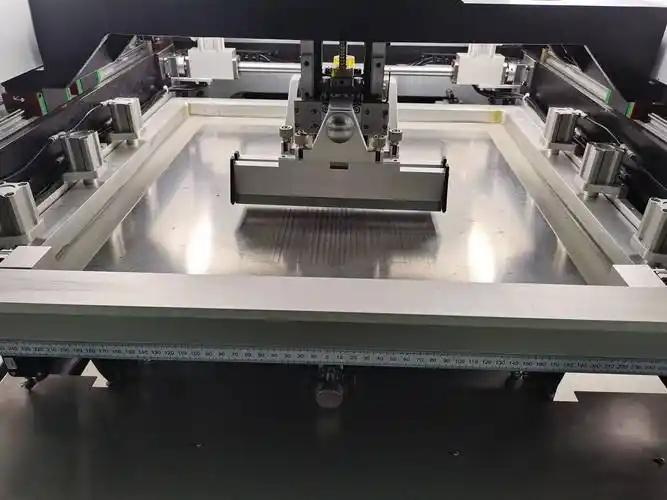

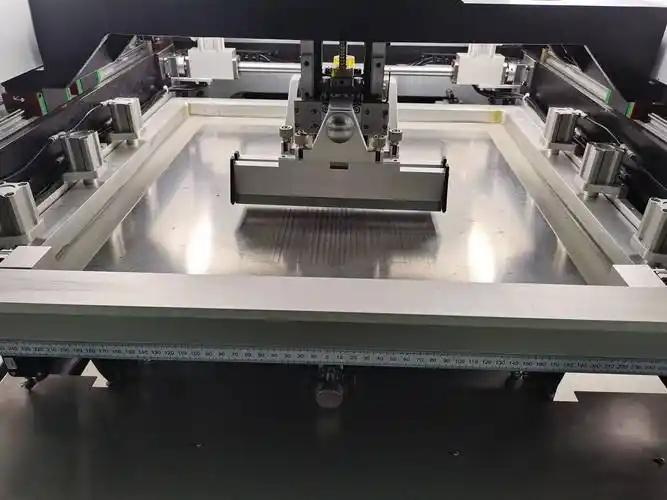

Maintaining an SMT screen stencil printer is crucial for ensuring longevity, consistent print quality, and reducing downtime in electronics manufacturing. This article will delve into the essential practices for maintaining and optimizing your SMT stencil printer, focusing on regular inspections, cleaning techniques, and operational best practices.

Introduction to SMT Screen Stencil Printers

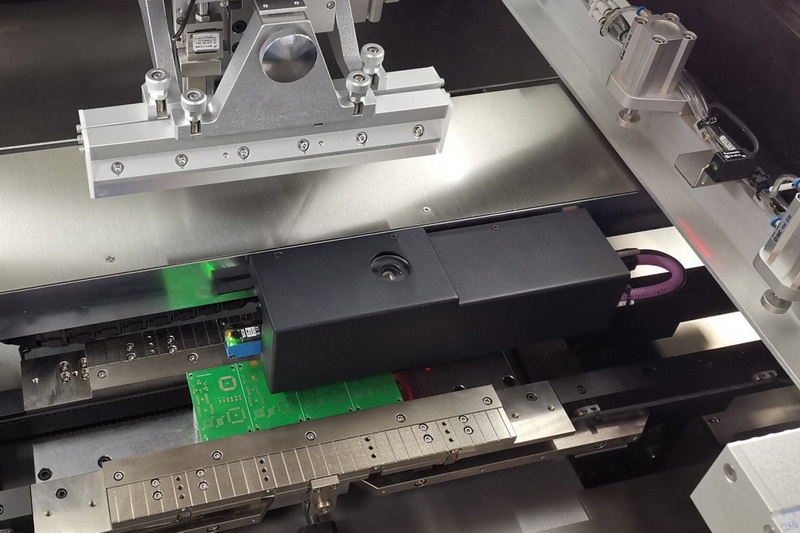

SMT (Surface Mount Technology) screen stencil printers are vital tools in the electronics manufacturing process, used for applying solder paste onto printed circuit boards (PCBs). These printers rely on stencils, which are precision-cut templates that define the solder paste pattern. The lifespan of these stencils can vary significantly based on usage, material, and maintenance practices. Generally, stainless steel stencils can last for 20,000 to 50,000 prints, while electroformed nickel stencils can endure up to 100,000 prints or more.

Importance of Maintenance

Regular maintenance is key to extending the lifespan of both the stencil and the printer. It ensures consistent print quality, reduces defects, and minimizes production delays. Here are some reasons why maintenance is essential:

- Consistent Print Quality: Regular cleaning and inspection help maintain the stencil's integrity, ensuring that solder paste is applied accurately and consistently.

- Extended Lifespan: Proper care prevents wear and tear on both the stencil and printer components, reducing the need for premature replacements.

- Reduced Downtime: By addressing issues promptly, you can avoid unexpected production halts due to equipment failure or poor print quality.

- Improved Efficiency: Well-maintained equipment operates more efficiently, leading to higher productivity and lower operational costs.

Maintenance and Cleaning Practices

Daily Maintenance

1. Visual Inspection: Begin each day by inspecting the printer for signs of wear, damage, or misalignment. Check the stencil surface, alignment pins, squeegee blades, and frame for any issues.

2. Cleaning: Clean the stencil and printer components thoroughly after each use. Use isopropyl alcohol or specialized stencil cleaning solutions to avoid damaging the stencil surface.

3. Solder Paste Management: Ensure that solder paste is stored properly and used within its shelf life to maintain its rheological properties.

Weekly Maintenance

1. Stencil Tension Check: Verify and adjust the stencil tension if necessary to ensure proper alignment and print quality.

2. Underside Cleaning: Inspect and clean the underside of the stencil to prevent solder paste buildup.

3. Alignment Verification: Use a test print to verify the alignment of the printer.

4. Lubrication: Lubricate moving parts as recommended by the manufacturer.

5. Tighten Loose Parts: Check and tighten any loose screws or bolts.

Monthly Maintenance

1. Comprehensive Inspection: Perform a thorough inspection of all components.

2. Procedure Review: Review and update maintenance procedures based on equipment performance.

3. Training: Ensure all operators are trained on maintenance procedures.

4. Log Keeping: Maintain a log of all inspections, cleanings, and repairs.

Operational Best Practices

Stencil Handling and Storage

- Handle with Care: Always handle stencils carefully to avoid damage.

- Proper Storage: Store stencils in a dry, clean environment, away from other metal objects to prevent corrosion.

Solder Paste Management

- Paste Selection: Use the appropriate solder paste type for your application. Different pastes have varying rheological properties and flux activities.

- Paste Conditioning: Ensure solder paste is fully conditioned before use to prevent defects like insufficient fills.

Printer Settings Optimization

- Squeegee Speed and Pressure: Optimize squeegee speed and pressure to ensure proper solder paste deposition without scooping or bridging.

- Print Alignment: Verify the alignment of stencil apertures to PCB pads to prevent bridging and ensure accurate solder paste application.

Environmental Considerations

- Temperature and Humidity Control: Maintain a stable temperature and humidity environment to prevent solder paste degradation and stencil warping.

- Cleanliness: Ensure the production area is clean and free from dust to prevent contamination.

Troubleshooting Common Issues

Solder Bridging

- Causes: Incorrect stencil alignment, excessive solder paste, or poor reflow profiles can cause bridging.

- Solutions: Adjust stencil alignment, reduce solder paste deposition, and optimize reflow profiles.

Insufficient Fills

- Causes: Blocked stencil apertures or insufficient squeegee pressure can lead to insufficient fills.

- Solutions: Regularly clean the stencil, ensure proper squeegee pressure, and check solder paste viscosity.

Misregistration

- Causes: Misaligned stencils or PCBs can cause misregistration.

- Solutions: Verify stencil and PCB alignment, adjust printer settings as needed.

Advanced Maintenance Techniques

Laser-Cut Stencil Maintenance

- Specialized Cleaning: Use specialized cleaning solutions for laser-cut stencils to prevent damage to the fine features.

- Handling Care: Handle laser-cut stencils with extra care due to their delicate nature.

Electroformed Nickel Stencil Maintenance

- Corrosion Prevention: Store electroformed nickel stencils in a dry environment to prevent corrosion.

- Cleaning Methods: Use gentle cleaning methods to avoid damaging the stencil surface.

Automated Maintenance Tools

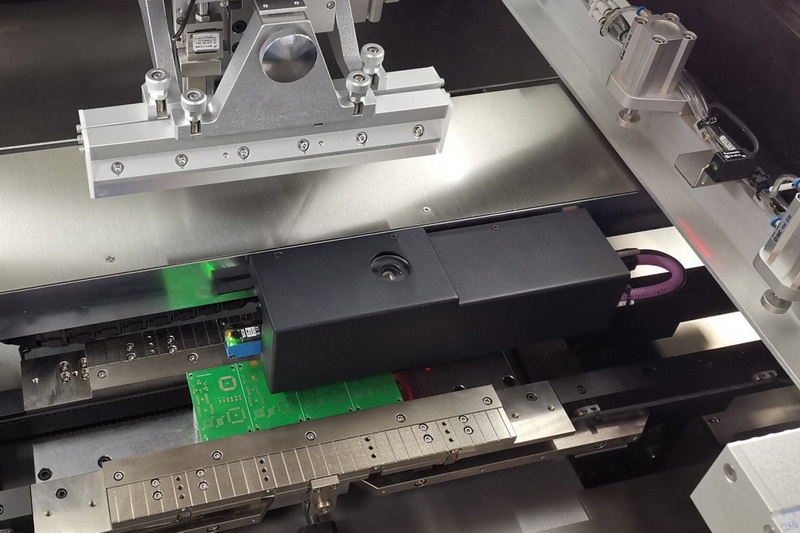

- Stencil Inspection Systems: Utilize automated systems for stencil inspection to detect defects early.

- Cleaning Robots: Implement robotic cleaning systems for consistent and efficient stencil cleaning.

Role of Technology in Maintenance

- Predictive Maintenance: Use data analytics and sensors to predict when maintenance is needed, reducing downtime.

- Remote Monitoring: Implement remote monitoring systems to track printer performance and detect issues in real-time.

Training and Documentation

- Operator Training: Ensure all operators are well-trained on maintenance procedures and troubleshooting techniques.

- Documentation: Maintain detailed documentation of maintenance activities, repairs, and performance metrics.

Conclusion

Maintaining an SMT screen stencil printer requires a combination of regular inspections, thorough cleaning practices, and adherence to operational best practices. By implementing these strategies, manufacturers can significantly extend the lifespan of their equipment, improve print quality, and reduce production downtime. Proper maintenance not only saves costs but also enhances overall production efficiency.

FAQ

1. How Often Should I Clean My SMT Stencil?

Clean your SMT stencil every 4 to 8 hours of continuous printing or whenever print quality begins to deteriorate. For high-volume operations, clean the stencil daily or after each production run.

2. What Are the Signs That My Stencil Needs Replacement?

Signs that your stencil may need replacement include visible damage or deformation, consistent print quality issues, apertures that no longer meet specifications, difficulty maintaining tension, and excessive wear around high-use areas.

3. Can I Use the Same Stencil for Different Solder Paste Types?

It is generally recommended to use a separate stencil for each solder paste type to avoid cross-contamination and compatibility issues. Different solder pastes have varying properties that can affect stencil life and print performance.

4. How Do I Optimize Squeegee Settings for Better Print Quality?

Optimize squeegee speed and pressure to ensure proper solder paste deposition. Too much pressure can cause scooping, while too little may result in insufficient fills. Adjust settings based on solder paste type and PCB design.

5. What Are the Benefits of Regular Maintenance for My SMT Stencil Printer?

Regular maintenance ensures consistent print quality, extends the lifespan of both the stencil and printer, reduces downtime, minimizes defects, and improves overall production efficiency. It also helps in early detection and resolution of potential issues.