Content Menu

● Introduction to LED SMD Mounting Machines

● Importance of Maintenance

>> Cleaning

>> Lubrication

>> Calibration

>> Inspection and Replacement of Parts

● Operational Precautions

>> Handling Components

>> Machine Operation

● Advanced Maintenance Techniques

>> Monthly Maintenance

>> Quarterly Maintenance

● Troubleshooting Common Issues

>> Component Misplacement

>> Soldering Defects

● Environmental Considerations

● Training and Documentation

● Operator Competencies

● Quality Control Measures

● Conclusion

● FAQ

>> 1. What are the key maintenance tasks for an LED SMD mounting machine?

>> 2. How often should I clean the nozzles and feeders of the machine?

>> 3. Why is calibration important for an LED SMD mounting machine?

>> 4. What precautions should be taken when handling electronic components like LEDs?

>> 5. How does regular maintenance impact the longevity of an LED SMD mounting machine?

● Citations:

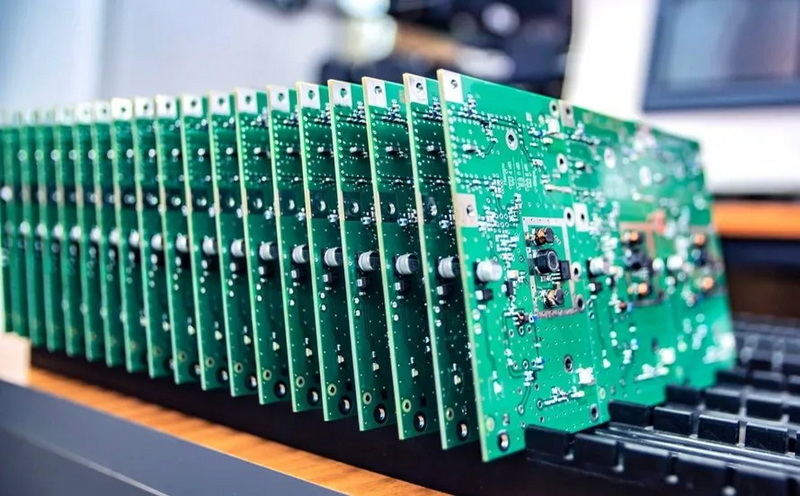

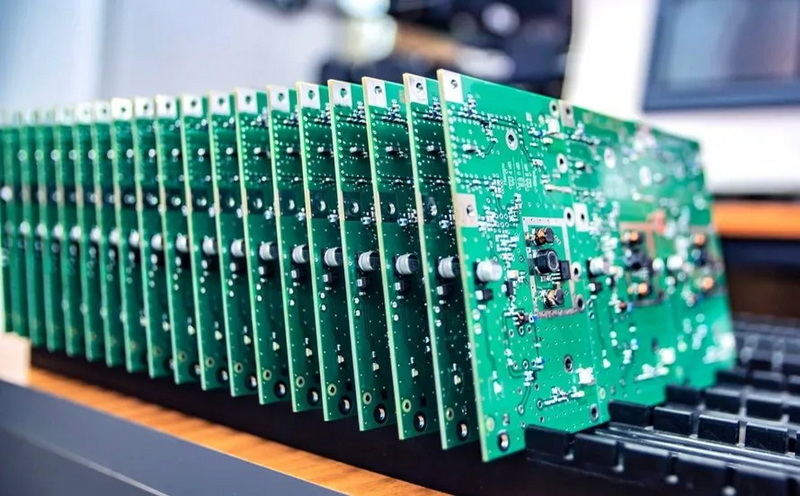

Maintaining an LED SMD mounting machine is crucial for ensuring its longevity and optimal performance in the production of electronic components. These machines are integral to the Surface Mount Technology (SMT) process, which involves mounting electronic components onto a printed circuit board (PCB). The SMT process is widely used in the electronics industry due to its efficiency and precision. In this article, we will explore the essential maintenance practices for an LED SMD mounting machine to maximize its lifespan and efficiency.

Introduction to LED SMD Mounting Machines

LED SMD mounting machines are specialized equipment designed to handle the precise placement of Surface Mount Devices (SMDs), including LEDs, onto PCBs. These machines are equipped with advanced vision systems and pick-and-place mechanisms that allow for high-speed and accurate component placement. The longevity of these machines depends on regular maintenance, proper operation, and adherence to best practices.

Importance of Maintenance

Regular maintenance is vital for maintaining the performance and longevity of LED SMD mounting machines. It helps prevent unexpected downtime, reduces the risk of component misplacement, and ensures consistent product quality. Maintenance tasks include cleaning, lubrication, calibration, and inspection of critical components.

Cleaning

Cleaning is a fundamental aspect of maintaining an LED SMD mounting machine. Dust and debris can accumulate on the machine's components, such as nozzles, feeders, and conveyor belts, leading to malfunctions and reduced accuracy. Regular cleaning using soft cloths and mild cleaning solutions helps maintain the machine's efficiency. For more thorough cleaning, ultrasonic cleaning methods can be employed to remove stubborn contaminants[1].

Lubrication

Lubrication is essential for the smooth operation of moving parts within the machine. Proper lubrication reduces friction, preventing wear and tear on components like guide rails and conveyor belts. It is important to use the recommended lubricants and avoid over-lubrication, which can lead to residue buildup and affect machine performance[1].

Calibration

Calibration ensures that the machine's components are accurately aligned and functioning as intended. Regular calibration checks should be performed according to the manufacturer's guidelines to maintain precision and prevent errors in component placement[1].

Inspection and Replacement of Parts

Regular inspections help identify worn or damaged parts, such as nozzles, feeders, and belts, which should be replaced promptly to prevent machine downtime. Keeping spare parts on hand can expedite repairs and minimize production delays.

Operational Precautions

Operational precautions are crucial for maintaining the integrity of the machine and ensuring safe working conditions.

Handling Components

- ESD Protection: Electronic components, including LEDs, are sensitive to electrostatic discharge (ESD). Operators should use ESD-protective equipment to prevent damage during handling.

- Component Storage: Store components in a clean, dry environment, away from moisture and static electricity. LEDs, especially SMD LEDs, are sensitive to humidity and should be stored according to their Moisture Sensitivity Level (MSL)[2].

Machine Operation

- Feeder Management: Ensure that feeders are properly aligned and secured before operation to prevent component misfeeds.

- Production Monitoring: Continuously monitor machine performance during production to address any issues promptly and maintain quality standards.

Advanced Maintenance Techniques

Advanced maintenance techniques involve more detailed procedures that are typically performed less frequently but are essential for maintaining the machine's optimal performance.

Monthly Maintenance

- Deep Cleaning: Perform a thorough cleaning of all machine components, including vision systems and conveyor belts.

- Performance Testing: Conduct comprehensive tests to evaluate machine accuracy and identify potential issues before they become critical.

Quarterly Maintenance

- Detailed Inspection: Conduct a detailed inspection of all machine parts, including electrical connections and mechanical components.

- Software Updates: Ensure that the machine's software is up-to-date to incorporate any improvements or bug fixes.

Troubleshooting Common Issues

Troubleshooting is an essential skill for operators to quickly identify and resolve common issues that may arise during operation.

Component Misplacement

- Nozzle Blockage: Check for blockages in the nozzles and clean them as necessary.

- Feeder Alignment: Ensure that feeders are properly aligned with the machine's placement head.

Soldering Defects

- Temperature Control: Verify that soldering temperatures are within the recommended range for the components being used.

- Solder Paste Quality: Check the quality and application of solder paste to ensure proper solder joints.

Environmental Considerations

The environment in which an LED SMD mounting machine operates can significantly impact its performance and longevity. Factors such as temperature, humidity, and cleanliness should be carefully controlled.

- Temperature Control: Ensure that the operating environment maintains a stable temperature within the recommended range for the machine and components.

- Humidity Management: Maintain a controlled humidity level to prevent moisture-related issues with components and machine parts.

- Cleanliness: Maintain a clean workspace to prevent dust and debris from accumulating on the machine[5].

Training and Documentation

Proper training of operators and maintenance personnel is crucial for effective machine maintenance. Documentation of maintenance procedures and schedules helps ensure consistency and compliance with best practices.

- Operator Training: Provide comprehensive training on machine operation, maintenance, and troubleshooting.

- Maintenance Records: Keep detailed records of maintenance activities to track machine performance and identify trends[3].

Operator Competencies

Operators should possess specific competencies to effectively manage and maintain LED SMD mounting machines. These include understanding SMT processes, operating machine software, and performing quality control checks.

- SMT Process Knowledge: Familiarity with the SMT process, including component placement, soldering, and inspection.

- Machine Operation Skills: Ability to operate the machine's software interface and adjust parameters for optimal performance[6].

Quality Control Measures

Implementing robust quality control measures is essential to ensure the high quality of assembled PCBs. This includes regular inspections and testing of solder joints and component placement.

- Visual Inspection: Conduct visual inspections of PCBs to verify component alignment and solder joint integrity.

- Automated Testing: Use automated testing equipment to detect defects and ensure consistency in production[4].

Conclusion

Maintaining an LED SMD mounting machine requires a comprehensive approach that includes regular cleaning, lubrication, calibration, and inspection. By following these practices and adhering to operational precautions, manufacturers can ensure the longevity and optimal performance of their equipment. Regular maintenance not only reduces downtime but also enhances product quality and consistency, which are critical in the competitive electronics manufacturing industry.

FAQ

1. What are the key maintenance tasks for an LED SMD mounting machine?

- Key maintenance tasks include cleaning, lubrication, calibration, and regular inspection of machine components.

2. How often should I clean the nozzles and feeders of the machine?

- Nozzles and feeders should be cleaned daily to prevent debris buildup and ensure accurate component placement.

3. Why is calibration important for an LED SMD mounting machine?

- Calibration ensures that the machine's components are accurately aligned, which is crucial for precise component placement and preventing errors.

4. What precautions should be taken when handling electronic components like LEDs?

- Components should be handled with ESD protection, stored in a clean, dry environment, and managed according to their moisture sensitivity level.

5. How does regular maintenance impact the longevity of an LED SMD mounting machine?

- Regular maintenance extends the machine's lifespan by preventing wear and tear, reducing downtime, and ensuring optimal performance.

Citations:

[1] https://www.zjyingxing.com/info/what-are-the-cleaning-and-maintenance-methods-82799641.html

[2] https://www.kingbrightusa.com/ApplicationNotes/ApplicationNotesFor_SMD_LEDs.pdf

[3] https://s3vi.ndc.nasa.gov/ssri-kb/static/resources/NASA-STD-8739-2.pdf

[4] https://de.hct-smt.com/blog/how-to-masterfully-operate-fully-automatic-led-smt-machines

[5] https://www.zjyingxing.com/info/what-are-the-requirements-for-the-work-environ-88626082.html

[6] https://www.cstaricalcutta.gov.in/images/FLX1.0_Smart%20Mfg%20Operator%20(Electronics)_NSQF-4.pdf

[7] https://www.jrpanel.com/engineerhome/keyword/JRPanel_Maintenance_of_Surface_Mount_Technology_SMT_Equipm.html

[8] https://essc-india.org/participant-handook/English/Pick-and-Place%20Assembly%20Operator.pdf

[9] https://www.hct-smt.com/blog/keep-your-machines-running-smoothly--expert-tips-for-automatic-smt-mounter-pick-and-place-machine-maintenance

[10] https://www.dominant-semi.com/cdn/application-notes/SMD%20Handling%20and%20Application%20Precautions%20-%20VerE.pdf

[11] https://education.ipc.org

[12] https://www.smtfactory.com/Importance-And-Steps-of-Routine-Maintenance-on-A-Chip-Mounter-id65408017.html

[13] https://www.ipcb.com/pcba-tech/8931.html

[14] https://vicoimaging.com/smd-and-smt-comprehensive-guide/

[15] https://rolecatcher.com/en/skills/hard-skills/working-with-machinery-and-specialised-equipment/using-precision-instrumentation-and-equipment/operate-smt-placement-equipment/

[16] https://www.mtek.co.uk/5-environmental-considerations-in-smt-assembly

[17] https://www.seamarkzm.com/maintaining-and-calibrating-an-smd-reel-counter.html

[18] https://www.pnnl.gov/main/publications/external/technical_reports/pnnl-21443.pdf

[19] https://www.onsemi.com/pub/collateral/solderrm-d.pdf

[20] https://tech-led.com/epitex-series-handling-and-use-precautions/