Content Menu

● Introduction to SMT Automatic PCB Conveyors

>> Types of SMT Conveyors

● Key Factors to Consider When Choosing an SMT Automatic PCB Conveyor

>> 1. Production Volume and Flexibility

>> 2. PCB Complexity and Component Mix

>> 3. Accuracy and Quality

>> 4. Software Integration and Industry 4.0 Compatibility

>> 5. Safety and Ergonomics

● Features of SMT Automatic PCB Conveyors

● Installation and Maintenance of SMT Automatic PCB Conveyors

>> Advanced Maintenance Techniques

● Integration with Other Manufacturing Systems

>> Role of MES in Integration

● Future Trends in SMT Conveyors

>> Impact of Industry 4.0

● Conclusion

● FAQ

>> 1. What types of SMT conveyors are available for different applications?

>> 2. How do I ensure the SMT conveyor integrates well with my existing production line?

>> 3. What are the key safety features to look for in an SMT automatic PCB conveyor?

>> 4. How often should I perform maintenance on my SMT conveyor?

>> 5. Can SMT conveyors be customized for specific PCB sizes and production requirements?

Choosing the right SMT automatic PCB conveyor is crucial for optimizing the efficiency and productivity of your electronics manufacturing line. These conveyors play a vital role in transporting printed circuit boards (PCBs) between different stages of the assembly process, ensuring smooth transitions and minimizing downtime. In this article, we will explore the key factors to consider when selecting an SMT automatic PCB conveyor tailored to your specific needs.

Introduction to SMT Automatic PCB Conveyors

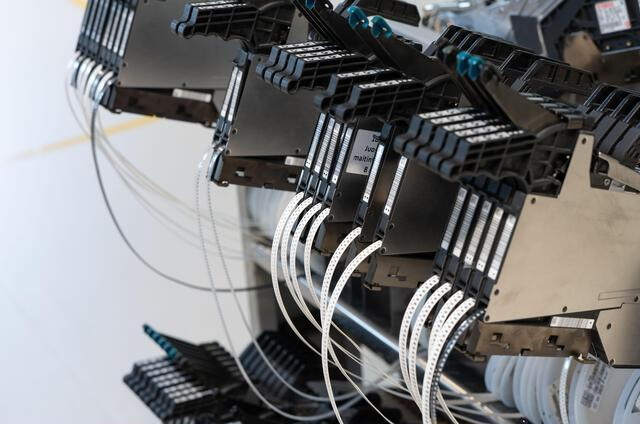

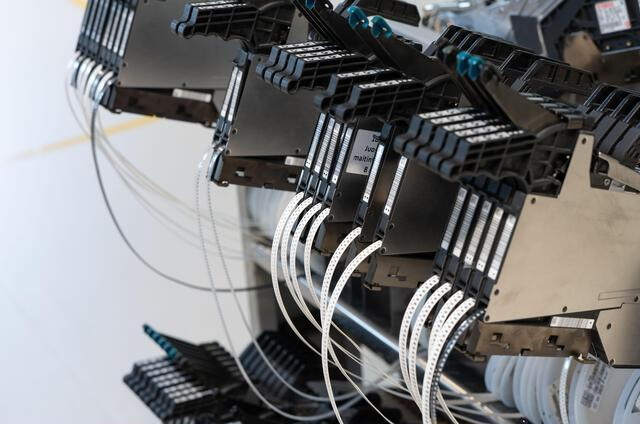

SMT (Surface Mount Technology) conveyors are designed to automate and streamline the production process in electronics manufacturing. They are used to connect various machines such as screen printers, pick-and-place machines, and reflow ovens, ensuring that PCBs are moved efficiently and accurately throughout the assembly line. The choice of conveyor type depends on factors like the type of PCBs being processed, production volume, required precision, and the layout of the assembly line.

Types of SMT Conveyors

There are several types of SMT conveyors available, each with its unique features and applications:

- PCB Belt Conveyors: These are popular for transferring components due to their accuracy, reliability, and cost-effectiveness. They consist of rotating belts driven by motors.

- Inspection Conveyors: Equipped with lighting and inspection stations, these conveyors are essential for quality control, allowing operators to closely examine PCBs during assembly.

- Slat Chain Conveyors: Ideal for applications requiring stability and precision, they use interlocking slats to transport PCBs.

- Link Conveyors: Provide a stable platform for PCB transport, used in environments where precision and synchronization are critical.

- Buffer Conveyors: Temporarily store PCBs between assembly stages to prevent production bottlenecks.

- Turn Conveyors: Change the direction of PCB flow for smooth transitions between assembly stations.

Key Factors to Consider When Choosing an SMT Automatic PCB Conveyor

When selecting an SMT automatic PCB conveyor, several factors must be considered to ensure that the chosen equipment meets your production needs effectively.

1. Production Volume and Flexibility

- Production Volume: High-volume production requires faster and more automated equipment, while lower volumes may benefit from more flexible, multi-purpose machines.

- Flexibility: The ability to handle various component sizes and types is crucial for adapting to different product runs.

2. PCB Complexity and Component Mix

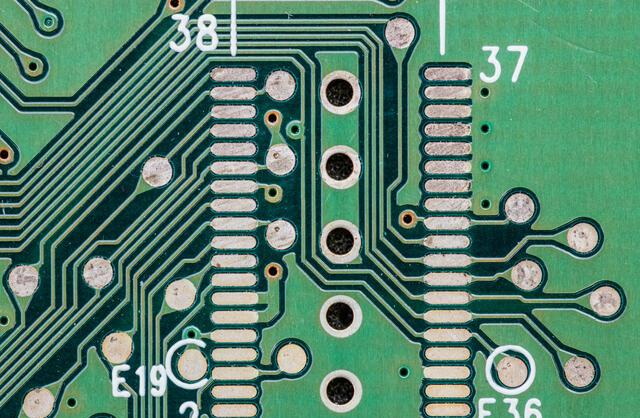

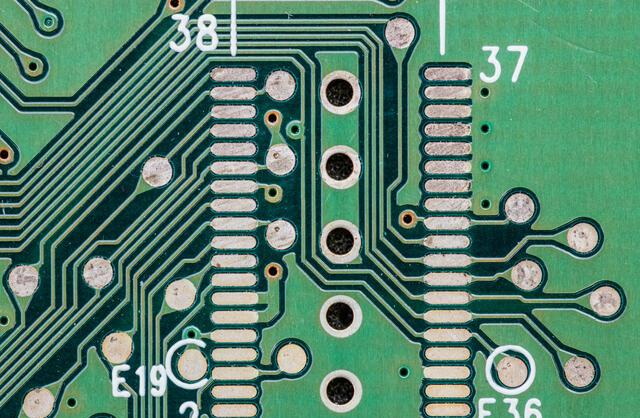

- Component Sizes: Ensure the equipment can handle a range of component sizes, from large ICs to tiny 01005 components.

- Mixed Technology Requirements: Consider the need for both through-hole and surface mount technologies.

3. Accuracy and Quality

- Placement Accuracy: High precision is essential for fine-pitch components, with placement accuracy of ±0.05mm or better.

- Vision Systems: Advanced vision systems are necessary for component recognition and alignment.

4. Software Integration and Industry 4.0 Compatibility

- MES Compatibility: Ensure seamless integration with Manufacturing Execution Systems (MES) for data collection and analysis.

- Remote Monitoring: Features for remote diagnostics and monitoring support Industry 4.0 initiatives.

5. Safety and Ergonomics

- Safety Features: Look for enclosed designs with built-in torque limiters to ensure operational safety.

- Ergonomic Design: Ensure the conveyor is designed to reduce operator fatigue and enhance user experience.

Features of SMT Automatic PCB Conveyors

SMT automatic PCB conveyors come with a variety of features that enhance their functionality and efficiency:

- Modular Design: Allows for customization and flexibility in production lines.

- Adjustable Speed Control: Enables setting the optimal speed for different production processes.

- Multi-zone Position Accuracy: Ensures precise positioning of PCBs during transfer.

- Inspection Mode: Facilitates quality control by allowing operators to inspect PCBs during assembly.

Installation and Maintenance of SMT Automatic PCB Conveyors

Proper installation and regular maintenance are crucial for the optimal performance of SMT automatic PCB conveyors:

- Installation: Ensure the conveyor is securely fixed and aligned with other machines in the production line. It is important to follow the manufacturer's guidelines for installation to avoid any misalignment or operational issues.

- Maintenance: Regularly clean rollers or belts, check for wear, and lubricate moving parts as recommended. Regular maintenance not only extends the lifespan of the conveyor but also ensures consistent performance and reduces downtime.

Advanced Maintenance Techniques

Incorporating advanced maintenance techniques can further enhance the reliability and efficiency of SMT conveyors. This includes predictive maintenance, where sensors and data analytics are used to anticipate potential issues before they occur. Additionally, using automation tools for routine maintenance tasks can reduce manual labor and improve overall productivity.

Integration with Other Manufacturing Systems

Effective integration with other manufacturing systems is essential for maximizing the benefits of SMT automatic PCB conveyors. This includes seamless communication with pick-and-place machines, reflow ovens, and inspection systems to ensure a smooth flow of PCBs throughout the assembly process.

Role of MES in Integration

Manufacturing Execution Systems (MES) play a critical role in integrating SMT conveyors with other manufacturing systems. MES provides real-time data on production status, allowing for adjustments to be made quickly in response to changes in demand or production bottlenecks. This integration also supports Industry 4.0 initiatives by enabling remote monitoring and predictive maintenance.

Future Trends in SMT Conveyors

As technology continues to evolve, future trends in SMT conveyors are likely to focus on increased automation, improved precision, and enhanced connectivity. The use of AI and machine learning will become more prevalent, enabling conveyors to adapt to changing production conditions autonomously. Additionally, there will be a greater emphasis on sustainability, with conveyors designed to reduce energy consumption and environmental impact.

Impact of Industry 4.0

Industry 4.0 technologies, such as IoT sensors and cloud computing, will continue to transform the manufacturing landscape. SMT conveyors will need to be compatible with these technologies to support real-time monitoring, predictive maintenance, and data-driven decision-making. This integration will not only improve efficiency but also enhance the overall competitiveness of manufacturing operations.

Conclusion

Choosing the right SMT automatic PCB conveyor is a critical decision that can significantly impact the efficiency and productivity of your electronics manufacturing line. By considering factors such as production volume, PCB complexity, accuracy requirements, and software integration, you can select a conveyor that meets your specific needs and enhances your overall production process.

FAQ

1. What types of SMT conveyors are available for different applications?

- There are several types of SMT conveyors, including PCB belt conveyors, inspection conveyors, slat chain conveyors, link conveyors, buffer conveyors, and turn conveyors. Each type is suited for different applications based on factors like precision, stability, and production volume.

2. How do I ensure the SMT conveyor integrates well with my existing production line?

- Ensure that the conveyor is compatible with your existing machines and software systems. Consider factors like MES compatibility and remote monitoring capabilities to support Industry 4.0 initiatives.

3. What are the key safety features to look for in an SMT automatic PCB conveyor?

- Key safety features include enclosed designs with built-in torque limiters and ergonomic designs that reduce operator fatigue. These features ensure a safe working environment and enhance user experience.

4. How often should I perform maintenance on my SMT conveyor?

- Regular maintenance is crucial for optimal performance. This includes cleaning rollers or belts, checking for wear, and lubricating moving parts as recommended by the manufacturer.

5. Can SMT conveyors be customized for specific PCB sizes and production requirements?

- Yes, many SMT conveyors offer modular designs that can be customized according to specific PCB sizes and production requirements. This includes adjustable rail widths and custom machine lengths.