Content Menu

● Introduction to PCB Loaders

>> Types of PCB Loaders

● Key Considerations for Choosing a PCB Loader

● Features of Advanced PCB Loaders

● Applications of PCB Loaders

● Benefits of Using PCB Loaders

● Case Study: Automation in PCB Loading and Unloading

● Conclusion

● Frequently Asked Questions

>> 1. What is the primary function of a PCB loader?

>> 2. What types of PCB loaders are available?

>> 3. How do PCB loaders improve manufacturing efficiency?

>> 4. Can PCB loaders handle different sizes of PCBs?

>> 5. What industries benefit most from PCB loaders?

● Citations:

Choosing the right PCB loader for your Surface Mount Technology (SMT) needs is crucial for optimizing production efficiency, reducing costs, and ensuring high-quality output. In this article, we will explore the key factors to consider when selecting a PCB loader, discuss different types of loaders, and highlight their applications in various manufacturing environments.

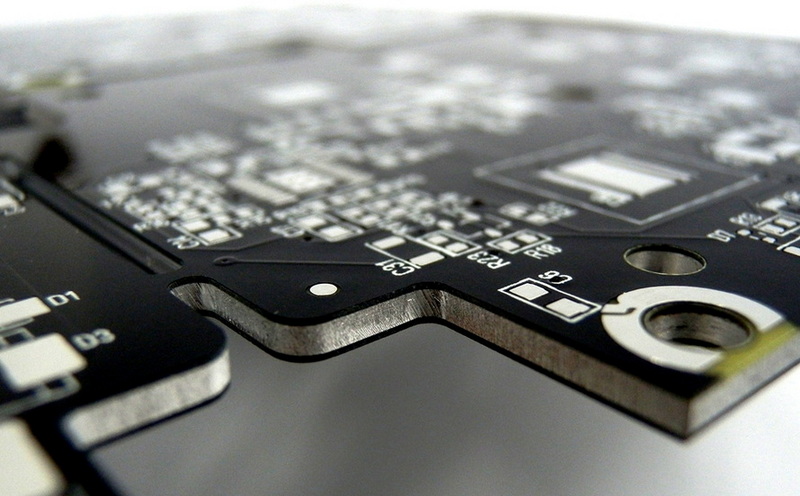

Introduction to PCB Loaders

PCB loaders are automated machines used in the electronics manufacturing industry to transfer Printed Circuit Boards (PCBs) into various stages of the production process. Their primary function is to automate the loading and unloading of PCBs, enhancing efficiency and reducing the risk of damage during handling. These loaders play a vital role in maintaining a steady flow of production and minimizing manual handling errors.

Types of PCB Loaders

There are several types of PCB loaders available, each designed for different production environments and needs:

- Automatic PCB Loaders: These are equipped with advanced technology that allows them to operate without human intervention. They are highly efficient and suitable for high-volume production lines where speed and precision are critical. Automatic loaders often feature advanced vision systems that enable accurate detection of component positions and orientations, ensuring precise placement on the PCB[1]. They also offer significant cost savings by reducing manual labor and increasing production volumes[1].

- Manual PCB Loaders: These require some level of human involvement to operate. They are generally used in smaller production environments or for specialized applications where automation is not necessary.

- Magazine PCB Loaders: These use magazines to store and transport PCBs. They are particularly useful in environments where multiple PCBs need to be handled simultaneously, ensuring that production lines remain uninterrupted. Magazine loaders are designed to be space-efficient and can handle more than one PCB magazine at a time, enhancing production efficiency[4].

Key Considerations for Choosing a PCB Loader

When selecting a PCB loader, several factors must be considered to ensure that the chosen machine meets your specific SMT needs:

1. Space Efficiency: The machine should be less space-consuming to fit into existing production lines without requiring significant layout adjustments[4].

2. Efficiency and Reliability: The loader must have efficient working capabilities on daily use and be reliable to minimize downtime. High reliability is often achieved through robust designs and minimal moving parts, reducing wear and tear[2][7].

3. Durability: It should be durable and capable of handling the workload and massive weight without collapsing even after long use[4].

4. PCB Size Compatibility: Ensure the loader can accommodate the size of PCBs you are working with. Common sizes include PCBs up to 250mm, 300mm, or 350mm in width.

5. Magazine Capacity: The ability to load more than one PCB magazine at a time can enhance production efficiency by reducing the need for frequent magazine changes[4].

6. Integration with Other Equipment: The loader should be able to integrate seamlessly with other SMT machines, such as pick-and-place machines or reflow ovens, to enhance overall manufacturing efficiency. Features like SMEMA compliance facilitate communication between machines[2].

7. User Interface and Control: A user-friendly interface, such as touch panels or buttons, can simplify operation and reduce training time for operators. Advanced control systems, such as PLCs, offer precise control over the loading process[1].

Features of Advanced PCB Loaders

Modern PCB loaders come with several advanced features that enhance their functionality and efficiency:

- Microcomputer Control: Ensures stable and reliable operation.

- Adjustable Lifting Distance: Allows for customization based on PCB thickness.

- Automatic Counting Function: Facilitates production statistics and inventory management.

- SMEMA Compliance: Enables communication between machines for streamlined production.

- Pneumatic Clamping Structure: Provides secure handling of PCBs to prevent damage.

- Advanced Vision Systems: Enable accurate detection of component positions and orientations, ensuring precise placement on the PCB[1].

Applications of PCB Loaders

PCB loaders are widely used in various industries, including consumer electronics, automotive, aerospace, and medical devices. They are essential for manufacturing devices like smartphones, tablets, laptops, and other electronic products where high-speed and precision are crucial.

In the future, trends such as miniaturization and AI-driven manufacturing will continue to shape the PCB assembly industry. Miniaturization demands more precise and efficient SMT processes, while AI enhances automation and quality control[3]. PCB loaders will play a critical role in adapting to these trends by integrating advanced automation features and improving connectivity with other equipment in the assembly line[6].

Benefits of Using PCB Loaders

The use of PCB loaders offers several benefits:

- Increased Efficiency: Automates the loading and unloading process, reducing manual labor and increasing production speed. This leads to higher throughput and reduced bottlenecks[7].

- Reduced Defects: Minimizes the risk of PCB damage during handling, leading to fewer defects and less waste. Automated systems ensure consistent positioning, improving quality[7].

- Improved Safety: Reduces the risk of accidents and injuries by minimizing human intervention. This allows workers to focus on safer, more creative tasks[8].

- Cost Savings: Lowers operational costs by reducing labor requirements and minimizing waste. The reduction in manual labor and increased efficiency lead to substantial cost savings[1][6].

Case Study: Automation in PCB Loading and Unloading

A notable example of the benefits of automation in PCB loading and unloading is the use of collaborative robots (cobots) in flexible printed circuit manufacturing. By automating the loading and unloading process with cobots, one company achieved a 15% increase in production efficiency. This not only improved productivity but also freed human workers from repetitive tasks, enhancing job satisfaction and reducing staff turnover[8].

Conclusion

Choosing the right PCB loader for your SMT needs involves careful consideration of several factors, including space efficiency, durability, PCB size compatibility, and integration capabilities. By selecting a loader that meets these criteria, manufacturers can significantly enhance production efficiency, reduce costs, and improve product quality.

Frequently Asked Questions

1. What is the primary function of a PCB loader?

A PCB loader is designed to automate the loading and unloading of PCBs onto a conveyor system, enhancing efficiency and reducing manual handling errors.

2. What types of PCB loaders are available?

There are automatic, manual, and magazine PCB loaders, each suited for different production environments and needs.

3. How do PCB loaders improve manufacturing efficiency?

By automating the handling of PCBs, loaders streamline the production process, reduce manual labor, and minimize handling errors.

4. Can PCB loaders handle different sizes of PCBs?

Many PCB loaders are adjustable and can accommodate various PCB sizes, making them versatile for different manufacturing applications.

5. What industries benefit most from PCB loaders?

PCB loaders are particularly beneficial in industries such as consumer electronics, automotive, aerospace, and medical devices, where high-speed and precision are critical.

Citations:

[1] https://www.hct-smt.com/blog/boost-your-pcb-production-with-smt-automatic-loader-machines

[2] https://www.tronstol.com/smt-assembly/loader-and-unloader/

[3] https://novaenginc.com/future-of-circuit-board-assembly/

[4] https://cnsmtline.com/pcb-magazine-loader/

[5] https://www.pcbjhy.com/blog/pros-and-cons-of-smt-pcb-assembly/

[6] https://www.hct-smt.com/blog/maximizing-efficiency-with-the-smd-pcb-loader-set--a-comprehensive-guide

[7] https://www.smtsite.com/resources/pcb-loader-unloader-improve-efficiency-and-accuracy-65976e0df4173.html

[8] https://www.jakarobotics.com/project/pcb-loading-and-unloading/

[9] https://www.wellpcb.com/blog/pcb-manufacturing/latest-advances-in-pcb-manufacturing-technology/

[10] https://www.zjyingxing.com/info/what-are-the-common-smt-pick-and-place-machine-88387624.html

[11] https://smtmachineline.com/i-c-t-bld600-advanced-upscale-smt-pcb-loader-for-semiconductor/

[12] https://www.1stsmt.com/blog/the-advantages-of-using-a-fully-automatic-pcb-loader

[13] https://www.linkedin.com/pulse/pcb-loader-market-outlook-2024-analysis-type-application-rvorf

[14] https://pcbstator.com/case-studies/ecm-proves-feasibility-of-pcb-stator-motors-for-marine-hvac-applications/

[15] https://www.electronicdesign.com/technologies/eda/printed-circuit-boards/article/55041417/viasion-technology-top-5-miniaturization-challenges-in-pcb-assembly-and-their-solutions

[16] https://faroads.com/pcb-loader-250l/

[17] https://www.zjyingxing.com/info/the-function-of-smt-loader-69563920.html

[18] https://www.rs-online.com/designspark/latest-pcb-technology-and-industry-trends

[19] https://www.dobot-robots.com/insights/case-studies/pcb-board-burn-in-assembly-line-handling-by-cr.html

[20] https://www.myemssolutions.com/6-considerations-for-smt-pcb-design/