Content Menu

● Understanding Surface Mount Devices

>> Advantages of Surface Mount Devices

● The Role of SMDs in Modern Electronics

>> Consumer Electronics

>> Automotive Industry

>> Telecommunications

>> Medical Devices

● Design Considerations When Using SMDs

● The Future of Surface Mount Technology

● Conclusion

● FAQ

>> 1. What are the main advantages of using surface mount devices?

>> 2. How do surface mount devices impact PCB design?

>> 3. Are there any challenges associated with using surface mount devices?

>> 4. In which industries are surface mount devices commonly used?

>> 5. What does the future hold for surface mount technology?

In today's fast-paced technological landscape, the efficiency of circuit design is paramount. Engineers and designers are constantly seeking ways to enhance performance while reducing costs and time. One of the most significant advancements in this domain is the adoption of Surface Mount Devices (SMDs). These compact components have transformed the way electronic circuits are designed and manufactured. This article delves into how surface mount devices improve circuit design efficiency, exploring their advantages, applications, and impact on the electronics industry.

Understanding Surface Mount Devices

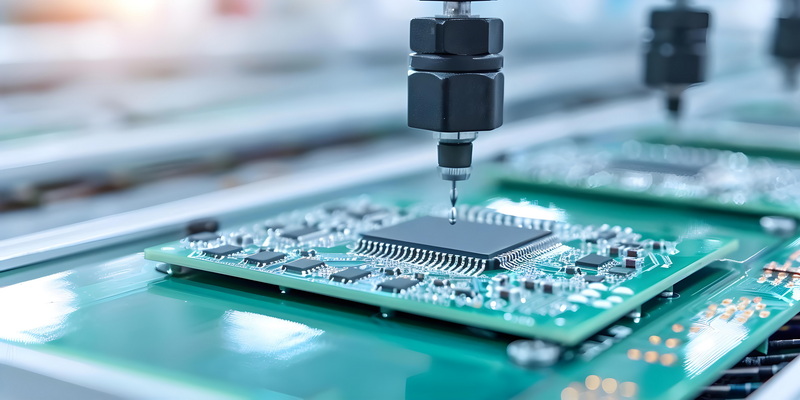

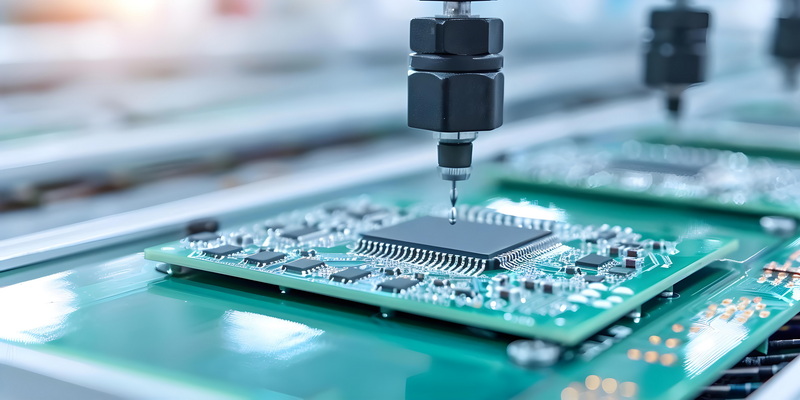

Surface Mount Devices are electronic components that are mounted directly onto the surface of printed circuit boards (PCBs). Unlike traditional through-hole components, which require holes to be drilled into the PCB, SMDs are soldered onto pads on the board's surface. This fundamental difference in mounting technology offers several advantages that significantly enhance circuit design efficiency.

Advantages of Surface Mount Devices

The benefits of using SMDs in circuit design are numerous and impactful:

- Reduced Size and Weight: SMDs are typically smaller and lighter than their through-hole counterparts. This reduction in size allows for more compact designs, which is crucial for modern electronics that demand miniaturization.

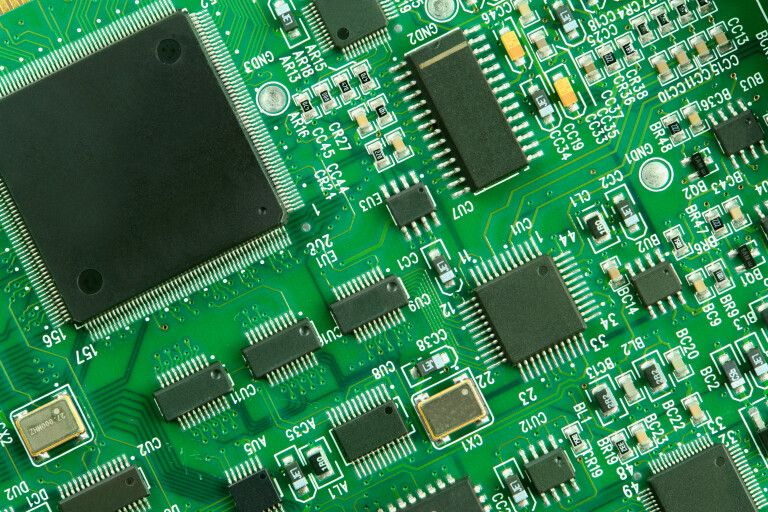

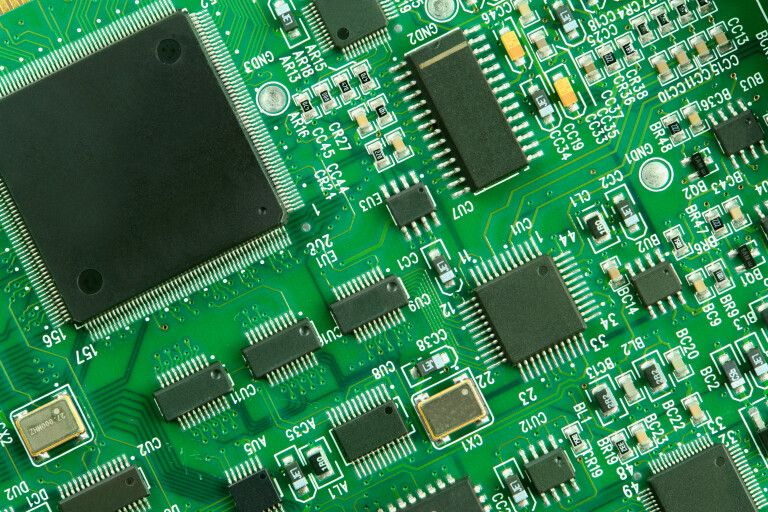

- Higher Component Density: Because SMDs can be placed on both sides of a PCB, designers can achieve higher component density. This capability enables more complex circuits to fit into smaller spaces, enhancing functionality without increasing the overall size.

- Improved Performance: SMDs often have shorter leads than traditional components, which reduces inductance and resistance. This design feature can lead to improved electrical performance, particularly at high frequencies.

- Automated Assembly: The flat design of SMDs makes them ideal for automated assembly processes. Pick-and-place machines can quickly and accurately place these components on PCBs, significantly speeding up production times and reducing labor costs.

- Cost Efficiency: While SMDs may have a higher initial cost than through-hole components, their benefits often lead to lower overall production costs. The reduction in board size, increased assembly speed, and lower material costs contribute to this efficiency.

- Enhanced Reliability: SMDs are generally more resistant to mechanical stress and vibration due to their low profile and solid mounting method. This reliability is essential for devices used in harsh environments or applications requiring high durability.

The Role of SMDs in Modern Electronics

The integration of SMD technology has revolutionized various sectors within electronics:

Consumer Electronics

In consumer electronics, such as smartphones and tablets, the demand for compactness and lightweight designs has driven the adoption of SMDs. These devices allow manufacturers to create slimmer products without sacrificing performance or functionality.

Automotive Industry

The automotive industry has also embraced surface mount technology to meet the growing complexity of vehicle electronics. Modern vehicles contain numerous electronic systems for safety, navigation, and entertainment, all benefiting from the space-saving advantages of SMDs.

Telecommunications

Telecommunications equipment relies heavily on high-frequency signals and compact designs. SMDs facilitate these requirements by providing efficient performance in a small footprint, making them ideal for devices like routers and switches.

Medical Devices

In medical technology, reliability is crucial. The robustness of surface mount devices makes them suitable for critical applications such as diagnostic equipment and wearable health monitors, where performance consistency is vital.

Design Considerations When Using SMDs

While the advantages of surface mount devices are clear, designers must also consider specific factors when integrating them into their circuits:

- Thermal Management: Due to their compact nature, SMDs can generate heat during operation. Designers must implement effective thermal management strategies to prevent overheating, which can lead to component failure.

- PCB Layout: The layout of a PCB becomes more critical when using SMDs. Designers need to ensure proper spacing between components to facilitate soldering and avoid interference from adjacent parts.

- Testing Challenges: Testing circuits with SMDs can be more complex than with through-hole components. Specialized equipment may be required for effective testing and troubleshooting.

The Future of Surface Mount Technology

As technology continues to advance, the role of surface mount devices in circuit design is expected to grow even further. Innovations such as flexible PCBs and 3D printing may enhance the capabilities of SMDs, allowing for even more intricate designs and applications.

Moreover, as industries push towards miniaturization and increased functionality in electronic devices, surface mount technology will likely play a pivotal role in meeting these demands. The ongoing development of new materials and manufacturing techniques will further enhance the performance characteristics of SMDs.

Conclusion

Surface mount devices have undeniably transformed circuit design efficiency across various industries. Their advantages—ranging from reduced size and weight to improved performance and cost-effectiveness—make them an essential component in modern electronics. As technology evolves, the importance of SMDs will continue to rise, driving innovation in circuit design and manufacturing processes.

By understanding both the benefits and considerations associated with surface mount technology, engineers can leverage these devices to create more efficient, reliable, and compact electronic solutions that meet the demands of today's fast-paced market.

FAQ

1. What are the main advantages of using surface mount devices?

Surface mount devices offer several advantages including reduced size and weight, higher component density, improved electrical performance due to shorter leads, automated assembly capabilities that speed up production times, cost efficiency over time due to lower material costs, and enhanced reliability under mechanical stress.

2. How do surface mount devices impact PCB design?

SMDs allow for more compact PCB designs because they can be mounted on both sides of the board. This increases component density without increasing board size. However, designers must pay careful attention to thermal management and spacing during layout.

3. Are there any challenges associated with using surface mount devices?

Yes, challenges include thermal management due to heat generation during operation, complexities in PCB layout requiring careful planning for spacing between components, and potential difficulties in testing circuits that utilize SMDs which may require specialized equipment.

4. In which industries are surface mount devices commonly used?

Surface mount devices are widely used across various industries including consumer electronics (like smartphones), automotive (for complex vehicle electronics), telecommunications (such as routers), and medical devices (for reliable diagnostic equipment).

5. What does the future hold for surface mount technology?

The future of surface mount technology looks promising with ongoing advancements in materials and manufacturing techniques that will enhance performance characteristics. As industries continue pushing for miniaturization and increased functionality in electronic devices, SMDs will likely play a crucial role in meeting these demands.