Content Menu

● Introduction

● Understanding Surface Mount Devices (SMD)

>> Key Features of SMDs

● Understanding Axial Components

>> Key Features of Axial Components

● Surface Mount Device vs Axial: A Comparative Analysis

>> Manufacturing Process

>> Design Flexibility

>> Electrical Performance

>> Cost Considerations

>> Applications

● Conclusion

● Related Questions

>> 1. What are the main advantages of using surface mount devices over axial components?

>> 2. In what applications are axial components preferred over surface mount devices?

>> 3. How does the manufacturing process differ between SMDs and axial components?

>> 4. Can surface mount devices be repaired easily compared to axial components?

>> 5. What factors should be considered when choosing between SMDs and axial components for a PCB design?

Introduction

In the realm of printed circuit board (PCB) design, the choice of components significantly influences the performance, size, and manufacturability of electronic devices. Among the various types of components, Surface Mount Devices (SMD) and Axial Components are two prominent categories that engineers frequently consider. This article delves into the comparison between surface mount devices and axial components, exploring their characteristics, advantages, disadvantages, and applications in PCB design.

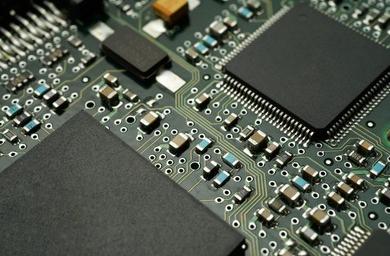

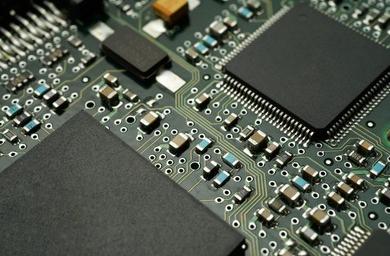

Understanding Surface Mount Devices (SMD)

Surface mount devices are electronic components that are mounted directly onto the surface of a PCB. Unlike traditional components that require holes drilled into the board, SMDs are soldered onto pads on the surface, allowing for a more compact design. This technology has revolutionized PCB manufacturing, enabling higher component density and automated assembly processes.

Key Features of SMDs

1. Size and Weight: SMDs are generally smaller and lighter than their through-hole counterparts, making them ideal for compact electronic devices.

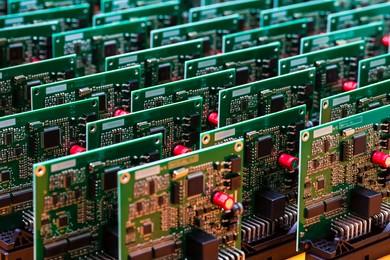

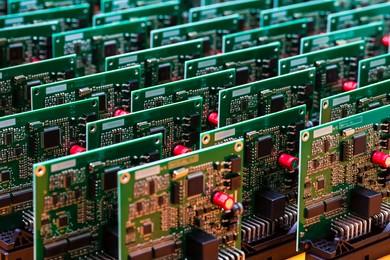

2. Automated Assembly: The surface mounting process can be automated, significantly reducing labor costs and assembly time.

3. Higher Component Density: SMDs allow for a greater number of components to be placed on a PCB, which is crucial for modern electronic devices that require miniaturization.

4. Performance: SMDs often exhibit better electrical performance due to shorter lead lengths, which can reduce inductance and resistance.

Understanding Axial Components

Axial components, on the other hand, are characterized by their leads that extend from both ends of the component. These components are inserted into holes drilled into the PCB and are soldered on the opposite side. Axial components have been a staple in electronics for decades, particularly in applications where robustness and ease of handling are paramount.

Key Features of Axial Components

1. Robustness: Axial components tend to provide a stronger mechanical bond due to their leads being inserted through the PCB, making them suitable for applications that experience physical stress.

2. Ease of Replacement: The design of axial components allows for easier replacement and repair, as they can be desoldered and replaced without specialized equipment.

3. Cost-Effectiveness: In low-volume production, axial components can be more cost-effective due to simpler assembly processes.

Surface Mount Device vs Axial: A Comparative Analysis

Manufacturing Process

The manufacturing process for SMDs involves applying solder paste to the PCB pads, placing the components, and then reflowing the solder to create a permanent bond. This process is highly automated, which enhances efficiency and reduces costs.

In contrast, axial components require manual insertion into drilled holes, followed by wave soldering or hand soldering. This process can be more labor-intensive and time-consuming, particularly for large production runs.

Design Flexibility

SMDs offer greater design flexibility due to their smaller size and ability to be placed on both sides of the PCB. This allows for more complex circuit designs and higher component density.

Axial components, while robust, limit design flexibility due to their size and the need for drilled holes. This can lead to larger PCB footprints and less efficient use of space.

Electrical Performance

SMDs typically provide superior electrical performance due to shorter lead lengths, which minimize parasitic inductance and resistance. This is particularly important in high-frequency applications.

Axial components, while reliable, may not perform as well in high-frequency applications due to longer lead lengths, which can introduce unwanted inductance.

Cost Considerations

While SMDs can be more expensive per unit due to their advanced manufacturing processes, the overall cost can be lower in high-volume production due to reduced assembly time and labor costs.

Axial components may be cheaper in low-volume applications, but the increased labor costs associated with manual assembly can offset these savings in larger production runs.

Applications

SMDs are widely used in modern electronics, including smartphones, tablets, and compact consumer devices. Their ability to support high-density designs makes them ideal for applications where space is at a premium.

Axial components are often found in older electronic devices, power supplies, and applications where durability is critical. They are also preferred in situations where repairs and replacements are common.

Conclusion

In conclusion, the choice between surface mount devices and axial components in PCB design hinges on various factors, including size constraints, manufacturing processes, electrical performance, and application requirements. While SMDs offer significant advantages in terms of compactness and automation, axial components provide robustness and ease of repair. Ultimately, the decision should be guided by the specific needs of the project, balancing performance, cost, and design flexibility.

Related Questions

1. What are the main advantages of using surface mount devices over axial components?

Surface mount devices offer advantages such as smaller size, higher component density, automated assembly, and better electrical performance due to shorter lead lengths.

2. In what applications are axial components preferred over surface mount devices?

Axial components are preferred in applications requiring robustness, ease of replacement, and where physical stress is a concern, such as in power supplies and older electronic devices.

3. How does the manufacturing process differ between SMDs and axial components?

SMDs are typically assembled using automated processes involving solder paste and reflow soldering, while axial components require manual insertion into drilled holes and wave soldering.

4. Can surface mount devices be repaired easily compared to axial components?

Axial components are generally easier to repair due to their design, allowing for straightforward desoldering and replacement, whereas SMDs may require specialized equipment for repair.

5. What factors should be considered when choosing between SMDs and axial components for a PCB design?

Factors to consider include size constraints, manufacturing capabilities, electrical performance requirements, cost implications, and the intended application of the device.