Content Menu

● Introduction

● Understanding Surface Mount Technology (SMT)

● Advantages of SMT

● Understanding Through-Hole Technology (THT)

● Advantages of THT

● Impact on PCB Design

>> Layout Considerations

>> Design Density

>> Trace Routing

>> Signal Integrity

>> Layer Count

>> Multilayer Design Benefits

>> Manufacturing Processes

>> Automation in SMT

>> Testing and Repair

>> Repairability Considerations

>> Cost Implications

>> Long-Term Cost Analysis

>> Environmental Considerations

>> Sustainability in SMT

● Conclusion

● Related Questions

>> 1. What are the main differences between SMT and THT?

>> 2. When should I choose SMT over THT?

>> 3. Are there any components that can only be used with THT?

>> 4. How does the choice of technology affect PCB manufacturing costs?

>> 5. Can I mix SMT and THT components on the same PCB?

Introduction

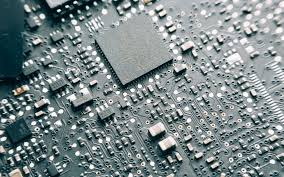

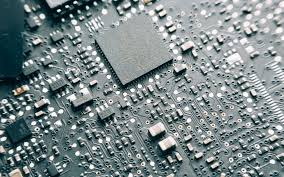

In the world of electronics, the design and assembly of printed circuit boards (PCBs) are critical processes that determine the performance, reliability, and cost-effectiveness of electronic devices. Two primary methods for mounting components on PCBs are Surface Mount Technology (SMT) and Through-Hole Technology (THT). Each method has its unique advantages and disadvantages, influencing various aspects of PCB design. This article explores how these technologies impact PCB design, focusing on their implications for layout, manufacturing, and overall product performance.

Understanding Surface Mount Technology (SMT)

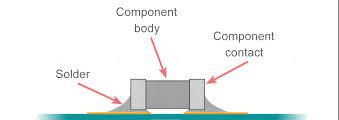

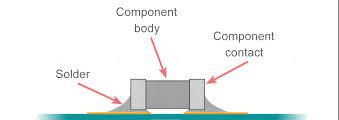

Surface Mount Technology (SMT) involves mounting electronic components directly onto the surface of a PCB. This method has gained popularity due to its ability to accommodate smaller components, which are essential for modern electronic devices that demand compact designs. SMT components are soldered onto the PCB using a process called reflow soldering, where solder paste is applied to the pads on the PCB, and components are placed on top before being heated to create a solid connection.

Advantages of SMT

1. Space Efficiency: SMT allows for a higher density of components on a PCB, enabling smaller and lighter designs. This is particularly beneficial in consumer electronics, where space is at a premium.

2. Automated Assembly: SMT is highly compatible with automated assembly processes, which can significantly reduce manufacturing time and costs. Automated pick-and-place machines can quickly and accurately position components on the PCB.

3. Improved Performance: SMT components typically have shorter leads, which can reduce inductance and resistance, leading to better electrical performance. This is crucial for high-frequency applications.

4. Flexibility in Design: Designers can create more complex circuit layouts with SMT, as the smaller size of components allows for more intricate routing of traces on the PCB.

5. Lower Production Costs: The efficiency of SMT in high-volume production can lead to lower costs per unit, making it an attractive option for manufacturers looking to scale production.

6. Enhanced Thermal Management: SMT components can be designed with thermal relief features that help dissipate heat more effectively, which is essential for high-power applications.

Understanding Through-Hole Technology (THT)

Through-Hole Technology (THT) involves inserting component leads through holes drilled in the PCB and soldering them on the opposite side. This method was the standard for many years before SMT became prevalent. THT is still widely used, especially in applications where durability and mechanical strength are paramount.

Advantages of THT

1. Mechanical Strength: THT components are generally more robust than SMT components, making them suitable for applications that experience physical stress or vibration, such as automotive and industrial equipment.

2. Easier Prototyping: THT is often easier for prototyping and hand assembly, as components can be inserted and soldered manually without the need for specialized equipment.

3. Better Heat Dissipation: THT components can handle higher power levels and dissipate heat more effectively due to their larger size and the way they are mounted on the PCB.

4. Compatibility with Larger Components: Some components, such as connectors and large capacitors, are only available in through-hole formats, making THT necessary for certain designs.

5. Soldering Flexibility: THT allows for various soldering techniques, including wave soldering and hand soldering, which can be advantageous in different manufacturing environments.

Impact on PCB Design

Layout Considerations

The choice between SMT and THT significantly impacts the layout of a PCB. SMT allows for more compact designs, which can lead to shorter trace lengths and reduced signal degradation. Designers can utilize multiple layers in a PCB to optimize space, while THT may require more space due to the larger size of components and the need for additional clearance around the holes.

Design Density

With SMT, designers can achieve higher component density, which is essential for modern electronics that require miniaturization. This increased density can lead to more efficient use of board space, allowing for additional features or functionalities within the same footprint.

Trace Routing

In SMT designs, the shorter leads of components allow for tighter trace routing, which can improve signal integrity and reduce electromagnetic interference (EMI). Conversely, THT designs may necessitate longer traces, which can introduce additional resistance and potential signal loss.

Signal Integrity

Maintaining signal integrity is crucial in high-speed applications. SMT's ability to minimize trace lengths helps reduce the potential for signal degradation, making it a preferred choice for RF and high-frequency circuits.

Layer Count

SMT often enables the use of multilayer PCBs, as the compact nature of the components allows for more layers without significantly increasing the board size. This is particularly advantageous for complex circuits that require extensive routing. THT, on the other hand, may limit the number of layers due to the need for larger pads and traces.

Multilayer Design Benefits

Multilayer PCBs can provide significant advantages, including reduced electromagnetic interference, improved thermal performance, and enhanced routing capabilities. SMT's compatibility with multilayer designs allows engineers to create more sophisticated and capable electronic devices.

Manufacturing Processes

The manufacturing processes for SMT and THT differ significantly. SMT typically involves automated processes, which can lead to lower production costs and faster turnaround times. THT, while still widely used, often requires more manual labor, especially in prototyping and small-batch production.

Automation in SMT

The automation of SMT processes not only speeds up production but also enhances consistency and quality control. Automated inspection systems can quickly identify defects, ensuring that only high-quality products reach the market.

Testing and Repair

Testing and repairing PCBs can also be influenced by the choice of mounting technology. SMT components are often more challenging to replace due to their small size and the need for specialized tools. THT components, with their larger leads, are generally easier to access and replace, making repairs more straightforward.

Repairability Considerations

In applications where maintenance and repair are critical, THT may be the preferred choice. The ease of access to through-hole components can reduce downtime and maintenance costs, making THT a practical option for certain industries.

Cost Implications

The cost implications of choosing between SMT and THT can be significant. While SMT may offer lower production costs in high-volume scenarios, THT can be more economical for low-volume or prototype runs due to its simpler assembly processes.

Long-Term Cost Analysis

When evaluating the long-term costs of SMT versus THT, it is essential to consider factors such as production volume, assembly complexity, and potential rework costs. For high-volume production, SMT may provide a more cost-effective solution, while THT may be advantageous for specialized or low-volume applications.

Environmental Considerations

As the electronics industry moves towards more sustainable practices, the environmental impact of manufacturing processes is becoming increasingly important. SMT and THT have different implications for waste generation and energy consumption.

Sustainability in SMT

SMT processes often generate less waste due to the precision of automated assembly and the smaller size of components. Additionally, the ability to use smaller boards can lead to reduced material usage, contributing to more sustainable manufacturing practices.

Conclusion

The choice between Surface Mount Technology and Through-Hole Technology has a profound impact on PCB design. Each method offers distinct advantages that can influence the overall performance, cost, and manufacturability of electronic devices. As technology continues to evolve, the trend towards miniaturization and increased functionality will likely favor SMT in many applications. However, THT remains relevant, particularly in industries where mechanical strength and ease of repair are critical.

Ultimately, the decision between SMT and THT should be based on the specific requirements of the project, including size constraints, performance needs, and manufacturing capabilities. Understanding the implications of each technology on PCB design is essential for engineers and designers aiming to create efficient and effective electronic products.

Related Questions

1. What are the main differences between SMT and THT?

Answer: The main differences include the mounting method (surface vs. through holes), component size, manufacturing processes, and mechanical strength. SMT is more space-efficient and suitable for automated assembly, while THT offers better mechanical strength and is easier for manual assembly.

2. When should I choose SMT over THT?

Answer: Choose SMT when designing compact devices that require high component density, faster production times, and improved electrical performance. SMT is ideal for consumer electronics and high-frequency applications.

3. Are there any components that can only be used with THT?

Answer: Yes, certain components, such as large connectors, high-power resistors, and some capacitors, are typically only available in through-hole formats, necessitating the use of THT in those cases.

4. How does the choice of technology affect PCB manufacturing costs?

Answer: SMT generally leads to lower manufacturing costs due to its compatibility with automated assembly processes, while THT may incur higher labor costs due to manual assembly requirements.

5. Can I mix SMT and THT components on the same PCB?

Answer: Yes, it is possible to mix SMT and THT components on the same PCB. However, careful design considerations must be made to accommodate the different mounting methods and ensure proper layout and routing.