Content Menu

● Introduction to SMT Stencil Printers

>> Key Components of SMT Stencil Printers

● Mechanisms for Ensuring Precision

>> Precision Placement

>> Adjustable Parameters

>> Quality Assurance Measures

>> Advanced Equipment

● Types of SMT Stencil Printers

>> Full-Auto SMT Stencil Printers

>> Semi-Auto SMT Stencil Printers

● Solder Paste Application Techniques

>> Stencil Printing

>> Jet Printing

>> Manual Dispensing

● Factors Affecting Solder Paste Performance

>> Viscosity and Thixotropy

>> Particle Size and Distribution

● Strategies for Optimizing Efficiency

>> Fine-Tuning Process Parameters

>> Implementing Quality Assurance Measures

>> Investing in Advanced Equipment

>> Training and Maintenance

>> Integration with Other Processes

● Challenges and Future Developments

>> Miniaturization of Components

>> Environmental Considerations

>> Automation and AI Integration

● Case Studies and Examples

● Conclusion

● FAQs

>> 1. What is the primary function of SMT stencil printers in PCB assembly?

>> 2. How do SMT stencil printers ensure precision in solder paste application?

>> 3. What are the main types of stencils used in SMT assembly?

>> 4. What factors affect the performance of solder paste during application?

>> 5. How do full-auto and semi-auto SMT stencil printers differ?

SMT stencil printers play a crucial role in the surface mount technology (SMT) assembly process by ensuring precise application of solder paste onto printed circuit boards (PCBs). This precision is vital for achieving reliable electrical connections and high-quality electronic products. In this article, we will delve into the mechanisms and strategies that SMT stencil printers employ to guarantee accurate solder paste application.

Introduction to SMT Stencil Printers

SMT stencil printers are specialized machines designed to apply solder paste onto PCBs with high precision. These printers use a stencil, typically made of stainless steel, which has precise openings corresponding to the PCB pads where solder paste needs to be deposited. The solder paste is spread evenly across the stencil using a squeegee blade, ensuring a controlled amount of paste is applied to each pad.

Key Components of SMT Stencil Printers

1. Stencils: Laser-cut or electroformed stencils are used for precise solder paste application. Laser-cut stencils are cost-effective and suitable for most PCB designs, while electroformed stencils offer higher accuracy and durability, making them ideal for complex PCBs with densely packed components.

2. Squeegee Blades: These are used to spread the solder paste evenly across the stencil openings. The pressure and speed of the squeegee can be adjusted to optimize paste deposition.

3. Alignment Systems: Advanced vision systems are integrated into SMT stencil printers to ensure accurate alignment of the PCB and stencil. This is crucial for precise solder paste application and prevents defects.

Mechanisms for Ensuring Precision

Precision Placement

SMT stencil printers ensure that solder paste is applied precisely to designated areas of the PCB. This is achieved through accurate alignment of the stencil with the PCB pads, reducing the risk of soldering defects and improving product quality.

Adjustable Parameters

Operators can fine-tune parameters such as squeegee speed, pressure, and stencil alignment to optimize print quality. These adjustments help reduce defects and enhance overall efficiency in the soldering process.

Quality Assurance Measures

Regular monitoring of solder paste printing defects and implementation of quality assurance measures are essential. This includes inspecting the stencil for cleanliness and ensuring consistent paste viscosity to maintain reliable solder paste application.

Advanced Equipment

Investing in high-quality SMT stencil printers with advanced features like automatic fiducial recognition and closed-loop feedback systems can further enhance precision and productivity.

Types of SMT Stencil Printers

Full-Auto SMT Stencil Printers

These are fully automated machines ideal for mass production environments where efficiency and consistency are critical. They offer high-speed and precise placement of solder paste, making them suitable for large-scale manufacturing.

Semi-Auto SMT Stencil Printers

Semi-auto printers combine manual control with automated precision, providing flexibility for operators while ensuring accurate solder paste application. They are suitable for smaller production volumes or prototyping.

Solder Paste Application Techniques

Besides stencil printing, other techniques include jet printing and manual dispensing. However, stencil printing remains the most widely used method due to its precision and efficiency.

Stencil Printing

- Process: A laser-cut stainless-steel stencil is aligned over the PCB, and a squeegee blade spreads solder paste evenly across the openings.

- Advantages: Uniform application, high precision, and cost-effective for high-volume production.

Jet Printing

- Process: Solder paste is dispensed in precise droplets without a stencil.

- Advantages: Ideal for prototyping, low-volume production, and complex PCB layouts.

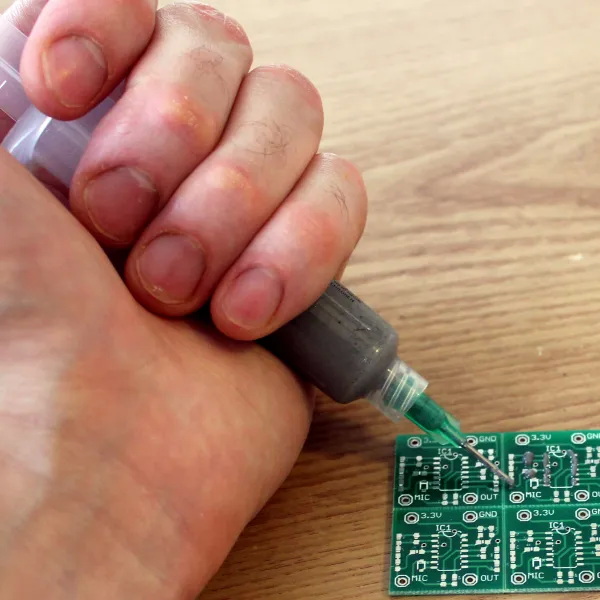

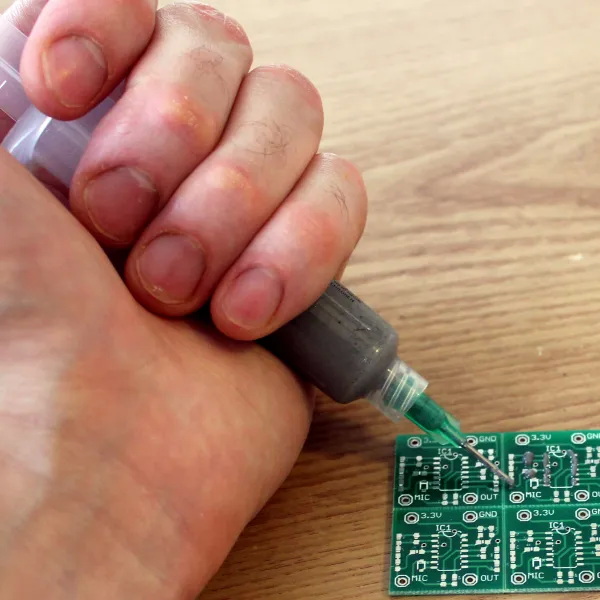

Manual Dispensing

- Process: Solder paste is applied manually using syringes.

- Advantages: Suitable for repair work and low-volume assemblies, but lacks precision and repeatability.

Factors Affecting Solder Paste Performance

Viscosity and Thixotropy

Solder paste must maintain the right viscosity to flow smoothly yet retain its shape on PCB pads. Thixotropic behavior ensures that paste spreads under pressure but retains structure once applied.

Particle Size and Distribution

The size and distribution of solder particles affect the paste's performance. Different grades of solder paste are used for various applications based on particle size.

Strategies for Optimizing Efficiency

Fine-Tuning Process Parameters

Adjusting squeegee speed, pressure, and stencil alignment can improve print quality and reduce defects. Regular calibration ensures consistent results.

Implementing Quality Assurance Measures

Monitoring solder paste printing defects and implementing quality assurance measures ensure consistent and reliable solder paste application.

Investing in Advanced Equipment

Upgrading to high-quality SMT stencil printers with advanced features enhances precision and productivity, contributing to overall efficiency in the PCB soldering process.

Training and Maintenance

Proper training of operators and regular maintenance of equipment are crucial for maintaining optimal performance. This includes cleaning the stencil regularly and ensuring that the squeegee blades are in good condition.

Integration with Other Processes

SMT stencil printers are often integrated with other assembly processes such as pick-and-place machines and reflow ovens. This integration streamlines the production line, reducing manual handling and increasing throughput.

Challenges and Future Developments

Miniaturization of Components

As electronic components continue to shrink, SMT stencil printers must adapt to apply solder paste accurately on smaller pads. This requires advancements in stencil manufacturing and printer technology.

Environmental Considerations

The use of lead-free solder pastes and environmentally friendly manufacturing processes is becoming increasingly important. SMT stencil printers must be compatible with these materials to support sustainable manufacturing practices.

Automation and AI Integration

Future developments may include the integration of artificial intelligence (AI) to predict and prevent defects, further enhancing precision and efficiency in solder paste application.

Case Studies and Examples

Several companies have successfully implemented SMT stencil printers to improve their PCB assembly processes. For instance, a leading electronics manufacturer increased its production efficiency by 30% after upgrading to a full-auto SMT stencil printer. This upgrade allowed for higher precision and faster production rates, meeting the demand for complex electronic devices.

Conclusion

SMT stencil printers are indispensable in ensuring precision in solder paste application during the PCB assembly process. By leveraging advanced technologies such as precise alignment systems and adjustable printing parameters, these printers streamline production, reduce defects, and enhance product quality. As the electronics industry continues to evolve, the role of SMT stencil printers will remain critical in achieving high-quality electronic products efficiently.

FAQs

1. What is the primary function of SMT stencil printers in PCB assembly?

SMT stencil printers are primarily used to apply solder paste onto PCBs with precision, ensuring reliable electrical connections and high-quality electronic products.

2. How do SMT stencil printers ensure precision in solder paste application?

Precision is ensured through accurate alignment of the stencil with PCB pads, adjustable printing parameters, and advanced vision systems for fiducial recognition.

3. What are the main types of stencils used in SMT assembly?

The main types include laser-cut stencils, which are cost-effective and suitable for most designs, and electroformed stencils, which offer higher accuracy and durability for complex PCBs.

4. What factors affect the performance of solder paste during application?

Key factors include viscosity, thixotropy, particle size, and distribution. These factors influence how well the solder paste flows and retains its shape on PCB pads.

5. How do full-auto and semi-auto SMT stencil printers differ?

Full-auto printers are fully automated and ideal for mass production, offering high-speed and precise solder paste application. Semi-auto printers combine manual control with automation, providing flexibility for smaller production volumes or prototyping.