Content Menu

● Understanding SMT PCB Pallets

● The Role of SMT PCB Pallets in Wave Soldering

● Advantages of Using SMT PCB Pallets in Wave Soldering

>> 1. Improved Solder Joint Quality

>> 2. Enhanced Production Efficiency

>> 3. Protection of Sensitive Components

>> 4. Support for Complex PCB Designs

>> 5. Durability and Cost-Effectiveness

● Design Considerations for SMT PCB Pallets

>> Material Selection

>> Geometry and Features

>> Compatibility and Customization

● Integration with Surface Mount Technology (SMT)

● Challenges Without SMT PCB Pallets

● Future Trends in SMT PCB Pallets

● Conclusion

● FAQ

>> 1. What materials are commonly used to make SMT PCB pallets?

>> 2. How do SMT PCB pallets improve solder flow during wave soldering?

>> 3. Can SMT PCB pallets be used for both SMT and through-hole components?

>> 4. What are the benefits of using nano-coated SMT pallets?

>> 5. How do SMT PCB pallets contribute to automation in PCB assembly?

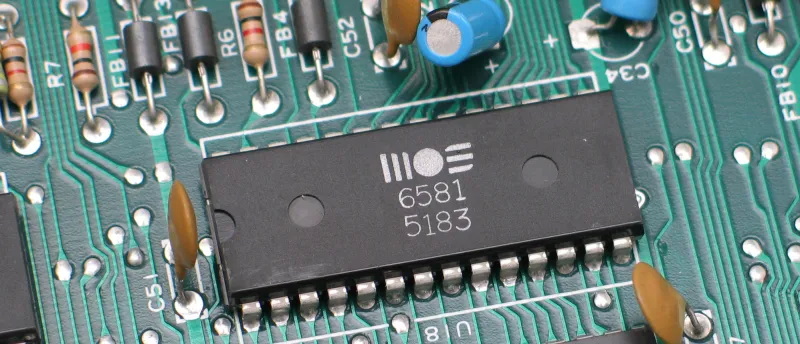

Wave soldering remains a critical step in the manufacturing of printed circuit board assemblies (PCBAs), especially for pin-through-hole (PTH) components. The use of SMT PCB pallets during this process has become increasingly important to improve solder quality, efficiency, and reliability. This article explores how SMT PCB pallets enhance the wave soldering process, their design, advantages, and impact on modern electronics manufacturing.

Understanding SMT PCB Pallets

An SMT PCB pallet, sometimes referred to as a solder paste stencil or wave solder pallet, is a specialized tool used to support and protect printed circuit boards (PCBs) during surface mount technology (SMT) assembly and wave soldering processes. Typically made from materials such as stainless steel or polyester film, these pallets serve multiple functions:

- Solder paste application: Acting as a stencil, SMT pallets allow precise application of solder paste onto PCB pads, ensuring accurate solder joint formation.

- Alignment and registration: They help in the precise positioning of components on the PCB through fiducial marks and alignment holes.

- Protection and support: SMT pallets protect the PCB from warping and prevent solder paste from spreading to undesired areas during assembly.

The importance of SMT PCB pallets lies in their ability to maintain the integrity of the PCB throughout the soldering process. Without pallets, PCBs can warp or flex, leading to poor solder joints and increased defects.

The Role of SMT PCB Pallets in Wave Soldering

Wave soldering involves passing the PCB over a wave of molten solder to create permanent electrical connections between component leads and the board. This process is especially vital for through-hole components that cannot be soldered by reflow soldering alone.

SMT PCB pallets play a crucial role in this process by:

- Supporting the PCB: They hold the board securely during the wave soldering operation, preventing warping or damage caused by the heat and mechanical forces.

- Optimizing solder flow: Advanced pallets are designed with complex geometries to control the flow of molten solder, ensuring consistent solder joints without defects like solder bridging or insufficient solder.

- Reducing wear and tear: Durable pallets made from stainless steel or nano-coated materials resist warping and degradation under high temperatures, maintaining performance over multiple production cycles.

- Facilitating mixed technology soldering: Many modern PCBs combine SMT and through-hole components. SMT pallets enable these mixed assemblies to be wave soldered efficiently by protecting SMT components from excess solder and heat.

By stabilizing the PCB and controlling the solder wave interaction, SMT PCB pallets ensure that the soldering process is both reliable and repeatable.

Advantages of Using SMT PCB Pallets in Wave Soldering

1. Improved Solder Joint Quality

The precision provided by SMT pallets in solder paste application and wave soldering leads to superior solder joint quality. The pallets ensure that the right amount of solder reaches each pad, reducing common defects such as:

- Cold solder joints: Caused by insufficient solder or poor wetting.

- Solder bridging: Occurs when excess solder connects adjacent pads or leads.

- Solder balls: Small spheres of solder that can cause shorts or reliability issues.

By minimizing these defects, SMT PCB pallets contribute to higher first-pass yields and more reliable electronic products.

2. Enhanced Production Efficiency

Using SMT PCB pallets reduces the need for manual handling and rework by stabilizing the PCB and optimizing solder flow. This leads to:

- Faster wave soldering cycles.

- Reduced inspection and repair time.

- Better compatibility with automated assembly lines.

The pallets' ability to withstand repeated thermal cycles without deformation also means less downtime for tool replacement.

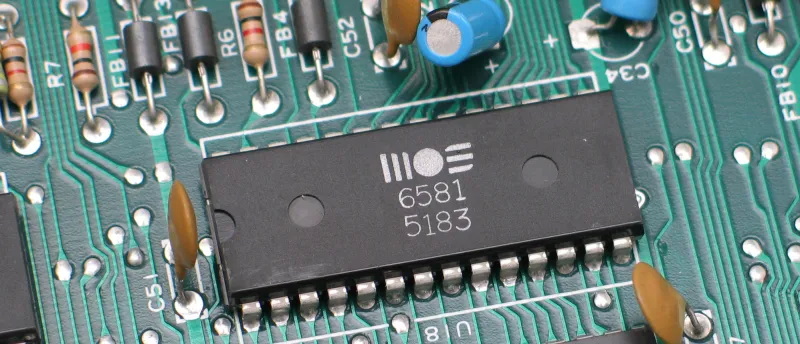

3. Protection of Sensitive Components

During wave soldering, SMT components and delicate PCB areas are vulnerable to damage from heat and solder splash. SMT pallets act as shields, preventing solder from flowing onto sensitive areas and protecting components from mechanical stress.

This protection is especially important for fine-pitch components and high-density PCB designs where even minor damage can cause functional failures.

4. Support for Complex PCB Designs

Modern electronics demand PCBs with high component density, mixed SMT and through-hole components, and intricate layouts. SMT PCB pallets can be custom-designed with:

- Multiple cutouts and openings to accommodate component placement.

- Microfluidic channels to direct solder flow precisely.

- Fiducial marks for automated alignment.

This flexibility allows manufacturers to wave solder complex boards without compromising quality.

5. Durability and Cost-Effectiveness

High-quality SMT pallets made from stainless steel or coated materials resist corrosion, warping, and mechanical wear. Their longevity reduces the frequency of pallet replacement, lowering overall manufacturing costs.

Additionally, improved soldering quality reduces the cost associated with rework and scrap.

Design Considerations for SMT PCB Pallets

To maximize their benefits, SMT PCB pallets are designed with several critical factors in mind:

Material Selection

- Stainless Steel: Offers excellent dimensional stability, heat resistance, and durability. Ideal for high-volume production.

- Polyester Film: Flexible and cost-effective, often used for prototyping or low-volume runs.

- Nano-Coatings: Applied to improve solder paste release, reduce solder paste bleed-under, and enhance pallet lifespan.

Geometry and Features

- Cutouts and Openings: Precisely sized and located to expose only the solder pads, preventing solder paste from spreading to unwanted areas.

- Microfluidic Channels: Designed to control solder flow during wave soldering, ensuring uniform solder coverage.

- Fiducial Marks and Alignment Holes: Facilitate automated placement and inspection processes.

Compatibility and Customization

- Pallets must match PCB dimensions and layout exactly.

- Custom pallets can be designed for unique or complex PCB assemblies.

- Integration with automated assembly lines requires precise tolerances and consistent quality.

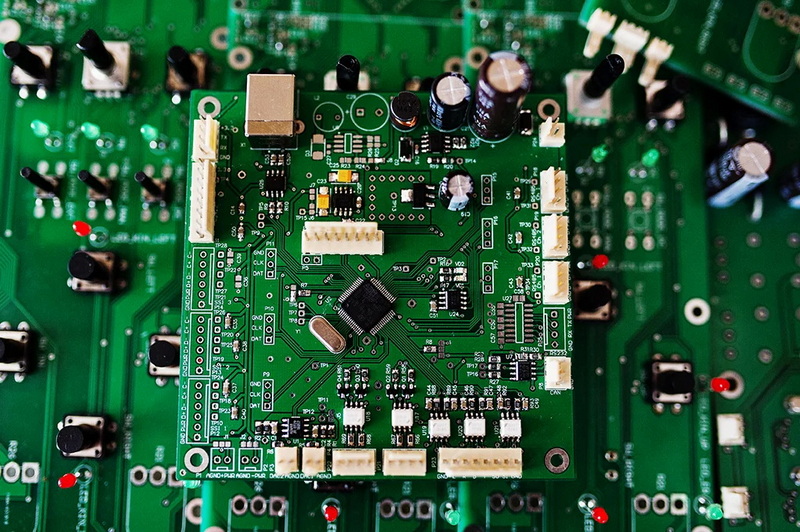

Integration with Surface Mount Technology (SMT)

Surface Mount Technology (SMT) involves mounting components directly onto the PCB surface without through-holes. SMT offers benefits such as:

- Higher component density.

- Smaller PCB size.

- Improved electrical performance.

SMT PCB pallets are integral to the SMT process by enabling:

- Accurate solder paste printing for SMT components.

- Protection during reflow soldering and wave soldering.

- Enhanced automation compatibility, reducing manual intervention and errors.

By supporting both SMT and through-hole components, SMT pallets allow manufacturers to combine the strengths of both technologies in a single assembly process.

Challenges Without SMT PCB Pallets

Without the use of SMT PCB pallets, wave soldering faces several challenges:

- Board Warping: Heat and mechanical forces can deform the PCB, causing misalignment and poor solder joints.

- Solder Defects: Excess solder can cause bridging, shorts, or insufficient soldering.

- Component Damage: Sensitive SMT components may be exposed to solder splash or thermal damage.

- Reduced Throughput: Increased rework and inspection slow down production.

Using SMT PCB pallets effectively mitigates these issues, ensuring a more robust and efficient wave soldering process.

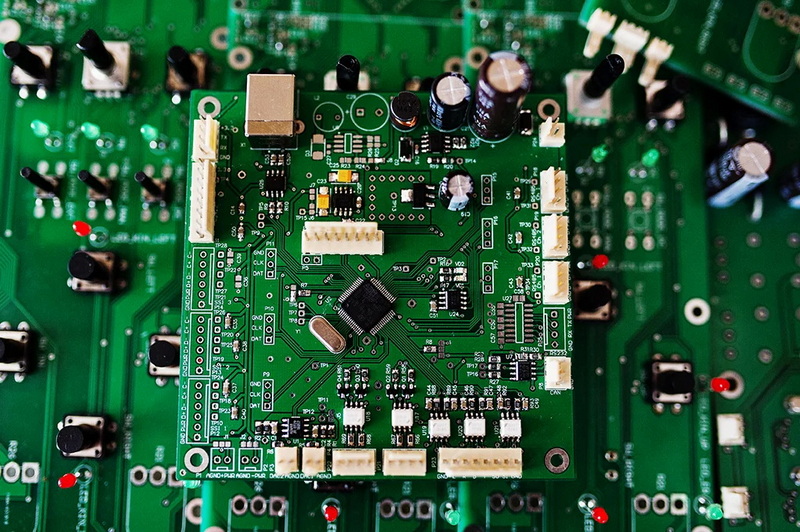

Future Trends in SMT PCB Pallets

As electronics manufacturing evolves, so do the technologies around SMT PCB pallets:

- Advanced Materials: Development of heat-resistant polymers and nano-coatings to extend pallet life and improve solder paste release.

- Smart Pallets: Integration of sensors to monitor temperature, solder flow, and pallet condition in real-time.

- Microfluidic Design: More sophisticated solder flow control using microchannels and surface treatments.

- Sustainability: Use of recyclable materials and processes to reduce environmental impact.

These innovations will further enhance the role of SMT PCB pallets in wave soldering and overall PCB assembly.

Conclusion

SMT PCB pallets significantly enhance the wave soldering process by ensuring precise solder application, optimizing solder flow, and protecting the PCB and components. Their advanced design and material properties contribute to improved solder joint quality, higher production efficiency, and support for complex PCB assemblies. As PCB designs continue to evolve with higher densities and mixed technologies, SMT PCB pallets will remain essential tools for achieving reliable and cost-effective wave soldering in modern electronics manufacturing.

By investing in high-quality SMT PCB pallets, manufacturers can reduce defects, increase throughput, and ultimately deliver superior electronic products to market faster and more cost-effectively.

FAQ

1. What materials are commonly used to make SMT PCB pallets?

SMT PCB pallets are commonly made from stainless steel for durability and dimensional stability, polyester film for flexibility in prototyping, and nano-coated materials to improve solder paste release and reduce solder bleed-under.

2. How do SMT PCB pallets improve solder flow during wave soldering?

They are designed with complex geometries that control the speed, volume, and direction of molten solder, ensuring optimal solder flow for consistent and defect-free solder joints.

3. Can SMT PCB pallets be used for both SMT and through-hole components?

Yes, SMT PCB pallets are designed to support PCBs with mixed technology, accommodating both surface mount and pin-through-hole components during wave soldering.

4. What are the benefits of using nano-coated SMT pallets?

Nano-coated pallets reduce solder paste bleed-under and improve solder paste release, which is particularly beneficial for fine-pitch components and miniaturized PCB designs.

5. How do SMT PCB pallets contribute to automation in PCB assembly?

They provide precise alignment and support for PCBs during solder paste printing and wave soldering, facilitating automated pick-and-place and soldering processes with reduced human intervention and errors.