Content Menu

● Understanding SMT Nuts and Their Role in PCB Assembly

>> The Advantages of SMT Nuts

● The Impact of SMT Nuts on PCB Reliability

>> Enhanced Mechanical Stability

>> Improved Thermal Management

>> Resistance to Environmental Factors

● SMT Nuts in Modern Electronics Manufacturing

>> Integration with Automated Assembly Processes

>> Compatibility with Reflow Soldering

● Challenges and Considerations in SMT Nut Implementation

>> Proper Design and Placement

>> Inspection and Quality Control

● Advancements in SMT Nut Technology

>> Pilotless SMT Standoffs

>> Materials and Coatings

● Applications of SMT Nuts in Various Industries

>> Consumer Electronics

>> Automotive Electronics

>> Aerospace and Defense

>> Industrial Automation

● Future Trends in SMT Nut Technology

>> Miniaturization

>> Integration with Flexible and 3D-Printed Electronics

>> Smart Manufacturing and Industry 4.0

● Best Practices for Implementing SMT Nuts

>> Design Considerations

>> Assembly Process Optimization

>> Reliability Testing

● Case Studies: SMT Nuts in Action

>> Improving Reliability in Automotive Electronics

>> Enhancing Miniaturization in Wearable Devices

● The Environmental Impact of SMT Nuts

>> Reduction in Material Waste

>> Energy Efficiency in Manufacturing

● Conclusion

● Frequently Asked Questions (FAQ)

>> 1. What are the main advantages of using SMT nuts over traditional through-hole fasteners?

>> 2. How do SMT nuts contribute to the miniaturization of electronic devices?

>> 3. What are the challenges in implementing SMT nuts in PCB design?

>> 4. How does the reliability of SMT nuts compare to traditional fastening methods?

>> 5. What future developments can we expect in SMT nut technology?

● Citations:

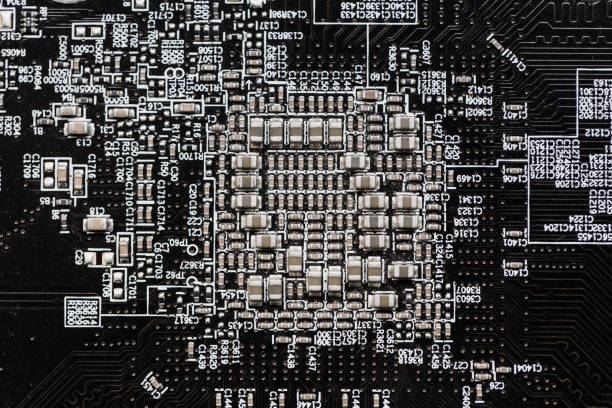

In the ever-evolving world of electronics, the quest for more reliable and efficient connections is constant. Surface Mount Technology (SMT) has revolutionized the way components are attached to printed circuit boards (PCBs), and SMT nuts are playing a crucial role in enhancing the reliability of electronic connections. This article delves into the world of SMT nuts, exploring their benefits, applications, and impact on the electronics industry.

Understanding SMT Nuts and Their Role in PCB Assembly

SMT nuts are specialized fasteners designed for surface mounting on PCBs. Unlike traditional through-hole components, SMT nuts are soldered directly onto the surface of the board, eliminating the need for drilling holes and reducing the overall footprint of the assembly[1].

The Advantages of SMT Nuts

1. Space Efficiency: SMT nuts allow for higher component density on PCBs, crucial for miniaturization in modern electronics.

2. Simplified Assembly: The elimination of through-holes simplifies the PCB design and assembly process.

3. Improved Electrical Performance: With shorter connection paths, SMT nuts can contribute to better electrical characteristics.

4. Cost-Effectiveness: SMT assembly processes are generally more cost-effective for high-volume production.

The Impact of SMT Nuts on PCB Reliability

Enhanced Mechanical Stability

SMT nuts provide a robust mechanical connection between components and the PCB. When properly soldered, they offer excellent resistance to vibration and shock, crucial for devices operating in harsh environments[1].

Improved Thermal Management

The direct surface contact between SMT nuts and the PCB allows for better heat dissipation. This improved thermal management can significantly enhance the longevity and reliability of electronic components.

Resistance to Environmental Factors

SMT nuts, when combined with appropriate solder and coating techniques, can offer superior resistance to moisture, dust, and other environmental contaminants that could compromise the integrity of electronic connections.

SMT Nuts in Modern Electronics Manufacturing

Integration with Automated Assembly Processes

SMT nuts are compatible with automated pick-and-place machines, enabling high-speed, high-precision assembly. This integration streamlines the manufacturing process and reduces the likelihood of human error[6].

Compatibility with Reflow Soldering

SMT nuts are designed to withstand the high temperatures of reflow soldering processes. This compatibility ensures a strong and reliable solder joint between the nut and the PCB[4].

Challenges and Considerations in SMT Nut Implementation

Proper Design and Placement

The effectiveness of SMT nuts heavily relies on proper PCB design and component placement. Engineers must consider factors such as pad size, solder paste volume, and thermal profiles to ensure optimal performance[4].

Inspection and Quality Control

While SMT nuts offer numerous advantages, they also present challenges in terms of visual inspection. Manufacturers must implement robust quality control measures, often utilizing X-ray or automated optical inspection systems to ensure proper solder joints[5].

Advancements in SMT Nut Technology

Pilotless SMT Standoffs

Recent innovations have introduced pilotless SMT standoffs, which can be placed directly on PCB surfaces without the need for pre-drilled holes. This advancement further simplifies the assembly process and offers greater flexibility in component placement[5].

Materials and Coatings

Ongoing research in materials science is yielding SMT nuts with enhanced properties, such as improved thermal conductivity and corrosion resistance. These advancements are pushing the boundaries of what's possible in electronic design.

Applications of SMT Nuts in Various Industries

Consumer Electronics

In smartphones, tablets, and wearable devices, SMT nuts play a crucial role in maintaining compact designs while ensuring robust connections for components like displays and sensors.

Automotive Electronics

The automotive industry relies heavily on SMT nuts for creating reliable connections in engine control units, infotainment systems, and advanced driver assistance systems (ADAS)[1].

Aerospace and Defense

In aerospace applications, where reliability is paramount, SMT nuts provide the necessary mechanical stability and electrical performance for critical systems.

Industrial Automation

SMT nuts are essential in creating durable connections in industrial control systems, robotics, and IoT devices deployed in harsh manufacturing environments.

Future Trends in SMT Nut Technology

Miniaturization

As electronics continue to shrink, we can expect to see even smaller SMT nuts designed for ultra-compact PCB assemblies.

Integration with Flexible and 3D-Printed Electronics

The future may see SMT nuts adapted for use with flexible PCBs and 3D-printed electronic structures, opening up new possibilities in product design.

Smart Manufacturing and Industry 4.0

SMT nuts may incorporate features that enable easier traceability and integration with smart manufacturing systems, aligning with Industry 4.0 principles.

Best Practices for Implementing SMT Nuts

Design Considerations

- Ensure proper pad design and solder mask clearance

- Consider thermal management in component placement

- Use appropriate solder paste volume for optimal joint formation

Assembly Process Optimization

- Fine-tune reflow profiles for different SMT nut sizes and materials

- Implement proper handling and storage procedures to prevent contamination

- Utilize automated optical inspection (AOI) systems for quality control

Reliability Testing

- Conduct thermal cycling tests to assess solder joint reliability

- Perform vibration and shock testing to evaluate mechanical stability

- Implement accelerated life testing to predict long-term performance

Case Studies: SMT Nuts in Action

Improving Reliability in Automotive Electronics

A major automotive supplier implemented SMT nuts in their engine control units, resulting in a 30% reduction in connection failures and improved resistance to vibration-induced issues.

Enhancing Miniaturization in Wearable Devices

A smartwatch manufacturer utilized custom SMT nuts to achieve a 15% reduction in PCB thickness, enabling a sleeker design without compromising on durability.

The Environmental Impact of SMT Nuts

Reduction in Material Waste

The use of SMT nuts can lead to a reduction in PCB material waste, as they eliminate the need for through-holes and allow for more compact designs.

Energy Efficiency in Manufacturing

SMT assembly processes, including those involving SMT nuts, are generally more energy-efficient than traditional through-hole assembly methods, contributing to a lower carbon footprint in electronics manufacturing.

Conclusion

SMT nuts have become an integral part of modern electronic design and manufacturing, offering significant enhancements to the reliability of electronic connections. Their ability to provide robust mechanical and electrical connections while enabling miniaturization and efficient assembly processes makes them invaluable in a wide range of applications.

As technology continues to advance, we can expect to see further innovations in SMT nut design and implementation. These advancements will likely focus on even greater miniaturization, improved thermal management, and enhanced reliability in extreme environments.

The adoption of SMT nuts, along with other SMT components, is driving the electronics industry towards more compact, efficient, and reliable products. As manufacturers and engineers continue to push the boundaries of what's possible in electronic design, SMT nuts will undoubtedly play a crucial role in shaping the future of our interconnected world.

Frequently Asked Questions (FAQ)

1. What are the main advantages of using SMT nuts over traditional through-hole fasteners?

SMT nuts offer several advantages over traditional through-hole fasteners:

- Space efficiency: They allow for higher component density on PCBs.

- Simplified assembly: No need for drilling holes, which streamlines the PCB design process.

- Improved electrical performance: Shorter connection paths can lead to better electrical characteristics.

- Cost-effectiveness: SMT assembly processes are generally more economical for high-volume production.

- Enhanced reliability: When properly soldered, SMT nuts provide excellent resistance to vibration and shock.

2. How do SMT nuts contribute to the miniaturization of electronic devices?

SMT nuts contribute to miniaturization in several ways:

- Reduced footprint: They occupy less space on the PCB compared to through-hole components.

- Elimination of through-holes: This allows for more compact PCB designs and potentially thinner boards.

- Compatibility with high-density layouts: SMT nuts can be placed closer together, enabling more components in a smaller area.

- Integration with other SMT components: They work seamlessly with other surface-mount components, facilitating overall miniaturization.

3. What are the challenges in implementing SMT nuts in PCB design?

Implementing SMT nuts comes with several challenges:

- Proper design and placement: Engineers must carefully consider pad size, solder paste volume, and thermal profiles.

- Inspection difficulties: Visual inspection of solder joints can be more challenging compared to through-hole components.

- Rework complexity: Replacing or repairing SMT nuts can be more difficult than through-hole fasteners.

- Thermal management: Ensuring proper heat dissipation in compact designs can be challenging.

- Mechanical stress considerations: Designers must account for potential mechanical stresses on SMT connections.

4. How does the reliability of SMT nuts compare to traditional fastening methods?

When properly implemented, SMT nuts can offer reliability comparable to or even exceeding traditional fastening methods:

- Vibration resistance: SMT nuts, when correctly soldered, provide excellent resistance to vibration.

- Thermal cycling performance: They can withstand thermal cycling well, crucial for automotive and aerospace applications.

- Environmental protection: SMT assembly allows for better sealing against environmental factors.

- Electrical reliability: Shorter connection paths can lead to more stable electrical characteristics.

- Long-term stability: With proper design and assembly, SMT nuts can provide long-lasting, reliable connections.

5. What future developments can we expect in SMT nut technology?

The future of SMT nut technology is likely to include:

- Further miniaturization: Even smaller SMT nuts for ultra-compact designs.

- Advanced materials: Development of nuts with enhanced thermal and electrical properties.

- Integration with flexible electronics: Adaptation for use with flexible and stretchable PCBs.

- Smart features: Incorporation of traceability and smart manufacturing capabilities.

- Improved automation: Enhanced compatibility with advanced pick-and-place and inspection systems.

- Eco-friendly options: Development of more environmentally sustainable materials and processes.

Citations:

[1] https://www.fivetk.com/e-news/pcb-standoffs/

[2] https://patents.google.com/patent/CN109195354A/zh

[3] https://www.electronicdesign.com/technologies/embedded/article/55134971/design-essentials-for-robust-and-reliable-systems

[4] https://suddendocs.samtec.com/processing/edge-mount-processing-ch.pdf

[5] https://www.pemnet.com/products-overview/surface-mounting/

[6] https://www.techtarget.com/iotagenda/blog/IoT-Agenda/3-key-steps-for-IoT-PCB-SMT-and-microelectronics-assembly

[7] https://www.reddit.com/r/AskElectronics/comments/1h3fe1t/durability_of_smt_connectors/

[8] https://patents.google.com/patent/WO2018214372A1/zh