Content Menu

● Understanding the SMT Process

● Optimizing Process Flow

>> Streamlining Component Placement

>> Balancing Machine Load

● Leveraging Advanced Technology

>> Automation Integration

>> Implementing Smart Factory Concepts

● Enhancing Equipment Performance

>> Equipment Optimization

>> Preventive Maintenance

● Improving Material Management

>> Component Standardization

>> Just-in-Time Inventory

● Enhancing Quality Control

>> Advanced Inspection Techniques

>> Statistical Process Control

● Investing in Employee Training

● Implementing Lean Manufacturing Principles

>> Value Stream Mapping

>> Continuous Improvement (Kaizen)

● Leveraging Data Analytics

>> Production Data Analysis

>> Supply Chain Optimization

● Conclusion

● FAQ

>> 1. What are the main advantages of SMT over traditional through-hole technology?

>> 2. How does automation contribute to improving PCB production efficiency in SMT factories?

>> 3. What role does employee training play in improving SMT factory efficiency?

>> 4. How can SMT factories optimize their material management to improve efficiency?

>> 5. What are some key quality control measures that can improve PCB production efficiency?

● Citations:

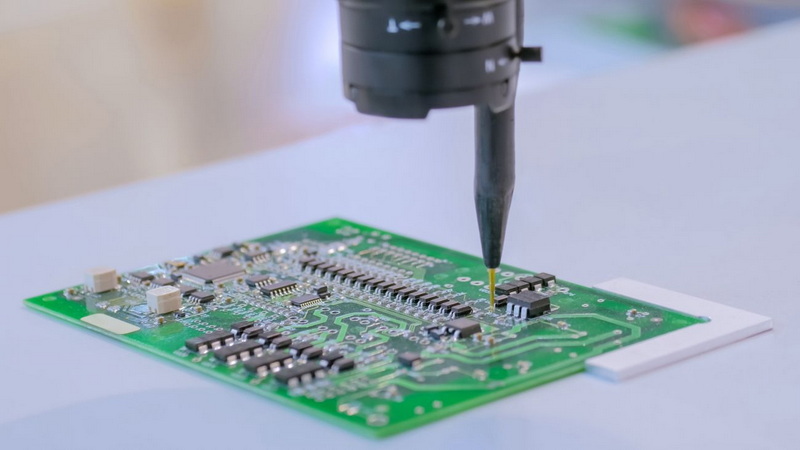

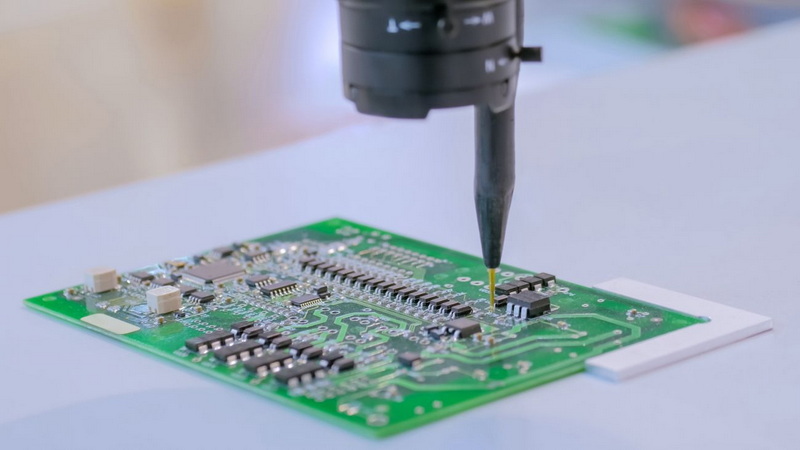

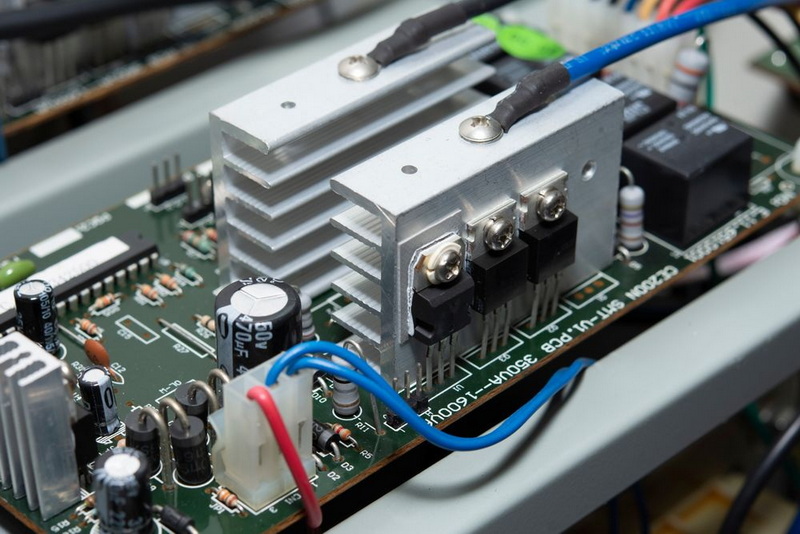

In the rapidly evolving world of electronics manufacturing, Surface Mount Technology (SMT) has become the cornerstone of efficient PCB (Printed Circuit Board) production. SMT factories are constantly seeking ways to enhance their productivity and quality while meeting the increasing demands of the industry. This article explores various strategies and techniques that SMT factories employ to improve PCB production efficiency, ensuring they remain competitive in this fast-paced sector.

Understanding the SMT Process

Before delving into efficiency improvement methods, it's crucial to understand the SMT process. Surface Mount Technology involves directly mounting electronic components onto the surface of a PCB. This method has largely replaced the traditional through-hole technology due to its numerous advantages, including smaller component sizes, increased automation possibilities, and improved overall performance[2].

The typical SMT process flow includes:

1. Solder paste application

2. Component placement

3. Reflow soldering

4. Inspection and testing

Each of these steps plays a vital role in the production of high-quality PCBs, and optimizing each stage can significantly enhance overall efficiency.

Optimizing Process Flow

One of the primary ways SMT factories improve PCB production efficiency is by optimizing their process flow. This involves a careful review and refinement of each step in the production line to ensure maximum efficiency[1].

Streamlining Component Placement

Efficient component placement is crucial for improving production speed and accuracy. SMT factories can achieve this by:

1. Optimizing the order of component placement to minimize head movement

2. Grouping similar components together to reduce nozzle changes

3. Placing frequently used components closer to the PCB for quicker access[3]

Balancing Machine Load

Distributing the workload evenly across all SMT machines is essential for maintaining a smooth production flow. Factories should aim to allocate components in a way that ensures each machine operates for approximately the same amount of time, preventing bottlenecks and idle periods[3].

Leveraging Advanced Technology

SMT factories can significantly boost their PCB production efficiency by incorporating cutting-edge technology into their processes.

Automation Integration

Automation is a key driver of efficiency in SMT production. By implementing advanced automated systems, factories can:

1. Reduce human error

2. Increase production speed

3. Improve consistency in component placement

4. Minimize labor costs[7]

Implementing Smart Factory Concepts

The adoption of Industry 4.0 principles and smart factory concepts can revolutionize PCB production efficiency. This includes:

1. Real-time data collection and analysis

2. Predictive maintenance to reduce downtime

3. AI-driven process optimization

4. Internet of Things (IoT) integration for improved connectivity and control[6]

Enhancing Equipment Performance

The efficiency of SMT production heavily relies on the performance of the equipment used. SMT factories can improve their PCB production efficiency by focusing on equipment optimization and maintenance.

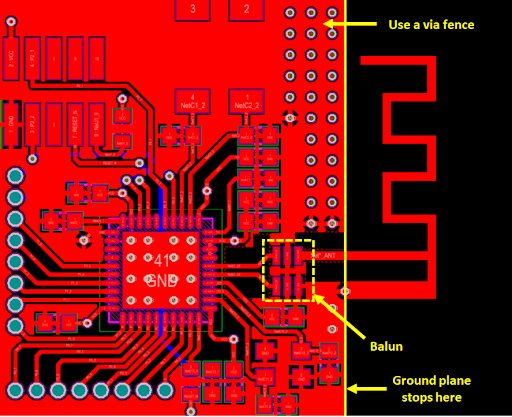

Equipment Optimization

To maximize the potential of SMT machines, factories should:

1. Regularly update and optimize machine software

2. Fine-tune pick-and-place machines for optimal speed and accuracy

3. Ensure proper calibration of all equipment[3]

Preventive Maintenance

Regular maintenance is crucial for ensuring the reliability and longevity of SMT equipment. Factories should implement a comprehensive preventive maintenance program that includes:

1. Scheduled inspections and cleaning

2. Timely replacement of wear parts

3. Regular software updates

4. Performance monitoring and analysis[7]

Improving Material Management

Efficient material management is essential for maintaining a smooth production flow in SMT factories.

Component Standardization

Using standardized components across different PCB designs can significantly improve efficiency by:

1. Reducing the variety of components needed in stock

2. Minimizing setup time for different production runs

3. Increasing the potential for bulk purchasing and cost savings[5]

Just-in-Time Inventory

Implementing a just-in-time inventory system can help SMT factories:

1. Reduce storage costs

2. Minimize the risk of component obsolescence

3. Improve cash flow by reducing tied-up capital in inventory[7]

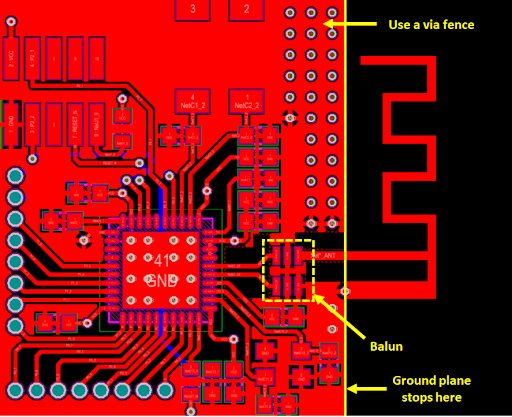

Enhancing Quality Control

Improving quality control processes not only ensures better product quality but also contributes to overall production efficiency by reducing rework and waste.

Advanced Inspection Techniques

SMT factories can improve their inspection processes by implementing:

1. Automated Optical Inspection (AOI) systems

2. X-ray inspection for hidden solder joints

3. In-line electrical testing[9]

Statistical Process Control

By implementing statistical process control methods, SMT factories can:

1. Identify and address process variations early

2. Reduce defect rates

3. Continuously improve production processes[7]

Investing in Employee Training

Well-trained employees are crucial for maintaining high efficiency in SMT factories. Investing in comprehensive training programs can:

1. Reduce errors and improve quality

2. Increase productivity through better understanding of processes

3. Enhance problem-solving skills

4. Foster a culture of continuous improvement[7]

Implementing Lean Manufacturing Principles

Adopting lean manufacturing principles can significantly improve PCB production efficiency in SMT factories.

Value Stream Mapping

By creating a detailed map of the production process, factories can:

1. Identify and eliminate non-value-adding activities

2. Streamline workflows

3. Reduce waste and improve overall efficiency[7]

Continuous Improvement (Kaizen)

Encouraging a culture of continuous improvement allows SMT factories to:

1. Constantly refine and optimize processes

2. Empower employees to suggest and implement improvements

3. Adapt quickly to changing market demands and technological advancements[7]

Leveraging Data Analytics

In the era of big data, SMT factories can harness the power of analytics to drive efficiency improvements.

Production Data Analysis

By collecting and analyzing production data, factories can:

1. Identify bottlenecks and inefficiencies

2. Optimize machine settings and process parameters

3. Predict and prevent potential issues before they occur[6]

Supply Chain Optimization

Data analytics can also be applied to supply chain management, allowing factories to:

1. Optimize inventory levels

2. Improve supplier performance

3. Reduce lead times and costs[7]

Conclusion

Improving PCB production efficiency in SMT factories is a multifaceted endeavor that requires a holistic approach. By optimizing process flows, leveraging advanced technology, enhancing equipment performance, improving material management, strengthening quality control, investing in employee training, implementing lean principles, and harnessing the power of data analytics, SMT factories can significantly boost their productivity and competitiveness.

As the electronics industry continues to evolve, with demands for smaller, more complex PCBs increasing, SMT factories must remain agile and innovative in their approach to efficiency improvement. By continuously refining their processes and embracing new technologies, these factories can ensure they meet the challenges of tomorrow while delivering high-quality PCB boards today.

FAQ

1. What are the main advantages of SMT over traditional through-hole technology?

SMT offers several advantages over through-hole technology, including:

- Smaller component sizes, allowing for more compact PCB designs

- Increased automation possibilities, leading to higher production speeds

- Improved overall performance and reliability of the final product

- Better use of PCB real estate, as components can be placed on both sides of the board

- Reduced drilling requirements, simplifying the PCB manufacturing process[2]

2. How does automation contribute to improving PCB production efficiency in SMT factories?

Automation plays a crucial role in enhancing PCB production efficiency by:

- Reducing human error and increasing consistency in component placement

- Speeding up the production process, particularly in high-volume manufacturing

- Allowing for 24/7 operation with minimal human intervention

- Enabling real-time monitoring and data collection for process optimization

- Improving overall quality control through automated inspection systems[7][9]

3. What role does employee training play in improving SMT factory efficiency?

Employee training is essential for maintaining high efficiency in SMT factories because:

- Well-trained employees make fewer mistakes, reducing rework and waste

- Comprehensive training enables workers to operate complex equipment more effectively

- Knowledgeable staff can troubleshoot issues quickly, minimizing downtime

- Ongoing education keeps employees up-to-date with the latest technologies and best practices

- Training fosters a culture of continuous improvement, encouraging innovation and efficiency[7]

4. How can SMT factories optimize their material management to improve efficiency?

SMT factories can optimize material management by:

- Implementing a just-in-time inventory system to reduce storage costs and minimize obsolescence

- Standardizing components across different PCB designs to simplify procurement and reduce setup times

- Using advanced inventory tracking systems to ensure accurate stock levels and timely reordering

- Developing strong relationships with suppliers to ensure reliable and timely deliveries

- Regularly reviewing and optimizing the bill of materials for each product to identify cost-saving opportunities[5][7]

5. What are some key quality control measures that can improve PCB production efficiency?

Key quality control measures that can enhance PCB production efficiency include:

- Implementing Automated Optical Inspection (AOI) systems for rapid and accurate defect detection

- Using X-ray inspection for checking hidden solder joints and internal component structures

- Conducting in-line electrical testing to catch functional issues early in the production process

- Applying statistical process control methods to identify and address process variations

- Implementing a robust traceability system to quickly isolate and resolve quality issues[9][7]

Citations:

[1] https://www.smtneoden.com/news/how-to-effectively-improve-the-production-efficiency-of-pcb-smt-machine/

[2] https://www.wevolver.com/article/smt-process

[3] https://www.neodensmt.com/news/improve-smt-production-efficiency-48868013.html

[4] https://baike.baidu.com/item/%E7%94%B5%E5%AD%90%E7%BB%84%E8%A3%85%E6%8A%80%E6%9C%AF%E4%B8%93%E4%B8%9A%E8%8B%B1%E8%AF%AD/12086345

[5] https://www.hoyogo.com/news/How-Can-SMT-Factories-Improve-SMT-Processing-Efficiency.html

[6] https://www.techtarget.com/iotagenda/blog/IoT-Agenda/3-key-steps-for-IoT-PCB-SMT-and-microelectronics-assembly

[7] https://www.adoptsmt.com/en/efficiency-enhancement-in-smt-manufacturing/

[8] https://www.allion.com/tech_surface_mount_tech/

[9] https://blog.matric.com/smt-production-for-pcbs-matric

[10] https://blogs.sw.siemens.com/valor-dfm-solutions/how-to-optimize-pcb-design-for-the-smt-assembly-process-flow/