Content Menu

● Introduction

● Understanding PCB SMT Assembly

>> What is SMT?

>> The Role of PCB SMT Assembly Machines

● Key Benefits of PCB SMT Assembly Machines

>> 1. Increased Production Speed

>> 2. Enhanced Precision and Quality

>> 3. Cost Reduction

>> 4. Flexibility in Production

>> 5. Improved Workflow and Space Utilization

● The Technology Behind PCB SMT Assembly Machines

>> Pick-and-Place Machines

>> Reflow Ovens

>> Inspection Systems

● Challenges in PCB SMT Assembly

>> Initial Investment Costs

>> Complexity of Setup and Maintenance

>> Need for Skilled Workforce

● Future Trends in PCB SMT Assembly

>> Increased Automation

>> Smart Manufacturing

>> Sustainable Practices

● Detailed Analysis of PCB SMT Assembly Machines

>> Component Density and Miniaturization

>> Thermal Management

>> Advanced Materials

>> Industry-Specific Applications

>> Integration with Other Manufacturing Processes

● Conclusion

● FAQ

>> 1. What is the main advantage of using PCB SMT assembly machines?

>> 2. How do SMT machines improve product quality?

>> 3. What types of machines are involved in SMT assembly?

>> 4. Are there any challenges associated with SMT assembly?

>> 5. What future trends are expected in PCB SMT assembly?

Introduction

In the fast-paced world of electronics manufacturing, efficiency is paramount. The advent of PCB SMT assembly machines has revolutionized the way printed circuit boards (PCBs) are assembled, leading to significant improvements in manufacturing processes. This article delves into how these machines enhance efficiency, reduce costs, and improve product quality in the electronics industry.

Understanding PCB SMT Assembly

What is SMT?

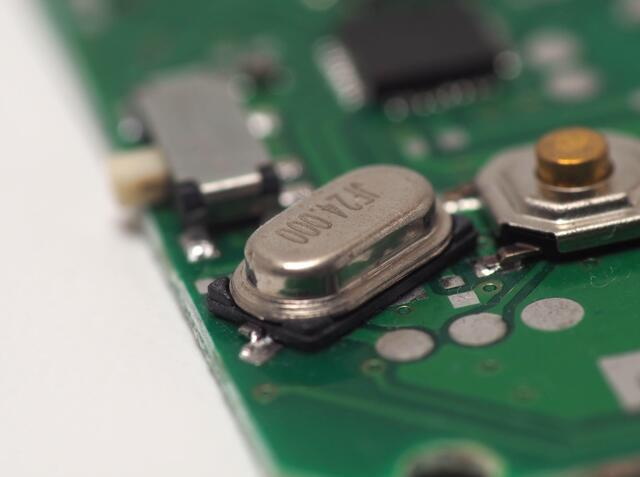

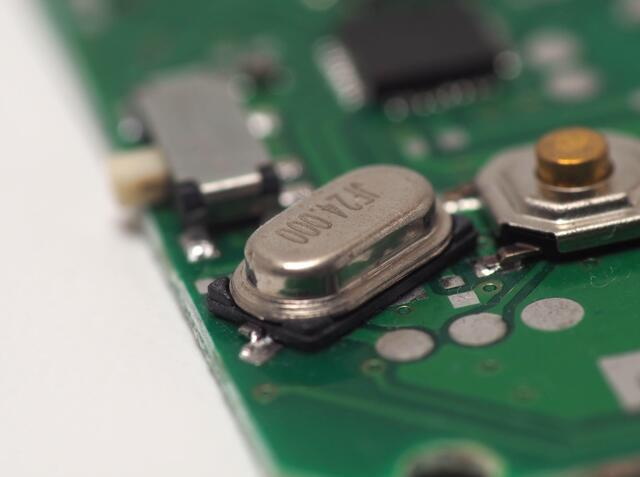

Surface Mount Technology (SMT) is a method used to mount electronic components directly onto the surface of a PCB. Unlike traditional through-hole technology, where components are inserted into holes on the board, SMT allows for a more compact design and higher component density. This technology is crucial for modern electronics, where space and performance are critical.

The Role of PCB SMT Assembly Machines

PCB SMT assembly machines automate the process of placing components on PCBs. These machines include various types of equipment, such as pick-and-place machines, reflow ovens, and inspection systems. By automating these processes, manufacturers can achieve higher production rates and improved accuracy.

Key Benefits of PCB SMT Assembly Machines

1. Increased Production Speed

One of the most significant advantages of using PCB SMT assembly machines is the increase in production speed. Automated machines can place thousands of components per hour, far exceeding the capabilities of manual assembly. This rapid production is essential for meeting the high demand for electronic devices.

2. Enhanced Precision and Quality

Automation in SMT assembly reduces the likelihood of human error. Machines are programmed to place components with high precision, ensuring that each component is correctly positioned. This accuracy leads to fewer defects and higher quality products, which is crucial in industries where reliability is paramount.

3. Cost Reduction

While the initial investment in PCB SMT assembly machines can be substantial, the long-term cost savings are significant. Automation reduces labor costs and minimizes material waste. Additionally, the increased efficiency allows manufacturers to produce more units in less time, further driving down costs.

4. Flexibility in Production

Modern SMT assembly machines are highly flexible. They can be easily reconfigured to handle different types of components and PCB designs. This adaptability is essential for manufacturers who need to respond quickly to changing market demands or customer specifications.

5. Improved Workflow and Space Utilization

Automated assembly lines streamline the manufacturing process, reducing the need for manual handling and transportation of materials. This efficiency not only speeds up production but also optimizes the use of factory space, allowing for a more organized and productive work environment.

The Technology Behind PCB SMT Assembly Machines

Pick-and-Place Machines

Pick-and-place machines are the heart of SMT assembly. These machines use robotic arms to pick components from a feeder and place them onto the PCB. Advanced models can handle a wide variety of component sizes and types, making them versatile for different production needs.

Reflow Ovens

After components are placed on the PCB, they need to be soldered. Reflow ovens heat the boards to melt solder paste, creating a strong electrical connection between the components and the PCB. The precision of reflow ovens ensures that soldering is consistent and reliable.

Inspection Systems

Quality control is critical in electronics manufacturing. Automated inspection systems, such as Automated Optical Inspection (AOI) machines, check for defects in the assembly process. These systems can identify misaligned components, soldering issues, and other potential problems before the product moves to the next stage.

Challenges in PCB SMT Assembly

Initial Investment Costs

The cost of purchasing and installing PCB SMT assembly machines can be a barrier for some manufacturers. However, the long-term savings and efficiency gains often justify this initial expenditure.

Complexity of Setup and Maintenance

Setting up SMT assembly lines requires skilled personnel who understand the technology and processes involved. Additionally, regular maintenance is necessary to keep machines running smoothly, which can add to operational costs.

Need for Skilled Workforce

While automation reduces the need for manual labor, it increases the demand for skilled workers who can operate and maintain these machines. Manufacturers must invest in training programs to ensure their workforce is equipped with the necessary skills.

Future Trends in PCB SMT Assembly

Increased Automation

The trend towards greater automation in manufacturing is expected to continue. Advances in robotics and artificial intelligence will further enhance the capabilities of PCB SMT assembly machines, making them even more efficient and reliable.

Smart Manufacturing

The integration of IoT (Internet of Things) technology into SMT assembly lines will enable real-time monitoring and data analysis. This connectivity will allow manufacturers to optimize their processes and respond quickly to any issues that arise.

Sustainable Practices

As environmental concerns grow, manufacturers are increasingly looking for ways to reduce waste and energy consumption. SMT assembly machines are being designed with sustainability in mind, using energy-efficient technologies and minimizing material waste.

Detailed Analysis of PCB SMT Assembly Machines

Component Density and Miniaturization

One of the most significant advantages of SMT is the ability to achieve higher component density on PCBs. This miniaturization allows for the development of smaller, lighter electronic devices without compromising functionality. As consumer electronics trend towards compact designs, the demand for SMT assembly machines that can handle smaller components continues to rise.

Thermal Management

With the increase in component density, managing heat dissipation becomes critical. SMT assembly machines are designed to accommodate advanced thermal management solutions, such as heat sinks and thermal pads, which are essential for maintaining the performance and longevity of electronic devices. The ability to integrate these solutions during the assembly process enhances the overall reliability of the final product.

Advanced Materials

The evolution of materials used in PCB manufacturing also impacts SMT assembly. New materials, such as flexible PCBs and high-frequency substrates, require specialized SMT machines capable of handling their unique properties. Manufacturers are increasingly investing in machines that can adapt to these advanced materials, ensuring they remain competitive in the market.

Industry-Specific Applications

Different industries have unique requirements for PCB assembly. For instance, the automotive industry demands high reliability and durability, while the consumer electronics sector focuses on cost-effectiveness and speed. PCB SMT assembly machines can be tailored to meet these specific needs, allowing manufacturers to serve a diverse range of markets effectively.

Integration with Other Manufacturing Processes

The future of PCB manufacturing lies in the integration of SMT assembly with other processes, such as testing and packaging. By creating a seamless workflow that connects these stages, manufacturers can further enhance efficiency and reduce lead times. This holistic approach to manufacturing is becoming increasingly important as companies strive to meet the demands of a fast-paced market.

Conclusion

PCB SMT assembly machines play a crucial role in improving manufacturing efficiency in the electronics industry. By increasing production speed, enhancing precision, reducing costs, and providing flexibility, these machines have transformed the way PCBs are assembled. As technology continues to advance, the benefits of SMT assembly will only grow, making it an essential component of modern manufacturing.

FAQ

1. What is the main advantage of using PCB SMT assembly machines?

The main advantage is increased production speed, allowing manufacturers to produce more units in less time while maintaining high quality.

2. How do SMT machines improve product quality?

SMT machines reduce human error by automating the placement of components, ensuring precise positioning and consistent soldering.

3. What types of machines are involved in SMT assembly?

Key machines include pick-and-place machines, reflow ovens, and inspection systems, each playing a vital role in the assembly process.

4. Are there any challenges associated with SMT assembly?

Yes, challenges include high initial investment costs, the complexity of setup and maintenance, and the need for a skilled workforce.

5. What future trends are expected in PCB SMT assembly?

Future trends include increased automation, smart manufacturing through IoT integration, and a focus on sustainable practices.