Content Menu

● Understanding SMT Components and Lead Types

>> Common SMT Component Packages

>> Lead Types in SMT Kits

● Factors to Consider When Choosing a PCB SMT Lead Kit

>> 1. Project Requirements and Complexity

>> 2. Component Size and Density

>> 3. Soldering Method

>> 4. Thermal Considerations

>> 5. Electrical Performance

>> 6. Availability and Cost

>> 7. Manufacturing Process Compatibility

● Recommended PCB SMT Lead Kits for Different Applications

>> Hobbyist and Prototyping Kit

>> High-Density Commercial Product Kit

>> Industrial and Rugged Application Kit

>> High-Frequency RF Kit

● Best Practices for Working with PCB SMT Lead Kits

● Conclusion

● FAQ

>> 1. What is the difference between SMT and through-hole components?

>> 2. How do I determine the appropriate component size for my PCB design?

>> 3. What are the advantages of using a PCB SMT lead kit?

>> 4. How do I handle and store SMT components to prevent damage?

>> 5. Can I mix SMT and through-hole components on the same PCB?

● Citations:

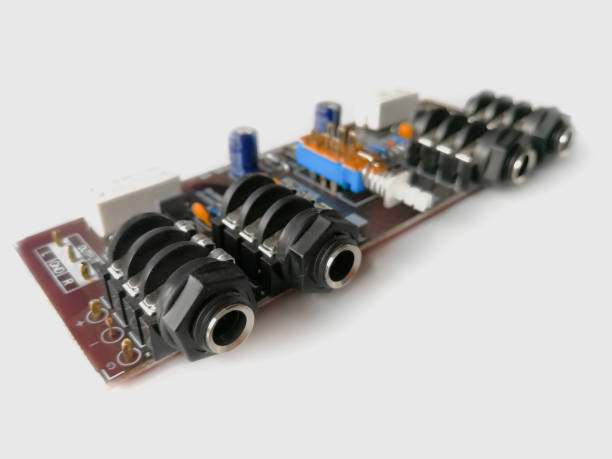

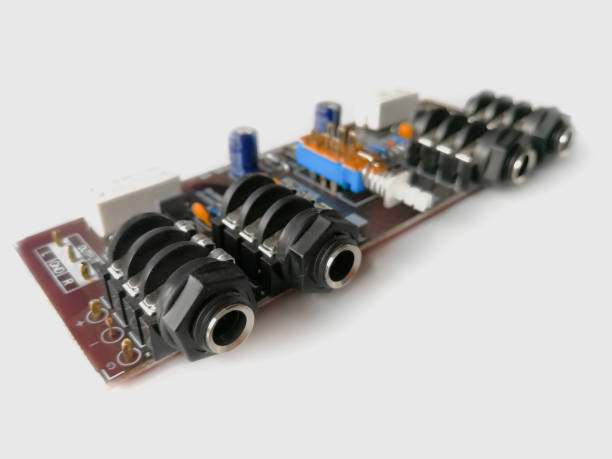

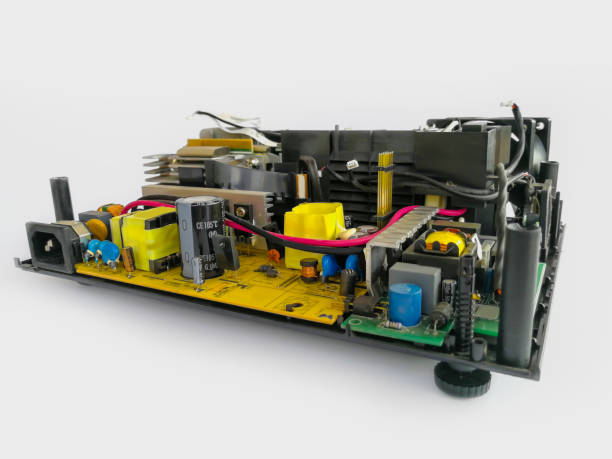

Selecting the appropriate PCB SMT lead kit for your project is a crucial decision that can significantly impact the success of your electronic design. Surface Mount Technology (SMT) has revolutionized the electronics industry, allowing for smaller, more efficient, and cost-effective circuit boards. However, with the wide variety of SMT components and lead types available, choosing the right kit can be a daunting task. This comprehensive guide will walk you through the key factors to consider when selecting a PCB SMT lead kit, helping you make an informed decision for your specific project needs.

Understanding SMT Components and Lead Types

Before delving into the selection process, it's essential to have a solid understanding of SMT components and the various lead types available in PCB SMT lead kits[1].

Common SMT Component Packages

- Chip components: These include resistors, capacitors, and inductors in packages like 0805, 0603, and 0402.

- SOT (Small Outline Transistor): Used for transistors, diodes, and voltage regulators.

- SOIC (Small Outline Integrated Circuit): A common package for integrated circuits with a pitch of 1.27mm.

- QFP (Quad Flat Package): Used for microcontrollers and other complex ICs with leads on all four sides.

- BGA (Ball Grid Array): High-density package with solder balls on the bottom for connection.

Lead Types in SMT Kits

- Gull Wing: Common in SOIC and QFP packages, with leads extending outward and downward.

- J-Lead: Found in PLCC (Plastic Leaded Chip Carrier) packages, with leads curving inward.

- Leadless: Components like QFN (Quad Flat No-leads) that have pads instead of protruding leads.

- Ball: Used in BGA packages, with solder balls for connection.

Factors to Consider When Choosing a PCB SMT Lead Kit

1. Project Requirements and Complexity

The first step in selecting the right PCB SMT lead kit is to assess your project's specific requirements and complexity[2]. Consider the following:

- Circuit complexity: More complex circuits may require a wider variety of component types and lead configurations.

- Board size: Smaller boards may necessitate the use of more compact SMT packages.

- Performance requirements: High-frequency or high-power applications may demand specific lead types for optimal performance.

- Production volume: For high-volume production, consider kits that are compatible with automated assembly processes.

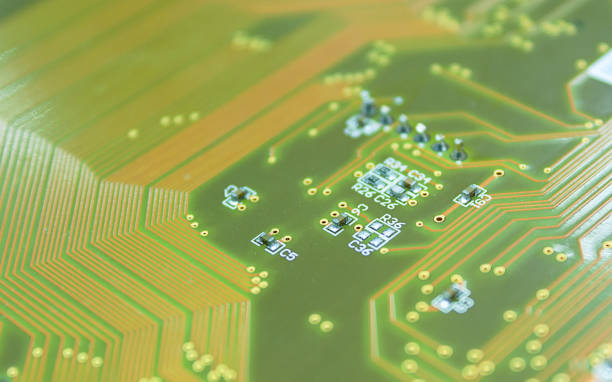

2. Component Size and Density

The size and density of components on your PCB will significantly influence your choice of SMT lead kit. Smaller components allow for higher density but may be more challenging to work with, especially for hobbyists or small-scale production[2].

- 0805 and 0603 packages: These are generally considered the sweet spot for hand soldering and are suitable for many projects.

- 0402 and smaller: These packages offer higher density but require more precise equipment and skilled handling.

- Larger packages: For power components or where space is not a constraint, larger packages like 1206 may be preferred.

3. Soldering Method

Your chosen soldering method will impact the type of SMT lead kit you should select[4].

- Hand soldering: For hobbyist or low-volume production, choose kits with components that are easier to hand solder, such as 0805 or larger packages.

- Reflow soldering: If using a reflow oven, ensure your kit components are compatible with the reflow profile.

- Wave soldering: For mixed technology boards, select components that can withstand the wave soldering process.

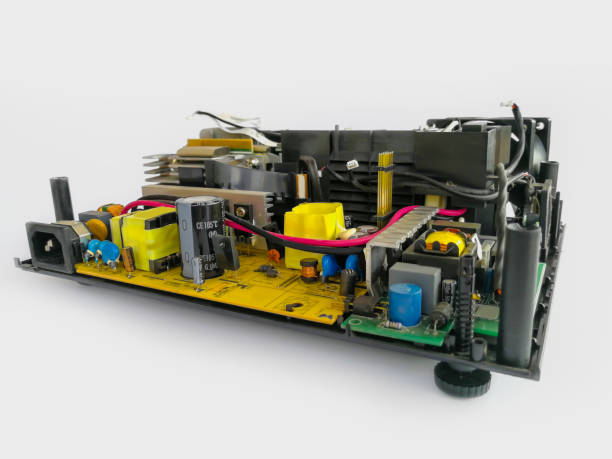

4. Thermal Considerations

The thermal characteristics of your PCB and components are crucial factors in selecting an SMT lead kit[1].

- Heat dissipation: For high-power components, choose packages with better thermal performance, such as those with exposed pads.

- Thermal expansion: Consider the coefficient of thermal expansion (CTE) mismatch between the PCB and components, especially for applications with wide temperature ranges.

5. Electrical Performance

The electrical requirements of your circuit will influence the choice of SMT lead kit[1].

- Signal integrity: For high-speed circuits, choose lead types and packages that minimize parasitic inductance and capacitance.

- Power handling: For power circuits, select packages with appropriate current-carrying capacity and thermal performance.

- EMI/EMC considerations: Some lead configurations may offer better electromagnetic compatibility.

6. Availability and Cost

Practical considerations such as component availability and cost should not be overlooked when selecting a PCB SMT lead kit[2].

- Supply chain reliability: Choose components that are readily available from multiple suppliers to avoid production delays.

- Cost-effectiveness: Balance the cost of components with their performance and reliability requirements.

- Future availability: Consider the long-term availability of components, especially for products with extended lifecycles.

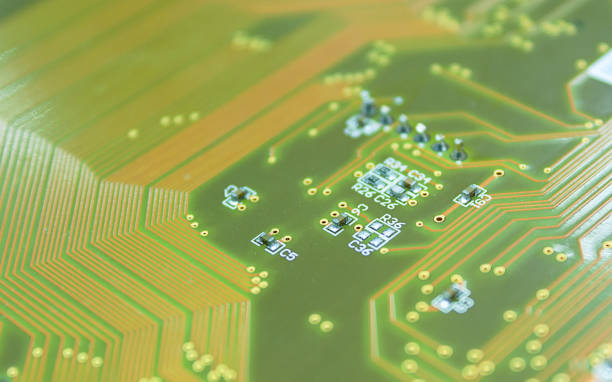

7. Manufacturing Process Compatibility

Ensure that your chosen SMT lead kit is compatible with your manufacturing process and equipment[4].

- Pick-and-place compatibility: Components should be suitable for automated placement if using pick-and-place machines.

- Stencil design: Consider the stencil requirements for applying solder paste to the PCB.

- Inspection and testing: Choose components that allow for easy visual inspection and in-circuit testing.

Recommended PCB SMT Lead Kits for Different Applications

Based on the factors discussed above, here are some recommendations for PCB SMT lead kits suitable for various applications:

Hobbyist and Prototyping Kit

For hobbyists and prototype development, a kit containing the following components is recommended:

- Resistors and capacitors in 0805 and 0603 packages

- SOT-23 transistors and diodes

- SOIC-8 and SOIC-16 ICs

- QFP packages with 0.5mm or larger pitch

- A selection of passive components in 1206 packages for easier handling

This kit provides a good balance between ease of use and component density, making it suitable for hand soldering and small-scale production[2].

High-Density Commercial Product Kit

For commercial products requiring higher component density:

- Resistors and capacitors in 0402 and 0201 packages

- QFN and BGA packages for complex ICs

- Fine-pitch QFP packages (0.4mm or 0.3mm pitch)

- Micro-BGA packages for memory and processors

- Specialized RF components for wireless applications

This kit is suitable for products that require miniaturization and high performance, such as smartphones or wearable devices[1].

Industrial and Rugged Application Kit

For industrial applications that require robustness and reliability:

- Larger package sizes (1206, 1210) for improved power handling

- SOIC and SOT packages with wide leads for better mechanical strength

- QFP packages with exposed pads for enhanced thermal performance

- Hermetically sealed components for harsh environment protection

- High-reliability versions of standard components

This kit is ideal for applications in automotive, aerospace, and industrial control systems where reliability and environmental resistance are critical[1].

High-Frequency RF Kit

For projects involving high-frequency RF circuits:

- Low-loss ceramic capacitors in 0402 and 0201 packages

- High-Q inductors in various SMT packages

- RF-specific transistors and ICs in QFN packages

- Shielded components for EMI reduction

- Specialized RF connectors and transmission line components

This kit is tailored for applications such as wireless communication devices, radar systems, and high-speed digital circuits[1].

Best Practices for Working with PCB SMT Lead Kits

To ensure success when working with your chosen PCB SMT lead kit, consider the following best practices:

1. Proper storage: Store components in a dry, static-free environment to prevent moisture absorption and ESD damage.

2. Handling precautions: Use ESD-safe tools and workstations when handling SMT components.

3. Solder paste application: Use a high-quality stencil and solder paste appropriate for your component sizes and lead types.

4. Component placement: Invest in precision tweezers or a vacuum pickup tool for accurate placement of small components.

5. Reflow profile optimization: Carefully adjust your reflow profile to match the thermal requirements of all components in your kit.

6. Inspection and rework: Use magnification tools for visual inspection and have appropriate rework equipment on hand for any necessary corrections.

7. Documentation: Maintain detailed records of your component choices and assembly processes for future reference and troubleshooting.

Conclusion

Choosing the right PCB SMT lead kit for your project is a critical decision that requires careful consideration of various factors, including project requirements, component size, soldering method, thermal considerations, electrical performance, availability, and manufacturing process compatibility. By thoroughly evaluating these aspects and selecting a kit that aligns with your specific needs, you can ensure the success of your PCB design and assembly process.

Remember that the world of SMT components is constantly evolving, with new package types and technologies emerging regularly. Stay informed about the latest developments in SMT technology to make the most informed decisions for your future projects. Whether you're a hobbyist working on a prototype or an engineer designing a high-volume commercial product, the right PCB SMT lead kit can make all the difference in achieving your design goals efficiently and effectively.

FAQ

1. What is the difference between SMT and through-hole components?

SMT (Surface Mount Technology) components are designed to be mounted directly onto the surface of a PCB, while through-hole components have leads that are inserted through holes in the board. SMT components are generally smaller, allow for higher component density, and are more suitable for automated assembly processes. Through-hole components, on the other hand, provide stronger mechanical connections and are often used for components that may experience mechanical stress or require heat dissipation.

2. How do I determine the appropriate component size for my PCB design?

The appropriate component size depends on several factors:

- Available PCB space

- Required component density

- Soldering method (hand soldering vs. automated assembly)

- Electrical and thermal requirements

For hand soldering, 0805 or 0603 packages are often recommended as a good balance between size and ease of use. For automated assembly or high-density designs, smaller packages like 0402 or 0201 may be more appropriate. Always consider the specific requirements of your project when selecting component sizes.

3. What are the advantages of using a PCB SMT lead kit?

Using a PCB SMT lead kit offers several advantages:

- Consistency in component selection across projects

- Reduced time spent on component sourcing

- Assurance of component compatibility

- Cost savings through bulk purchasing

- Simplified inventory management

Additionally, many kits are curated to include commonly used components, which can be particularly helpful for hobbyists or those new to SMT design.

4. How do I handle and store SMT components to prevent damage?

Proper handling and storage of SMT components is crucial:

- Use ESD-safe containers and packaging

- Store components in a cool, dry environment

- Avoid exposing components to extreme temperatures or humidity

- Use ESD-safe tools and workstations when handling components

- For moisture-sensitive components, follow proper baking procedures if the moisture barrier packaging has been compromised

Adhering to these practices will help prevent damage from electrostatic discharge, moisture, and physical handling.

5. Can I mix SMT and through-hole components on the same PCB?

Yes, it is possible to mix SMT and through-hole components on the same PCB, a practice known as mixed technology assembly. This approach can be useful when certain components are only available in through-hole packages or when specific components require the mechanical strength of through-hole mounting. However, mixing technologies can complicate the assembly process, potentially requiring both reflow and wave soldering steps. When designing a mixed technology board, carefully consider the assembly process and component placement to ensure manufacturability.

Citations:

[1] https://solutions.mccsemi.com/news/smd-package-sizes-a-simple-selection-guide

[2] https://es.hayawin.com/resources/what-is-smt-assembly-the-advantages-and-applications-of-smt-64f6e8bd90b55.html

[3] https://www.analog.com/jp/resources/design-notes/smt-assembly-and-pcb-design-guidelines-for-leaded-packages.html

[4] https://www.protoexpress.com/kb/kitting-guidelines/

[5] https://fancort.com/pages/lead-forming-equipment-custom-applications

[6] https://baike.baidu.com/item/%E7%94%B5%E5%AD%90%E7%BB%84%E8%A3%85%E6%8A%80%E6%9C%AF%E4%B8%93%E4%B8%9A%E8%8B%B1%E8%AF%AD/12086345

[7] https://electronics.stackexchange.com/questions/1530/sizing-smd-components-for-hobbyist-kits

[8] https://www.vakits.com/linear-ic-smt-design-kit-1-smt-pcb-2660

[9] https://suddendocs.samtec.com/processing/edge-mount-processing-ch.pdf

[10] https://community.sparkfun.com/t/smt-starter-kits/7225

[11] https://finestpcb.com/smt-assembly/