Content Menu

● Introduction to SMT Stencils

>> Frameless vs. Framed SMT Stencils

● Benefits of Framed SMT Stencils

● Challenges and Considerations

● Future Trends and Developments

● Role of Technology in Enhancing Framed SMT Stencils

● Impact on Production Workflow

● Case Studies and Real-World Applications

● Conclusion

● Frequently Asked Questions

>> 1. What is the primary advantage of using framed SMT stencils over frameless ones?

>> 2. How do framed SMT stencils contribute to cost efficiency in production?

>> 3. What materials are commonly used for framed SMT stencils?

>> 4. Can framed SMT stencils be used for fine-pitch components?

>> 5. How do framed stencils support automated assembly lines?

● Citations:

In the realm of Surface Mount Technology (SMT), the efficiency and precision of PCB assembly are paramount. One crucial tool that enhances production efficiency in this process is the framed SMT stencil. This article delves into the role of framed SMT stencils, their benefits, and how they contribute to streamlined production in high-volume manufacturing environments.

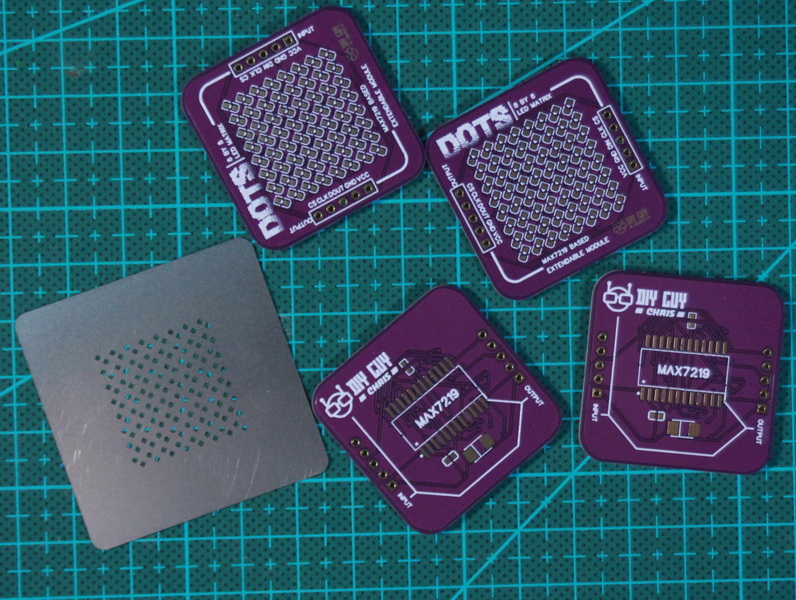

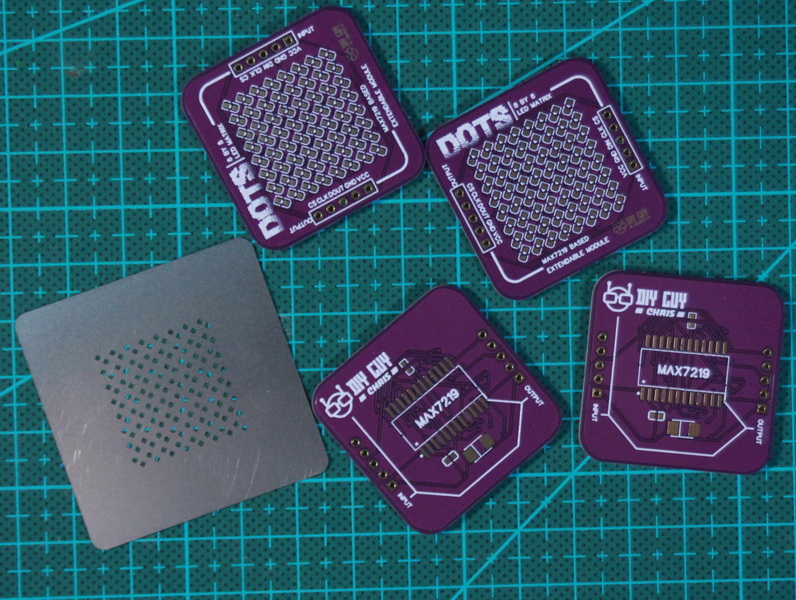

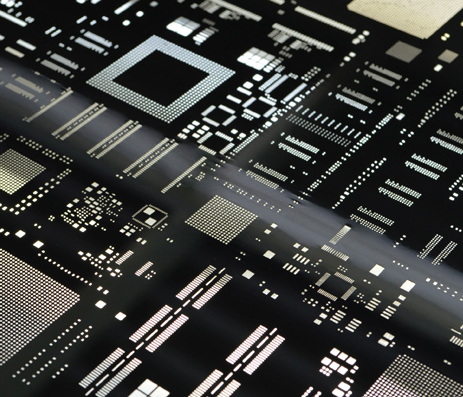

Introduction to SMT Stencils

SMT stencils are essential for applying solder paste onto PCBs during the SMT assembly process. They ensure precise solder paste deposition, which is critical for achieving high-quality solder joints and minimizing defects such as bridging or tombstoning. SMT stencils come in various forms, including frameless and framed stencils, each suited to different production needs.

Frameless vs. Framed SMT Stencils

- Frameless SMT Stencils: These are flexible and cost-effective, ideal for prototypes and small-scale production. They are made from materials like stainless steel or nickel alloys and are easy to handle and store. However, they require manual alignment, which can be time-consuming and prone to errors.

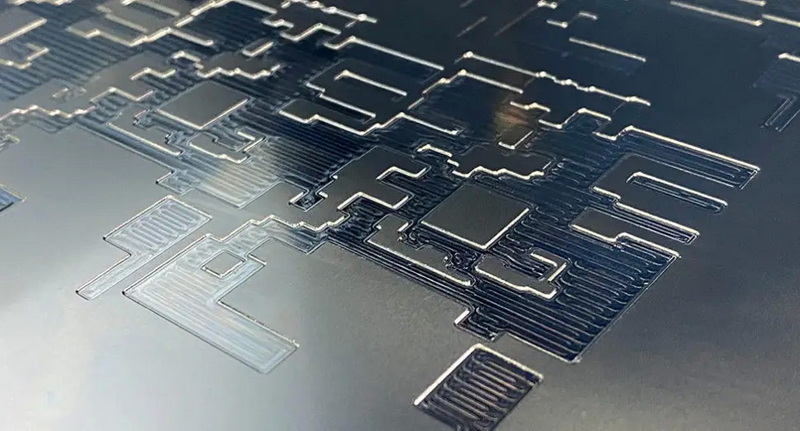

- Framed SMT Stencils: Framed stencils are designed for high-volume manufacturing. They consist of a laser-cut stencil foil permanently mounted in a rigid frame, typically made of aluminum. This setup ensures stability and precision during solder paste application, making them indispensable for mass production lines where consistency is crucial.

Benefits of Framed SMT Stencils

Framed SMT stencils offer several advantages that enhance production efficiency:

1. Precision and Consistency: The rigid frame ensures that the stencil remains taut and aligned, reducing misalignment issues that can lead to defects. This precision is particularly important for fine-pitch components where even slight misalignments can cause significant problems.

2. High-Volume Production Capability: Framed stencils are designed for continuous operation in high-volume manufacturing environments. They enable the use of automated solder paste printers, which can quickly apply solder paste to multiple PCBs in succession, significantly increasing production speed and consistency.

3. Optimal Solder Paste Volume Control: The thickness of the stencil determines the amount of solder paste deposited on each pad. Framed stencils provide consistent solder paste volumes, which is essential for achieving high-quality solder joints and minimizing defects.

4. Durability and Reliability: Framed stencils are more durable than their frameless counterparts, offering robustness and reliability over long production runs. This durability reduces downtime and maintenance costs associated with frequent stencil replacements.

5. Cost Efficiency: While framed stencils may have a higher upfront cost, they reduce waste and minimize the need for rework by ensuring precise solder paste application. This precision leads to higher production yields and lower overall costs in the long run.

Challenges and Considerations

Despite their benefits, framed SMT stencils also present some challenges:

- Initial Investment: The cost of acquiring framed stencils can be higher compared to frameless options. However, the long-term benefits in terms of efficiency and quality often justify this investment.

- Maintenance and Storage: Framed stencils require careful handling and storage to maintain their precision and prevent damage. This can add to operational costs if not managed properly.

- Design and Manufacturing Complexity: The design and manufacturing of framed stencils require precise specifications to ensure they meet the needs of high-volume production. This complexity can increase production time and costs if not optimized.

Future Trends and Developments

The future of SMT stencils is likely to involve advancements in materials and manufacturing techniques. Innovations such as nanocoatingless materials and improved laser cutting technologies are expected to enhance the performance and durability of stencils further. Additionally, there may be a greater emphasis on sustainability and reducing waste in the production process.

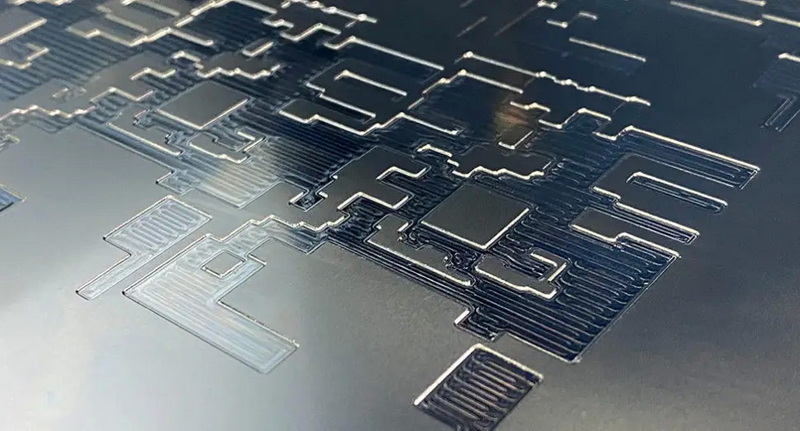

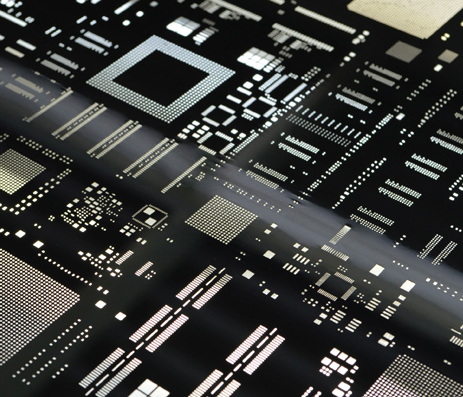

Role of Technology in Enhancing Framed SMT Stencils

Advancements in technology are continually improving the efficiency and effectiveness of framed SMT stencils:

- Laser Cutting Technology: High-precision laser cutting allows for intricate designs and precise aperture control, enabling the production of stencils for complex PCBs with fine-pitch components.

- Automated Inspection Systems: These systems help in detecting defects and ensuring that stencils meet quality standards before they are used in production, further enhancing reliability.

- Material Innovations: New materials and coatings are being developed to improve stencil durability and reduce maintenance needs, contributing to longer stencil lifetimes and reduced operational costs.

Impact on Production Workflow

The integration of framed SMT stencils into production workflows can significantly streamline operations:

- Reduced Setup Time: Framed stencils are designed to work seamlessly with automated systems, reducing setup times and allowing for quicker transitions between different PCB designs.

- Improved Quality Control: The precision offered by framed stencils allows for better quality control, as they ensure consistent solder paste application across all PCBs, reducing variability and defects.

- Increased Throughput: By enabling high-speed, high-volume production, framed stencils help manufacturers meet demanding production schedules while maintaining quality standards.

Case Studies and Real-World Applications

Several manufacturers have seen significant improvements in production efficiency by adopting framed SMT stencils:

- Example 1: A leading electronics manufacturer reported a 30% increase in production speed and a 25% reduction in defects after switching to framed stencils for their high-volume PCB assembly lines.

- Example 2: A smaller electronics firm noted that while the initial investment in framed stencils was higher, the long-term savings from reduced rework and waste justified the cost, allowing them to expand their production capacity.

Conclusion

Framed SMT stencils play a vital role in enhancing production efficiency in high-volume PCB manufacturing. Their precision, consistency, and durability make them indispensable for achieving high-quality solder joints and minimizing defects. While they present some challenges, the benefits they offer in terms of increased production speed, reduced waste, and improved product quality make them a crucial investment for manufacturers seeking to optimize their SMT assembly processes.

Frequently Asked Questions

1. What is the primary advantage of using framed SMT stencils over frameless ones?

Framed SMT stencils offer better stability and precision during solder paste application, making them ideal for high-volume manufacturing where consistency is key.

2. How do framed SMT stencils contribute to cost efficiency in production?

Framed stencils reduce waste and minimize the need for rework by ensuring precise solder paste application, leading to higher production yields and lower overall costs.

3. What materials are commonly used for framed SMT stencils?

Framed SMT stencils are typically made from stainless steel or nickel alloys for the stencil foil, with the frame usually being aluminum.

4. Can framed SMT stencils be used for fine-pitch components?

Yes, framed SMT stencils are well-suited for fine-pitch components due to their precision and ability to maintain consistent solder paste volumes.

5. How do framed stencils support automated assembly lines?

Framed stencils enable the use of automated solder paste printers, which can quickly apply solder paste to multiple PCBs in succession, significantly increasing production speed and consistency.

Citations:

[1] https://rigidflexpcb.org/smt-stencil-why-you-need-one/

[2] https://learn.adafruit.com/smt-manufacturing/framed-stencils

[3] https://www.wevolver.com/article/pcb-stencil

[4] https://www.soldertools.net/smt-framed-stencils/

[5] https://www.elepcb.com/blog/pcb-stencil-smt-assembly/

[6] https://jlcpcb.com/blog/guide-to-smt-stencils-in-pcb-assembly

[7] https://www.pcbunlimited.com/products/framed-smt-stencils

[8] https://www.datumalloys.com/stencils-and-their-ultimate-influence/

[9] https://www.instructables.com/How-to-Order-a-SMT-Stencil/

[10] https://pcbpit.com/smt-stencil-a-comprehensive-guide/

[11] https://www.pcbasic.com/blog/pcb_stencils_key_to_high-quality.html