Content Menu

● Understanding EIA and Metric Standards

>> What is EIA?

>> What are Metric Standards?

● EIA vs. Metric Standards

>> Key Differences

● Implications for SMT Components

>> Design Considerations

>> Manufacturing Processes

● Challenges Associated with EIA and Metric Standards

>> Compatibility Issues

>> Increased Complexity

>> Cost Implications

● Future Trends in SMT Standards

>> Increased Globalization

>> Adoption of Advanced Technologies

>> Sustainability Initiatives

>> Enhanced Collaboration Among Stakeholders

● Conclusion

● FAQ

>> 1. What are SMT components?

>> 2. Why do we need different standards like EIA and metric?

>> 3. How do I choose between EIA or metric when designing PCBs?

>> 4. Can I mix components from both EIA and metric specifications?

>> 5. What future trends should we expect regarding SMT component standards?

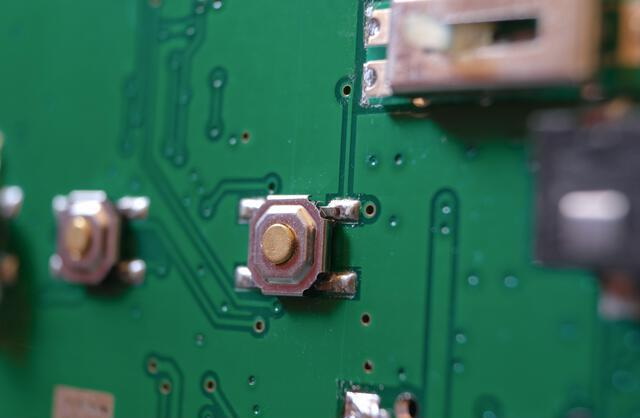

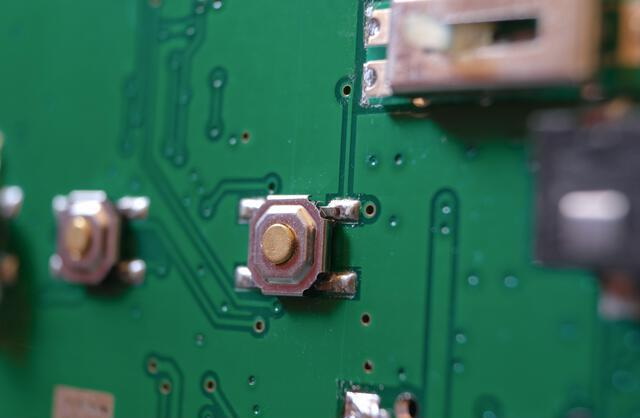

Surface Mount Technology (SMT) has revolutionized the electronics manufacturing industry by allowing for more compact designs and higher component densities. As the technology continues to evolve, the standards governing SMT components play a crucial role in ensuring compatibility, reliability, and performance. Among these standards, the Electronic Industries Alliance (EIA) and various metric standards are significant players. This article explores how these standards impact SMT components, focusing on their definitions, comparisons, implications for design and manufacturing, and future trends.

Understanding EIA and Metric Standards

What is EIA?

The Electronic Industries Alliance (EIA) is a trade organization that develops standards for the electronics industry. Established in the 1920s, the EIA has created numerous standards that govern various aspects of electronics manufacturing, including:

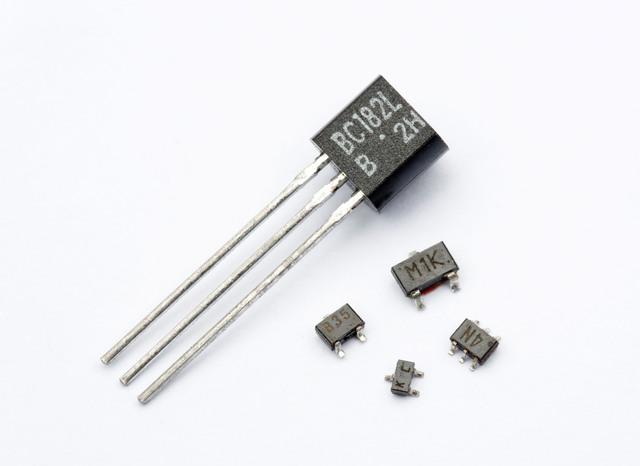

- Component dimensions: Specifications for sizes and footprints of SMT components.

- Electrical characteristics: Standards related to voltage, current ratings, and other electrical parameters.

- Testing methods: Guidelines for evaluating component performance.

EIA standards are widely accepted in North America and have a significant influence on the design and manufacturing processes of SMT components.

What are Metric Standards?

Metric standards refer to a set of international guidelines that utilize the metric system for measurements. These standards are adopted globally and aim to promote uniformity in manufacturing processes. In the context of SMT components, metric standards cover:

- Dimensions: Specifications for component sizes in millimeters rather than inches.

- Performance metrics: Standards that define how components should perform under various conditions.

Metric standards are particularly important in Europe and Asia, where they are often preferred over EIA standards.

EIA vs. Metric Standards

The debate between EIA and metric standards is ongoing within the electronics industry. Each standard has its advantages and disadvantages, impacting how SMT components are designed and manufactured.

| Aspect | EIA Standards | Metric Standards |

| Measurement Units | Inches (imperial) | Millimeters (metric) |

| Regional Adoption | Predominantly North America | Global, especially Europe and Asia |

| Component Footprints | Defined in inches | Defined in millimeters |

| Industry Usage | Common in consumer electronics | Preferred in automotiv |

Key Differences

1. Measurement Units: EIA uses imperial units while metric standards use millimeters. This difference can lead to challenges when integrating components from different regions.

2. Footprint Specifications: The specifications for component footprints vary between EIA and metric standards. For example, an SMT resistor may have different footprint dimensions depending on which standard is being followed.

3. Design Considerations: Designers must be aware of which standard they are working with to ensure compatibility with other components on the PCB.

Implications for SMT Components

Design Considerations

When designing SMT components, engineers must consider both EIA and metric standards to ensure their products meet industry requirements. This includes:

- Footprint Compatibility: Designers need to ensure that the footprints of their components align with those defined by either standard to avoid issues during assembly.

- Tolerance Levels: Different standards may specify varying tolerance levels for component dimensions. Understanding these tolerances is crucial for ensuring reliable performance.

- Material Selection: The choice of materials may also be influenced by the standards being followed. For instance, certain materials may be preferred in regions that adhere strictly to metric specifications.

- Thermal Management: As electronic devices become more compact, thermal management becomes critical. Designers must consider how different standards address thermal performance specifications, such as heat dissipation capabilities of SMT components.

Manufacturing Processes

Manufacturers must adapt their processes based on the standards they choose to follow. This can include:

- Equipment Calibration: Machinery used for assembling SMT components may need calibration adjustments depending on whether EIA or metric dimensions are being used.

- Quality Control Measures: Quality assurance processes must be tailored to meet the specific requirements of each standard, ensuring that components meet all necessary specifications before reaching customers.

- Supply Chain Management: Manufacturers often source components from various suppliers who may adhere to different standards. Effective supply chain management is essential to ensure compatibility across all sourced parts.

- Training and Skill Development: Employees involved in manufacturing must be trained on both sets of standards to minimize errors during production. This includes understanding how to interpret specifications correctly and apply them during assembly processes.

Challenges Associated with EIA and Metric Standards

While both EIA and metric standards provide frameworks for designing and manufacturing SMT components, they also present several challenges:

Compatibility Issues

One of the primary challenges arises from compatibility issues when mixing components from different standards. For example:

- A PCB designed using EIA specifications may not accommodate metric-standardized components without modifications.

- Assemblers might face difficulties when sourcing parts from global suppliers who adhere to different measurement systems.

Increased Complexity

The existence of two primary systems can complicate product development cycles:

- Engineers must spend additional time ensuring that all parts fit together seamlessly.

- Documentation needs to be meticulously maintained to reflect which standard was used during each stage of design and production.

Cost Implications

Adhering to multiple standards can also lead to increased costs:

- Manufacturers might need specialized equipment capable of handling both imperial and metric dimensions.

- There may be additional costs associated with retraining staff or retooling production lines.

Future Trends in SMT Standards

As technology continues to advance, so too do the standards governing SMT components. Some emerging trends include:

Increased Globalization

With globalization driving collaboration between manufacturers worldwide, there is a growing trend toward harmonizing EIA and metric standards. This could lead to more standardized practices across borders, simplifying design and manufacturing processes.

Adoption of Advanced Technologies

The rise of advanced technologies such as artificial intelligence (AI) and machine learning (ML) is influencing how standards are developed and implemented. These technologies can enhance quality control processes, making it easier for manufacturers to adhere to both EIA and metric specifications.

Sustainability Initiatives

As environmental concerns grow, there is an increasing emphasis on sustainability within the electronics industry. Future standards may incorporate guidelines aimed at reducing waste and promoting eco-friendly practices throughout the lifecycle of SMT components.

Enhanced Collaboration Among Stakeholders

The future will likely see enhanced collaboration among stakeholders—manufacturers, designers, regulatory bodies—to create unified guidelines that address both sets of requirements while promoting innovation in SMT technology.

Conclusion

The impact of EIA and metric standards on SMT components cannot be overstated. These standards shape every aspect of design and manufacturing processes within the electronics industry. As globalization continues to blur regional boundaries, understanding how these two sets of standards interact will be essential for engineers and manufacturers alike. By embracing both EIA and metric specifications, stakeholders can ensure their products remain competitive in an increasingly interconnected marketplace.

In summary, while both EIA and metric standards serve vital roles in shaping SMT components, their differences necessitate careful consideration during design and manufacturing phases. As technology evolves, so too will these standards—creating new opportunities for innovation while ensuring product reliability across global markets.

FAQ

1. What are SMT components?

SMT components are electronic parts designed for surface mount technology assembly on printed circuit boards (PCBs). They are smaller than traditional through-hole components, allowing for higher density designs.

2. Why do we need different standards like EIA and metric?

Different regions have different preferences when it comes to measurement systems; hence having multiple standards ensures compatibility across diverse markets while catering to local practices.

3. How do I choose between EIA or metric when designing PCBs?

Choosing between EIA or metric depends on your target market; if you're designing for North America primarily, you might lean towards EIA specifications, whereas global designs might benefit from adhering to metric standards.

4. Can I mix components from both EIA and metric specifications?

While it's possible to mix them, doing so requires careful consideration of footprint compatibility and tolerances to avoid assembly issues or performance problems.

5. What future trends should we expect regarding SMT component standards?

Expect increased globalization leading towards harmonization of EIA and metric standards along with advancements in technology influencing quality control measures as well as sustainability initiatives within the industry.