Content Menu

● Understanding SMT Feeders

>> Types of SMT Feeders

>>> 1. Tape Feeders

>>> 2. Tray Feeders

>>> 3. Stick Feeders

>>> 4. Tube Feeders

● Impact of SMT Feeders on Manufacturing Processes

>> 1. Production Speed

>> 2. Component Placement Accuracy

>> 3. Flexibility and Adaptability

>> 4. Cost Efficiency

>> 5. Maintenance and Reliability

● Choosing the Right SMT Feeder

● Conclusion

● Frequently Asked Questions

>> 1. What is the primary function of an SMT feeder?

>> 2. What are the main types of SMT feeders?

>> 3. How does the choice of feeder affect production speed?

>> 4. What factors should be considered when selecting an SMT feeder?

>> 5. Why is component placement accuracy important in SMT manufacturing?

Surface Mount Technology (SMT) has revolutionized the electronics manufacturing industry by allowing for the efficient assembly of printed circuit boards (PCBs). A critical component of this process is the SMT feeder, which plays a vital role in the accurate and efficient placement of electronic components. This article explores the various types of SMT feeders, their impact on manufacturing processes, and how choosing the right feeder can enhance production efficiency.

Understanding SMT Feeders

SMT feeders are devices that supply electronic components to pick-and-place machines during the PCB assembly process. They are designed to hold and deliver components in a manner that ensures precise placement on the PCB. The choice of feeder can significantly affect the speed, accuracy, and overall efficiency of the manufacturing process. Understanding the mechanics and functionalities of SMT feeders is essential for manufacturers aiming to optimize their production lines. Each feeder type is engineered to cater to specific component shapes and sizes, which directly influences the assembly process's effectiveness.

Types of SMT Feeders

There are several types of SMT feeders, each suited for different types of components and manufacturing needs. The main categories include:

1. Tape Feeders

2. Tray Feeders

3. Stick Feeders

4. Tube Feeders

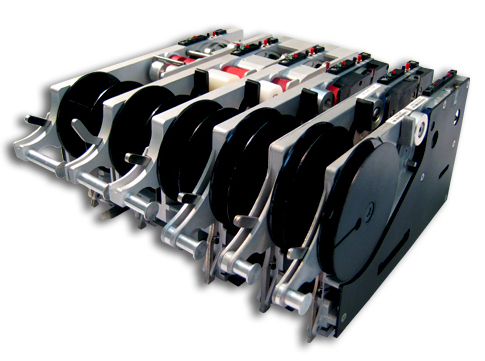

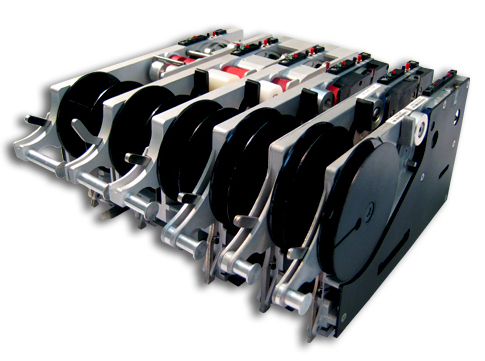

1. Tape Feeders

Tape feeders are the most commonly used type of SMT feeder. They are designed to handle components that are packaged in tape-and-reel format. This type of feeder uses a sprocket mechanism to pull the tape forward, exposing the components for the pick-and-place machine. Tape feeders are known for their high speed and efficiency, making them ideal for high-volume production runs. The design of tape feeders allows for quick reloading and minimal downtime, which is crucial in fast-paced manufacturing environments.

Advantages:

- High-speed operation enables rapid production cycles, which is essential for meeting tight deadlines.

- Suitable for a wide range of component sizes, from small resistors to larger ICs, making them versatile.

- Minimal component damage during feeding due to their gentle handling mechanisms, which reduces waste and increases yield.

Disadvantages:

- Limited to components that can be packaged in tape-and-reel format, which may restrict the types of components that can be used in certain applications.

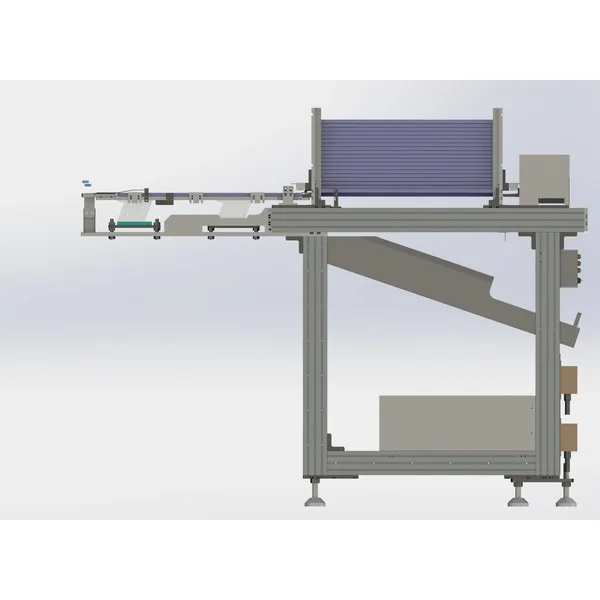

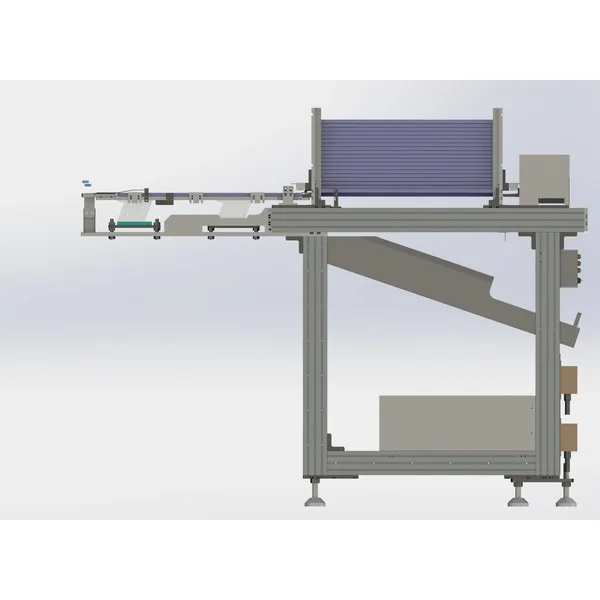

2. Tray Feeders

Tray feeders are used for components that are too large or irregularly shaped to be placed in tape. These feeders hold components in trays, allowing for easy access by the pick-and-place machine. Tray feeders are often used for larger components such as integrated circuits (ICs) and connectors. The design of tray feeders facilitates the handling of delicate components, ensuring they remain intact during the feeding process.

Advantages:

- Accommodates larger and irregularly shaped components, providing flexibility in component selection.

- Reduces the risk of component damage, which is particularly important for sensitive electronic parts that may be easily broken.

Disadvantages:

- Slower than tape feeders, which can impact overall production speed if not managed properly.

- Requires more space on the production line, which may be a consideration for manufacturers with limited floor space.

3. Stick Feeders

Stick feeders are designed for bulk components that are loaded into a stick or tube. These feeders use a vibrating mechanism to align and feed components to the pick-and-place machine. Stick feeders are particularly useful for small components that are not suitable for tape or tray packaging. Their design allows for efficient handling of components that are often used in lower-volume production runs.

Advantages:

- Cost-effective for bulk components, making them an economical choice for manufacturers.

- Flexible in handling various component types, allowing for quick adjustments to accommodate different production needs.

Disadvantages:

- May require more frequent reloading, which can lead to increased downtime if not managed effectively.

- Can be less precise than tape feeders, potentially affecting placement accuracy if not calibrated properly.

4. Tube Feeders

Tube feeders are similar to stick feeders but are specifically designed for cylindrical components. They use a gravity-fed system to deliver components to the pick-and-place machine. Tube feeders are often used for components like resistors and capacitors, which are commonly found in many electronic devices. Their design ensures that components are fed smoothly and consistently, minimizing the risk of jams.

Advantages:

- Efficient for cylindrical components, allowing for quick and easy feeding without the need for complex mechanisms.

- Simple design with low maintenance requirements, making them a reliable choice for manufacturers.

Disadvantages:

- Limited to specific component shapes, which may restrict their use in diverse manufacturing environments.

- Slower than other feeder types, which can impact production speed if not balanced with other feeder types.

Impact of SMT Feeders on Manufacturing Processes

The choice of SMT feeder can have a profound impact on various aspects of the manufacturing process, including:

1. Production Speed

The speed at which components are fed to the pick-and-place machine directly affects the overall production speed. Tape feeders, for example, are designed for high-speed operation, allowing manufacturers to achieve faster cycle times. In contrast, tray and stick feeders may slow down the process due to their loading mechanisms. This difference in speed can be critical in high-demand environments where time-to-market is a key competitive factor.

2. Component Placement Accuracy

Accurate component placement is crucial for the functionality of the final product. SMT feeders that provide consistent and reliable feeding mechanisms, such as tape feeders, enhance placement accuracy. Inaccurate feeding can lead to misalignment, which may result in defects and increased rework. The precision of the feeder directly correlates with the quality of the final assembly, making it essential for manufacturers to invest in high-quality feeders.

3. Flexibility and Adaptability

Manufacturers often need to switch between different types of components. Feeders that can accommodate a variety of packaging formats, such as tape feeders, offer greater flexibility. This adaptability allows manufacturers to respond quickly to changing production demands without significant downtime. The ability to easily switch between feeder types can also facilitate the introduction of new products, enhancing a manufacturer's ability to innovate.

4. Cost Efficiency

The choice of feeder can also impact production costs. High-speed tape feeders may have a higher initial investment but can lead to lower operational costs due to their efficiency. Conversely, using less efficient feeders may result in higher labor costs and increased material waste. Manufacturers must carefully analyze the total cost of ownership for each feeder type, considering both initial costs and long-term operational efficiencies.

5. Maintenance and Reliability

The reliability of SMT feeders is essential for maintaining production flow. Feeders that require frequent maintenance or are prone to jams can disrupt the manufacturing process. Choosing high-quality feeders from reputable SMT feeder manufacturers can minimize these issues and ensure smoother operations. Regular maintenance schedules and proper training for operators can further enhance the reliability of the feeding systems.

Choosing the Right SMT Feeder

When selecting an SMT feeder, manufacturers should consider several factors:

- Component Type: The packaging and size of the components will dictate the type of feeder required. Understanding the specific needs of the components being used is crucial for selecting the appropriate feeder.

- Production Volume: High-volume production may benefit from high-speed tape feeders, while low-volume runs might be better suited for tray or stick feeders. Manufacturers should assess their production needs to determine the best fit.

- Budget: Initial costs versus long-term operational costs should be evaluated to determine the most cost-effective solution. A thorough cost-benefit analysis can help in making informed decisions.

- Space Constraints: The physical layout of the production line may limit the types of feeders that can be used. Manufacturers should consider their available space and how different feeders will fit into their existing workflows.

Conclusion

In conclusion, the type of SMT feeder chosen can significantly impact the efficiency, accuracy, and cost-effectiveness of the manufacturing process. By understanding the different types of feeders available and their respective advantages and disadvantages, manufacturers can make informed decisions that enhance their production capabilities. Investing in high-quality SMT feeders from reputable manufacturers can lead to improved operational efficiency and product quality. As the electronics industry continues to evolve, staying informed about advancements in feeder technology will be essential for maintaining a competitive edge.

Frequently Asked Questions

1. What is the primary function of an SMT feeder?

- The primary function of an SMT feeder is to supply electronic components to pick-and-place machines for accurate placement on printed circuit boards.

2. What are the main types of SMT feeders?

- The main types of SMT feeders include tape feeders, tray feeders, stick feeders, and tube feeders.

3. How does the choice of feeder affect production speed?

- The choice of feeder affects production speed by determining how quickly components can be fed to the pick-and-place machine. Tape feeders are generally faster than tray or stick feeders.

4. What factors should be considered when selecting an SMT feeder?

- Factors to consider include component type, production volume, budget, and space constraints.

5. Why is component placement accuracy important in SMT manufacturing?

- Component placement accuracy is crucial for ensuring the functionality of the final product and minimizing defects that can lead to costly rework.