Content Menu

● The Importance of SMT Accessories in PCB Production

● Key SMT Accessories and Their Impact on PCB Quality

>> Solder Paste Printing Equipment

>> Pick-and-Place Machines

>> Reflow Ovens

● Advanced SMT Accessories for Enhanced Quality Control

>> Automated Optical Inspection (AOI) Systems

>> X-ray Inspection Systems

>> Conformal Coating Equipment

● Impact of SMT Accessories on Production Efficiency

>> Automated Material Handling Systems

>> Intelligent Feeder Systems

>> Software Integration and Data Analytics

● Customization and Flexibility in SMT Accessories

>> Modular Production Line Configurations

>> Specialized Tooling for Unique Components

● Quality Assurance Through Process Control

>> Statistical Process Control (SPC) Integration

>> Traceability and Documentation

● Environmental Considerations and Quality

>> Energy-Efficient Equipment

>> Low-Waste Solutions

● Training and Operator Expertise

>> Operator Training Programs

>> Remote Support and Diagnostics

● Conclusion

● Frequently Asked Questions

>> 1. How do OEM SMT accessories differ from generic alternatives?

>> 2. What are the most critical SMT accessories for ensuring PCB quality?

>> 3. How often should SMT accessories be upgraded to maintain production quality?

>> 4. Can SMT accessories compensate for poor PCB design?

>> 5. How do environmental factors affect the performance of SMT accessories?

● Citations:

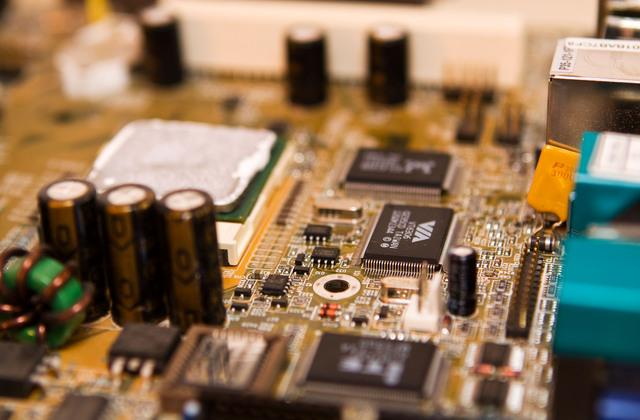

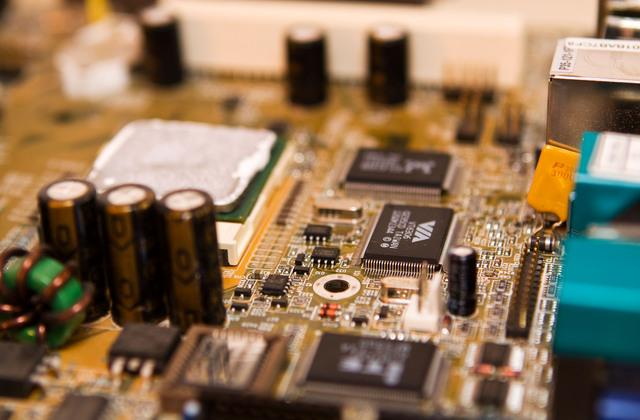

Surface Mount Technology (SMT) has revolutionized the electronics manufacturing industry, enabling the production of smaller, more complex, and highly efficient printed circuit boards (PCBs). The quality of PCB production in SMT lines is significantly influenced by the various accessories and equipment used throughout the process. This article explores how different SMT accessories impact the quality of PCB production, with a focus on OEM SMT accessories for PCB production lines.

The Importance of SMT Accessories in PCB Production

SMT accessories play a crucial role in ensuring the efficiency, accuracy, and reliability of the PCB assembly process. These accessories range from simple tools to sophisticated machinery, each contributing to the overall quality of the final product. OEM SMT accessories for PCB production lines are particularly important as they are designed to meet specific manufacturing requirements and standards.

Key SMT Accessories and Their Impact on PCB Quality

Solder Paste Printing Equipment

Solder paste printing is one of the first and most critical steps in the SMT process. The quality of solder paste deposition directly affects the reliability of solder joints and, consequently, the overall PCB quality.

Stencil Printers: High-precision stencil printers ensure accurate solder paste deposition. OEM stencil printers equipped with advanced features such as automatic alignment and pressure control systems contribute to consistent solder paste application, reducing defects like solder bridging or insufficient solder[1].

Solder Paste Inspection (SPI) Systems: SPI systems are essential for verifying the quality of solder paste printing. These systems detect issues such as insufficient paste volume, misalignment, or bridging before component placement, allowing for immediate corrections and preventing downstream defects[5].

Pick-and-Place Machines

Pick-and-place machines are the workhorses of SMT assembly lines, responsible for accurately placing components onto the PCB.

High-Speed Placement Machines: Modern high-speed placement machines can handle a wide range of component sizes and types. OEM machines with advanced vision systems and precise placement mechanisms ensure accurate component positioning, reducing the risk of misalignments or tombstoning[2].

Nozzle Sets: A comprehensive set of nozzles is crucial for handling various component sizes and shapes. OEM nozzle sets designed for specific component types improve placement accuracy and reduce the risk of component damage during handling[2].

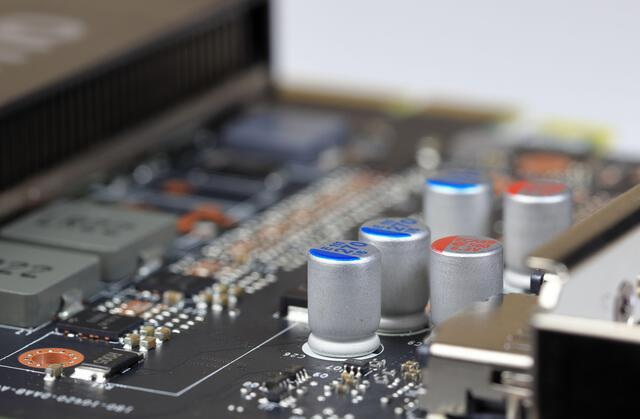

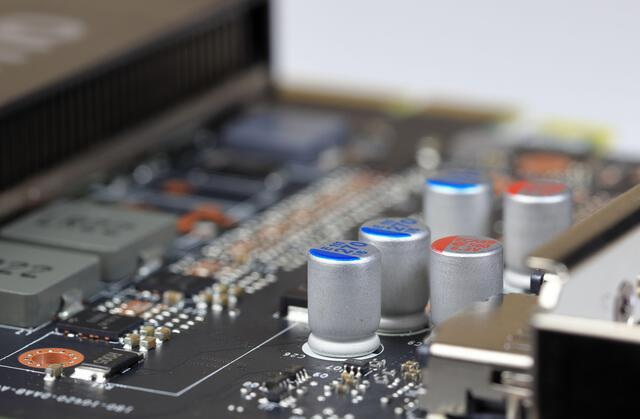

Reflow Ovens

The reflow process is critical for forming reliable solder joints. The quality of the reflow oven significantly impacts the final PCB quality.

Multi-Zone Reflow Ovens: OEM reflow ovens with multiple heating zones allow for precise temperature control throughout the soldering process. This ensures proper solder melting and cooling, resulting in strong and reliable solder joints[4].

Thermal Profiling Systems: Integrated thermal profiling systems help maintain consistent temperature profiles across different PCB designs. This consistency is crucial for achieving uniform solder joint quality across all components[4].

Advanced SMT Accessories for Enhanced Quality Control

Automated Optical Inspection (AOI) Systems

AOI systems are essential for detecting visual defects in assembled PCBs. Advanced OEM AOI systems equipped with high-resolution cameras and sophisticated algorithms can identify a wide range of defects, including:

- Misaligned components

- Solder bridging

- Missing components

- Polarity issues

By implementing AOI systems at various stages of the production line, manufacturers can catch and correct defects early, significantly improving overall PCB quality[3].

X-ray Inspection Systems

X-ray inspection is particularly valuable for inspecting hidden solder joints, such as those found in Ball Grid Array (BGA) components. OEM X-ray systems with advanced imaging capabilities allow for:

- Detection of voids in solder joints

- Inspection of internal connections in multi-layer PCBs

- Identification of hidden defects that may lead to field failures

Incorporating X-ray inspection into the quality control process ensures that even the most complex PCB assemblies meet high-quality standards[4].

Conformal Coating Equipment

For PCBs destined for harsh environments, conformal coating provides an additional layer of protection. OEM conformal coating equipment, including spray systems and UV curing units, ensures:

- Uniform coating application

- Proper curing and adhesion

- Protection against moisture, dust, and chemical contaminants

High-quality conformal coating significantly enhances the reliability and longevity of PCBs in challenging operating conditions[4].

Impact of SMT Accessories on Production Efficiency

While quality is paramount, the efficiency of the production line also plays a crucial role in overall PCB manufacturing. OEM SMT accessories contribute to improved efficiency in several ways:

Automated Material Handling Systems

Automated material handling systems, such as conveyor belts and board loaders/unloaders, streamline the movement of PCBs through the production line. These systems reduce human error, minimize handling damage, and increase throughput, all of which contribute to higher quality and consistency in PCB production[2].

Intelligent Feeder Systems

Advanced feeder systems with smart recognition capabilities ensure that the correct components are loaded and available for pick-and-place machines. This reduces setup times, minimizes component mix-ups, and improves overall production efficiency[2].

Software Integration and Data Analytics

Modern OEM SMT accessories often come with integrated software that allows for:

- Real-time monitoring of production parameters

- Data collection and analysis for process optimization

- Predictive maintenance to reduce downtime

These software solutions contribute to continuous improvement in PCB quality by identifying trends, predicting potential issues, and suggesting process optimizations[3].

Customization and Flexibility in SMT Accessories

The ability to customize and adapt SMT accessories to specific production requirements is crucial for maintaining high-quality standards across diverse PCB designs.

Modular Production Line Configurations

OEM SMT accessories designed with modularity in mind allow manufacturers to:

- Easily reconfigure production lines for different PCB types

- Scale production capacity as needed

- Integrate new technologies without overhauling the entire line

This flexibility ensures that the production line can maintain high-quality standards even as product requirements evolve[5].

Specialized Tooling for Unique Components

As PCB designs become more complex, they often incorporate unique or non-standard components. OEM SMT accessory providers offer specialized tooling solutions, such as:

- Custom nozzles for odd-shaped components

- Specialized stencils for unusual solder paste requirements

- Adapters for handling delicate or sensitive components

These specialized tools ensure that even the most challenging components can be handled with precision, maintaining overall PCB quality[1].

Quality Assurance Through Process Control

The impact of SMT accessories on PCB quality extends beyond the physical assembly process. Many OEM accessories incorporate advanced process control features that contribute to consistent quality.

Statistical Process Control (SPC) Integration

SMT accessories equipped with SPC capabilities allow manufacturers to:

- Monitor key process parameters in real-time

- Identify trends and deviations before they lead to defects

- Implement corrective actions proactively

By leveraging SPC data from various SMT accessories, manufacturers can maintain tight control over the entire production process, ensuring consistent PCB quality[3].

Traceability and Documentation

Advanced OEM SMT accessories often include features for comprehensive traceability, such as:

- Component-level tracking through the production process

- Detailed logs of machine settings and process parameters

- Integration with Manufacturing Execution Systems (MES)

This level of traceability not only aids in quality control but also facilitates root cause analysis in the event of any quality issues, leading to continuous improvement in PCB production[4].

Environmental Considerations and Quality

The environmental impact of PCB production is an increasingly important consideration, and many OEM SMT accessories are designed with sustainability in mind.

Energy-Efficient Equipment

Modern SMT accessories are often designed for improved energy efficiency, which not only reduces operational costs but also contributes to more stable production conditions. For example:

- Reflow ovens with advanced insulation and heat recovery systems

- Pick-and-place machines with energy-saving modes during idle periods

- LED-based inspection systems that consume less power and generate less heat

These energy-efficient designs help maintain consistent production environments, which is crucial for maintaining PCB quality, especially in temperature-sensitive processes[5].

Low-Waste Solutions

OEM SMT accessories that minimize material waste contribute to both environmental sustainability and production quality. Examples include:

- Precision dispensing systems that reduce solder paste waste

- Component feeders designed to minimize component loss

- Automated cleaning systems that optimize the use of cleaning agents

By reducing waste, these accessories not only improve the environmental footprint of PCB production but also ensure that materials are used efficiently, contributing to consistent quality[2].

Training and Operator Expertise

While the quality of SMT accessories is crucial, the expertise of the operators using them is equally important. OEM SMT accessory providers often offer comprehensive training programs and support to ensure that equipment is used optimally.

Operator Training Programs

Effective training programs cover:

- Proper setup and operation of SMT accessories

- Troubleshooting common issues

- Best practices for maintaining equipment

Well-trained operators can leverage the full capabilities of SMT accessories, ensuring that the equipment contributes maximally to PCB quality[1].

Remote Support and Diagnostics

Many modern OEM SMT accessories come with remote support capabilities, allowing manufacturers to:

- Receive expert assistance in real-time

- Perform remote diagnostics to quickly identify and resolve issues

- Access software updates and performance optimizations

This level of support ensures that SMT accessories continue to perform at their best, maintaining high PCB quality standards over time[3].

Conclusion

The quality of PCB production in SMT lines is intrinsically linked to the performance and capabilities of the SMT accessories used throughout the manufacturing process. OEM SMT accessories for PCB production lines play a crucial role in ensuring high-quality outputs, from precise solder paste application to accurate component placement and thorough inspection.

By investing in advanced SMT accessories, manufacturers can significantly enhance their PCB production quality, reduce defects, and improve overall efficiency. The integration of these accessories with sophisticated software and data analytics further enables continuous process improvement and adaptation to evolving manufacturing challenges.

As PCB designs become increasingly complex and quality standards more stringent, the role of SMT accessories in maintaining and improving production quality will only grow in importance. Manufacturers who prioritize the selection and implementation of high-quality OEM SMT accessories will be well-positioned to meet the demands of modern electronics production, ensuring the reliability and performance of their PCBs in diverse applications.

Frequently Asked Questions

1. How do OEM SMT accessories differ from generic alternatives?

OEM SMT accessories are specifically designed and optimized for particular production lines or equipment, ensuring seamless integration and optimal performance. They often come with specialized features, better quality control, and dedicated support, which can significantly impact the overall quality of PCB production. Generic alternatives may offer cost savings but can lack the precision, reliability, and compatibility needed for high-quality PCB manufacturing.

2. What are the most critical SMT accessories for ensuring PCB quality?

The most critical SMT accessories for PCB quality include high-precision stencil printers, advanced pick-and-place machines, reliable reflow ovens, and sophisticated inspection systems (AOI and X-ray). These accessories directly influence the accuracy of component placement, solder joint quality, and defect detection, which are fundamental to producing high-quality PCBs.

3. How often should SMT accessories be upgraded to maintain production quality?

The frequency of SMT accessory upgrades depends on various factors, including production volume, technological advancements, and changing product requirements. Generally, manufacturers should review their equipment every 3-5 years to assess whether upgrades are necessary. Regular software updates and maintenance can extend the life of existing accessories while maintaining quality standards.

4. Can SMT accessories compensate for poor PCB design?

While advanced SMT accessories can mitigate some issues, they cannot fully compensate for poor PCB design. High-quality accessories can improve manufacturing precision and reduce defects, but fundamental design flaws may still lead to reliability issues or performance problems. It's crucial to prioritize both good PCB design practices and the use of quality SMT accessories for optimal results.

5. How do environmental factors affect the performance of SMT accessories?

Environmental factors such as temperature, humidity, and air quality can significantly impact the performance of SMT accessories and, consequently, PCB quality. For example, fluctuations in temperature can affect solder paste viscosity and reflow profiles, while high humidity can lead to component oxidation. Maintaining a controlled production environment and using accessories designed to operate in specific conditions is crucial for consistent PCB quality.

Citations:

[1] https://www.protoexpress.com/blog/good-not-so-good-sides-surface-mount-technology/

[2] https://core-emt.com

[3] https://pmc.ncbi.nlm.nih.gov/articles/PMC9228397/

[4] https://www.raypcb.com/smt-production/

[5] https://www.pcbasic.com/blog/smt_production_line.html

[6] https://www.electronicdesign.com/markets/automation/article/21142075/rush-pcb-how-to-handle-small-components

[7] https://www.linkedin.com/pulse/impact-smt-printing-pcb-assembly-quality-0c0mc

[8] https://www.pcbonline.com/blog/oem-pcb-assembly.html

[9] https://smtnet.com/library/index.cfm?fuseaction=browse_articles&start_at=296

[10] https://blogs.sw.siemens.com/valor-dfm-solutions/how-to-optimize-pcb-design-for-the-smt-assembly-process-flow/