Content Menu

● Understanding SMT PCB Nozzles and Their Role

>> Key Functions of SMT PCB Nozzles

● How Custom SMT PCB Nozzles Enhance Placement Accuracy

>> 1. Tailored Fit for Component Geometry

>> 2. Improved Calibration and Alignment

>> 3. Enhanced Compatibility with PCB Design

>> 4. Flexibility for Diverse Component Types

● Factors Influencing Custom SMT PCB Nozzle Design

>> Component Size and Shape

>> Vacuum Suction Area and Pressure

>> Material and Durability

>> PCB Layout and Component Density

● Best Practices for Using Custom SMT PCB Nozzles

>> Regular Calibration

>> Proper Cleaning

>> Optimized Nozzle Selection

>> PCB Design Optimization

>> Flexible Programming

● Advanced Innovations in Custom SMT PCB Nozzles

>> Adaptive Nozzle Technology

>> 3D Printed Custom Nozzles

>> Anti-Static and Anti-Wear Coatings

● Conclusion

● FAQ

>> 1. What is an SMT PCB nozzle, and why is it important?

>> 2. How does nozzle calibration affect placement accuracy?

>>> 3. Can one nozzle be used for all component types?

>>> 4. How do custom nozzles improve SMT assembly efficiency?

>>> 5. What PCB design considerations affect nozzle selection?

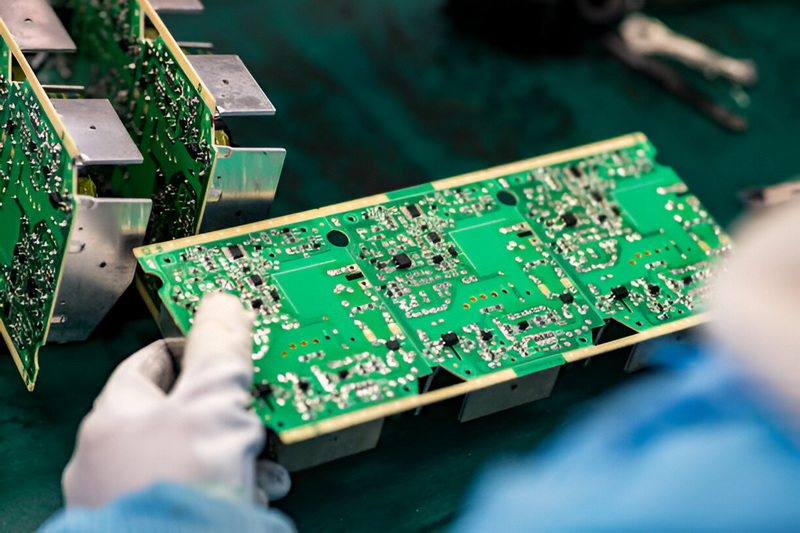

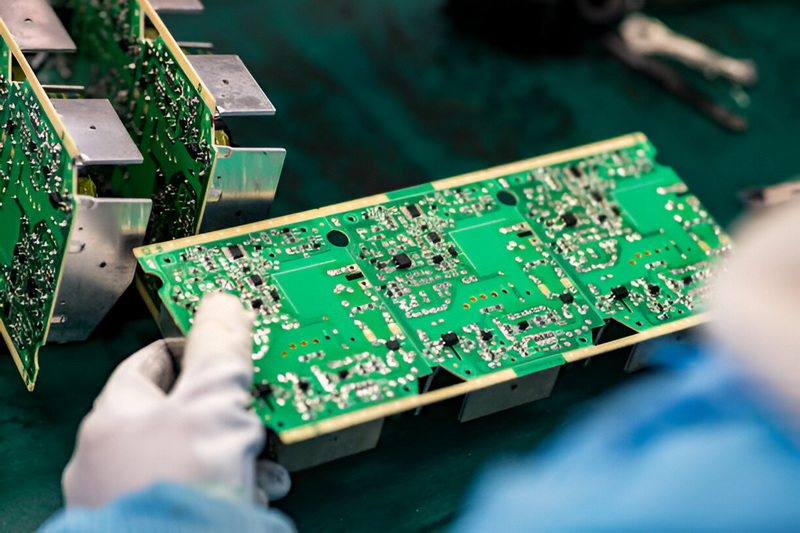

Surface Mount Technology (SMT) has revolutionized electronics manufacturing by enabling the precise and efficient placement of components on printed circuit boards (PCBs). At the heart of this process lies the SMT PCB nozzle, a critical tool that directly influences the accuracy, speed, and quality of component placement. Custom SMT PCB nozzles, tailored to specific component types and PCB designs, play a pivotal role in enhancing placement accuracy, reducing defects, and improving overall manufacturing efficiency.

This article explores how custom SMT PCB nozzles contribute to superior component placement accuracy, the factors influencing nozzle design and selection, and best practices for optimizing SMT assembly processes.

Understanding SMT PCB Nozzles and Their Role

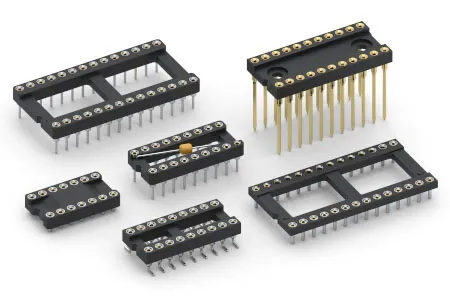

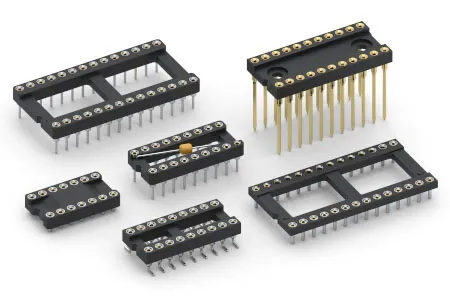

An SMT PCB nozzle is a specialized suction tool attached to the pick-and-place machine's head, responsible for picking up surface mount components from feeders and placing them precisely onto the PCB. The nozzle uses vacuum suction to securely hold components during transfer and placement.

Key Functions of SMT PCB Nozzles

- Component Handling: The nozzle must securely grip components of various sizes and shapes without causing damage.

- Precision Placement: It ensures components are placed at exact locations on the PCB, aligning with solder pads.

- Adaptability: Different nozzles are designed to handle different component types, from tiny 0402 resistors to larger TQFP packages.

The accuracy of the entire SMT assembly process heavily depends on the nozzle's design, calibration, and compatibility with the components and PCB layout.

How Custom SMT PCB Nozzles Enhance Placement Accuracy

1. Tailored Fit for Component Geometry

Custom nozzles are designed to match the exact size, shape, and height of specific components. This tailored fit ensures:

- Secure Suction: The suction area and shape conform to the component profile, preventing slippage or misalignment during pick-up.

- Stable Placement: Symmetrical suction holes and appropriate nozzle length maintain component stability, reducing tilt or rotation errors.

For example, a custom nozzle designed for a 0603 resistor will have suction holes and a diameter optimized to hold the component firmly without damaging it. This precision reduces the risk of component misplacement or dropping during transfer.

2. Improved Calibration and Alignment

Nozzle calibration is critical for precise placement. Custom nozzles allow for:

- Accurate Centering: The nozzle's vacuum center aligns perfectly with the component's center, minimizing offset errors.

- Consistent Rotation Control: Proper calibration ensures the component rotates correctly to the desired orientation before placement.

Calibration routines tailored to custom nozzles maintain high placement accuracy over long production runs, reducing defects and rework. This is especially important for fine-pitch components where even a slight misalignment can cause solder bridging or open circuits.

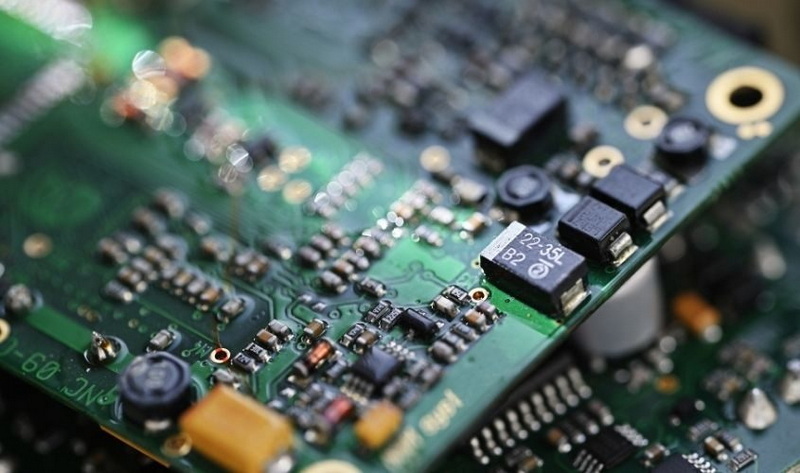

3. Enhanced Compatibility with PCB Design

Custom nozzles consider PCB layout constraints such as component density, height restrictions, and pad sizes. This compatibility allows:

- Efficient Access: Nozzles designed to reach components in tight spaces without interference.

- Optimized Vacuum Pressure: Adjusted suction strength prevents component damage or dropping, especially for delicate or irregularly shaped parts.

For densely populated PCBs, standard nozzles may be too large or bulky, causing collisions or placement errors. Custom nozzles with slim profiles or specialized shapes can navigate these challenges, ensuring components are placed accurately without damaging neighboring parts.

4. Flexibility for Diverse Component Types

Using a set of custom nozzles optimized for different component families (e.g., resistors, capacitors, ICs) improves placement accuracy by:

- Reducing Nozzle Changeover Time: Quick switching between nozzles designed for specific components enhances throughput.

- Minimizing Placement Errors: Each nozzle is optimized for the component it handles, reducing misplacement caused by improper nozzle fit.

For example, a nozzle designed for a QFN package will differ significantly from one designed for a small chip resistor. Having a custom nozzle for each component type ensures the pick-and-place machine can handle a wide variety of parts with maximum precision.

Factors Influencing Custom SMT PCB Nozzle Design

Component Size and Shape

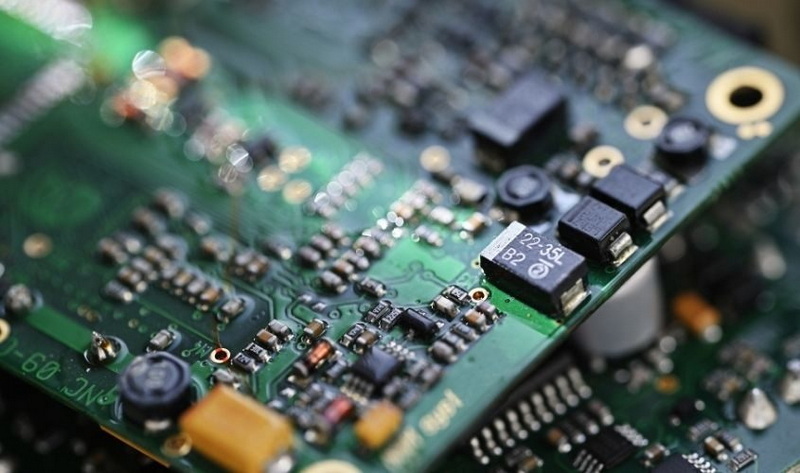

The nozzle must accommodate the component's footprint and height. For example, small components like 0805 resistors require smaller nozzles (e.g., nozzle 503 or 504), while larger components like 1210 resistors or TQFP packages need larger nozzles (e.g., nozzle 506 or 507). The nozzle's diameter, suction hole placement, and length are all tailored to the component's dimensions.

Vacuum Suction Area and Pressure

The suction area must match the component's surface to ensure a firm grip without deformation. Vacuum pressure settings are adjusted based on component weight and fragility to avoid damage or misplacement. For delicate components such as ceramic capacitors or thin ICs, lower vacuum pressure combined with a nozzle designed to distribute suction evenly prevents cracking or chipping.

Material and Durability

Nozzles are made from anti-static, abrasion-resistant materials such as PEEK (polyether ether ketone) or stainless steel to prevent component damage and ensure long service life. The choice of material also affects the nozzle's weight and thermal stability, which can influence placement speed and accuracy.

PCB Layout and Component Density

Custom nozzles are designed considering PCB design factors such as component spacing, height restrictions, and pad sizes to avoid collisions and ensure smooth placement. For example, a PCB with high component density may require nozzles with a slim profile or angled tips to access components without disturbing adjacent parts.

Best Practices for Using Custom SMT PCB Nozzles

Regular Calibration

Perform frequent nozzle calibration to maintain alignment accuracy and compensate for wear or contamination. Calibration involves verifying the nozzle's vacuum center alignment with the component center and adjusting machine parameters accordingly.

Proper Cleaning

Keep nozzles free from dust, solder paste residue, and debris to prevent suction loss and misalignment. Regular cleaning extends nozzle life and maintains consistent placement accuracy.

Optimized Nozzle Selection

Use the right nozzle for each component type to maximize placement precision and efficiency. Avoid using generic nozzles for all components, as this can lead to increased placement errors and component damage.

PCB Design Optimization

Design PCBs with SMT assembly in mind, using proper footprints, adequate spacing, and logical component grouping to facilitate nozzle access and placement accuracy. Collaboration between PCB designers and assembly engineers can significantly improve manufacturability.

Flexible Programming

Optimize pick-and-place machine programming to minimize nozzle changes and passes, improving throughput without sacrificing accuracy. Grouping components by nozzle type and placement sequence reduces machine downtime and enhances efficiency.

Advanced Innovations in Custom SMT PCB Nozzles

Adaptive Nozzle Technology

Some modern SMT machines incorporate adaptive nozzles that can adjust suction pressure and shape dynamically based on component feedback. These nozzles use sensors to detect component size and orientation, automatically optimizing placement parameters in real-time.

3D Printed Custom Nozzles

Additive manufacturing (3D printing) allows rapid prototyping and production of highly customized nozzles tailored to unique component geometries or challenging PCB layouts. This technology reduces lead times and costs associated with traditional nozzle manufacturing.

Anti-Static and Anti-Wear Coatings

Advanced coatings on nozzles reduce static electricity buildup and wear, protecting sensitive components and extending nozzle lifespan. These coatings also improve component release during placement, reducing the risk of misplacement.

Conclusion

Custom SMT PCB nozzles are indispensable for achieving high placement accuracy in modern electronics manufacturing. By tailoring nozzle design to component geometry, ensuring precise calibration, and aligning with PCB layout constraints, custom nozzles significantly reduce placement errors, component damage, and production defects. Their use enhances the efficiency and reliability of SMT assembly lines, ultimately leading to higher quality finished products and cost savings.

Manufacturers who invest in custom SMT PCB nozzles and adhere to best practices in calibration, maintenance, and PCB design optimization will realize substantial improvements in their SMT assembly processes. As SMT technology continues to evolve, innovations such as adaptive nozzles and 3D printed custom tools will further push the boundaries of placement accuracy and manufacturing efficiency.

FAQ

1. What is an SMT PCB nozzle, and why is it important?

An SMT PCB nozzle is a vacuum suction tool used in pick-and-place machines to pick up and place surface mount components on PCBs. It is crucial because it directly affects the accuracy and quality of component placement.

2. How does nozzle calibration affect placement accuracy?

Nozzle calibration ensures the vacuum center aligns with the component center, maintaining precise placement. Poor calibration leads to misalignment, increased defects, and potential component damage.

3. Can one nozzle be used for all component types?

No, different components require nozzles of varying sizes and shapes to ensure secure handling and accurate placement. Using the correct nozzle for each component type improves accuracy and efficiency.

4. How do custom nozzles improve SMT assembly efficiency?

Custom nozzles reduce placement errors, minimize component damage, and allow faster nozzle changes tailored to component types, enhancing throughput and yield.

5. What PCB design considerations affect nozzle selection?

PCB layout factors such as component size, spacing, height restrictions, and pad design influence nozzle choice to ensure nozzles can access components without interference and place them accurately.