Content Menu

● Understanding Surface Mount Technology (SMT)

● The Role of Pick-and-Place Machines

● How Pick-and-Place Machines Work

>> Component Feeding

>> Vision Systems

>> Picking Mechanism

>> Placement on PCB

>> Soldering Process

>> Quality Control

● Advantages of Automated Pick-and-Place Machines

● Challenges and Considerations

● Conclusion

● Related Questions

>> 1. What types of components can be placed using pick-and-place machines?

>> 2. How do pick-and-place machines ensure accuracy in component placement?

>> 3. What is the typical speed of a pick-and-place machine?

>> 4. Are pick-and-place machines suitable for small production runs?

>> 5. What maintenance is required for pick-and-place machines?

Automated pick-and-place machines are essential components in the realm of surface mount technology (SMT), revolutionizing the way electronic components are assembled onto printed circuit boards (PCBs). These machines enhance efficiency, accuracy, and speed in the manufacturing process, making them indispensable in modern electronics production. This article delves into the workings of automated pick-and-place machines, their components, and their significance in surface mount assembly.

Understanding Surface Mount Technology (SMT)

Surface mount technology is a method used to mount electronic components directly onto the surface of PCBs. Unlike traditional through-hole technology, where components are inserted into holes in the PCB, SMT allows for a more compact design and higher component density. This technology has become the standard in the electronics industry due to its numerous advantages, including reduced manufacturing costs, improved performance, and the ability to automate assembly processes.

The Role of Pick-and-Place Machines

Pick-and-place machines are robotic systems designed to automate the placement of surface mount devices (SMDs) onto PCBs. These machines are crucial in SMT assembly lines, where they perform the following functions:

1. Component Handling: They pick components from feeders or trays and place them accurately on the PCB.

2. Precision Placement: Utilizing advanced vision systems, these machines ensure that components are placed in the correct orientation and position.

3. Speed and Efficiency: Automated machines can place thousands of components per hour, significantly faster than manual assembly.

How Pick-and-Place Machines Work

Component Feeding

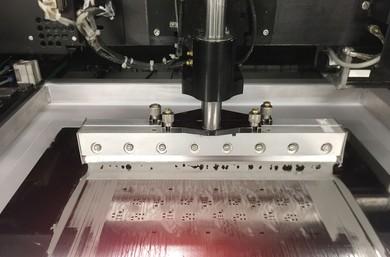

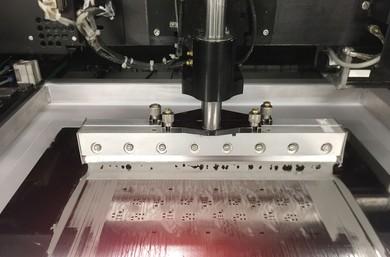

The process begins with the feeding of components into the machine. Components are typically stored in tape-and-reel packaging or trays. The pick-and-place machine is equipped with various feeders that can hold multiple component types, allowing for flexibility in assembly.

Vision Systems

Most modern pick-and-place machines are equipped with high-resolution cameras that scan the components before placement. This vision system verifies the component type, orientation, and position, ensuring that the correct part is picked and placed accurately. This step is crucial for minimizing errors and ensuring high-quality assembly.

Picking Mechanism

Once the component is verified, the machine's robotic arm, equipped with a vacuum nozzle or gripper, picks the component from the feeder. The picking mechanism is designed to handle various component sizes and shapes, from tiny resistors to larger integrated circuits.

Placement on PCB

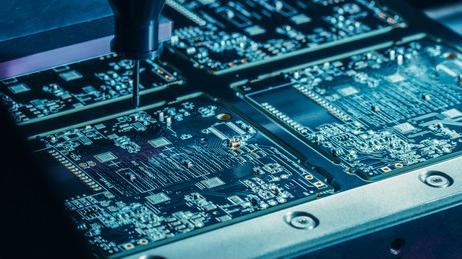

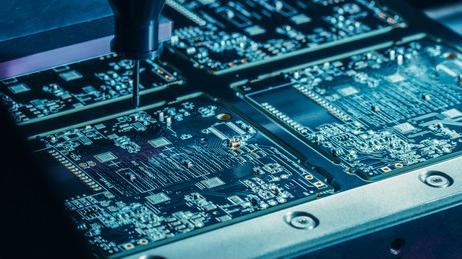

After picking, the machine moves to the PCB's designated placement area. The vision system again comes into play, guiding the robotic arm to place the component precisely on the solder paste applied to the PCB. The accuracy of this placement is vital for ensuring proper electrical connections.

Soldering Process

Once all components are placed, the PCB typically undergoes a soldering process, often using reflow soldering techniques. This involves heating the PCB to melt the solder paste, creating strong electrical connections between the components and the board.

Quality Control

After soldering, the assembled PCB may go through additional quality control checks, including automated optical inspection (AOI) to detect any placement errors or soldering defects. This ensures that only high-quality products proceed to the next stage of production.

Advantages of Automated Pick-and-Place Machines

Automated pick-and-place machines offer several advantages over manual assembly methods:

- Increased Speed: These machines can operate at high speeds, significantly reducing assembly time.

- Enhanced Accuracy: With advanced vision systems, the precision of component placement is greatly improved, reducing the likelihood of errors.

- Cost Efficiency: Automation reduces labor costs and minimizes waste, leading to lower overall production costs.

- Scalability: Automated systems can easily adapt to different production volumes and component types, making them suitable for both small and large-scale manufacturing.

Challenges and Considerations

While automated pick-and-place machines provide numerous benefits, there are challenges to consider:

- Initial Investment: The cost of purchasing and maintaining automated equipment can be high, which may be a barrier for smaller manufacturers.

- Complexity of Setup: Setting up the machines for different products requires expertise and can be time-consuming.

- Maintenance Requirements: Regular maintenance is necessary to ensure optimal performance and longevity of the machines.

Conclusion

Automated pick-and-place machines play a pivotal role in the efficiency and effectiveness of surface mount assembly processes. By automating the placement of electronic components, these machines not only enhance production speed and accuracy but also contribute to the overall quality of electronic products. As technology continues to advance, the capabilities of pick-and-place machines will likely expand, further solidifying their importance in the electronics manufacturing industry.

Related Questions

1. What types of components can be placed using pick-and-place machines?

Pick-and-place machines can handle a wide variety of surface mount devices, including resistors, capacitors, integrated circuits, and connectors, among others.

2. How do pick-and-place machines ensure accuracy in component placement?

These machines utilize advanced vision systems that scan and verify the components before placement, ensuring they are correctly oriented and positioned on the PCB.

3. What is the typical speed of a pick-and-place machine?

The speed can vary depending on the machine's specifications, but many modern machines can place thousands of components per hour, significantly faster than manual assembly.

4. Are pick-and-place machines suitable for small production runs?

Yes, many pick-and-place machines are designed to be flexible and can be programmed for small production runs, making them suitable for prototyping and low-volume manufacturing.

5. What maintenance is required for pick-and-place machines?

Regular maintenance includes cleaning the nozzles, calibrating the vision systems, and checking the mechanical components to ensure optimal performance and prevent breakdowns.