Content Menu

● Introduction to SMT and SMD

>> Advantages of SMT Over Through-Hole Technology

● Optimizing SMT Assembly Process

>> 1. Design for Manufacturability (DFM)

>> 2. Statistical Process Control (SPC)

>> 3. Poka-Yoke (Error-Proofing)

>> 4. Equipment Optimization

>> 5. Balancing Load Distribution

● Advanced Equipment in SMT Assembly

>> Chips Mounting Machines

● Best Practices in SMT Assembly

>> Streamlining the Assembly Process

>> Ensuring Accuracy and Reliability

>> Leveraging Emerging Technologies

>> Future Trends in SMT Assembly

>> Case Studies and Success Stories

● Conclusion

● FAQs

>> 1. What is the primary advantage of using SMT over through-hole technology?

>> 2. How does Design for Manufacturability (DFM) improve SMT assembly quality?

>> 3. What role does Statistical Process Control (SPC) play in optimizing the SMT process?

>> 4. How do chips mounting machines contribute to SMT assembly efficiency?

>> 5. What are some best practices for ensuring accuracy and reliability in SMT assembly?

● Citations:

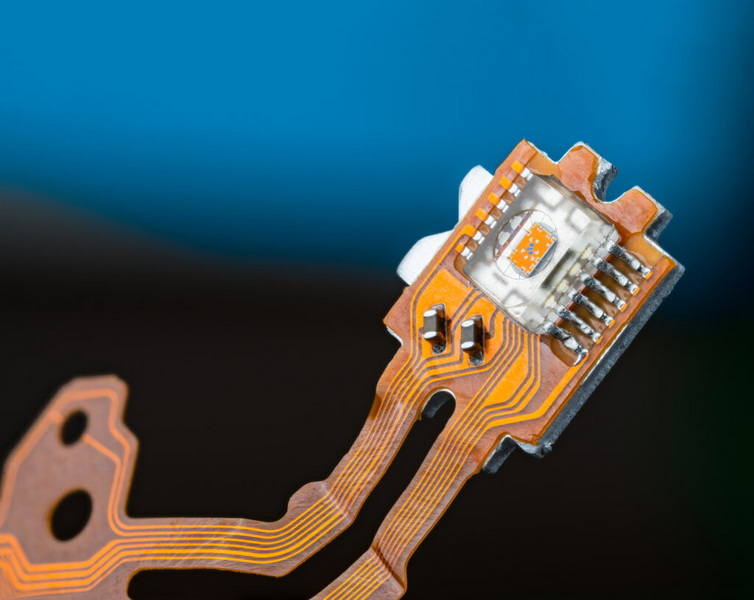

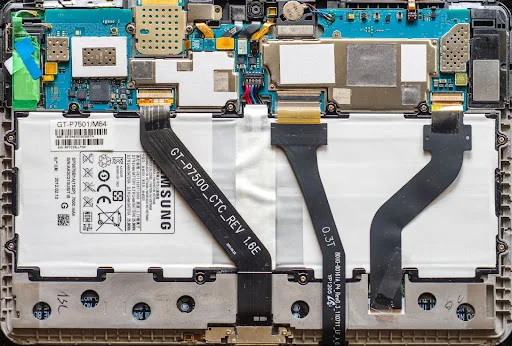

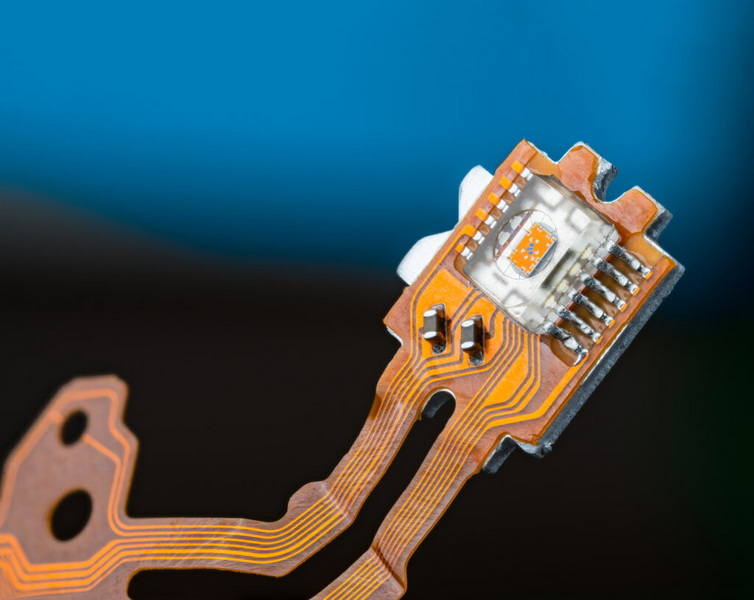

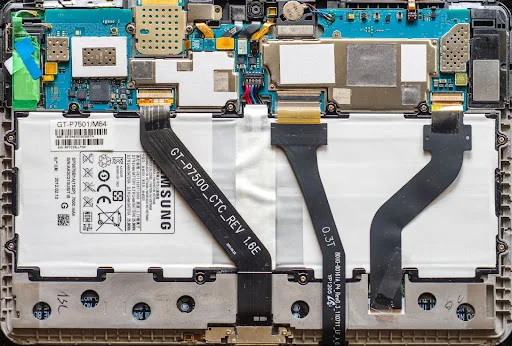

Optimizing the Surface Mount Technology (SMT) assembly process is crucial for enhancing the performance and efficiency of electronic manufacturing. SMT, which involves mounting surface-mount devices (SMDs) directly onto the surface of a printed circuit board (PCB), has become a cornerstone in modern electronics production due to its high component density and automation capabilities. In this article, we will explore various strategies to optimize the SMT assembly process, focusing on the use of advanced equipment like chips mounting machines and the integration of SMD components.

Introduction to SMT and SMD

SMT is a manufacturing method that allows for the placement of SMDs onto PCBs without the need for through-holes. This technology has revolutionized electronics manufacturing by enabling faster, more efficient, and cost-effective production processes. SMDs, being smaller and more compact than their through-hole counterparts, offer better mechanical performance under shock and vibration conditions, improved electromagnetic compatibility (EMC), and reduced lead inductance, which enhances high-frequency performance.

Advantages of SMT Over Through-Hole Technology

- Higher Component Density: SMT allows for more components to be placed on a given area of the PCB, increasing the complexity and functionality of electronic devices.

- Faster Assembly: Automated pick-and-place machines can place thousands of components per hour, significantly speeding up the assembly process.

- Lower Production Costs: The reduced need for drilling holes and the use of smaller components result in lower material and labor costs.

- Improved Performance: SMT components offer better EMC performance and reduced signal interference due to shorter lead lengths.

Optimizing SMT Assembly Process

1. Design for Manufacturability (DFM)

Implementing DFM principles early in the product development cycle can significantly enhance SMT assembly quality. Key considerations include:

- Component Selection and Placement Optimization: Choosing components with standardized footprints and optimizing their placement to minimize signal path lengths and thermal stress.

- Standardization of Pad Layouts: Ensuring consistent pad sizes and shapes to facilitate reliable solder joints.

- Thermal Relief Design: Incorporating thermal vias and heat sinks to manage heat dissipation effectively.

Advanced DFM software tools now enable real-time collaboration between design and manufacturing teams, automatically flagging potential issues like insufficient solder mask clearance or unbalanced copper distribution. This proactive approach reduces late-stage design changes by 40-60%, according to industry benchmarks[1].

2. Statistical Process Control (SPC)

SPC techniques help identify and address process variations before they lead to quality issues. Key tools include:

- Control Charts: Monitoring critical parameters such as temperature profiles in reflow ovens and component placement accuracy.

- Capability Analysis: Assessing process stability to ensure consistent output quality.

- Root Cause Analysis: Identifying and resolving recurring issues to prevent defects.

The implementation of SPC tools has revolutionized yield optimization in PCB assembly. By correlating stencil aperture designs with post-reflow inspection results, engineers can predict solder bridging risks with 98% confidence[1].

3. Poka-Yoke (Error-Proofing)

Implementing error-proofing mechanisms can prevent common assembly mistakes:

- Barcode Scanning: Verifying component identities before placement.

- Automated Optical Alignment: Ensuring precise stencil alignment during solder paste application.

- Sensor-Based Detection: Identifying missing or misaligned components during the assembly process.

4. Equipment Optimization

Optimizing SMT equipment, such as chips mounting machines, is essential for high-throughput and precision:

- Feeder Calibration: Ensuring consistent component feeding to reduce misalignment issues.

- Component Verification: Using camera-based inspection systems to identify incorrect or missing components during placement.

- Reflow Profile Tuning: Adjusting temperature profiles to prevent thermal stress and ensure proper soldering of delicate components.

5. Balancing Load Distribution

Efficiently allocating components across multiple SMT machines can improve production efficiency:

- Equalizing Mounting Times: Ensuring each machine has a balanced workload to maximize throughput.

- Component Grouping: Arranging similar components together to minimize nozzle changes and reduce setup times.

Advanced Equipment in SMT Assembly

Chips Mounting Machines

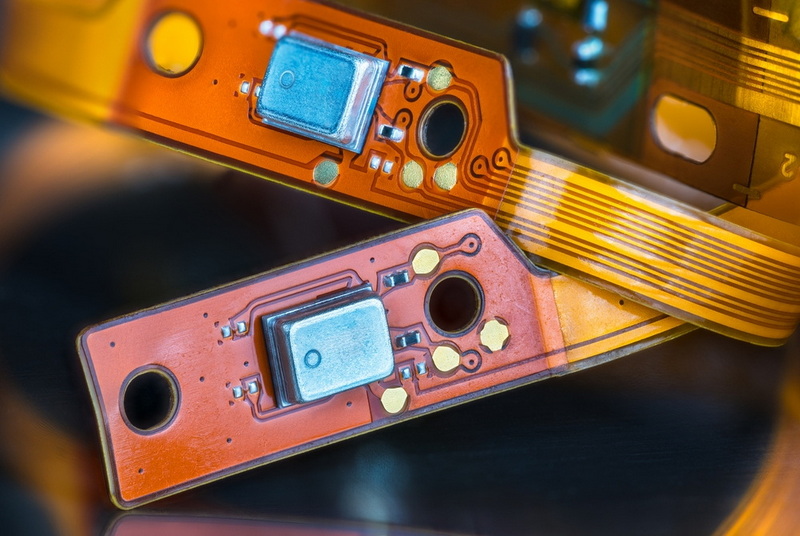

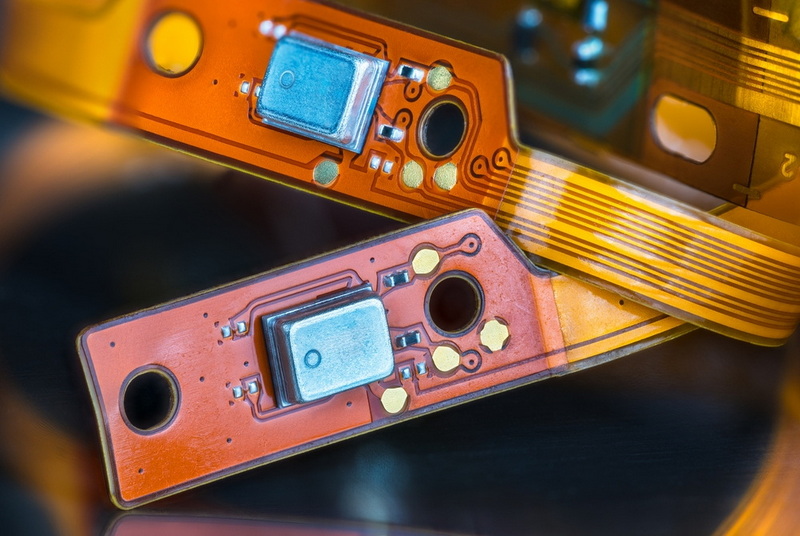

Chips mounting machines, such as LED pick-and-place machines, are designed for high-speed and precision mounting of SMD components. These machines often feature advanced vision systems for accurate component placement and can handle a variety of components, including LEDs, resistors, and capacitors.

- High-Speed Placement: Capable of mounting over 150,000 components per hour, significantly increasing production efficiency.

- Precision Placement: Achieving repeat precision of ±0.02mm, ensuring accurate component positioning.

- Multi-Component Handling: Supporting various component types, making them versatile for different applications.

Best Practices in SMT Assembly

Streamlining the Assembly Process

Streamlining the assembly process involves implementing automated assembly lines and integrating optical inspection systems to detect defects early. Standardizing component packages and sizes can also reduce machine recalibrations and enhance efficiency.

Ensuring Accuracy and Reliability

Ensuring accuracy in component placement is critical. Automated optical inspection (AOI) systems verify component positioning and detect solder defects, ensuring only flawless assemblies proceed to the next stage. Maintaining controlled reflow soldering processes helps prevent issues like overheating or cold solder joints.

Leveraging Emerging Technologies

Emerging technologies such as AI and machine learning are transforming SMT assembly by enhancing defect prediction and process optimization. AI-driven component placement systems optimize nozzle selection and feeder configurations in real time, reducing setup times by up to 40% while maintaining placement accuracy below 15µm[1].

3D automated optical inspection (AOI) systems integrated with spectral analysis capabilities perform volumetric solder joint inspections, detecting voids and heel fillet anomalies even in chip-scale package (CSP) components[1]. Industry 4.0 integration enables real-time equipment monitoring and predictive maintenance, reducing unplanned downtime by 37% in recent industry trials[1].

Future Trends in SMT Assembly

The future of SMT assembly will be shaped by trends such as miniaturization, automation, and the integration of emerging technologies like 3D printing and additive manufacturing. These technologies allow for the creation of complex electronic assemblies with intricate shapes and innovative features, catering to various markets[2][7].

Miniaturization continues to drive the demand for smaller, more powerful devices, necessitating advanced SMT techniques to handle high-density assemblies[7]. The rollout of 5G networks and the expansion of IoT applications further fuel the need for compact and reliable components, making SMT an ideal choice for these applications[7].

Case Studies and Success Stories

Companies like Rauland have seen significant improvements in SMT yield and defect reduction through process optimization. By focusing on the screen printing process and implementing systematic root cause analysis, Rauland reduced SMT-related defects by over 50% and increased throughput by over 20%, resulting in substantial cost savings[6].

GENEDGE's work with an electronic design and manufacturing company demonstrates how optimized line balancing and streamlined processes can lead to faster cycle times, higher output, and reduced costs. By eliminating bottlenecks and unnecessary steps, the company achieved a significant boost in productivity, meeting customer demand more effectively[3].

Conclusion

Optimizing the SMT assembly process is essential for achieving better performance and efficiency in electronic manufacturing. By implementing design for manufacturability principles, statistical process control, and error-proofing mechanisms, manufacturers can significantly enhance product quality. The use of advanced equipment like chips mounting machines further boosts production efficiency and precision. As technology continues to evolve, embracing these strategies will remain crucial for staying competitive in the electronics industry.

FAQs

1. What is the primary advantage of using SMT over through-hole technology?

The primary advantage of SMT is its ability to achieve higher component density and faster automated assembly, which reduces production costs and enhances product performance.

2. How does Design for Manufacturability (DFM) improve SMT assembly quality?

DFM improves SMT assembly quality by optimizing component selection and placement, standardizing pad layouts, and incorporating thermal relief designs, which enhance manufacturability and reduce defects.

3. What role does Statistical Process Control (SPC) play in optimizing the SMT process?

SPC helps identify and address process variations by monitoring critical parameters and assessing process stability, ensuring consistent output quality and reducing defects.

4. How do chips mounting machines contribute to SMT assembly efficiency?

Chips mounting machines contribute to SMT assembly efficiency by offering high-speed and precise component placement, handling a variety of components, and integrating advanced vision systems for accurate alignment.

5. What are some best practices for ensuring accuracy and reliability in SMT assembly?

Best practices include using automated optical inspection systems, maintaining controlled reflow soldering processes, and standardizing component packages to minimize errors and enhance efficiency.

Citations:

[1] https://www.andwinpcb.com/optimizing-smt-board-assembly-for-modern-electronics-manufacturing/

[2] https://emsginc.com/resources/the-evolution-of-surface-mount-technology/

[3] https://genedge.org/impact/genedge-success-stories/electronic-design-and-manufacturing-case-study/

[4] https://dev.to/yoy/pcb-assembly-process-optimization-techniques-for-high-throughput-and-precision-5bd3

[5] https://www.raypcb.com/effective-measures-to-improve-smt-assembly-quality/

[6] https://iconnect007.com/article/109010/improving-smt-yield-and-reducing-defects-a-rauland-case-study/109013/smt

[7] https://www.linkedin.com/pulse/future-surface-mount-technology-smt-industry-key-trends-p-virkhe-zxnyf

[8] https://blogs.sw.siemens.com/valor-dfm-solutions/how-to-optimize-pcb-design-for-the-smt-assembly-process-flow/

[9] https://www.andwinpcb.com/optimizing-pcb-smt-assembly-for-enhanced-efficiency-and-quality/

[10] https://www.andwinpcb.com/advanced-smt-techniques-revolutionizing-pcb-assembly-efficiency/

[11] https://www.linkedin.com/pulse/16-case-studies-improving-soldering-defects-through-optimization-%E6%99%93%E5%8D%8E-%E5%90%B4-sxfrc

[12] https://www.smtfactory.com/Optimizing-Efficiency-Strategies-for-A-Smooth-SMT-Line-Production-Process-id47463586.html

[13] https://www.mycronic.com/product-areas/pcb-assembly/news-and-press-releases/news/ten-key-smt-trends-you-need-to-know/

[14] https://www.prideindustries.com/our-stories/smt-process

[15] https://sfxpcb.com/exploring-advanced-techniques-next-level-pcb-smt-assembly-solutions/

[16] https://novaenginc.com/future-of-circuit-board-assembly/

[17] https://www.andwinpcb.com/advancements-in-smt-assembly-techniques-for-modern-manufacturing/

[18] https://www.pcbcart.com/article/content/measures-to-improve-smt-assembly-quality.html

[19] https://smttoday.com/2024/07/29/smt-component-market-trends-and-win-sources-strategic-responses/

[20] https://www.riverpublishers.com/downloadchapter.php?file=RP_9788770228282C17.pdf