Content Menu

● Introduction to SMT Stencils

>> Advantages of Using SMT Stencils

● Design Considerations for SMT Stencils

>> Aperture Shapes and Sizes

>> Stencil Thickness

>> Stencil Material

● Manufacturing Process with SMT Stencils

>> Steps in Solder Paste Printing

>> Quality Control Measures

● Optimizing PCB Assembly with China SMT Stencils

>> Design for Manufacture and Assembly (DFMA)

>> Automation in Assembly

>> Component Selection

● Challenges and Solutions

>> Common Challenges

>> Solutions

● Advanced Techniques in SMT Stencil Design

>> Step Stencils

>> Framed vs. Frameless Stencils

● Solder Paste Selection

● Stencil Maintenance and Repair

● Role of Automation in SMT Assembly

● Case Studies: Successful PCB Assembly Projects

● Advanced Aperture Design Techniques

● Conclusion

● FAQs

>> 1. What is the primary function of an SMT stencil in PCB assembly?

>> 2. How does the thickness of an SMT stencil affect solder paste deposition?

>> 3. What materials are commonly used for making SMT stencils?

>> 4. How does using an SMT stencil improve PCB assembly efficiency?

>> 5. What are the benefits of using laser-cut SMT stencils?

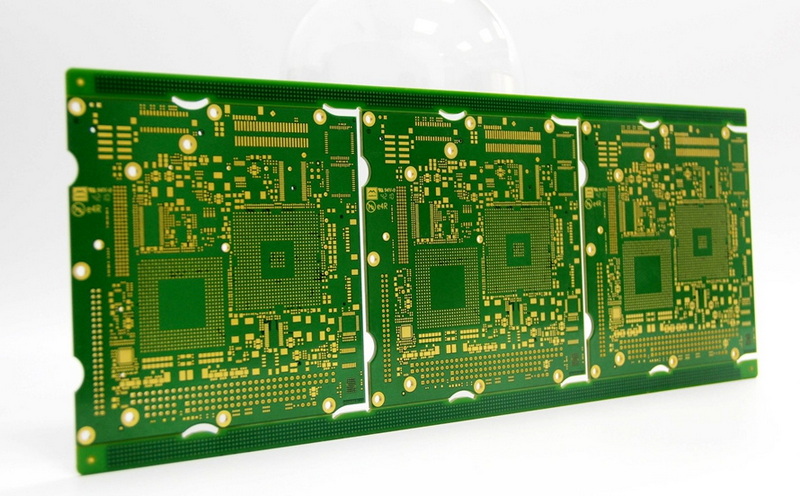

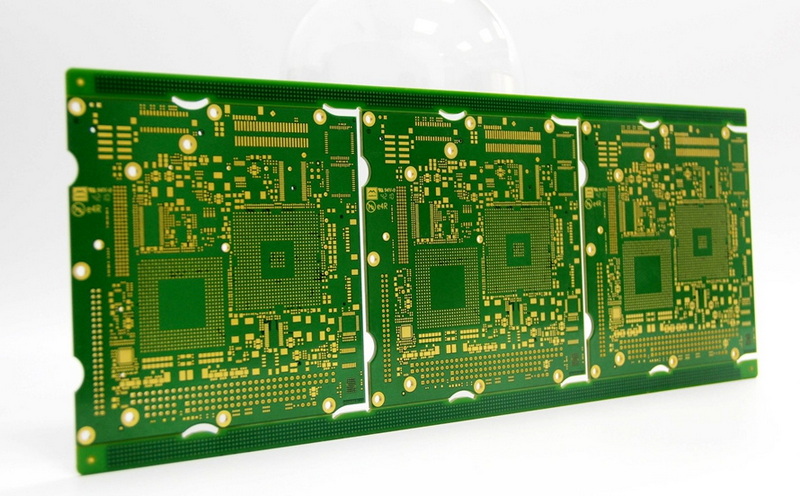

In the realm of electronic manufacturing, Printed Circuit Board (PCB) assembly is a critical process that involves soldering electronic components onto a PCB. One of the most crucial steps in this process is applying solder paste onto the PCB pads and holes before component placement. This is where China SMT stencils play a pivotal role, enabling precise and consistent solder paste deposition. In this article, we will explore how to optimize PCB assembly using China SMT stencils, focusing on design considerations, manufacturing processes, and quality control measures.

Introduction to SMT Stencils

SMT (Surface Mount Technology) stencils are thin metal sheets, typically made of stainless steel, with apertures that match the pads and holes on a PCB. These stencils are used to apply solder paste onto the PCB, ensuring that the right amount of solder is deposited for each component. The use of China SMT stencils in PCB assembly offers several advantages, including increased efficiency, reduced manual errors, and improved product quality.

Advantages of Using SMT Stencils

1. Efficiency and Consistency: SMT stencils automate the solder paste application process, saving time and ensuring consistency across multiple PCBs. This reduces the risk of defects and improves overall product quality.

2. Cost-Effectiveness: Compared to manual soldering methods, China SMT stencils are cost-effective, especially for prototype PCBs, as they eliminate the need for hand soldering and reduce material waste.

3. Precision: The precision of SMT stencils minimizes solder paste bridging, tombstoning, or balling, common issues in manual soldering.

Design Considerations for SMT Stencils

Aperture Shapes and Sizes

The design of the stencil apertures is crucial for achieving accurate solder paste deposition. Apertures should be tailored to match the size and shape of the PCB pads and components. For example, circular apertures are common for most components, while rectangular apertures might be used for specific types of components like capacitors or resistors.

Stencil Thickness

The thickness of the stencil affects the amount of solder paste deposited onto the PCB. Thicker stencils are suitable for components with larger spacings, while thinner stencils are better for components with narrow spacings. Typically, stencils range from 0.05mm to 0.2mm in thickness.

Stencil Material

Stainless steel is the most common material used for SMT stencils due to its durability and affordability. However, nickel alloy stencils are also used for high-density circuit boards where durability is paramount.

Manufacturing Process with SMT Stencils

Steps in Solder Paste Printing

1. Preparation: Ensure the solder paste is at room temperature and the PCB surface is clean and free of debris.

2. Alignment: Align the stencil with the PCB using fiducial marks to ensure accurate placement of solder paste.

3. Solder Paste Application: Apply solder paste to the stencil and use a squeegee to spread it evenly across the stencil apertures.

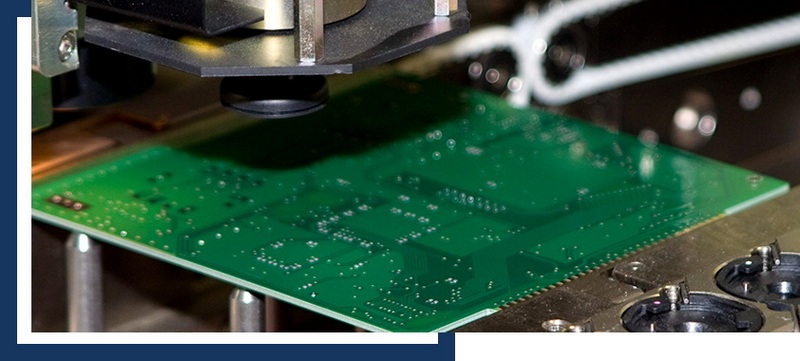

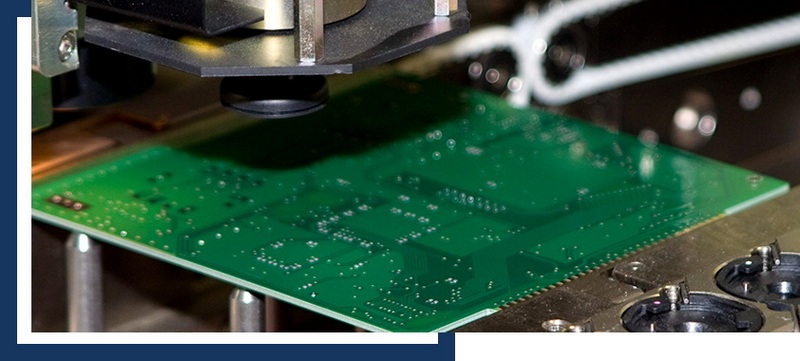

4. Component Placement: Place components onto the PCB pads using pick-and-place machines or manually with tweezers.

Quality Control Measures

- Stencil Cleaning: Regularly clean the stencil to prevent clogging and ensure consistent solder paste deposition.

- Inspection: Conduct optical inspections after component placement to detect any defects or misalignments.

Optimizing PCB Assembly with China SMT Stencils

Design for Manufacture and Assembly (DFMA)

Adopting DFMA principles in PCB design ensures that the board is optimized for SMT assembly. This includes positioning components to facilitate easy placement and minimizing unnecessary components to reduce assembly time and costs.

Automation in Assembly

Using automated pick-and-place machines and soldering equipment can significantly reduce assembly time and improve quality. China SMT stencils are compatible with these automated systems, enhancing production efficiency.

Component Selection

Choosing components that are compatible with SMT assembly and ensuring they are readily available can streamline the assembly process. This includes selecting components with standardized footprints to match the stencil apertures.

Challenges and Solutions

Common Challenges

1. Stencil Clogging: Regular cleaning with alcohol and drying with a hot air gun can prevent clogging.

2. Solder Paste Bridging: Adjusting stencil aperture sizes and using the right solder paste can minimize bridging.

Solutions

1. Use of Laser-Cut Stencils: Laser-cut stencils offer high precision and are cost-effective for both prototype and production PCBs.

2. Material Selection: Choosing the right material for the stencil, such as stainless steel, ensures durability and accuracy.

Advanced Techniques in SMT Stencil Design

Step Stencils

Step stencils are designed with varying aperture sizes to accommodate different component types on the same PCB. This allows for precise solder paste application, reducing waste and improving assembly quality. Additionally, optimizing the stencil's aperture-to-pad ratio is crucial for achieving consistent solder joints.

Framed vs. Frameless Stencils

- Framed Stencils: These are mounted on a frame, providing support and alignment during printing. They are ideal for large or complex PCBs but are more expensive and less flexible.

- Frameless Stencils: These are lighter and more flexible, suitable for smaller PCBs or when storage space is limited. However, they require additional support during printing.

Solder Paste Selection

Choosing the right solder paste is crucial for optimal printing results. Factors to consider include alloy composition, particle size, flux type, and viscosity. The solder paste should be compatible with the stencil material and PCB surface finish to ensure smooth paste transfer and reliable solder joints.

Stencil Maintenance and Repair

Regular maintenance is essential to extend the life of SMT stencils. This includes cleaning the stencil after each use and storing it properly to prevent damage. For damaged stencils, repair options may include re-cutting apertures or replacing the stencil entirely if damage is extensive.

Role of Automation in SMT Assembly

Automation plays a vital role in modern SMT assembly by integrating China SMT stencils with automated pick-and-place machines and soldering equipment. This integration not only speeds up production but also reduces human error, leading to higher quality PCB assemblies. Automated systems can handle complex PCB designs with precision, making them ideal for high-volume production.

Case Studies: Successful PCB Assembly Projects

Including real-world examples of successful PCB assembly projects that utilized China SMT stencils can provide valuable insights into the practical applications and benefits of these stencils. For instance, a case study on a high-density PCB assembly project could highlight how the use of laser-cut stencils improved production efficiency and reduced defects.

Advanced Aperture Design Techniques

Advanced aperture designs can significantly improve solder paste deposition accuracy. Techniques such as reducing aperture sizes for smaller components or using unique aperture shapes for specific components can enhance assembly quality. Additionally, optimizing the stencil's aperture-to-pad ratio is crucial for achieving consistent solder joints.

Conclusion

Optimizing PCB assembly with China SMT stencils involves careful design considerations, efficient manufacturing processes, and rigorous quality control measures. By leveraging the precision and cost-effectiveness of these stencils, manufacturers can enhance production efficiency, reduce defects, and improve the overall quality of PCB assemblies. Whether for prototype or mass production, China SMT stencils are an indispensable tool in modern electronic manufacturing.

FAQs

1. What is the primary function of an SMT stencil in PCB assembly?

- The primary function of an SMT stencil is to apply solder paste precisely onto the PCB pads, ensuring the right amount of solder for each component.

2. How does the thickness of an SMT stencil affect solder paste deposition?

- The thickness of the stencil determines the amount of solder paste deposited. Thicker stencils are used for components with larger spacings, while thinner stencils are better for components with narrow spacings.

3. What materials are commonly used for making SMT stencils?

- The most common materials used for SMT stencils are stainless steel and nickel alloy. Stainless steel is preferred for its affordability and durability.

4. How does using an SMT stencil improve PCB assembly efficiency?

- SMT stencils automate the solder paste application process, reducing manual errors and increasing production speed compared to manual soldering methods.

5. What are the benefits of using laser-cut SMT stencils?

- Laser-cut stencils offer high precision, are cost-effective, and suitable for both prototype and production PCBs. They provide a wide range of styles and are efficient for various component sizes.