Content Menu

● Understanding SMT Stencils and Their Role in PCB Assembly

>> Why SMT Stencils Are Essential

● Optimizing SMT Stencil Design for PCB Assembly

>> Aperture Shapes and Sizes

>> Stencil Thickness

>> Solder Mask Opening (SMO) and Pad Design

>> Stencil Framing and Mounting

● Enhancing the SMT Stencil Printing Process

>> Proper Alignment and Registration

>> Squeegee Pressure and Speed

>> Stencil Cleaning and Maintenance

>> Solder Paste Inspection (SPI)

● Best Practices for Using SMT Stencils in PCB Assembly

● Advanced Techniques in SMT Stencil Optimization

>> Laser Cutting and Electroforming Technologies

>> Step and Multi-Layer Stencils

>> Surface Treatments and Coatings

>> Integration with Automated Assembly Lines

● Common Challenges and How to Overcome Them

● Advantages of Optimizing SMT Stencil Use

● Conclusion

● FAQ

>> 1. What is an SMT stencil, and why is it important for PCB assembly?

>> 2. How do I choose the right thickness for an SMT stencil?

>> 3. What materials are SMT stencils made from?

>> 4. How often should SMT stencils be cleaned?

>> 5. What are the benefits of using automated stencil printing and inspection?

In the realm of modern electronics manufacturing, Surface Mount Technology (SMT) has revolutionized the way printed circuit boards (PCBs) are assembled. Central to this process is the SMT stencil for PCB assembly, a critical tool that ensures precise and consistent application of solder paste onto PCB pads. Optimizing the use of SMT stencils can dramatically enhance assembly quality, efficiency, and cost-effectiveness. This comprehensive article explores how to optimize your PCB assembly process with SMT stencils, covering stencil design, materials, printing techniques, maintenance, and best practices.

Understanding SMT Stencils and Their Role in PCB Assembly

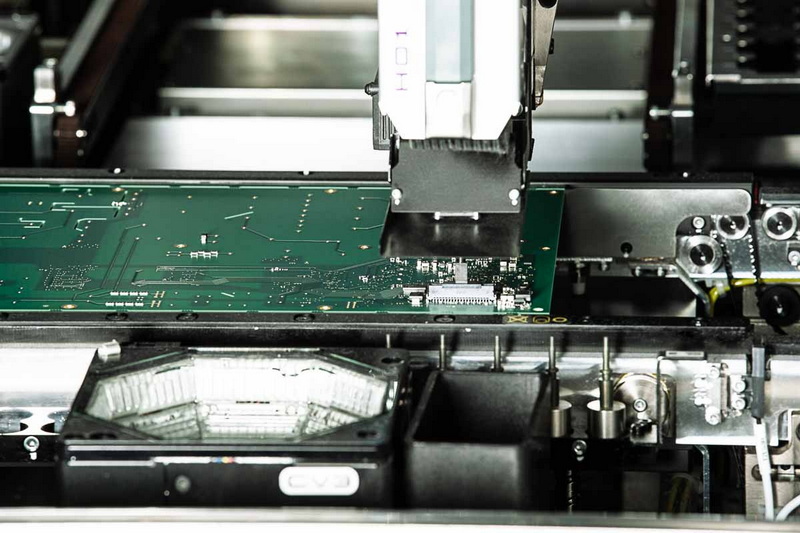

An SMT stencil is a thin metal sheet, typically made from stainless steel or nickel, laser-cut with apertures that correspond exactly to the pads on a PCB where solder paste must be applied. During assembly, the stencil is aligned over the PCB, and solder paste is spread across it, transferring the paste through the apertures onto the PCB pads. This process is essential for the subsequent placement and soldering of surface mount components, ensuring reliable electrical connections and mechanical bonds.

Why SMT Stencils Are Essential

- Precision and Consistency: SMT stencils control the volume and placement of solder paste, preventing defects such as solder bridging, insufficient solder, and tombstoning.

- Efficiency: Automated stencil printing accelerates the solder paste application process, reducing labor and cycle times.

- Cost Reduction: By minimizing solder paste waste and rework, stencils help lower production costs.

- Quality Assurance: Uniform solder paste deposition leads to higher yields and more reliable products.

Optimizing SMT Stencil Design for PCB Assembly

The design of the SMT stencil directly influences the quality of solder paste application. Key design considerations include aperture shape, size, stencil thickness, and alignment features.

Aperture Shapes and Sizes

Apertures in the stencil must match the PCB pad layout precisely. Common aperture shapes include rectangles, circles, and trapezoids, selected based on the pad shape and component type. The size of the aperture controls the volume of solder paste deposited. Adjusting aperture size can compensate for different component requirements, such as larger apertures for components needing more solder and smaller ones for fine-pitch devices.

In addition, advanced aperture designs such as step-down apertures and windowpane apertures have been developed to address specific solder paste volume and release characteristics. For example, step-down apertures reduce solder paste volume for fine-pitch components without compromising print quality, while windowpane apertures improve paste release and reduce bridging.

Stencil Thickness

The thickness of the SMT stencil typically ranges from 0.05mm to 0.2mm. Thicker stencils deposit more solder paste, suitable for larger components, while thinner stencils are used for fine-pitch or densely packed PCBs. When PCBs contain a mix of component sizes and pitches, an intermediate thickness or step stencil (with varying thicknesses in different areas) may be employed to optimize solder paste volume for each area.

Choosing the right stencil thickness is a balancing act. Too thick a stencil can lead to excessive solder paste, causing bridging and tombstoning, while too thin a stencil may result in insufficient solder, leading to weak joints and open circuits.

Solder Mask Opening (SMO) and Pad Design

Optimizing the solder mask opening in the PCB design software helps control solder paste volume and shape. Generally, a 1:1 ratio of aperture size to pad size is used, but adjustments of ±10-20% may be necessary depending on component type and pitch to prevent defects.

For example, for fine-pitch components, reducing the aperture size slightly below the pad size can help prevent solder bridging. Conversely, for larger components or those requiring more solder, increasing the aperture size can ensure adequate paste volume.

Stencil Framing and Mounting

SMT stencils come in framed, frameless, and prototype types. Framed stencils provide stability and are preferred for high-volume production, while frameless stencils offer flexibility and cost savings for prototyping and small runs. Proper mounting and tensioning of the stencil are essential to maintain alignment and print quality during the solder paste application process.

The choice between framed and frameless stencils also depends on the printing equipment used. Some printers require framed stencils for compatibility, while others can accommodate frameless or even flexible stencils.

Enhancing the SMT Stencil Printing Process

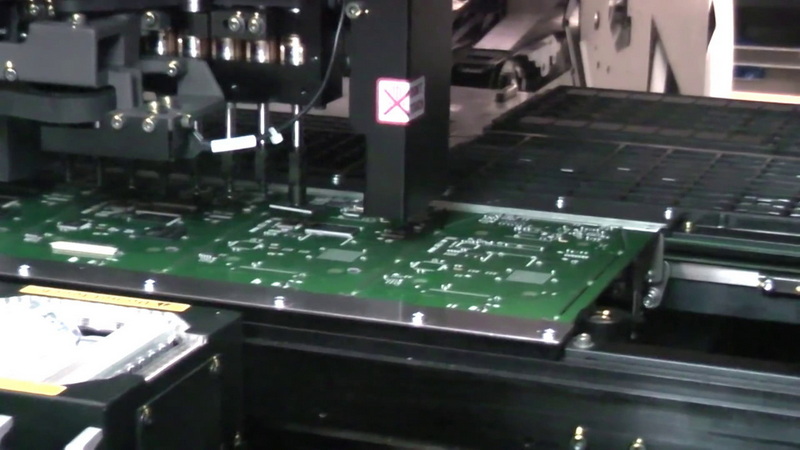

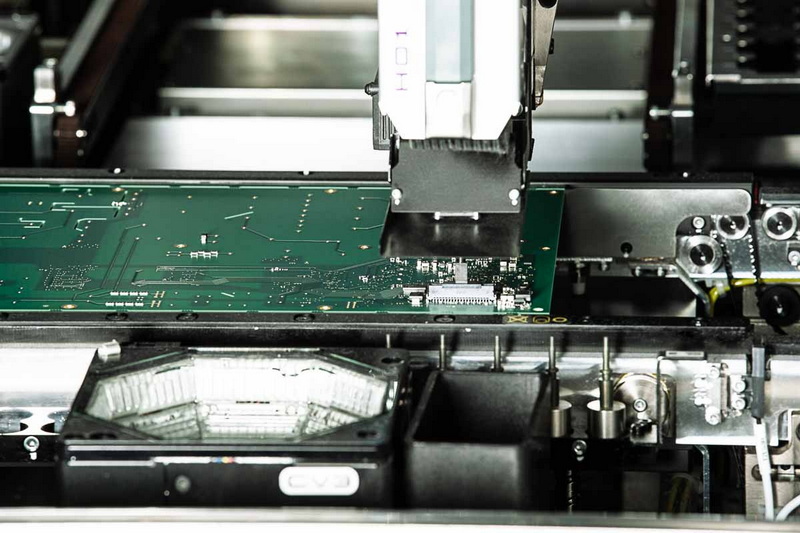

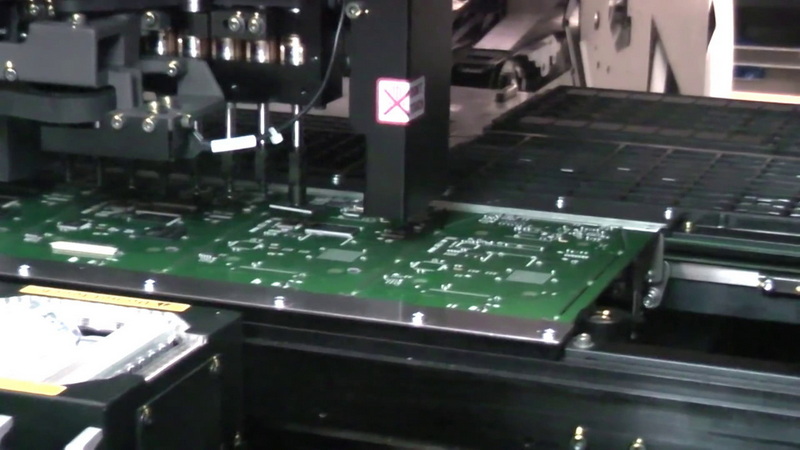

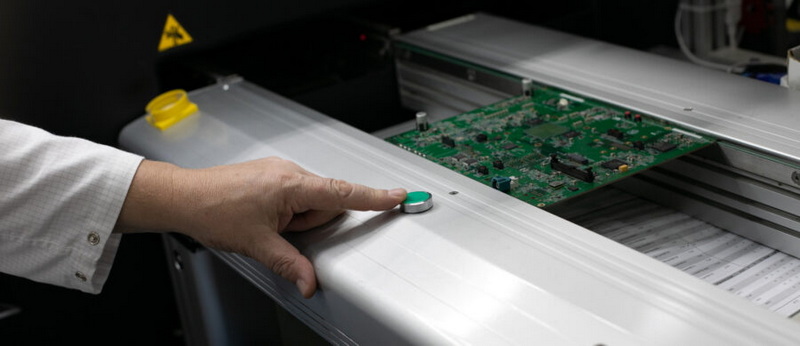

The stencil printing process is a critical step in PCB assembly, where solder paste is transferred from the stencil to the PCB pads. Optimizing this process involves several factors:

Proper Alignment and Registration

Accurate alignment between the stencil apertures and PCB pads is crucial. Misalignment can cause solder paste to miss pads or create bridging. Automated optical alignment systems improve precision and reduce errors.

In addition to automated alignment, using fiducial marks on both the PCB and stencil helps ensure repeatable and precise positioning. Regular calibration of the printing equipment is also necessary to maintain alignment accuracy over time.

Squeegee Pressure and Speed

The squeegee spreads solder paste across the stencil. The pressure and speed must be optimized to ensure consistent paste deposition without smearing or insufficient filling of apertures. Typically, a moderate pressure with a steady, uniform stroke yields the best results.

Too much pressure can cause the solder paste to squeeze out excessively, leading to bridging or smearing, while too little pressure may result in incomplete filling of apertures. The squeegee angle and blade material also influence paste transfer efficiency.

Stencil Cleaning and Maintenance

Solder paste residues accumulate on the stencil during printing, reducing aperture openings and print quality. Regular cleaning-using solvents, ultrasonic baths, or automated cleaning systems-maintains stencil performance and prolongs its life. Cleaning should be performed after each print cycle or batch to prevent defects.

In addition to cleaning, inspecting the stencil for damage such as burrs or stretched apertures is important. Damaged stencils can cause inconsistent solder paste deposition and must be repaired or replaced promptly.

Solder Paste Inspection (SPI)

SPI systems inspect the deposited solder paste for volume, height, and position immediately after printing. This feedback allows for quick adjustments to the stencil printing process, minimizing defects downstream in component placement and reflow soldering.

SPI data can be integrated into process control systems to continuously optimize printing parameters, reducing scrap rates and improving overall assembly quality.

Best Practices for Using SMT Stencils in PCB Assembly

To maximize the benefits of SMT stencils in your PCB assembly process, consider the following best practices:

- Design for Manufacturability: Collaborate with stencil manufacturers and PCB designers to ensure stencil apertures and PCB pads are optimized for your specific components and assembly process.

- Choose the Right Stencil Material: Stainless steel is the most common due to its durability and heat resistance, but nickel stencils offer finer aperture edges for high-precision applications.

- Optimize Stencil Thickness: Match stencil thickness to component pitch and solder paste volume requirements, using step stencils if necessary for mixed component sizes.

- Maintain Stencil Cleanliness: Implement routine cleaning schedules and use proper cleaning methods to prevent paste buildup and aperture clogging.

- Use Automated Printing and Inspection: Employ automated stencil printers and SPI systems to improve repeatability, reduce human error, and increase throughput.

- Regularly Review and Update Stencil Design: As PCB designs evolve, update stencil designs to accommodate new components, pad layouts, and solder paste requirements.

- Control Environmental Conditions: Maintain stable temperature and humidity in the assembly area to ensure consistent solder paste viscosity and printing performance.

- Train Operators Thoroughly: Skilled operators who understand the importance of stencil handling, cleaning, and printing parameters contribute significantly to process optimization.

Advanced Techniques in SMT Stencil Optimization

Beyond the basics, several advanced techniques can further optimize the SMT stencil for PCB assembly:

Laser Cutting and Electroforming Technologies

Modern laser cutting techniques enable extremely precise aperture edges, reducing solder paste smearing and improving release. Electroforming, a process where nickel stencils are built up layer by layer, produces ultra-thin, high-precision stencils ideal for ultra-fine pitch components.

Step and Multi-Layer Stencils

Step stencils feature areas of different thicknesses on the same stencil, allowing for tailored solder paste volumes for components of varying sizes on the same PCB. Multi-layer stencils, with two or more metal layers separated by a spacer, can further refine paste volume control.

Surface Treatments and Coatings

Applying special coatings such as non-stick coatings (e.g., DLC - Diamond-Like Carbon) to the stencil surface improves solder paste release and reduces paste sticking to the stencil, enhancing print quality and reducing cleaning frequency.

Integration with Automated Assembly Lines

Integrating stencil printing with automated pick-and-place machines and reflow ovens allows for synchronized process control and data collection, enabling real-time adjustments and continuous process improvement.

Common Challenges and How to Overcome Them

Despite the advantages, SMT stencil printing can face challenges that affect PCB assembly quality:

- Solder Paste Smearing: Often caused by incorrect squeegee pressure or speed, or stencil damage. Solution: Optimize printing parameters and maintain stencil condition.

- Aperture Clogging: Caused by dried solder paste or insufficient cleaning. Solution: Increase cleaning frequency and use appropriate cleaning methods.

- Misalignment: Due to poor fixture or printer calibration. Solution: Use automated alignment systems and regularly calibrate equipment.

- Inconsistent Paste Volume: May result from incorrect stencil thickness or aperture design. Solution: Review and adjust stencil design and materials.

- Stencil Damage: Burrs or stretched apertures degrade print quality. Solution: Inspect stencils regularly and replace damaged ones promptly.

By proactively addressing these issues, manufacturers can maintain high-quality SMT stencil printing and PCB assembly.

Advantages of Optimizing SMT Stencil Use

Optimizing the SMT stencil for PCB assembly yields numerous advantages:

- Improved Solder Joint Quality: Precise solder paste application reduces defects like bridging, insufficient solder, and tombstoning, enhancing reliability.

- Higher Assembly Efficiency: Faster solder paste application and reduced rework accelerate production cycles and increase throughput.

- Cost Savings: Reduced solder paste waste, fewer defects, and lower labor costs improve overall profitability.

- Support for Advanced PCB Designs: Optimized stencils enable assembly of fine-pitch, high-density, and complex PCBs required in modern electronics.

- Enhanced Product Reliability: Consistent solder joints contribute to long-term product durability and customer satisfaction.

Conclusion

Optimizing your PCB assembly process with SMT stencils is pivotal to achieving high-quality, efficient, and cost-effective electronics manufacturing. By carefully designing stencil apertures, selecting appropriate stencil thickness and materials, maintaining stencil cleanliness, and employing automated printing and inspection technologies, manufacturers can ensure precise solder paste application and superior solder joint quality. This optimization not only improves assembly yields and reduces costs but also supports the production of advanced, high-density PCBs critical for modern electronic devices. Embracing best practices in SMT stencil use is a strategic investment that pays dividends in product performance and manufacturing excellence.

FAQ

1. What is an SMT stencil, and why is it important for PCB assembly?

An SMT stencil is a thin metal sheet with laser-cut apertures matching PCB pad layouts. It is essential for accurately applying solder paste to PCB pads, ensuring reliable solder joints and high-quality assembly.

2. How do I choose the right thickness for an SMT stencil?

Stencil thickness depends on component size, pitch, and solder paste volume requirements. Thinner stencils (0.05-0.1mm) suit fine-pitch components, while thicker stencils (up to 0.2mm) are used for larger components. Step stencils can combine thicknesses for mixed designs.

3. What materials are SMT stencils made from?

Common materials include stainless steel and nickel. Stainless steel is durable and heat resistant, suitable for most applications. Nickel offers finer aperture edges for high-precision printing.

4. How often should SMT stencils be cleaned?

Stencils should be cleaned after each printing cycle or batch to remove solder paste residues, prevent aperture clogging, and maintain print quality.

5. What are the benefits of using automated stencil printing and inspection?

Automation improves alignment accuracy, print consistency, and throughput while reducing human error. Solder paste inspection (SPI) provides immediate feedback to correct defects early in the process.