Content Menu

● Understanding the Importance of Optimization

● Key Factors in Pick and Place Machine Optimization

>> Machine Selection

>> Feeder Setup Optimization

● Programming and Software Optimization

>> Optimized Placement Programs

>> Advanced Software Features

● Machine Calibration and Maintenance

>> Calibration Procedures

>> Maintenance Routines

● Optimizing for Different Project Types

>> High-Mix, Low-Volume Projects

>> High-Volume, Low-Mix Projects

● Advanced Optimization Techniques

>> Multi-Head Optimization

>> Vision System Enhancements

>> Nozzle Management

● PCB Design Considerations for Optimized Placement

● Continuous Improvement Strategies

● Leveraging Technology Advancements

● Conclusion

● FAQ

>> 1. What is the most critical factor in optimizing a pick and place machine for different projects?

>> 2. How often should a pick and place machine be calibrated for optimal performance?

>> 3. Can software upgrades significantly improve pick and place machine efficiency?

>> 4. What role does PCB design play in optimizing pick and place machine performance?

>> 5. How can manufacturers balance speed and accuracy in pick and place machine optimization?

● Citations:

In the world of electronics manufacturing, the pick and place machine is a crucial component of the surface mount technology (SMT) process. This automated system is responsible for accurately placing electronic components onto printed circuit boards (PCBs), significantly impacting production speed, quality, and overall efficiency. As manufacturers face diverse projects with varying requirements, optimizing the setup of pick and place machines becomes essential for maintaining competitiveness and meeting production goals.

Understanding the Importance of Optimization

Before delving into specific optimization strategies, it's crucial to understand why optimizing a pick and place machine setup is so important. In the fast-paced electronics industry, efficiency and accuracy are paramount. A well-optimized pick and place machine can:

1. Increase production throughput

2. Improve placement accuracy

3. Reduce component waste

4. Minimize downtime during changeovers

5. Enhance overall product quality

These benefits directly translate to cost savings, improved customer satisfaction, and a stronger market position for manufacturers.

Key Factors in Pick and Place Machine Optimization

Machine Selection

The foundation of an optimized setup begins with selecting the right pick and place machine for your specific needs. Consider factors such as:

- Speed and accuracy: Choose a machine that balances speed with the required placement accuracy for your projects[1].

- Flexibility: For manufacturers handling diverse projects, a machine that can accommodate a wide range of component sizes and board dimensions is crucial.

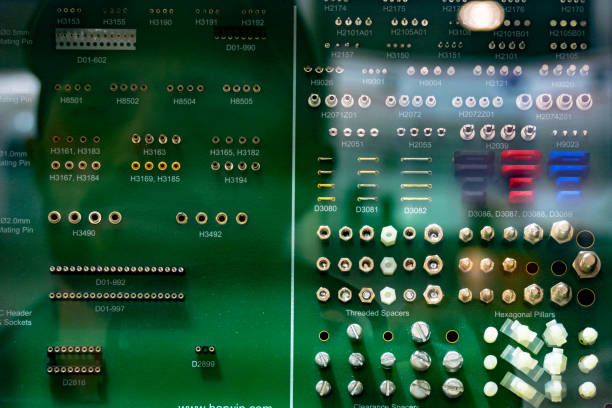

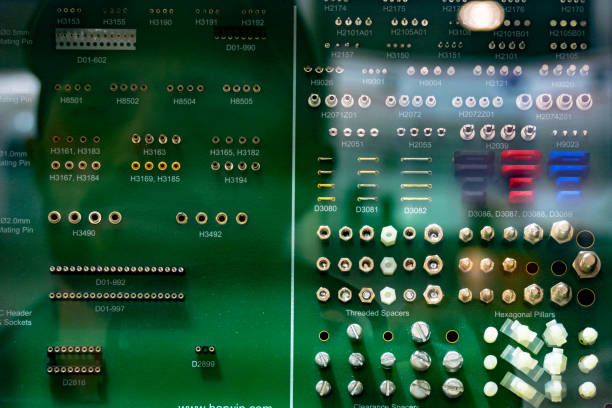

- Feeder capacity: Ensure the machine has sufficient feeder positions to handle the variety of components used in your projects.

- Vision system: Advanced vision systems can significantly improve placement accuracy and component recognition.

Feeder Setup Optimization

The arrangement of component feeders plays a critical role in the efficiency of a pick and place machine. Here are some strategies to optimize feeder setup:

1. Strategic component placement: Arrange feeders to minimize the travel distance of the pick and place head. Place frequently used components closer to the center of the machine[1].

2. Use of intelligent feeders: Implement smart feeders that can communicate with the machine, reducing setup time and minimizing manual errors[5].

3. Implement a double belt feeder system: This can increase the capacity for components and reduce the frequency of refills[5].

4. Utilize high-capacity feeders: For projects with high-volume components, use feeders that can hold more parts, reducing the need for frequent reloading[5].

5. Consider a replaceable trolley system: This allows for offline setup of feeders, minimizing machine downtime during changeovers[5].

Programming and Software Optimization

Efficient programming and software utilization can significantly enhance the performance of pick and place machines:

Optimized Placement Programs

Develop placement programs that:

1. Minimize nozzle changes

2. Reduce the travel distance for picking and placing components

3. Maximize the use of multi-head placement capabilities[5]

Advanced Software Features

Utilize software that offers:

1. Direct optimization of various PCB file formats

2. Offline programming capabilities for multi-project setups

3. Machine fault self-diagnosis systems

4. Intelligent operation systems for improved efficiency[5]

Machine Calibration and Maintenance

Regular calibration and maintenance are crucial for maintaining optimal performance:

Calibration Procedures

1. Bottom camera calibration: Ensure accurate alignment of components[7].

2. Nozzle calibration: Regularly check and adjust nozzle heights for precise component placement[7].

3. XYZ axis calibration: Maintain accurate positioning across the entire working area.

Maintenance Routines

1. Implement a regular cleaning schedule for nozzles, feeders, and vision systems.

2. Perform routine checks on mechanical components to prevent unexpected breakdowns.

3. Update software and firmware regularly to benefit from the latest optimizations.

Optimizing for Different Project Types

High-Mix, Low-Volume Projects

For manufacturers dealing with a variety of small-batch projects:

1. Utilize offline programming: Prepare programs for multiple projects in advance to minimize setup time[5].

2. Implement quick-change tooling: Use systems that allow for rapid changeover between different component types.

3. Optimize component management: Use a well-organized component storage system to quickly locate and load required parts.

High-Volume, Low-Mix Projects

For large-scale production runs:

1. Maximize feeder capacity: Use high-capacity feeders and consider implementing a non-stop refilling system[5].

2. Optimize board handling: Implement dual-track systems to reduce PCB loading and unloading times[5].

3. Fine-tune placement speed: Adjust acceleration and deceleration profiles for maximum throughput without compromising accuracy.

Advanced Optimization Techniques

Multi-Head Optimization

For machines with multiple placement heads:

1. Balance component distribution: Distribute components evenly among placement heads to maximize efficiency.

2. Optimize pick-up sequences: Program the machine to pick up multiple components in a single cycle, reducing overall placement time.

Vision System Enhancements

Improve component recognition and placement accuracy:

1. Implement dual camera systems: Use separate cameras for small chips and large ICs to improve recognition speed[5].

2. Utilize advanced image processing: Implement software that can quickly analyze and adjust for component variations.

Nozzle Management

Optimize nozzle usage for improved efficiency:

1. Implement automatic nozzle changing: Reduce downtime with systems that can quickly switch between different nozzle types.

2. Use multi-function nozzles: Where possible, employ nozzles that can handle a range of component sizes to minimize changes.

PCB Design Considerations for Optimized Placement

Collaborate with PCB designers to implement design-for-manufacturing (DFM) principles:

1. Standardize component orientations: Consistent orientation reduces the need for component rotation during placement.

2. Optimize component spacing: Ensure adequate clearance for efficient placement and to minimize the risk of placement errors.

3. Implement fiducial marks: Use clear, well-placed fiducial marks to improve alignment accuracy.

Continuous Improvement Strategies

To maintain optimal performance over time:

1. Monitor key performance indicators (KPIs): Track metrics such as placement accuracy, cycle time, and first-pass yield.

2. Analyze production data: Use machine-generated data to identify bottlenecks and areas for improvement.

3. Implement operator training programs: Ensure that machine operators are well-versed in optimization techniques and best practices.

Leveraging Technology Advancements

Stay ahead of the curve by incorporating the latest technological advancements:

1. AI-powered optimization: Implement machine learning algorithms that can predict and prevent potential issues.

2. IoT integration: Connect pick and place machines to a broader smart factory ecosystem for improved data analysis and predictive maintenance.

3. Augmented reality (AR) assistance: Use AR tools to aid in setup, maintenance, and troubleshooting procedures.

Conclusion

Optimizing the setup of a pick and place machine for different projects is a multifaceted process that requires attention to various aspects of the SMT assembly line. By focusing on machine selection, feeder setup, programming, maintenance, and project-specific optimizations, manufacturers can significantly enhance their production capabilities. The key to success lies in a holistic approach that considers not only the machine itself but also the broader context of PCB design, factory integration, and continuous improvement strategies.

As the electronics manufacturing industry continues to evolve, staying abreast of technological advancements and consistently refining optimization techniques will be crucial for maintaining a competitive edge. By implementing the strategies outlined in this article, manufacturers can ensure that their pick and place machines are operating at peak efficiency, regardless of the diversity or complexity of their projects.

FAQ

1. What is the most critical factor in optimizing a pick and place machine for different projects?

The most critical factor in optimizing a pick and place machine for different projects is flexibility. This includes the ability to quickly adapt to various component sizes, PCB dimensions, and production volumes. A flexible setup allows manufacturers to efficiently switch between different projects with minimal downtime, ensuring optimal productivity across diverse production runs.

2. How often should a pick and place machine be calibrated for optimal performance?

For optimal performance, a pick and place machine should be calibrated regularly, typically on a weekly or bi-weekly basis, depending on usage intensity. However, more frequent calibrations may be necessary for high-precision projects or after any significant changes to the machine setup. Daily checks of critical components like nozzles and vision systems can help maintain consistent performance between full calibrations.

3. Can software upgrades significantly improve pick and place machine efficiency?

Yes, software upgrades can significantly improve pick and place machine efficiency. Modern software solutions offer advanced features such as intelligent component recognition, optimized placement algorithms, and predictive maintenance capabilities. These upgrades can enhance placement accuracy, reduce cycle times, and minimize downtime, leading to substantial improvements in overall machine efficiency and production quality.

4. What role does PCB design play in optimizing pick and place machine performance?

PCB design plays a crucial role in optimizing pick and place machine performance. A well-designed PCB that follows design-for-manufacturing (DFM) principles can significantly enhance placement efficiency. Key considerations include standardized component orientations, optimal component spacing, and clear fiducial marks. These design elements can reduce placement errors, minimize nozzle changes, and improve overall placement speed and accuracy.

5. How can manufacturers balance speed and accuracy in pick and place machine optimization?

Balancing speed and accuracy in pick and place machine optimization requires a tailored approach based on project requirements. Manufacturers can achieve this balance by:

1. Adjusting acceleration and deceleration profiles for different component types

2. Implementing advanced vision systems for improved component recognition

3. Optimizing feeder arrangements to minimize head travel

4. Using multi-head placement strategies for increased throughput

5. Regularly calibrating and maintaining the machine to ensure consistent performance

The key is to find the optimal settings that maximize speed without compromising the required placement accuracy for each specific project.

Citations:

[1] https://www.linkedin.com/advice/1/how-can-you-optimize-your-pick-and-place-cwdje

[2] https://www.zaxis.net/video-smt-pick-and-place-process/

[3] https://www.restronicsmetro.com/blog/everything-you-need-to-know-about-smt-pick-and-place-machines

[4] https://blog.csdn.net/wuchenxy/article/details/50553641

[5] https://www.tronstol.com/ways-to-improve-the-speed-of-the-pick-and-place-machine.html

[6] https://www.youtube.com/watch?v=9uet6TNtUXI

[7] https://www.smallsmt.biz/home/know-how/faq-feeder-settings/

[8] https://www.cnblogs.com/luohenyueji/p/16990846.html

[9] https://www.tronstol.com/how-to-improve-the-efficiency-of-pick-and-place-ma.html

[10] https://www.tronstol.com/how-to-configure-the-pick-and-place-machine-correctly.html

[11] https://invsmt.com/optimizing/

[12] https://www.ddmnovastar.com/smt-quick-tips-selecting-a-pick-and-place-machine

</p>