Content Menu

● Understanding SMT Stencil Frame Size

>> Key Components of SMT Stencil Size

● Why Optimizing SMT Stencil Frame Size Matters

● Factors to Consider When Optimizing SMT Stencil Frame Size

>> 1. PCB Size and Layout

>> 2. Printing Method and Equipment

>> 3. Component Density and Aperture Design

>> 4. Stencil Thickness and Aperture Aspect Ratio

>> 5. Material and Frame Construction

● Steps to Optimize SMT Stencil Frame Size

>> Step 1: Measure PCB Dimensions Accurately

>> Step 2: Determine Required Margins

>> Step 3: Select Frame Type and Size

>> Step 4: Verify Compatibility with Printing Equipment

>> Step 5: Optimize Aperture Design and Stencil Thickness

>> Step 6: Implement Quality Control and Testing

● Additional Tips for Enhancing SMT Stencil Frame Efficiency

● Common Challenges in SMT Stencil Frame Size Optimization and How to Overcome Them

>> Challenge 1: Frame Warping and Foil Tension Loss

>> Challenge 2: Misalignment Due to Improper Frame Size

>> Challenge 3: Increased Cost from Oversized Frames

>> Challenge 4: Difficulty Handling Frameless Stencils

● Conclusion

● FAQ

>> 1. What is the recommended margin to add to PCB size for framed SMT stencil frame size?

>> 2. How does stencil thickness affect SMT stencil frame size optimization?

>> 3. What are the common frame types used for SMT stencils?

>> 4. Can frameless stencils be used for all SMT applications?

>> 5. How does the aperture area ratio relate to stencil efficiency?

● Citations:

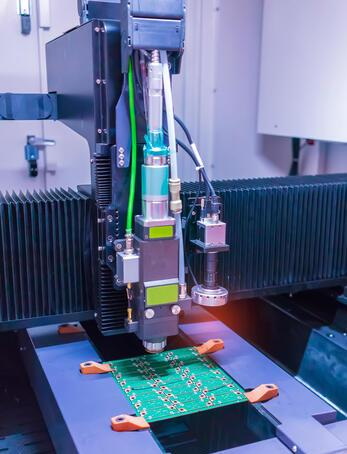

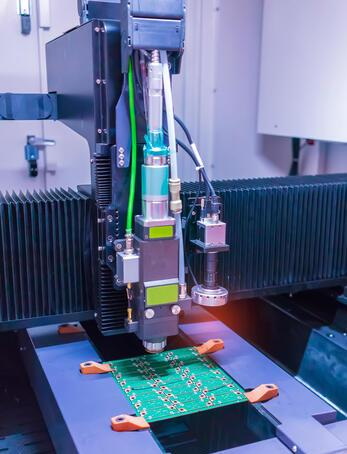

Surface Mount Technology (SMT) stencils are critical tools in the PCB assembly process, enabling precise solder paste application on printed circuit boards (PCBs). Among various factors influencing the quality and efficiency of SMT assembly, the SMT stencil frame size plays a pivotal role. Optimizing the stencil frame size not only ensures accurate paste deposition but also improves handling, alignment, and overall production efficiency. This article explores how to optimize SMT stencil frame size for maximum efficiency, considering design, manufacturing, and operational aspects.

Understanding SMT Stencil Frame Size

The SMT stencil frame size refers to the overall dimensions of the stencil, including the metal frame that holds the stainless steel foil with laser-cut apertures. The frame size must accommodate the PCB dimensions plus additional margins for handling and alignment during the solder paste printing process.

Key Components of SMT Stencil Size

- Internal dimensions: Correspond to the PCB size and the area where solder paste will be applied.

- Overall dimensions: Include the frame and margins required for mounting on stencil printers and for operator handling.

For example, a framed stencil's width is typically the PCB width plus 100 mm, and its length is the PCB length plus 100 mm. Frameless stencils require even larger margins, usually PCB size plus 200 mm in both directions.

Why Optimizing SMT Stencil Frame Size Matters

Optimizing the stencil frame size is essential for several reasons:

- Accurate alignment: Proper frame size facilitates precise alignment of the stencil with the PCB, reducing misprints and defects.

- Efficient handling: A frame that is too large or too small can complicate handling, increasing cycle times or risking damage.

- Compatibility with printing equipment: The stencil frame must fit the stencil printer's specifications to ensure smooth operation.

- Cost efficiency: Oversized frames increase material costs and shipping expenses, while undersized frames may reduce stencil life or printing quality.

- Stencil durability: Correct frame size maintains foil tension, preventing deformation and extending stencil lifespan.

Factors to Consider When Optimizing SMT Stencil Frame Size

1. PCB Size and Layout

The stencil frame size should be closely matched to the PCB dimensions. Adding a margin of about 100 mm around the PCB size for framed stencils is common to allow for proper mounting and alignment. The internal stencil area must cover all component pads requiring solder paste.

When dealing with panelized PCBs, the stencil frame size must accommodate the entire panel, including the rails and tooling holes. This ensures the stencil can be securely mounted and aligned during printing.

2. Printing Method and Equipment

Different stencil printers have varying maximum stencil frame sizes. For example, framed SMT stencils can come in standard frame sizes such as 8"x10", 10"x10", 12"x12", up to 29"x29" inches, depending on the printer capacity. Selecting a frame size compatible with your printer ensures efficient handling and consistent printing.

Additionally, some advanced printers support frameless stencils, which require larger margins to facilitate handling without a frame. Understanding your printer's capabilities is essential to optimize stencil frame size.

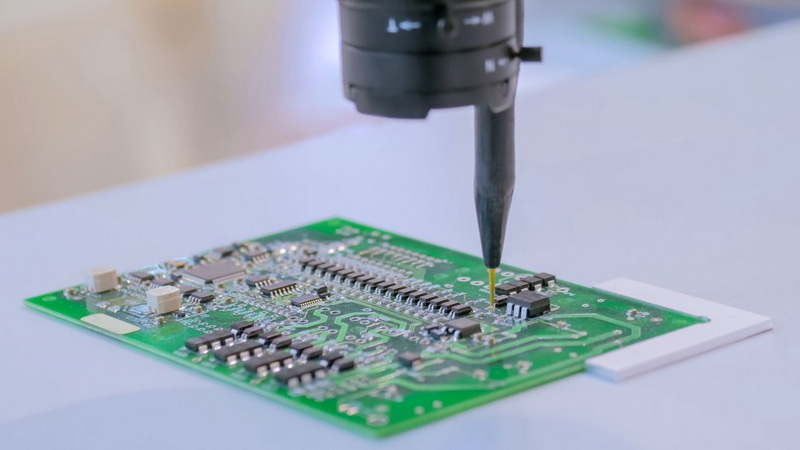

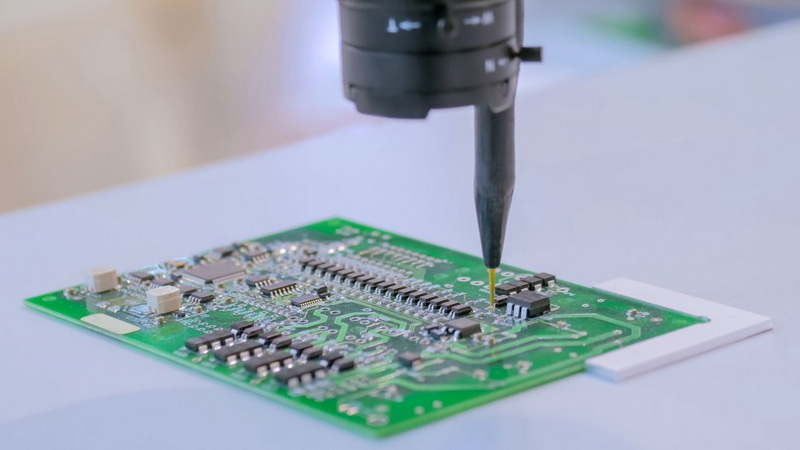

3. Component Density and Aperture Design

High-density PCBs with fine-pitch components may require smaller stencil thickness and precise aperture sizes. The frame size should allow for a stable foil tension to avoid deformation during printing, which is critical for fine pitch components.

In such cases, localized stencil thinning or step stencils may be used to optimize solder paste volume without altering the overall frame size. The frame must be rigid enough to support these advanced stencil designs.

4. Stencil Thickness and Aperture Aspect Ratio

The stencil thickness (typically between 0.002" to 0.016") affects the amount of solder paste deposited. The frame must hold the stencil foil taut to maintain the correct aperture aspect ratio (aperture width divided by stencil thickness), which should ideally be above 1.5 for good paste release.

A poor frame size or insufficient tension can cause aperture deformation, leading to inconsistent solder paste volume and defects such as insufficient solder joints or bridging.

5. Material and Frame Construction

The material and construction of the stencil frame also influence optimization. Aluminum frames are common due to their lightweight and rigidity. Cast frames provide better stability than extruded frames, especially for larger stencil sizes.

Choosing the right frame material and construction ensures the stencil maintains its shape and tension during repeated printing cycles, directly impacting efficiency and print quality.

Steps to Optimize SMT Stencil Frame Size

Step 1: Measure PCB Dimensions Accurately

Start by measuring the exact dimensions of the PCB, including any panelization if multiple boards are printed simultaneously. Accurate measurements prevent errors in stencil sizing that could lead to misalignment or incomplete paste coverage.

Step 2: Determine Required Margins

Add the appropriate margin for the frame based on whether you use framed or frameless stencils:

- Framed stencil margin: PCB size + 100 mm (approximately 4 inches)

- Frameless stencil margin: PCB size + 200 mm (approximately 8 inches)

These margins allow for proper mounting on the stencil printer and provide space for handling and alignment tooling.

Step 3: Select Frame Type and Size

Choose between cast (solid aluminum) or extruded (hollow) frames. Cast frames provide better rigidity and stability, which is important for larger stencil sizes or high-volume production.

Select a frame size that fits your printer's maximum supported stencil size while minimizing excess material to reduce cost and handling complexity.

Step 4: Verify Compatibility with Printing Equipment

Confirm that the chosen stencil frame size fits your stencil printer's maximum image and foil size specifications. For example, a 12"x12" frame supports a maximum foil size of 10"x10".

Also, check the printer's clamping mechanism to ensure it can securely hold the stencil frame without damage or slippage.

Step 5: Optimize Aperture Design and Stencil Thickness

Adjust aperture sizes and stencil thickness to balance solder paste volume and release efficiency. Use an area ratio (aperture opening area to aperture wall area) of at least 0.66 and an aspect ratio above 1.5 to ensure good paste transfer.

Consider using step stencils or varying stencil thickness in different regions if your design includes components with different solder paste volume requirements.

Step 6: Implement Quality Control and Testing

After stencil fabrication, conduct print tests to verify solder paste volume and alignment accuracy. Inspect the stencil frame for warping or defects that could affect performance.

Regular maintenance and cleaning of the stencil and frame help maintain optimal printing efficiency over time.

Additional Tips for Enhancing SMT Stencil Frame Efficiency

- Use framed stencils for high-volume production to improve durability and alignment speed.

- For smaller or prototype runs, frameless stencils reduce costs and simplify storage but require careful handling.

- Regularly inspect and clean stencils to prevent aperture clogging and maintain print quality.

- Consider localized stencil thinning for components with narrow pitch to optimize paste volume without changing the overall frame size.

- Use laser-cut stencils for precise apertures and better paste release, especially for fine-pitch components.

- Store stencils properly in dedicated racks or holders to prevent frame damage or foil deformation.

- Train operators on correct stencil handling and mounting procedures to avoid frame damage and ensure consistent print quality.

Common Challenges in SMT Stencil Frame Size Optimization and How to Overcome Them

Challenge 1: Frame Warping and Foil Tension Loss

Over time, stencil frames can warp due to mechanical stress or temperature changes, causing foil tension loss and print defects.

Solution: Use high-quality cast aluminum frames for better rigidity. Implement regular inspection and re-tensioning procedures. Avoid exposing stencils to extreme temperatures or mechanical shocks.

Challenge 2: Misalignment Due to Improper Frame Size

A frame that is too small or too large can cause misalignment between the stencil and PCB, leading to solder paste misplacement.

Solution: Precisely measure PCB and panel dimensions and add correct margins. Use frames compatible with the stencil printer and ensure proper mounting and alignment tooling.

Challenge 3: Increased Cost from Oversized Frames

Oversized stencil frames increase material cost and shipping expenses, especially for large or complex PCBs.

Solution: Optimize frame size to be just large enough to accommodate the PCB and necessary margins. Avoid excessive margins that add no functional benefit.

Challenge 4: Difficulty Handling Frameless Stencils

Frameless stencils require larger margins and careful handling, which can slow down production and increase risk of damage.

Solution: Train operators thoroughly and consider using framed stencils for high-volume or complex assemblies. Use dedicated tools for handling frameless stencils safely.

Conclusion

Optimizing the SMT stencil frame size is a crucial step in achieving efficient and high-quality SMT assembly. By carefully matching the stencil frame size to PCB dimensions, printing equipment capabilities, and component layout, manufacturers can ensure accurate solder paste application, reduce defects, and improve throughput. Selecting the appropriate frame type and size, maintaining proper stencil thickness and aperture design, and adhering to best practices in handling and cleaning all contribute to stencil efficiency. Ultimately, a well-optimized stencil frame size enhances production reliability and cost-effectiveness in SMT manufacturing.

FAQ

1. What is the recommended margin to add to PCB size for framed SMT stencil frame size?

For framed stencils, add approximately 100 mm (about 4 inches) to both the width and length of the PCB to determine the stencil frame size. This margin allows for proper mounting and alignment on the stencil printer.

2. How does stencil thickness affect SMT stencil frame size optimization?

Stencil thickness influences the amount of solder paste deposited and the aperture aspect ratio. The stencil frame must hold the foil taut to maintain the correct thickness and aperture shape, which is critical for efficient paste transfer and print quality.

3. What are the common frame types used for SMT stencils?

Common frame types include cast (solid aluminum) and extruded (hollow) frames. Cast frames offer better rigidity and are preferred for larger or high-volume stencils, while extruded frames are lighter but less rigid.

4. Can frameless stencils be used for all SMT applications?

Frameless stencils are cost-effective and suitable for smaller runs or prototypes but require careful handling and may not provide the same stability and ease of alignment as framed stencils in high-volume production.

5. How does the aperture area ratio relate to stencil efficiency?

An aperture area ratio (aperture opening area to wall area) of at least 0.66 is recommended to ensure efficient solder paste release and consistent printing quality. Maintaining a proper aspect ratio (aperture width to stencil thickness) above 1.5 also helps prevent paste smearing or insufficient deposition.

Citations:

1.https://jlcpcb.com/blog/413-how-to-choose-a-smt-stencil/

2.https://www.ipc.org/system/files/technical_resource/E38&S12-02%20-%20Chrys%20Shea.pdf

3.https://jlcpcb.com/blog/why-pcb-stencils-are-key-to-high-quality-smt-assembly

4.https://www.surfacemountprocess.com/a-guide-to-effective-stencil-design.html

5.http://www.qualiecocircuits.co.nz/stencil-technology-other-aspects.htm

6.https://www.pentalogix.com/products/framed-smt-stencils

7.https://www.nextpcb.com/blog/smt-stencil

8.https://pcbpit.com/smt-stencil-a-comprehensive-guide/

9.https://www.pcbunlimited.com/products/framed-smt-stencils

10.https://jlcpcb.com/blog/how-to-choose-a-smt-stencil

11.https://www.soldertools.net/smt-framed-stencils/

12.https://www.epectec.com/smt-stencils/