Content Menu

● Understanding the Importance of Pad Size Optimization

● Factors Affecting SMT Pad Size Design

● Optimizing Pad Sizes for Common Component Types

>> Chip Components (Resistors and Capacitors)

>> QFP (Quad Flat Package) Components

>> BGA (Ball Grid Array) Components

● Advanced Techniques for Pad Size Optimization

>> Differential Pad Sizing

>> Teardrop Pads

>> Overprinting Strategy

● Pad Design Guidelines for Specific Component Families

>> SOT, SOIC, and SOP Packages

>> QFN (Quad Flat No-Lead) Packages

>> TSOP (Thin Small Outline Package)

● The Role of Stencil Design in Pad Optimization

>> Aperture Size and Shape

>> Stencil Thickness

>> Scooping Effect Compensation

● PCB Layout Considerations for Optimal Pad Performance

>> Trace Connections

>> Solder Mask Design

>> Copper Balancing

● Manufacturing Process Optimization

>> Solder Paste Selection

>> Reflow Profile Tuning

>> Placement Accuracy

● Quality Control and Inspection

>> Automated Optical Inspection (AOI)

>> X-ray Inspection

● Future Trends in SMT Pad Design

>> Miniaturization

>> Embedded Components

>> Advanced Materials

● Conclusion

● FAQ

>> 1. What is the importance of optimizing SMT pad sizes?

>> 2. How does pad size affect the soldering process for SMT components?

>> 3. What are some common mistakes in SMT pad design?

>> 4. How can I determine the optimal pad size for a specific SMT component?

>> 5. What role does stencil design play in SMT pad optimization?

● Citations:

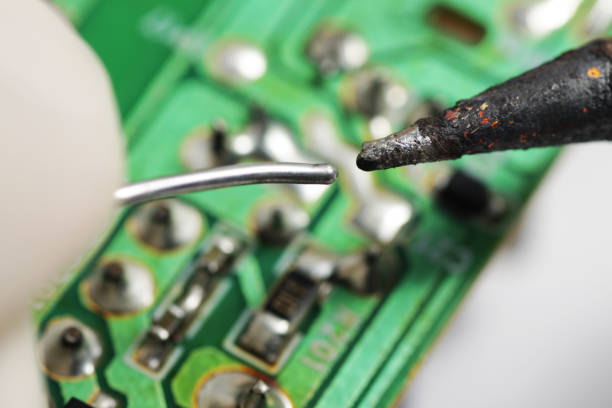

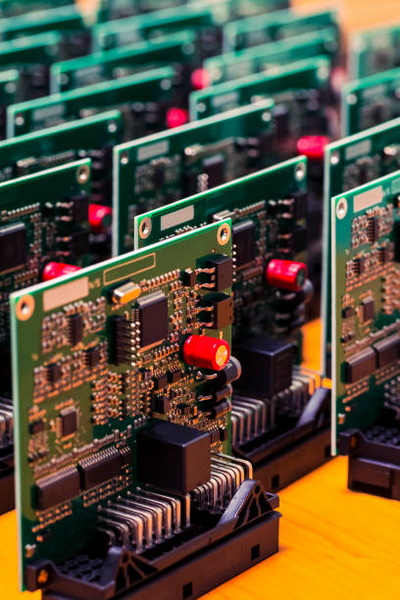

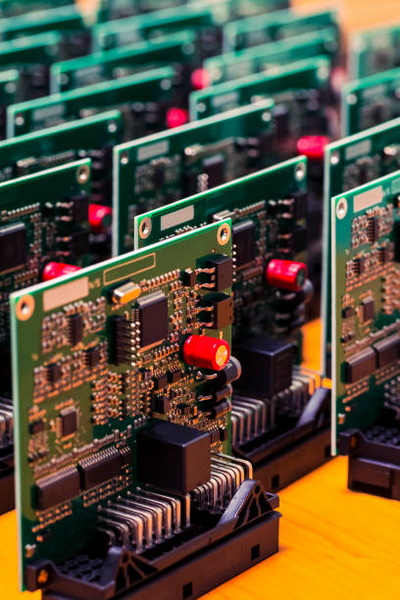

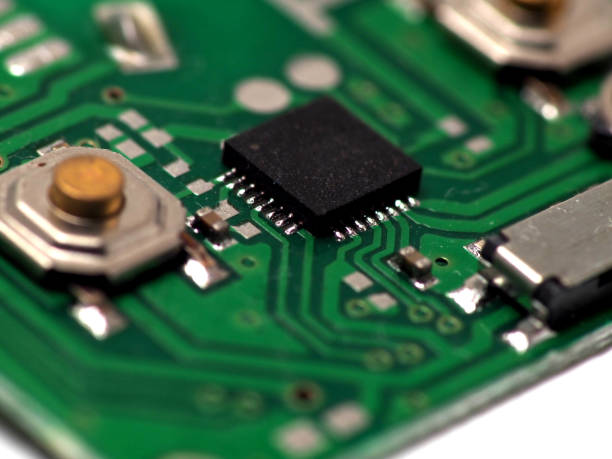

Surface Mount Technology (SMT) has revolutionized the electronics manufacturing industry, allowing for more compact and efficient circuit board designs. One crucial aspect of SMT is the design of pads on which components are soldered. Optimizing pad sizes for different component types is essential for ensuring reliable connections, improving manufacturing yield, and enhancing the overall performance of electronic devices. This article will explore various strategies and considerations for optimizing SMT pad sizes across different component types.

Understanding the Importance of Pad Size Optimization

The size and shape of SMT pads play a critical role in the quality of solder joints, the ease of component placement, and the reliability of the final product. Poorly designed pads can lead to a range of issues, including tombstoning, solder bridging, and insufficient solder coverage[1]. By optimizing pad sizes, manufacturers can mitigate these problems and improve the overall quality of their PCB assemblies.

Factors Affecting SMT Pad Size Design

Several factors must be considered when designing SMT pads:

1. Component Type and Size: Different components require different pad configurations. For instance, chip resistors, QFP packages, and BGA components each have unique pad requirements.

2. Solder Paste Properties: The characteristics of the solder paste, including its viscosity and metal content, can influence the optimal pad size.

3. PCB Material and Manufacturing Process: The substrate material and the PCB manufacturing process can affect pad design decisions.

4. Reflow Profile: The reflow soldering process parameters can impact the behavior of solder on the pads.

5. Environmental Conditions: Factors such as temperature fluctuations and mechanical stress should be considered in pad design.

Optimizing Pad Sizes for Common Component Types

Chip Components (Resistors and Capacitors)

For small chip components like 0402 and 0603 packages, pad size optimization is crucial to prevent tombstoning. Tombstoning occurs when one end of the component lifts during reflow, resembling a tombstone[1]. To mitigate this:

- Ensure that pad sizes are symmetrical to balance solder forces.

- For 0402 components, a typical pad size might be 0.6mm x 0.6mm with a 0.6mm gap between pads.

- For 0603 components, consider pads of 0.8mm x 0.8mm with a 0.8mm gap.

QFP (Quad Flat Package) Components

QFP components require careful pad design to ensure proper solder fillet formation and to prevent solder bridging:

- Pad width should be slightly wider than the lead width, typically by 0.1mm to 0.2mm.

- Pad length should extend beyond the lead foot by about 0.5mm to 1mm.

- For a QFP160 package, pad sizes might be 0.35mm wide and 1.5mm long, with the exact dimensions depending on the specific component[4].

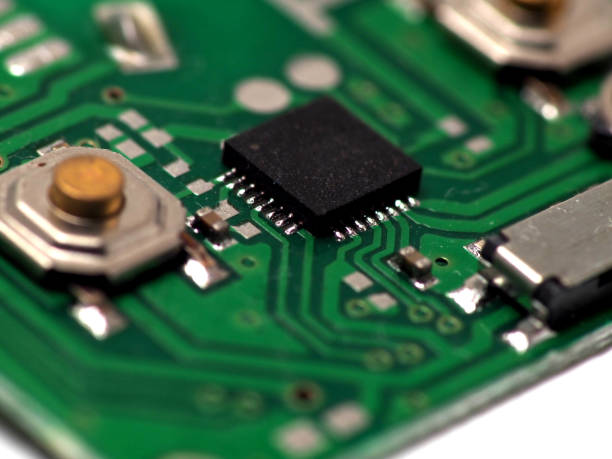

BGA (Ball Grid Array) Components

BGA pad design is critical for ensuring reliable connections and preventing solder ball collapse:

- Pad diameter is typically 80% to 90% of the solder ball diameter.

- For a 1mm pitch BGA, pad diameters might range from 0.4mm to 0.5mm.

- Consider using solder mask defined (SMD) pads for fine-pitch BGAs to improve solder joint reliability.

Advanced Techniques for Pad Size Optimization

Differential Pad Sizing

For components with many leads, such as high pin-count QFPs, differential pad sizing can be employed:

- Corner pads are made slightly larger to compensate for increased thermal mass.

- Inner pads can be made slightly smaller to prevent solder bridging.

Teardrop Pads

Teardrop-shaped pads can be used to improve solder joint reliability:

- The teardrop shape increases the pad area without increasing the risk of bridging.

- This design is particularly useful for components subjected to high mechanical stress.

Overprinting Strategy

An overprinting strategy involves designing stencil apertures larger than the PCB pads:

- This technique can be used to increase solder volume for certain components.

- For example, a BGA256 might use apertures 120%, 140%, or even 160% the size of the PCB pad[4].

Pad Design Guidelines for Specific Component Families

SOT, SOIC, and SOP Packages

For these common IC packages:

- The center-to-center distance between bonding pads should match the lead spacing.

- Pad width should be slightly wider than the lead width, typically by 0.1mm to 0.2mm.

- Pad length should extend beyond the lead foot by about 0.5mm to 1mm[8].

QFN (Quad Flat No-Lead) Packages

QFN packages require special consideration due to their lack of leads:

- Pad sizes should be slightly smaller than the package land pattern to prevent solder from wicking underneath the component.

- Consider adding a thermal pad in the center for heat dissipation.

- For a QFN32 package, pad sizes might be 110% to 130% of the nominal land size[4].

TSOP (Thin Small Outline Package)

TSOP packages are common in memory devices:

- Pad width should be slightly wider than the lead width, typically by 0.1mm to 0.2mm.

- Pad length should extend beyond the lead foot by about 0.5mm to 0.8mm.

- For a TSOP32 package, consider pad sizes 110% to 130% of the nominal land size[4].

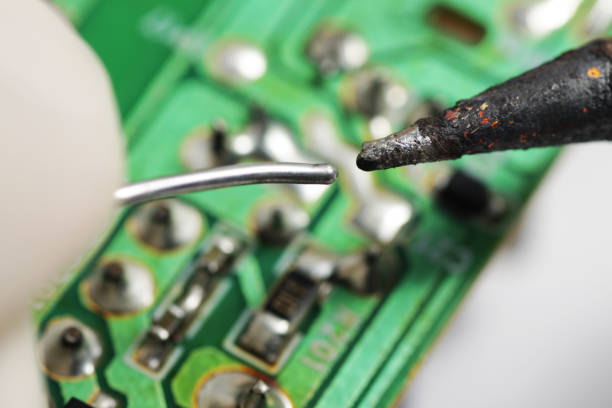

The Role of Stencil Design in Pad Optimization

Stencil design is closely related to pad optimization and plays a crucial role in achieving the right amount of solder paste deposition:

Aperture Size and Shape

- For most components, the stencil aperture should be slightly smaller than the pad to prevent solder bridging.

- For fine-pitch components, consider using home plate or U-shaped apertures to improve paste release.

Stencil Thickness

- Stencil thickness affects the volume of solder paste deposited.

- Thicker stencils (5-6 mil) are suitable for larger components, while thinner stencils (3-4 mil) work better for fine-pitch devices.

Scooping Effect Compensation

The scooping effect, where the squeegee removes more solder paste from the center of large apertures, can be compensated for by:

- Using stepped stencils for mixed-technology boards.

- Implementing special aperture designs, such as windowed or webbed apertures for large pads[9].

PCB Layout Considerations for Optimal Pad Performance

Trace Connections

- For high-frequency applications, consider using teardrop connections between pads and traces to reduce signal reflections.

- Ensure that traces are centered on pads to maintain symmetry and balance solder forces.

Solder Mask Design

- Use solder mask defined (SMD) pads for fine-pitch components to improve alignment and prevent solder bridging.

- For larger components, non-solder mask defined (NSMD) pads can provide better solder joint reliability.

Copper Balancing

- Maintain consistent copper distribution around pads to ensure even heat distribution during reflow.

- Consider using copper thieving or hatching in large open areas to improve thermal management.

Manufacturing Process Optimization

Solder Paste Selection

- Choose a solder paste with appropriate viscosity and metal content for your pad designs.

- Consider using Type 4 or Type 5 solder paste for fine-pitch components to improve printing accuracy.

Reflow Profile Tuning

- Adjust the reflow profile to match your pad designs and component mix.

- Implement a longer soak zone for boards with a wide variety of component sizes to ensure even heating.

Placement Accuracy

- Ensure that pick-and-place machines are calibrated for high accuracy, especially for fine-pitch components.

- Consider using fiducial marks to improve placement precision.

Quality Control and Inspection

Automated Optical Inspection (AOI)

- Program AOI systems to check for proper solder coverage and component alignment based on optimized pad designs.

- Use AOI feedback to refine pad designs and manufacturing processes continuously.

X-ray Inspection

- Implement X-ray inspection for BGA and other hidden-joint components to verify solder joint quality.

- Use X-ray data to validate and improve pad designs for these challenging component types.

Future Trends in SMT Pad Design

As electronic devices continue to shrink and become more complex, SMT pad design will face new challenges:

Miniaturization

- The trend towards smaller components, such as 01005 and 008004 packages, will require even more precise pad designs.

- Advanced manufacturing techniques, like laser-defined stencils, may become more common to achieve the necessary precision.

Embedded Components

- As more manufacturers explore embedded component technologies, pad design will need to adapt to these new integration methods.

- This may include the development of new pad structures for connecting to embedded devices.

Advanced Materials

- The adoption of new PCB materials and solder alloys may influence optimal pad designs.

- Designers will need to consider the interaction between these new materials and traditional pad geometries.

Conclusion

Optimizing SMT pad sizes for different component types is a complex but crucial aspect of PCB design and manufacturing. By carefully considering factors such as component characteristics, solder paste properties, and manufacturing processes, designers can create pad layouts that improve solder joint reliability, reduce defects, and enhance overall product quality. As technology continues to evolve, staying informed about the latest developments in SMT pad design will be essential for maintaining a competitive edge in the electronics manufacturing industry.

FAQ

1. What is the importance of optimizing SMT pad sizes?

Optimizing SMT pad sizes is crucial for several reasons:

- It ensures reliable solder connections between components and the PCB.

- It helps prevent manufacturing defects such as tombstoning, solder bridging, and insufficient solder coverage.

- It improves the overall yield and quality of PCB assemblies.

- It can enhance the electrical performance and long-term reliability of electronic devices.

2. How does pad size affect the soldering process for SMT components?

Pad size significantly impacts the soldering process in the following ways:

- It determines the amount of solder paste that can be deposited on the pad.

- It influences the surface tension forces during reflow, which can affect component self-alignment.

- It affects the formation of solder fillets, which are crucial for strong and reliable connections.

- Proper pad sizing can help prevent issues like solder bridging between adjacent pads or insufficient solder coverage.

3. What are some common mistakes in SMT pad design?

Common mistakes in SMT pad design include:

- Making pads too small, which can lead to insufficient solder coverage and weak joints.

- Making pads too large, which can cause solder bridging or component floating.

- Neglecting to account for different thermal characteristics of components, leading to uneven heating during reflow.

- Failing to consider the effects of copper thieving or uneven copper distribution around pads.

- Not adapting pad designs for different component types and sizes on the same board.

4. How can I determine the optimal pad size for a specific SMT component?

To determine the optimal pad size for a specific SMT component:

- Start with the manufacturer's recommended land pattern in the component datasheet.

- Consider industry standards like IPC-7351B for pad design guidelines.

- Take into account your specific manufacturing process capabilities and tolerances.

- Use design tools that can simulate solder joint formation and thermal characteristics.

- Conduct prototyping and testing to validate and refine pad designs for your specific application.

5. What role does stencil design play in SMT pad optimization?

Stencil design is closely related to pad optimization and plays a crucial role:

- The stencil aperture size and shape directly affect the amount and distribution of solder paste on the pad.

- Proper stencil design can help compensate for issues like the scooping effect on large pads.

- Stencil thickness must be balanced with pad size to achieve the right solder paste volume.

- Advanced stencil designs, such as step stencils, can help optimize solder deposition for mixed-technology boards with varying pad sizes.

Citations:

[1] https://www.vse.com/blog/2019/11/19/pcb-pad-design-guidelines-that-follow-dfm-best-practices/

[2] https://cdrdv2-public.intel.com/654881/an530.pdf

[3] https://patents.google.com/patent/CN112040669B/zh

[4] https://www.ipc.org/system/files/technical_resource/E8&S24_03.pdf

[5] https://www.pcbway.com/blog/Engineering_Technical/PCB_optimization_techniques.html

[6] https://blog.sina.com.cn/s/blog_4c10b9630100gcci.html

[7] https://www.protoexpress.com/blog/common-errors-surface-mount-technology-smt/

[8] https://www.pcbcart.com/article/content/design-requirement-of-SMT-PCB-1.html

[9] https://www.circuitinsight.com/pdf/optimization_stencil_apertures_scooping_printing_ipc.pdf