Content Menu

● Understanding SMT and Its Importance in PCB Design

● Key Considerations for Optimizing PCB Design for SMT Leads

>> Component Selection and Footprint Design

>> PCB Layout Optimization

>> Solder Paste Stencil Design

● Advanced Techniques for SMT Lead Optimization

>> High-Density Interconnect (HDI) Technology

>> Design for Manufacturing (DFM) and Assembly (DFA)

● Leveraging Advanced Software Tools

● Manufacturing Considerations for SMT Leads

>> Solder Paste Application

>> Reflow Soldering Process

>> Post-Assembly Inspection and Testing

● Emerging Trends and Future Considerations

● Conclusion

● FAQ

>> 1. What are the key advantages of using SMT leads in PCB design?

>> 2. How can I optimize pad design for SMT leads?

>> 3. What are some common challenges in PCB design for SMT leads?

>> 4. How does HDI technology impact SMT lead design?

>> 5. What future trends should I consider when optimizing PCB design for SMT leads?

● Citations:

In the ever-evolving world of electronics manufacturing, Surface Mount Technology (SMT) has become the standard for producing high-quality, compact, and efficient Printed Circuit Boards (PCBs). Optimizing PCB design for SMT leads is crucial for ensuring the reliability, performance, and cost-effectiveness of electronic devices. This article will explore various strategies and best practices to enhance PCB design for SMT leads, covering everything from component selection to manufacturing considerations.

Understanding SMT and Its Importance in PCB Design

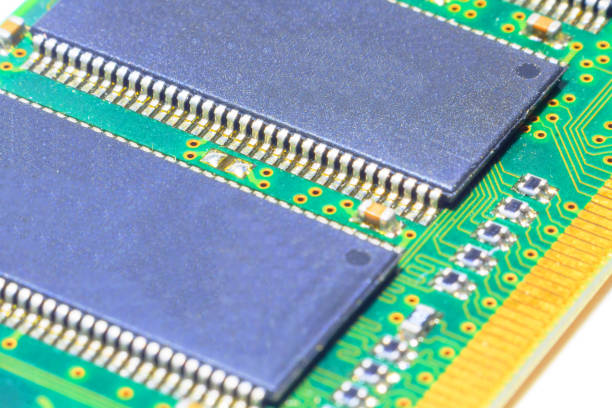

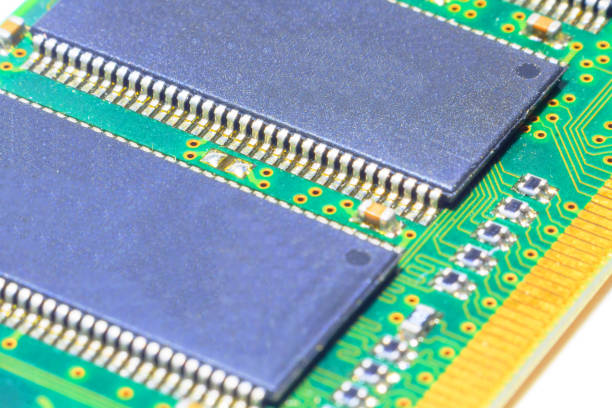

Surface Mount Technology involves directly mounting components onto the surface of a PCB, as opposed to through-hole technology where component leads are inserted through holes in the board. SMT offers numerous advantages, including higher component density, improved electrical performance, and reduced manufacturing costs[1]. However, to fully leverage these benefits, PCB designers must optimize their layouts specifically for SMT leads.

Key Considerations for Optimizing PCB Design for SMT Leads

Component Selection and Footprint Design

Selecting the right components and designing appropriate footprints are fundamental steps in optimizing PCB design for SMT leads. Consider the following aspects:

1. Choose appropriate package sizes: Select SMT components with package sizes that match your design requirements and manufacturing capabilities[4].

2. Use standardized footprints: Whenever possible, use standardized footprints provided by component manufacturers or industry standards. This ensures compatibility and reduces the risk of assembly issues[2].

3. Consider pad design: Optimize pad sizes and shapes for different component types. For example, use tear-drop shaped pads for better solder adhesion and to accommodate slight misalignments during assembly[1].

4. Account for thermal relief: Design pads with thermal relief connections to facilitate easier soldering and prevent heat sinking during the reflow process[2].

PCB Layout Optimization

Optimizing the PCB layout is crucial for ensuring the best performance and manufacturability of SMT leads. Key strategies include:

1. Component placement: Group related components together to minimize signal path lengths and reduce electromagnetic interference (EMI)[2].

2. Optimize trace routing: Use short, direct traces to connect components, avoiding 90-degree angles and long parallel runs that can cause crosstalk[4].

3. Consider thermal management: Place heat-generating components strategically and use thermal vias or copper planes for better heat dissipation[2].

4. Design for testability: Incorporate test points and consider in-circuit testing requirements during the layout phase[1].

Solder Paste Stencil Design

The solder paste stencil plays a crucial role in the SMT assembly process. Optimizing its design can significantly improve the quality and reliability of solder joints:

1. Aperture size and shape: Design apertures that match the pad size and shape, considering the component lead type and solder paste characteristics[4].

2. Stencil thickness: Choose an appropriate stencil thickness based on the smallest component pitch and the required solder volume[1].

3. Area ratio and aspect ratio: Maintain proper area and aspect ratios to ensure consistent solder paste release during the printing process[2].

4. Step stencils: Consider using step stencils for mixed-technology boards or when dealing with components that require different solder paste volumes[4].

Advanced Techniques for SMT Lead Optimization

High-Density Interconnect (HDI) Technology

For designs requiring extremely high component density, consider implementing HDI techniques:

1. Microvias: Use microvias to create connections between layers, allowing for more routing options and higher component density[8].

2. Buried and blind vias: Implement buried and blind vias to optimize layer-to-layer connections without consuming valuable surface real estate[8].

3. Fine-pitch components: Take advantage of fine-pitch SMT components to further increase circuit density and functionality[4].

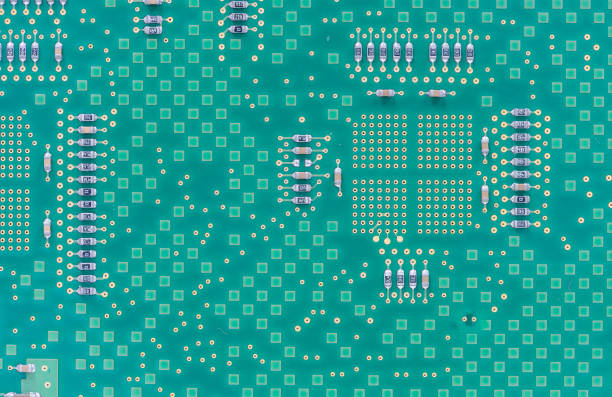

Design for Manufacturing (DFM) and Assembly (DFA)

Incorporating DFM and DFA principles into your PCB design process can significantly improve manufacturability and reduce costs:

1. Component orientation: Standardize component orientations to simplify pick-and-place programming and reduce assembly errors[4].

2. Fiducial marks: Include fiducial marks on the PCB to aid in automated assembly and ensure accurate component placement[1].

3. Panelization: Design PCB panels that optimize material usage and assembly efficiency[2].

4. Clearance and spacing: Maintain adequate clearance between components and board edges to prevent assembly issues and improve reliability[4].

Leveraging Advanced Software Tools

Modern PCB design software offers powerful features to optimize designs for SMT leads:

1. Auto-routing algorithms: Utilize advanced auto-routing algorithms to optimize trace layouts and minimize signal integrity issues[2].

2. 3D visualization: Use 3D visualization tools to check for component clearances and potential assembly conflicts[4].

3. Signal integrity analysis: Perform signal integrity simulations to identify and address potential issues before manufacturing[2].

4. DFM rule checking: Implement automated DFM rule checking to ensure compliance with manufacturing constraints[4].

Manufacturing Considerations for SMT Leads

Solder Paste Application

Proper solder paste application is critical for creating reliable solder joints:

1. Solder paste selection: Choose a solder paste that matches your PCB's surface finish and component requirements[1].

2. Stencil printing process: Optimize the stencil printing process by controlling factors such as squeegee pressure, speed, and snap-off distance[4].

3. Solder paste inspection: Implement automated solder paste inspection to detect and correct printing defects before component placement[2].

Reflow Soldering Process

The reflow soldering process is a crucial step in SMT assembly:

1. Thermal profiling: Develop and optimize thermal profiles that ensure proper solder joint formation without damaging components[1].

2. Nitrogen atmosphere: Consider using a nitrogen atmosphere during reflow to improve solder wetting and reduce oxidation[4].

3. Void reduction: Implement techniques to minimize voiding in solder joints, such as optimizing pad designs and using vacuum reflow systems[2].

Post-Assembly Inspection and Testing

Thorough inspection and testing are essential for ensuring the quality of SMT assemblies:

1. Automated Optical Inspection (AOI): Use AOI systems to detect visible defects such as misaligned components or solder bridging[4].

2. X-ray inspection: Implement X-ray inspection for detecting hidden defects, particularly for BGA and other complex package types[2].

3. In-Circuit Testing (ICT): Design boards with ICT in mind, incorporating test points and considering probe access during layout[1].

4. Functional testing: Develop comprehensive functional test procedures to verify the performance of the assembled PCB[4].

Emerging Trends and Future Considerations

As technology continues to advance, new trends are emerging in PCB design for SMT leads:

1. 5G and high-frequency designs: Optimize layouts for high-frequency applications, considering factors such as impedance control and signal integrity[2].

2. Flexible and rigid-flex PCBs: Adapt SMT design principles for flexible and rigid-flex PCBs, addressing unique challenges such as bend radii and stress relief[4].

3. Additive manufacturing: Explore the potential of additive manufacturing techniques for creating custom SMT pads and structures[2].

4. AI-assisted design: Leverage artificial intelligence and machine learning algorithms to optimize PCB layouts and component placement[4].

Conclusion

Optimizing PCB design for SMT leads is a multifaceted process that requires careful consideration of various factors, from component selection to manufacturing processes. By implementing the strategies and best practices outlined in this article, PCB designers can create high-quality, reliable, and cost-effective boards that meet the demands of modern electronic devices.

As technology continues to evolve, staying up-to-date with the latest trends and techniques in SMT design will be crucial for maintaining a competitive edge in the electronics industry. By embracing advanced tools, emerging technologies, and continuous improvement in design practices, PCB designers can ensure that their SMT-based designs remain at the forefront of innovation and performance.

FAQ

1. What are the key advantages of using SMT leads in PCB design?

SMT leads offer several advantages in PCB design, including:

- Higher component density, allowing for more compact designs

- Improved electrical performance due to shorter signal paths

- Reduced manufacturing costs through automated assembly processes

- Better mechanical performance under shock and vibration conditions

- Enhanced high-frequency performance for RF and microwave applications

2. How can I optimize pad design for SMT leads?

To optimize pad design for SMT leads:

- Use tear-drop shaped pads for better solder adhesion

- Implement thermal relief connections for easier soldering

- Adjust pad sizes based on component lead types and solder paste characteristics

- Consider using non-solder mask defined (NSMD) pads for improved reliability

- Ensure proper clearance between pads to prevent solder bridging

3. What are some common challenges in PCB design for SMT leads?

Common challenges in PCB design for SMT leads include:

- Ensuring proper component placement and orientation

- Managing thermal issues in high-density designs

- Achieving consistent solder joints across different component types

- Designing for testability and inspection

- Balancing signal integrity requirements with manufacturing constraints

4. How does HDI technology impact SMT lead design?

HDI technology impacts SMT lead design in several ways:

- Allows for higher component density through the use of microvias and finer trace widths

- Enables more complex routing solutions, reducing the number of PCB layers required

- Improves signal integrity by reducing via stubs and shortening signal paths

- Facilitates the use of smaller, fine-pitch SMT components

- Requires more advanced manufacturing processes and tighter tolerances

5. What future trends should I consider when optimizing PCB design for SMT leads?

When optimizing PCB design for SMT leads, consider these future trends:

- Increasing adoption of 5G and high-frequency designs requiring specialized layout techniques

- Growth in flexible and rigid-flex PCB applications

- Advancements in additive manufacturing for custom SMT structures

- Integration of AI and machine learning in PCB design software

- Continued miniaturization of components and increasing circuit densities

Citations:

[1] https://blogs.sw.siemens.com/valor-dfm-solutions/how-to-optimize-pcb-design-for-the-smt-assembly-process-flow/

[2] https://arshon.com/blog/pcb-design-optimization-enhance-performance-reduce-costs/

[3] https://www.analog.com/jp/resources/design-notes/smt-assembly-and-pcb-design-guidelines-for-leaded-packages.html

[4] https://www.hayawin.com/resources/how-to-optimize-pcb-design-for-smt-assembly-process-flow.html

[5] https://www.zachariahpeterson.com/pcb-design-optimization-what-it-means-and-new-methods/

[6] https://suddendocs.samtec.com/processing/edge-mount-processing-ch.pdf

[7] https://jlcpcb.com/blog/design-process-of-a-surface-mount-pcb

[8] https://camptechii.com/pcb-design-for-manufacturing-dfm-best-practices-and-optimization-strategies-for-2024/

[9] https://patents.google.com/patent/CN112040669B/zh