Content Menu

● Understanding SMD Prototyping Machines

>> The Significance of SMT

>> Key Components of an SMT Line

>> The Role of Prototyping Machines

● Optimizing Machine Settings and Operation

>> Regular Calibration and Maintenance

>> Programming and Software Optimization

>> Operator Training

● Implementing Best Practices for Speed Enhancement

>> Streamlining Workflow and Layout

>> Strategic Feeder Setup

>> Component Selection and Standardization

>> Optimizing Placement Programs

● Enhancing SMT Production Efficiency

>> Balancing Load Distribution

>> Equipment Optimization

>> Minimizing Component Changes

>> Solder Paste Printing Optimization

>> Reflow Soldering Optimization

● Addressing Common SMT Errors

>> Solder Bridging

>> Insufficient Solder

>> Component Misplacement

● Conclusion

● FAQ

>> 1. What is Surface Mount Technology (SMT)?

>> 2. What are the key steps in the SMT assembly process?

>> 3. What equipment is used in SMT PCB assembly?

>> 4. What industry standards ensure quality in SMT assembly?

>> 5. Can a PCB have both SMT and through-hole components?

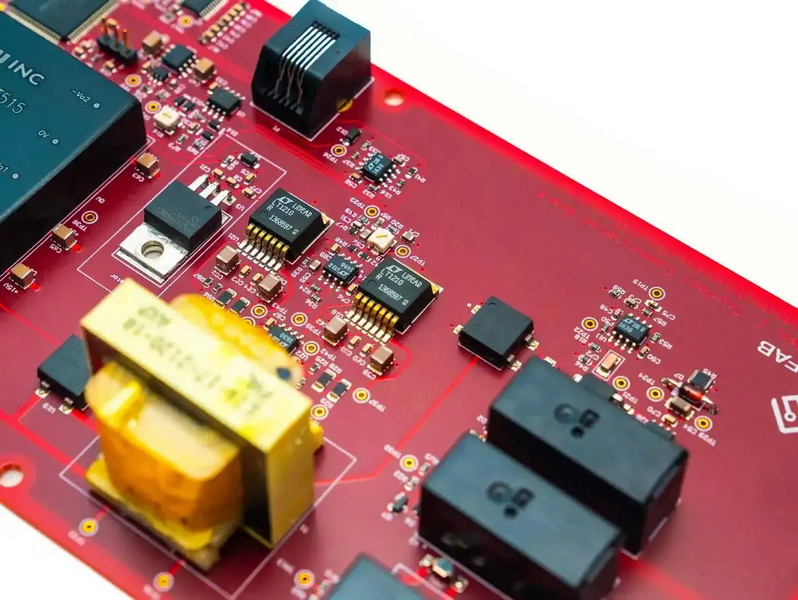

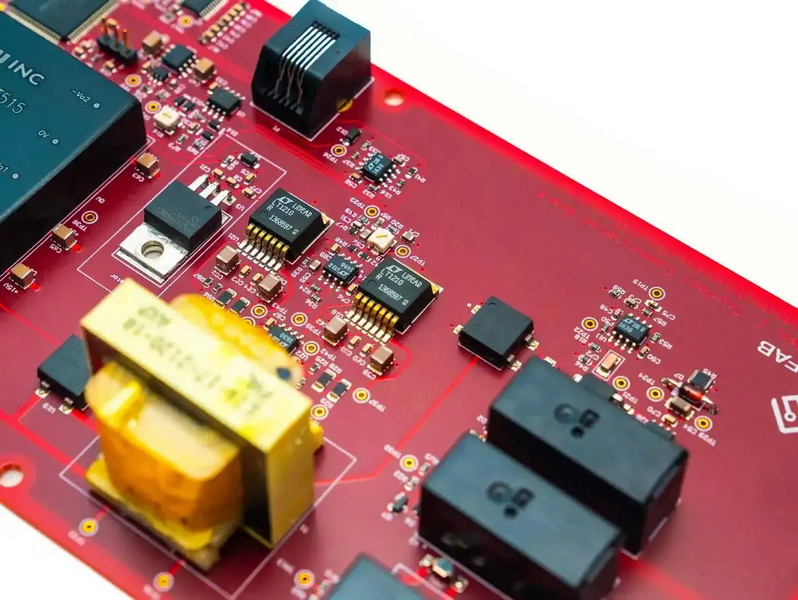

Surface Mount Device (SMD) prototyping machines are essential for modern electronics manufacturing, enabling the rapid assembly of intricate circuit boards with high precision and efficiency. Maximizing the performance of these machines involves a combination of strategic planning, meticulous maintenance, and the adoption of best practices across various stages of the prototyping process. This article delves into the key areas that can significantly enhance the performance of your SMD prototyping machine, ensuring optimal output and quality.

Understanding SMD Prototyping Machines

The Significance of SMT

Surface Mount Technology (SMT) has revolutionized the electronics industry by allowing components to be directly mounted onto the surface of printed circuit boards (PCBs). This approach offers numerous advantages over traditional through-hole methods, including higher component density, improved electrical performance, and reduced manufacturing costs. SMT is now the dominant assembly technology, used in over 90% of PCB assemblies worldwide.

The SMD prototyping machine is a vital tool in this context, designed specifically for small-scale production and experimental runs. It allows engineers and manufacturers to test new designs quickly, validate component placements, and refine processes before committing to mass production.

Key Components of an SMT Line

An SMT assembly line typically includes several key pieces of equipment:

- Solder Paste Printer: Applies solder paste to the PCB pads using a stencil. The quality of solder paste printing directly affects the solder joint integrity.

- Pick-and-Place Machine: Places SMD components onto the pasted pads with high precision and speed. This machine is often the centerpiece of the SMT line.

- Reflow Oven: Heats the assembly to melt the solder paste and create permanent solder joints. Proper temperature profiling within the oven is crucial.

- Inspection Equipment: Includes Automated Optical Inspection (AOI) and X-ray machines to check for defects such as misalignment, solder bridging, or insufficient solder.

The Role of Prototyping Machines

SMD prototyping machines are designed for flexibility and speed in small batch production. Unlike high-volume production lines, these machines prioritize adaptability to different board designs and component types. They allow for rapid iteration cycles, enabling engineers to identify and fix design flaws early, which saves time and cost in the long run.

Optimizing Machine Settings and Operation

Regular Calibration and Maintenance

Regular calibration and preventive maintenance are essential for ensuring that your SMD prototyping machines operate at peak efficiency. Machines that are calibrated correctly will place components accurately and swiftly, reducing errors that can lead to costly rework.

- Routine Checks: Regularly inspect critical components such as nozzles, feeders, and vision systems to prevent breakdowns. For example, clogged nozzles can cause misplacement or dropping of components.

- Calibration: Periodically calibrate machines to maintain placement accuracy, adjusting settings based on component specifications and PCB designs. Calibration should include checking the alignment of the vision system and the mechanical accuracy of the placement head.

Neglecting maintenance can lead to increased downtime and reduced quality, which ultimately affects the throughput of your prototyping machine.

Programming and Software Optimization

Advanced programming and software systems play a pivotal role in enhancing placement speed and accuracy. Utilizing sophisticated software solutions allows manufacturers to optimize the programming of their SMT machines, reducing cycle times and improving overall efficiency.

- Automated Project Setup: Use software that can automatically optimize placement programs based on component types and PCB layouts, reducing manual input errors and programming time.

- Real-Time Monitoring: Implement systems that provide real-time data on machine performance, allowing for quick adjustments to improve efficiency and detect issues before they escalate.

- Path Optimization: Software algorithms can optimize the travel path of the placement head, minimizing movement and reducing cycle time.

Operator Training

The skill level of machine operators significantly affects the efficiency of SMT processes. Well-trained operators are equipped to make quick adjustments and troubleshoot issues, enabling faster response times during operation.

- Comprehensive Training Programs: Invest in training programs that equip operators with the skills necessary to troubleshoot issues quickly and operate machinery efficiently.

- Continuous Learning: Encourage ongoing education about new technologies and techniques in SMT manufacturing, including updates on machine software and hardware.

An experienced operator can also better manage the nuances of the prototyping process, such as component handling and machine setup, which are critical for maximizing machine performance.

Implementing Best Practices for Speed Enhancement

Streamlining Workflow and Layout

An efficient factory layout is critical to optimizing production speed. By arranging workstations logically-placing SMT machines in a sequence that aligns with the production process-you can minimize material handling time and reduce bottlenecks.

- Logical Arrangement: Place SMT machines in a sequence that aligns with the production process to minimize material handling time, such as positioning solder paste printers near pick-and-place machines.

- Lean Manufacturing Principles: Implement lean principles to eliminate wasteful practices within the workflow, such as unnecessary movement of materials or waiting times.

A well-thought-out layout not only improves speed but also reduces the risk of damage to sensitive components during handling.

Strategic Feeder Setup

The configuration of feeders plays a significant role in machine efficiency. Proper feeder setup can minimize changeover times and reduce the risk of component jams.

- Strategic Arrangement: Organize feeders based on component usage frequency to minimize changeover times during production runs. High-usage components should be placed in easily accessible feeders.

- Feeder Maintenance: Keep feeders clean and in good condition to avoid jams that could halt production. Regular inspection and cleaning prevent feeder malfunctions.

Optimizing feeder setup is especially important in prototyping, where component variety can be high and frequent changes are common.

Component Selection and Standardization

Selecting the right components can significantly impact placement speed and soldering quality. Utilize components that are designed for high-speed assembly, such as those with standard sizes and shapes that are easier to handle.

- Standardized Sizes: Use components that conform to industry-standard package sizes (e.g., 0603, 0402) which simplifies handling and placement.

- Regular Inventory Evaluation: Ensure that inventory consists of components that align with your production needs, minimizing delays caused by component shortages or mismatches.

Standardizing components across designs can also reduce the complexity of feeder setups and programming.

Optimizing Placement Programs

Minimizing the complexity of placement programs can enhance efficiency. Efficient programming reduces nozzle changes and shortens travel distances.

- Reduce Nozzle Changes: Design programs that require fewer nozzle changes by grouping similar components together, which reduces the time spent switching nozzles.

- Shorten Travel Distances: Optimize the path that the machine head travels during operation to reduce cycle times, using software tools that calculate the most efficient route.

Additionally, balancing component placement order to reduce head movement and avoid unnecessary repositioning can significantly speed up the process.

Enhancing SMT Production Efficiency

Balancing Load Distribution

Reasonably allocate the number of mounting components for each SMT machine and try to make the mounting time of each machine equal. Balancing the load distribution across multiple machines ensures that no single machine is overburdened, which can slow down the entire production line.

This is particularly important when using multiple SMD prototyping machines in parallel. Equalizing workloads prevents bottlenecks and maximizes overall throughput.

Equipment Optimization

Each SMT machine has a maximum speed capability. To achieve high-speed SMT, it is essential to optimize the numerical control program of each piece of equipment. This means configuring the machine to operate at or near its maximum speed without sacrificing quality.

- Maximize Placement Speed: Adjust parameters such as acceleration, deceleration, and head movement speed.

- Avoid Overloading: Ensure the machine is not overloaded with excessive component variety or complexity that could slow it down.

Minimizing Component Changes

Frequent component changes during a run can significantly reduce efficiency. If there are various components, it is difficult to carry out efficient processing. In the process of patch processing, the fewer types of components the better, and the more unified the brand and model, the better. If changes are necessary, they should be minimized as much as possible.

Reducing component variety helps in faster feeder setup and reduces the risk of errors during placement.

Solder Paste Printing Optimization

Accurate deposition of solder paste is essential for creating reliable solder joints. Implementing advanced stencil designs and using high-precision deposition equipment can significantly improve this process.

- Stencil Design: Optimize aperture sizes and shapes to control solder volume accurately.

- Squeegee Pressure and Speed: Adjust these parameters to ensure even paste distribution without smearing or insufficient deposition.

- Regular Cleaning: Keep stencils clean to prevent clogging and inconsistent paste application.

Reflow Soldering Optimization

The reflow profile is critical to achieving high-quality solder joints. The profile can be broken down into four zones – the preheat, soak, reflow, and cool-down zones.

- Preheat Zone: Gradually raises the temperature to activate flux and reduce thermal shock.

- Soak Zone: Allows the temperature to stabilize and activates flux further.

- Reflow Zone: The temperature peaks to melt the solder paste and form joints.

- Cool-Down Zone: Rapid cooling solidifies the solder joints.

Proper profiling avoids defects such as solder bridging, tombstoning, and cold joints.

Addressing Common SMT Errors

Solder Bridging

Solder bridging is solder across two conductors that should not be electrically connected, causing electrical shorts.

Causes:

Too much deposition of solder paste.

Incorrect solder paste metal to flux weight proportion.

Placement inaccuracy.

Solutions:

Ensure an appropriate solder paste metal-to-flux weight ratio.

Proper attention should be given to the alignment of stencil apertures to pads.

Ensure on-point pressure and accuracy for component placement.

Insufficient Solder

Insufficient solder occurs when the amount of solder paste deposited is less than required, leading to poor solder joints.

Causes:

The stencil aperture can at times get blocked with dried-up paste.

Paste does not roll into the aperture due to too high squeegee speed.

Solutions:

The stencil must be cleaned at regular intervals and the paste should be checked for expiry or dryness.

Excessive squeegee speed is also undesirable and should be controlled.

Component Misplacement

Misplacement can cause functional failures and rework.

Causes:

Machine calibration errors.

Vision system misalignment.

Operator error during setup.

Solutions:

Regular calibration and maintenance.

Use of high-resolution vision systems.

Training operators on proper setup procedures.

Conclusion

Maximizing the performance of your SMD prototyping machine requires a multifaceted approach that includes regular maintenance, strategic feeder setup, optimized placement programs, and well-trained operators. By implementing these best practices, manufacturers can significantly enhance production speed, reduce errors, and maintain high-quality standards. In the fast-paced electronics market, these strategies are essential for staying competitive and meeting the growing demands for efficient and reliable PCB assembly.

Investing time in machine calibration, operator training, and process optimization will yield significant returns in throughput and product quality. Moreover, adopting lean manufacturing principles and leveraging advanced software tools can push your SMD prototyping machine to its full potential, enabling rapid prototyping cycles and smoother transitions to mass production.

FAQ

1. What is Surface Mount Technology (SMT)?

Surface Mount Technology (SMT) is a method for producing electronic circuits in which the components are mounted or placed directly onto the surface of printed circuit boards (PCBs). SMT has largely replaced through-hole assembly in modern manufacturing due to its efficiency and cost advantages.

2. What are the key steps in the SMT assembly process?

The key steps in the SMT assembly process include:

Solder paste printing: Applying solder paste to the PCB pads using a stencil.

Component placement: Placing SMD components onto the pasted pads using an automated machine.

Reflow soldering: Heating the assembly in a reflow oven to melt the paste and solder the components.

Inspection: Checking the assembled board for any placement or soldering defects using AOI or X-ray machines.

3. What equipment is used in SMT PCB assembly?

A typical SMT assembly line uses several specialized machines:

Stencil Printer: For solder paste application.

Pick-and-Place Machine: To automatically place components.

Reflow Oven: To solder the components by melting the paste.

SPI (Solder Paste Inspection) systems: To check paste deposition.

AOI (Automated Optical Inspection) machines: To inspect finished boards.

4. What industry standards ensure quality in SMT assembly?

The electronics industry relies on standards from organizations like IPC to maintain quality. For SMT assembly, IPC-A-610 is the key standard outlining the acceptable workmanship for assembled boards. IPC J-STD-001 defines requirements for the soldering process and materials.

5. Can a PCB have both SMT and through-hole components?

Yes, a PCB can have both SMT and through-hole components. Mixed technology methods allow for the combination of both SMT and PTH (plated-through hole) components on the same board.