Content Menu

● Understanding the SMT Process

● Optimizing the PCB SMT Work Station Layout

>> Ergonomic Considerations

>> Tool and Component Organization

● Enhancing SMT Machine Performance

>> Regular Maintenance

>> Program Optimization

● Improving Component Management

>> Implementing a Feeder Management System

>> Just-in-Time (JIT) Component Delivery

● Enhancing Operator Skills and Knowledge

>> Comprehensive Training Programs

>> Cross-Training and Skill Development

● Implementing Lean Manufacturing Principles

>> Value Stream Mapping

>> 5S Methodology

● Leveraging Technology for Efficiency Gains

>> Automated Optical Inspection (AOI)

>> Manufacturing Execution Systems (MES)

● Continuous Improvement and Performance Monitoring

>> Key Performance Indicators (KPIs)

>> Regular Performance Reviews

● Conclusion

● FAQ

>> 1. What are the most common bottlenecks in SMT production?

>> 2. How can I reduce setup times for different PCB designs?

>> 3. What role does data analysis play in improving SMT efficiency?

>> 4. How can I improve first-pass yield in SMT production?

>> 5. What are the benefits of implementing a Manufacturing Execution System (MES) in SMT production?

● Citations:

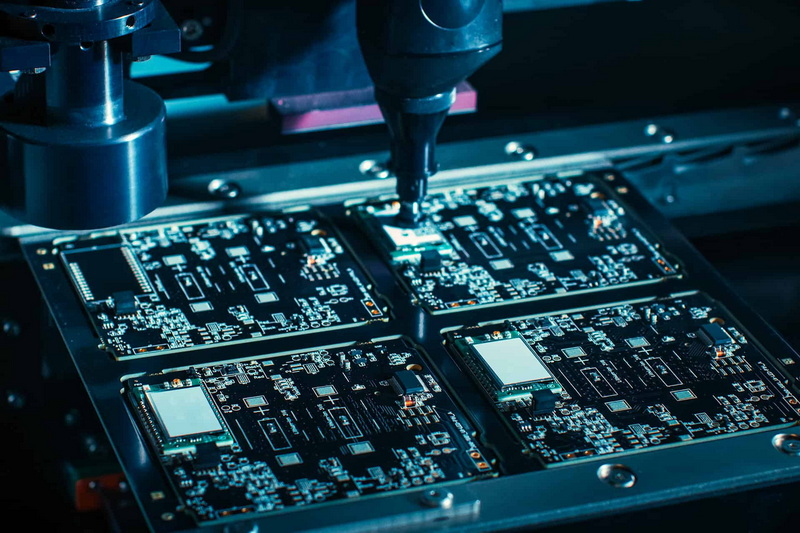

In the fast-paced world of electronics manufacturing, efficiency is key to staying competitive and meeting production demands. Surface Mount Technology (SMT) has revolutionized the production of printed circuit boards (PCBs), allowing for higher component density and faster assembly. However, to truly maximize the potential of SMT, it's crucial to optimize the efficiency of PCB SMT work stations. This article will explore various strategies and techniques to enhance productivity, reduce errors, and streamline operations at SMT work stations.

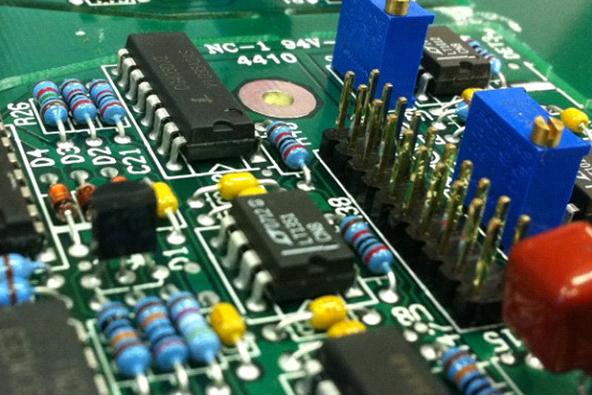

Understanding the SMT Process

Before delving into efficiency improvements, it's essential to have a clear understanding of the SMT process. SMT is a method for producing electronic circuits in which components are mounted directly onto the surface of PCBs. This process typically involves the following steps:

1. Solder paste application

2. Component placement

3. Reflow soldering

4. Inspection and testing

Each of these steps presents opportunities for optimization and efficiency gains.

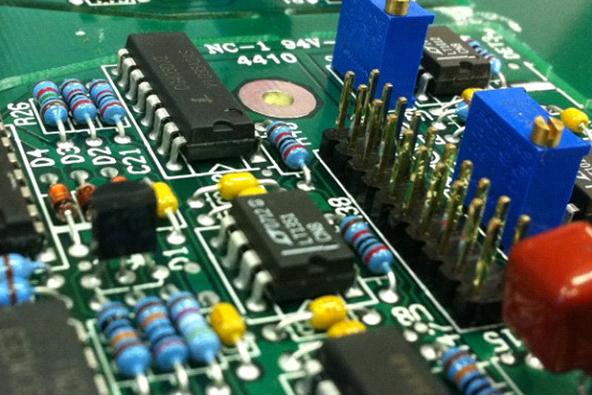

Optimizing the PCB SMT Work Station Layout

The layout of your SMT work station can significantly impact productivity. A well-designed workspace allows operators to move efficiently and access tools and components with ease.

Ergonomic Considerations

Ergonomics plays a crucial role in maintaining operator comfort and productivity over long periods. Consider the following:

- Adjustable chairs and workbenches to accommodate different operator heights

- Proper lighting to reduce eye strain

- Anti-fatigue mats to reduce operator fatigue during long standing periods

Tool and Component Organization

Organize tools and components in a logical manner to minimize unnecessary movement:

- Use shadow boards to ensure tools are always in their designated spots

- Implement a color-coding system for quick identification of components and tools

- Place frequently used items within easy reach of the operator

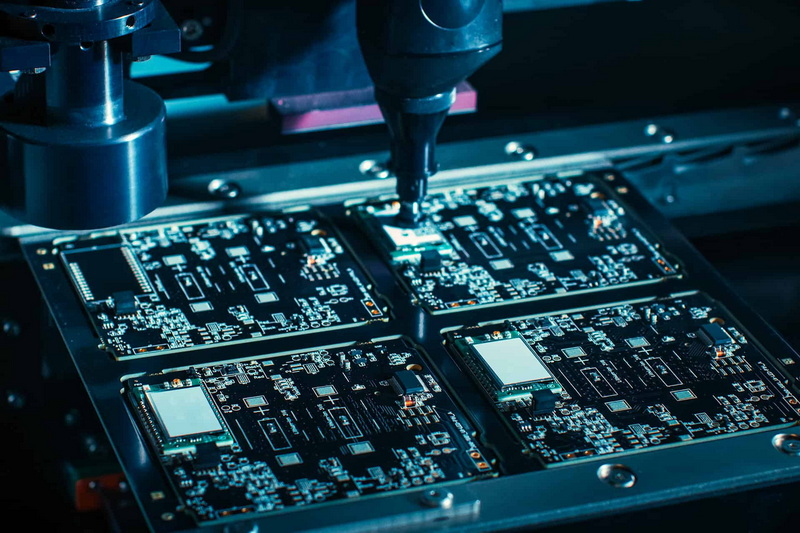

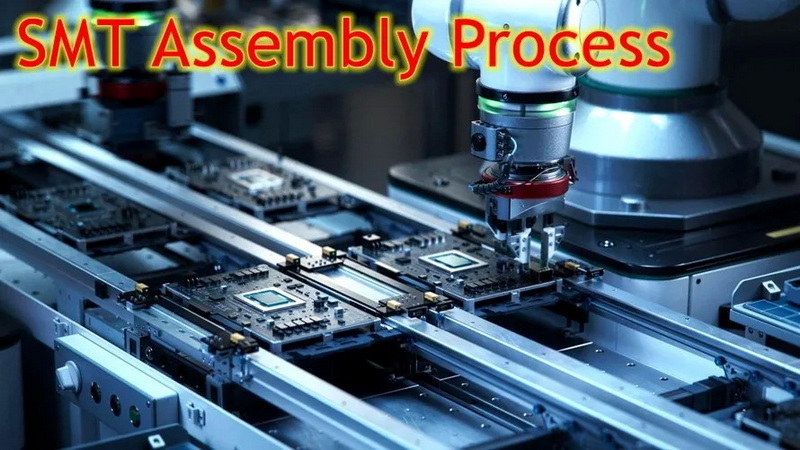

Enhancing SMT Machine Performance

The SMT machine is the heart of the PCB production process. Optimizing its performance can lead to significant efficiency gains[1].

Regular Maintenance

Implement a rigorous maintenance schedule to ensure optimal machine performance:

- Clean and lubricate moving parts regularly

- Replace worn components promptly

- Calibrate machines according to manufacturer specifications

Program Optimization

Optimize your SMT machine programs to reduce cycle times:

- Use optimization software to determine the most efficient component placement sequence

- Minimize head travel distance by grouping similar components

- Balance the workload across multiple machines when possible

Improving Component Management

Efficient component management is crucial for maintaining a smooth production flow.

Implementing a Feeder Management System

A well-organized feeder system can significantly reduce setup times and minimize errors:

- Use a barcode system to track and manage feeders

- Implement a first-in-first-out (FIFO) system for component usage

- Regularly audit and maintain feeders to ensure reliable performance

Just-in-Time (JIT) Component Delivery

Implement a JIT system to reduce inventory costs and ensure components are available when needed:

- Coordinate closely with suppliers to minimize lead times

- Use kanban systems to trigger component replenishment

- Consider implementing automated storage and retrieval systems for high-volume components

Enhancing Operator Skills and Knowledge

Well-trained operators are essential for efficient SMT production. Invest in your workforce to improve overall efficiency[3].

Comprehensive Training Programs

Develop and implement thorough training programs for SMT operators:

- Cover all aspects of the SMT process, including machine operation, troubleshooting, and quality control

- Provide hands-on training with actual equipment

- Regularly update training materials to reflect new technologies and processes

Cross-Training and Skill Development

Encourage operators to develop a broad skill set:

- Cross-train operators on different machines and processes

- Implement a skill matrix to track and manage operator capabilities

- Encourage continuous learning and improvement

Implementing Lean Manufacturing Principles

Lean manufacturing principles can significantly improve efficiency in SMT production[5].

Value Stream Mapping

Use value stream mapping to identify and eliminate waste in your production process:

- Map out the entire production process from raw materials to finished product

- Identify non-value-adding activities and work to eliminate them

- Continuously refine and improve the process based on mapping results

5S Methodology

Implement the 5S methodology to create a more organized and efficient workspace:

1. Sort: Remove unnecessary items from the work area

2. Set in Order: Organize remaining items for easy access

3. Shine: Clean and maintain the work area

4. Standardize: Create standard procedures for maintaining organization

5. Sustain: Regularly audit and maintain the 5S system

Leveraging Technology for Efficiency Gains

Modern technology offers numerous opportunities to enhance SMT work station efficiency.

Automated Optical Inspection (AOI)

Implement AOI systems to improve quality control and reduce manual inspection time:

- Use AOI for both pre- and post-reflow inspection

- Integrate AOI results with your manufacturing execution system (MES) for real-time quality tracking

Manufacturing Execution Systems (MES)

Implement an MES to improve production planning and tracking:

- Use real-time data to optimize production schedules

- Track key performance indicators (KPIs) to identify areas for improvement

- Integrate MES with other systems for seamless data flow

Continuous Improvement and Performance Monitoring

Establishing a culture of continuous improvement is crucial for long-term efficiency gains.

Key Performance Indicators (KPIs)

Define and track relevant KPIs to measure and improve efficiency:

- Overall Equipment Effectiveness (OEE)

- First Pass Yield (FPY)

- Cycle Time

- Setup Time

Regular Performance Reviews

Conduct regular performance reviews to identify areas for improvement:

- Analyze KPI data to identify trends and issues

- Solicit feedback from operators and supervisors

- Implement improvement plans based on review findings

Conclusion

Improving efficiency at a PCB SMT work station requires a multifaceted approach that addresses various aspects of the production process. By optimizing work station layout, enhancing machine performance, improving component management, investing in operator skills, implementing lean principles, leveraging technology, and fostering a culture of continuous improvement, manufacturers can significantly boost their SMT production efficiency. Remember that efficiency improvement is an ongoing process, and staying competitive in the fast-paced electronics manufacturing industry requires constant vigilance and adaptation to new technologies and methodologies.

FAQ

1. What are the most common bottlenecks in SMT production?

Common bottlenecks in SMT production include:

- Component shortages or misplacements

- Machine downtime due to maintenance issues

- Inefficient program optimization

- Quality control bottlenecks

- Operator skill limitations

To address these bottlenecks, implement robust inventory management systems, regular preventive maintenance schedules, optimize machine programs, enhance quality control processes, and invest in operator training and development.

2. How can I reduce setup times for different PCB designs?

To reduce setup times:

- Implement a standardized setup procedure

- Use quick-change fixtures and feeders

- Optimize your component library to minimize the number of unique parts

- Utilize offline programming and simulation tools

- Implement a feeder trolley system for quick changeovers

These strategies can significantly reduce the time required to switch between different PCB designs, improving overall production efficiency.

3. What role does data analysis play in improving SMT efficiency?

Data analysis is crucial for improving SMT efficiency:

- It helps identify trends and patterns in production data

- Enables predictive maintenance to reduce unplanned downtime

- Assists in optimizing machine parameters for different PCB designs

- Provides insights for continuous improvement initiatives

- Helps in tracking and improving key performance indicators (KPIs)

By leveraging data analysis tools and techniques, manufacturers can make informed decisions to enhance their SMT production efficiency.

4. How can I improve first-pass yield in SMT production?

To improve first-pass yield:

- Optimize solder paste printing process

- Implement automated optical inspection (AOI) at key stages

- Ensure proper component storage and handling

- Regularly maintain and calibrate equipment

- Provide comprehensive training to operators on quality standards

By focusing on these areas, you can significantly reduce defects and improve the overall quality of your SMT production.

5. What are the benefits of implementing a Manufacturing Execution System (MES) in SMT production?

Implementing an MES in SMT production offers several benefits:

- Real-time production tracking and monitoring

- Improved production planning and scheduling

- Enhanced quality control through data integration

- Better inventory management

- Increased visibility into production KPIs

- Facilitation of continuous improvement initiatives

An MES can provide the data and insights needed to make informed decisions and drive efficiency improvements across your SMT production process.

Citations:

[1] https://www.smtneoden.com/news/how-to-effectively-improve-the-production-efficiency-of-pcb-smt-machine/

[2] https://patents.google.com/patent/CN104244605B/zh

[3] https://www.adoptsmt.com/en/efficiency-enhancement-in-smt-manufacturing/

[4] https://smtnet.com/library/index.cfm?fuseaction=browse_articles&start_at=296

[5] https://www.neodensmt.com/news/improve-production-efficiency-on-smt-pcb-assem-17085331.html

[6] https://suddendocs.samtec.com/processing/edge-mount-processing-ch.pdf

[7] https://www.zjyingxing.com/info/how-to-improve-the-manufacturing-effici-102670373.html

[8] https://baike.baidu.com/item/%E7%94%B5%E5%AD%90%E7%BB%84%E8%A3%85%E6%8A%80%E6%9C%AF%E4%B8%93%E4%B8%9A%E8%8B%B1%E8%AF%AD/12086345